Patents

Literature

146results about How to "Avoid secondary cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel bridge deck pavement cold mixing maintenance material and manufacturing method thereof

ActiveCN103114526AImprove bonding effectImprove interlayer bond strengthIn situ pavingsBridge structural detailsStructural engineeringResin bonding

The invention discloses a steel bridge deck pavement cold mixing maintenance material and a manufacturing method thereof. The maintenance material comprises a resin detritus waterproof layer, a resin bonding layer and a resin concrete pavement layer. The resin detritus waterproof layer is coated on a steel bridge panel required maintenance and is formed by solidifying resin and detritus spread on the surface of the resin. The resin bonding layer is coated on the resin detritus waterproof layer. The resin concrete pavement layer is coated on the resin bonding layer and is formed by solidifying the resin and aggregate in a mixed mode. According to the maintenance material, construction is convenient, influence on construction conditions by temperature is small, performance is excellent, maintenance time is short, production is convenient and rapid, construction period is short and influence on traffic is small.

Owner:江苏苏科建设项目管理有限公司

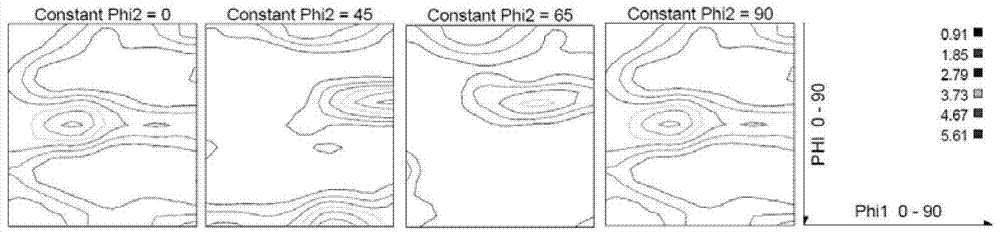

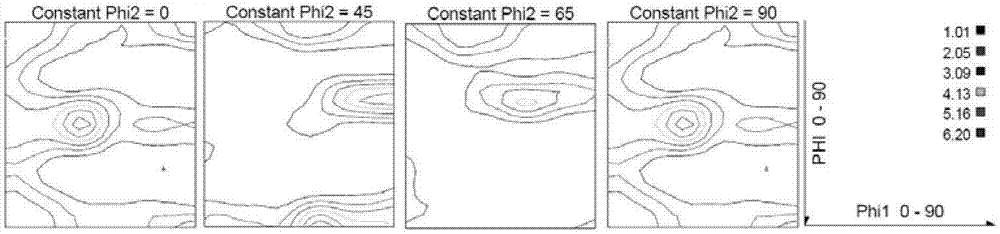

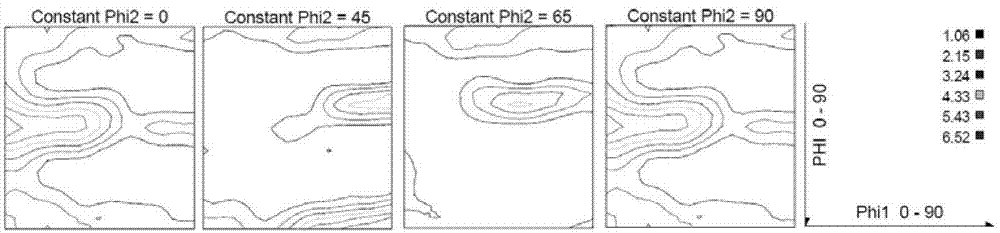

Heat treatment method capable of improving anti-fatigue performance of aluminum alloy

ActiveCN103045976AEliminate entangled dislocation configurationsStress reliefRoom temperatureCorrosion fatigue

The invention relates to a heat treatment method capable of improving the anti-fatigue performance of Al-Cu-Mg alloy. The method comprises the following steps: performing intermediate annealing on a cold-rolled plate at the temperature of between 300 and 440 DEG C for 20 to 120 minutes; performing solution hardening treatment at the temperature of between 475 and 505 DEG C for 10 to 120 minutes; and naturally ageing at room temperature for at least 100 hours. The Al-Cu-Mg alloy comprises the following components: Cu, Mg, Mn, Ti and Al. The process method is simple and reasonable. By the intermediate annealing heat treatment process, the Gauss texture score of the alloy is increased, and orientation of most of crystal faces {111} of crystal grains of the cold-rolled Al-Cu-Mg alloy is positioned or close to the direction of the maximum external shearing stress, so that reciprocating sliding dislocated under the action of alternating stress is promoted, the closed effect of fatigue crack is improved, the spreading rate of the fatigue crack is reduced, and the alloy has excellent stress corrosion resistance and anti-stripping corrosion fatigue performance and is suitable for industrialized application.

