Two-stage hydrocracking method used for producing high-quality jet fuel

A technology for hydrocracking and jet fuel, which is applied in hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of large circulating amount of kerosene fractions, increased investment in equipment, complicated operation, etc., so as to avoid secondary cracking, The effect of improving quality and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

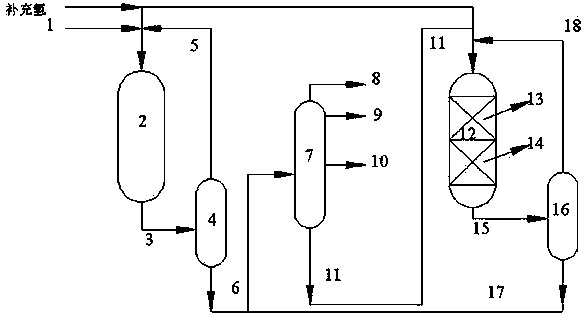

[0035] use figure 1 The process flow diagram shown. The hydrotreating reactor uses FF-46 hydrocracking pretreatment catalyst, and the hydrocracking reactor adopts a catalyst system of hydrocracking catalyst I / hydrocracking catalyst II graded in different volume ratios. Catalyst I and catalyst II are both supported by amorphous silica-alumina and modified Y molecular sieve. In Examples 1-3, in the hydrocracking reactor, the volume ratios of hydrocracking catalyst I / hydrocracking catalyst II were 2:1, 1:1 and 1:2 respectively, and the properties of the feed oil are shown in Table 1.

[0036] At a reaction pressure of 15.0MPa, the volume ratio of hydrogen to oil in the refining section and the cracking section is 900:1 and 1100:1 respectively, and the volume space velocity of the refining section and the cracking section is 1.0h -1 and 1.2h -1 Under the conditions of > 350 ° C, the process test with a conversion rate of about 70wt% was carried out, and the product quality of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com