Method for improving running period of hydrogenation plant for poor petroleum naphtha

A hydrogenation unit and naphtha technology, which is applied in the petroleum industry, hydroprocessing process, and hydrocarbon oil treatment, can solve the problems of unsuitable naphtha hydrogenation unit, environmental pollution, and long process, so as to improve the use of Long life, saving investment and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

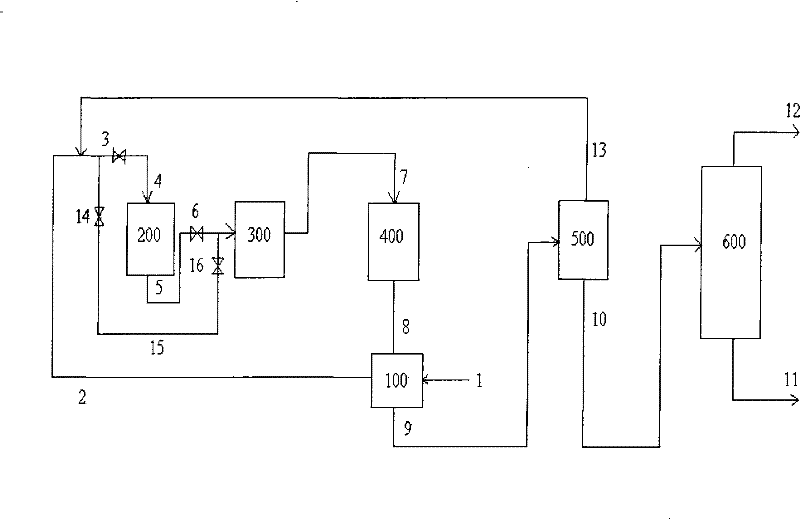

Image

Examples

Embodiment 1

[0032] The raw material used in the examples is sulfur-containing crude oil coking naphtha, and Table 1 shows the main properties.

[0033] The hydrofining catalyst with silicon trapping function can choose the FHRS-1 catalyst developed and produced by Fushun Petrochemical Research Institute. The conventional hydrogenation catalyst uses the commercial hydrofining catalyst FH-40C produced by Wenzhou Huahua Group Co., Ltd. developed by Fushun Petrochemical Research Institute. The properties are shown in Table 2.

[0034] Table 1 Raw Oil Properties

[0035] Raw oil name

[0036] Table 2 Main composition and properties of hydrotreating catalyst

[0037] catalyst

[0038] The 2000-hour stability test was carried out with sulfur-containing crude coker naphtha as raw material. The process conditions are shown in Table 3 and the test results are shown in Table 4.

[0039] When FH-40C is used alone, due to the acceleration of carbon deposition on the catalyst, the...

Embodiment 2

[0046] Using FH-40C as the pretreatment catalyst, a 4,000-hour stability comparison test was carried out with sulfur-containing crude coker naphtha as the feedstock oil. The process conditions are shown in Table 5 and the test results are shown in Table 6.

[0047] When FH-40C is used alone, the pressure drop of the reactor has reached 0.3MPa after 2000 hours, which is close to the allowable highest point for industrial devices, and shutdown treatment is adopted; the carbon content in the protective agent on the upper part of the catalyst is 88.9%; After 4000 hours, the combined process of the treatment reactor FH-40C and the main reactor FH-40C catalyst maintains good product quality, and the pressure of the reactor is reduced to 0.1MPa, which can ensure long-term operation.

[0048] Table 5 embodiment 2 technological conditions

[0049] Process conditions

pressure, MPa

4.0

Inlet hydrogen oil volume ratio

500∶1

volumetric space ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com