Owner:CENT SOUTH UNIV

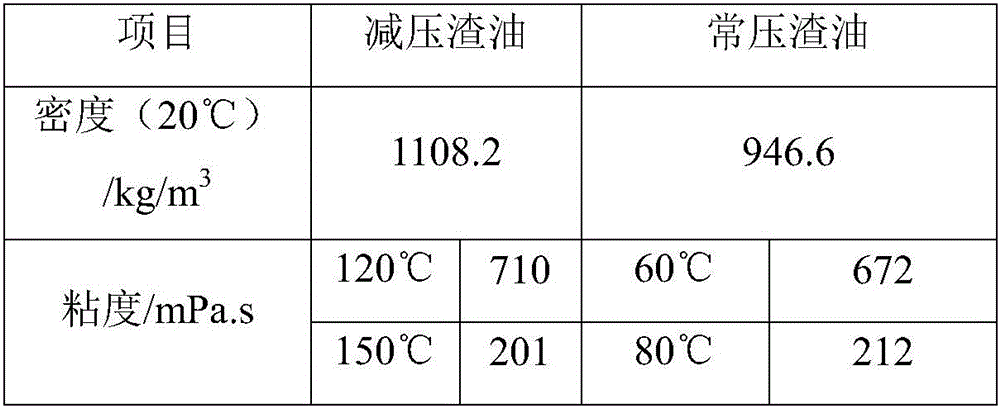

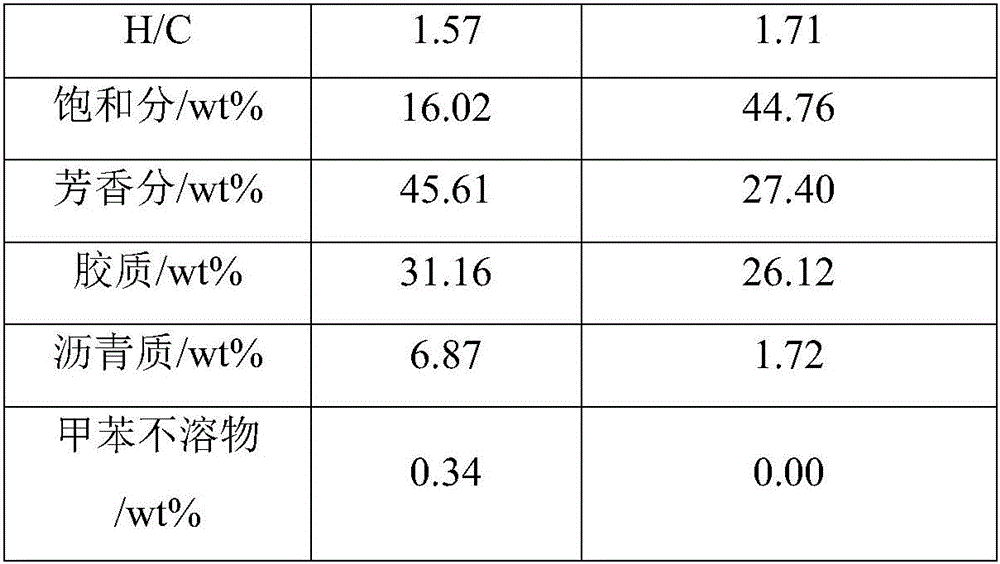

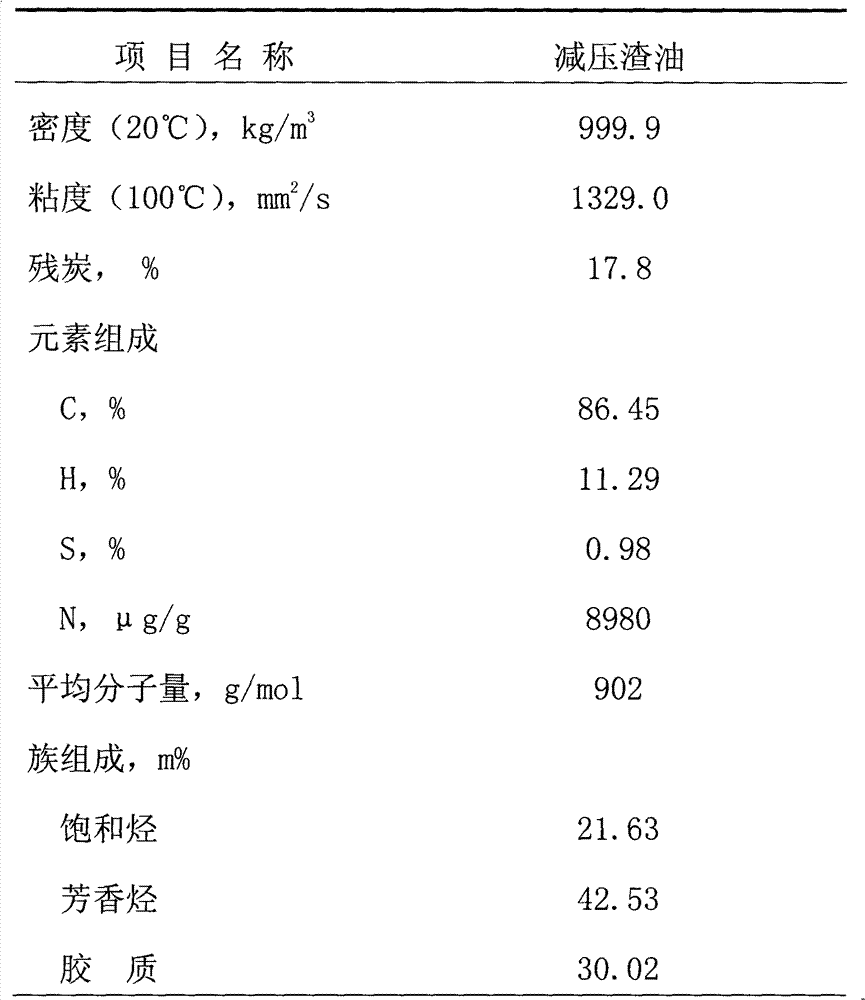

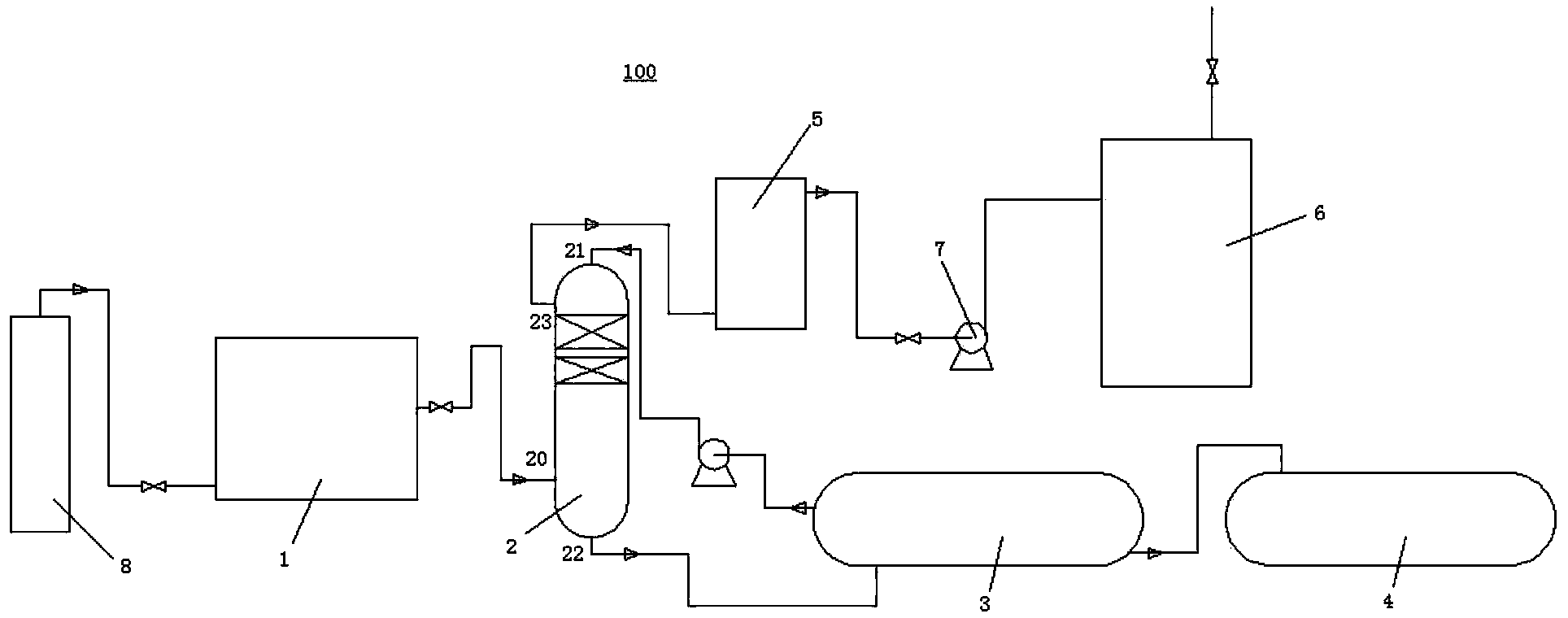

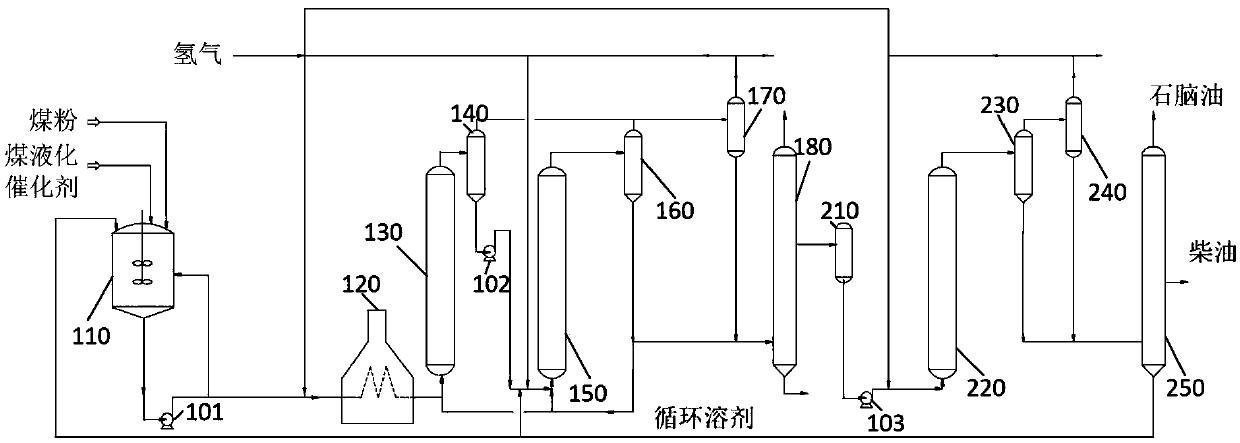

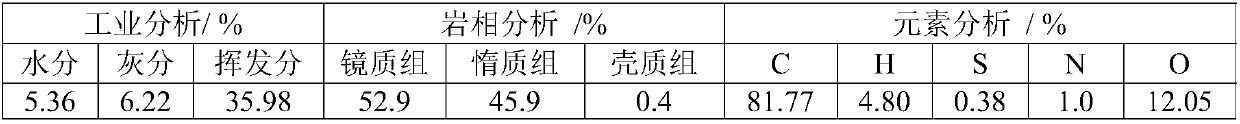

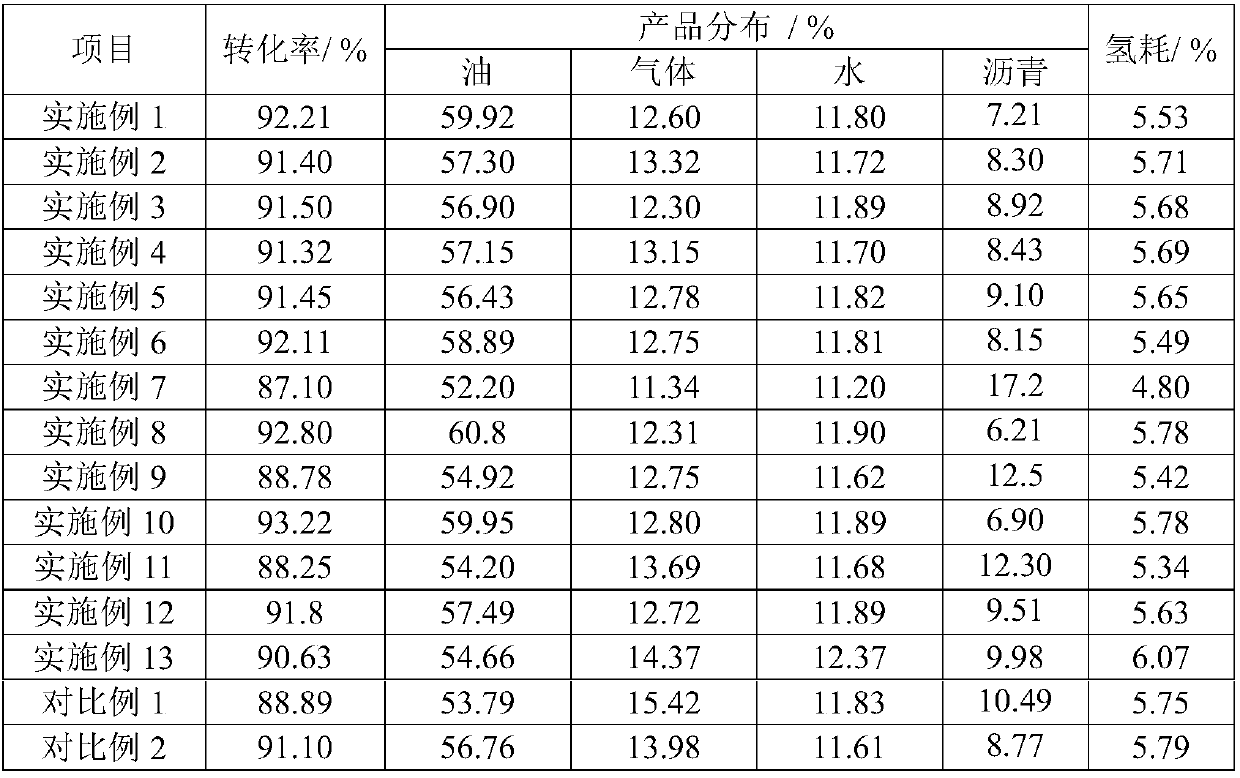

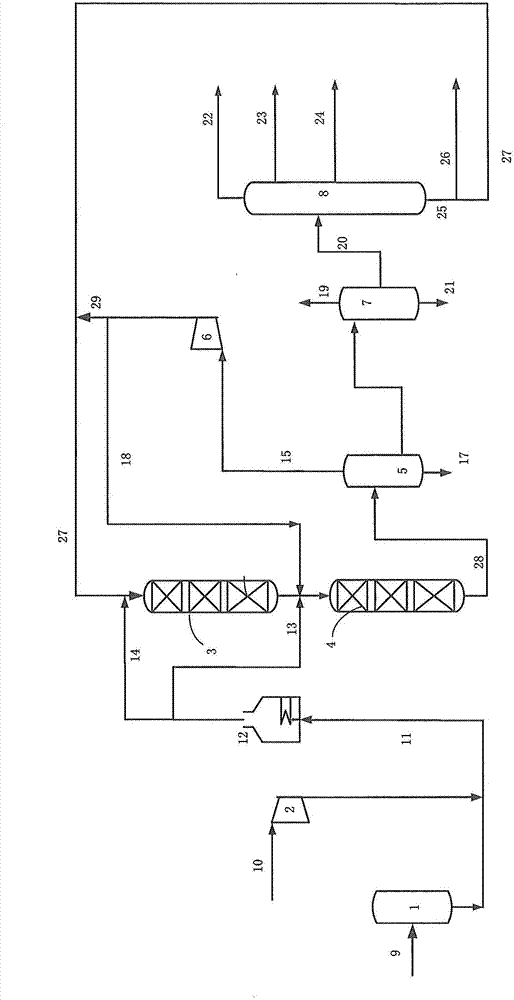

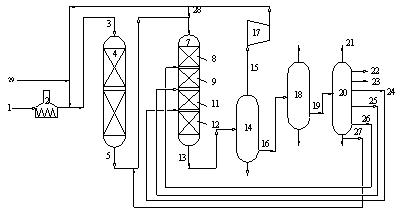

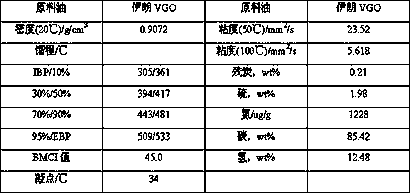

Coal and oil coprocessing method and device

ActiveCN106433775ALow viscosityImprove protectionTreatment with hydrotreatment processesSlurrySolvent

The invention relates to a coal and oil coprocessing method and device. The coprocessing method comprises steps as follows: step one, oil slurry pretreatment: heavy oil, a non-hydrogenated cycling solvent and a first catalyst are mixed, oil slurry is prepared and subjected to first hydrocracking reaction, a first product is obtained and separated, and first light distillate oil and first heavy distillate oil are obtained; step two, coal and oil coprocessing, solvent oil circulation and finished product separation. The coprocessing device comprises an oil slurry pretreatment device, a coal and oil coprocessing device body, a solvent oil circulating device and an oil product quality improving device. According to the coal and oil coprocessing method and device, selectivity for the heavy oil during coal and oil coprocessing is reduced, the percentage amount of pulverized coal in a coal and oil coprocessing process is increased, and the coal and oil coprocessing method and device are more suitable for practical application.

Owner:CCTEG CHINA COAL RES INST

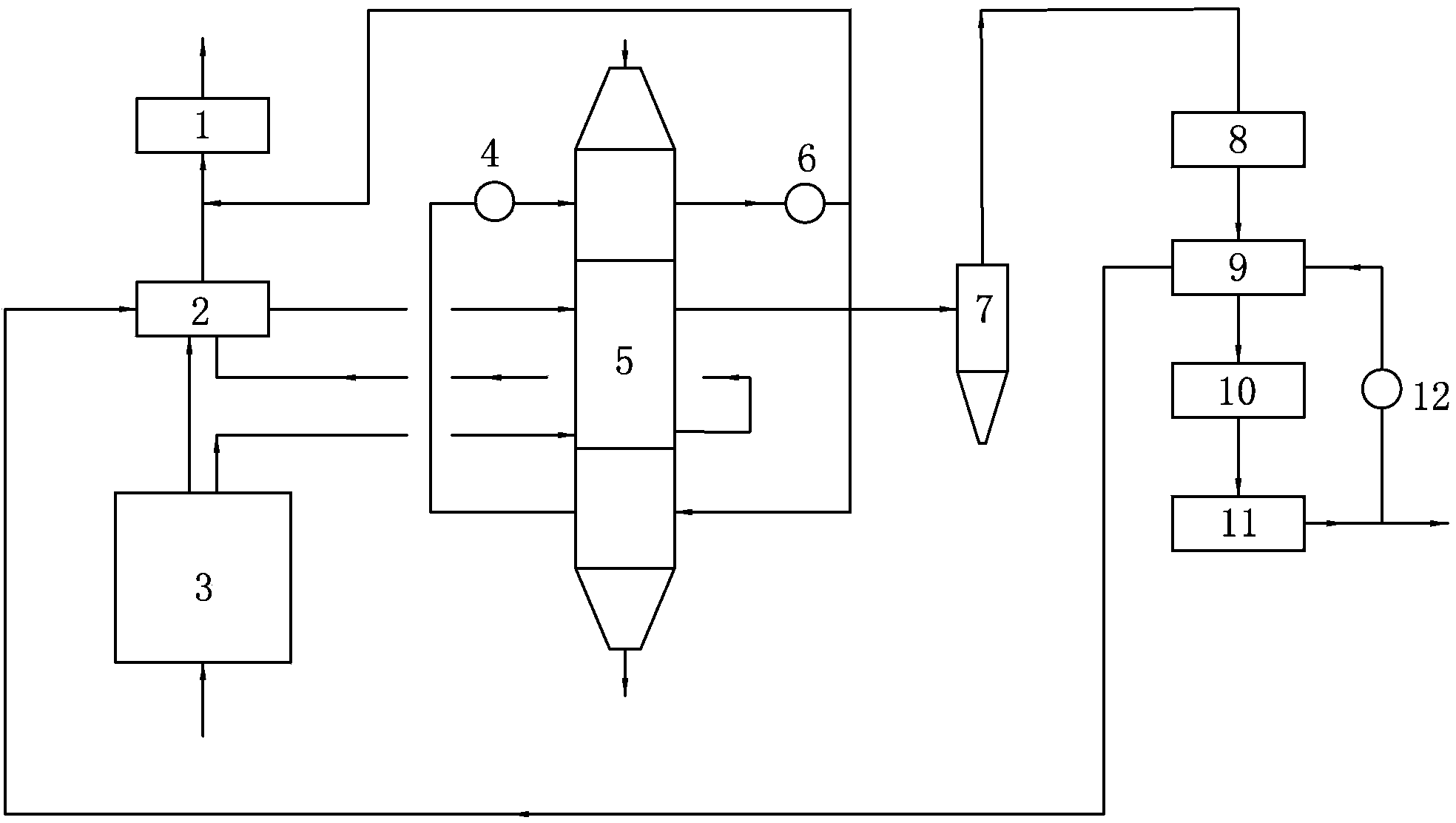

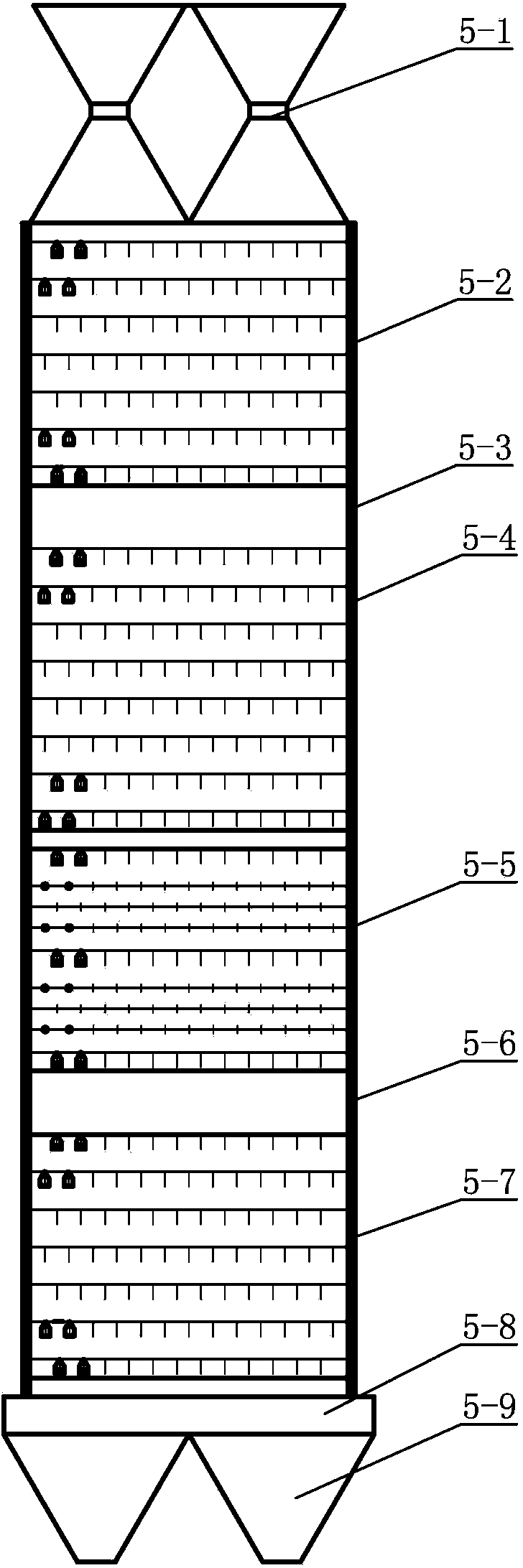

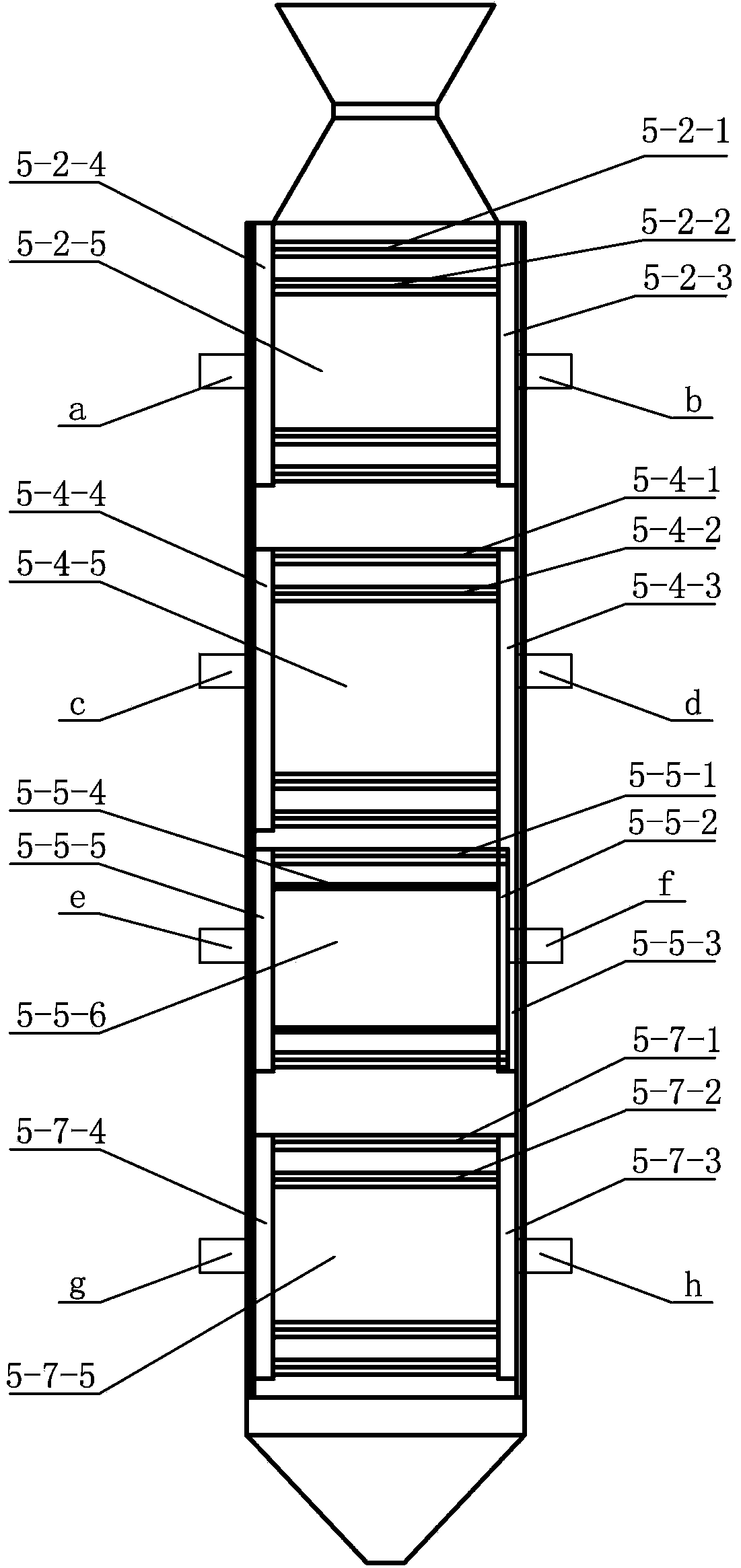

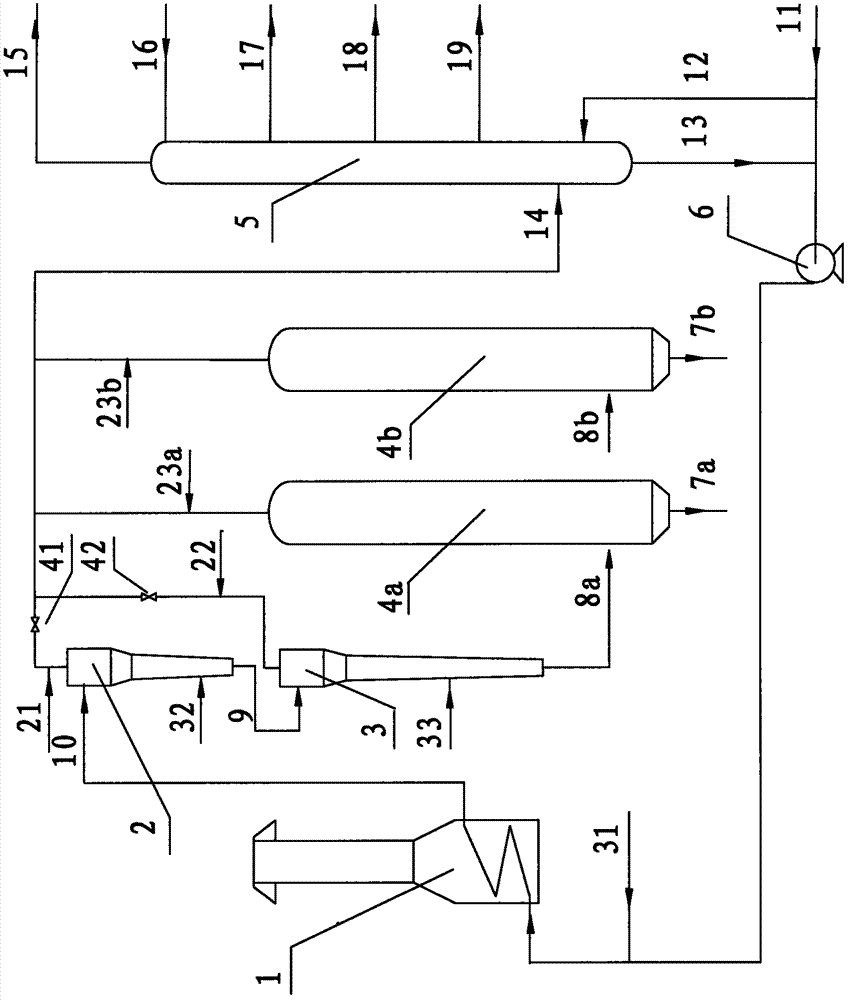

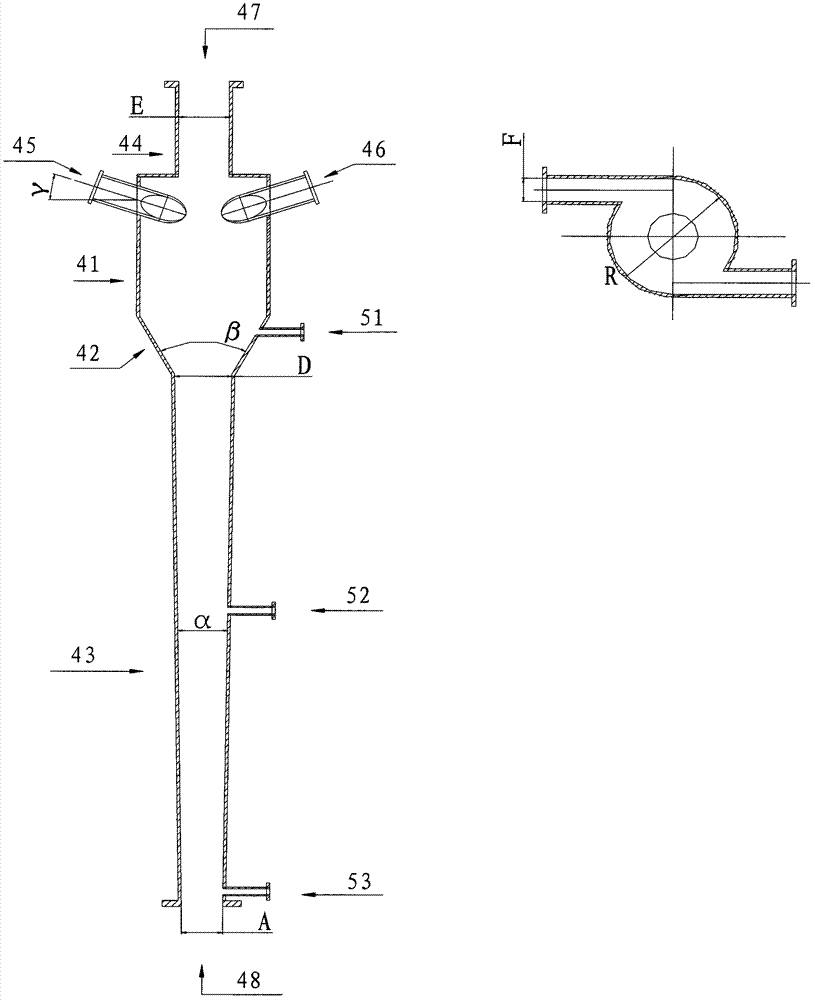

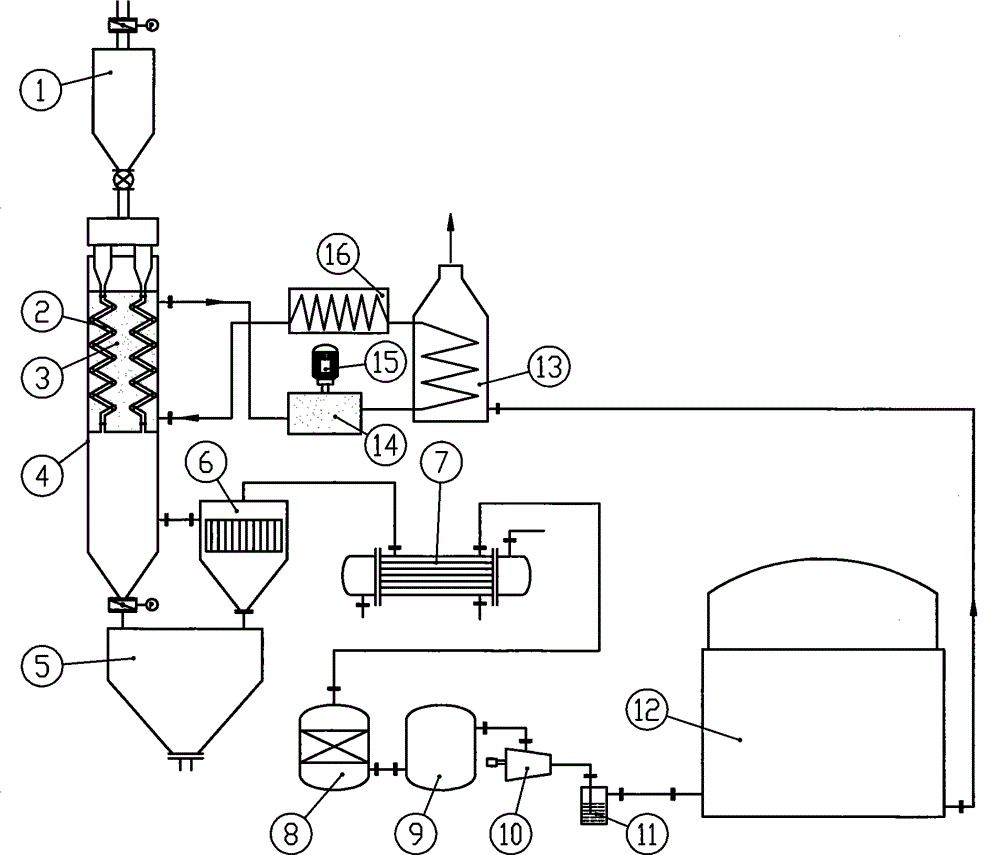

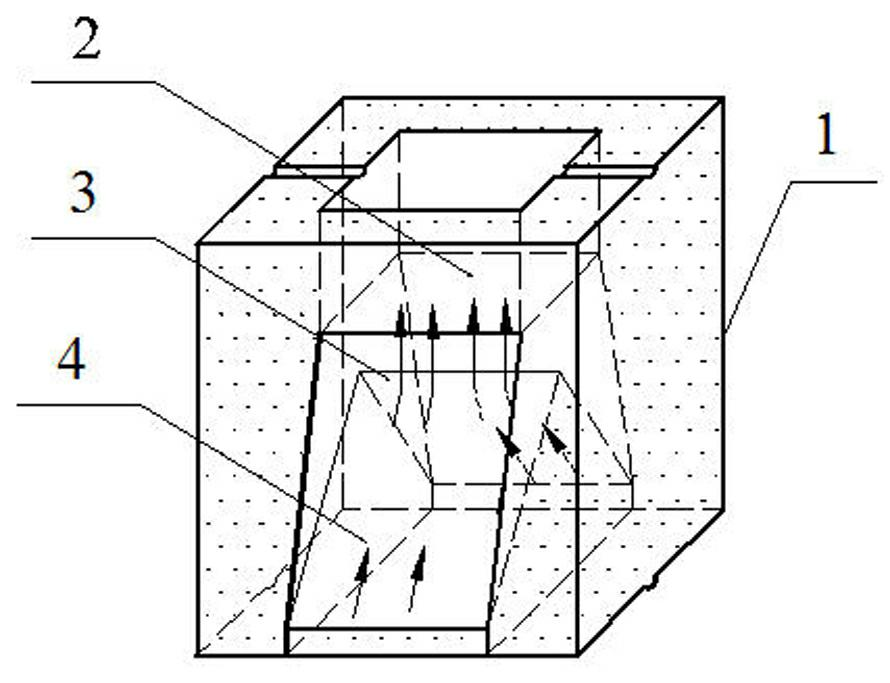

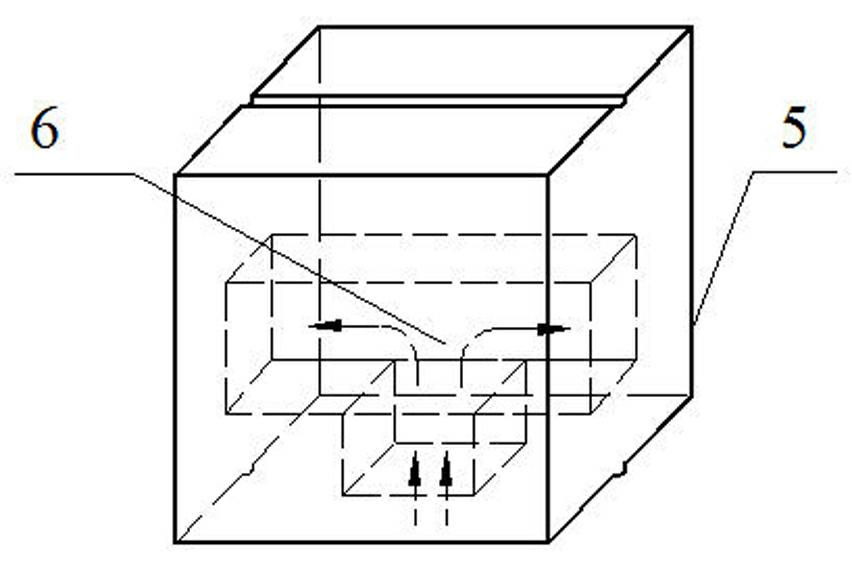

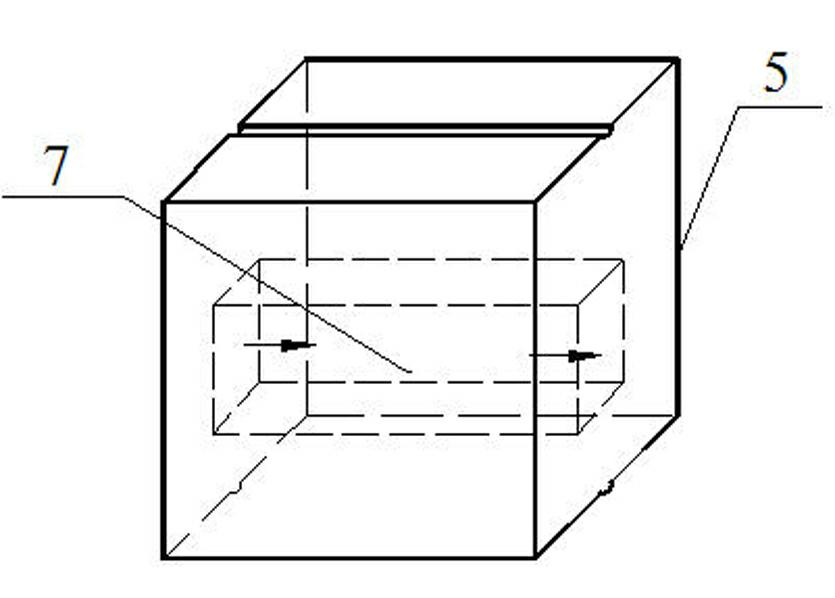

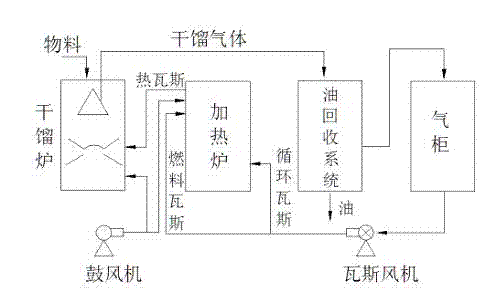

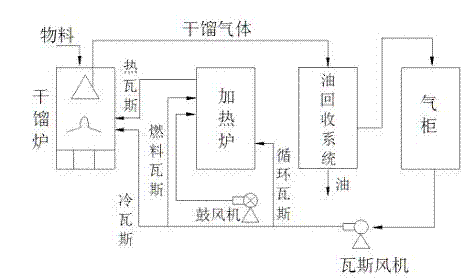

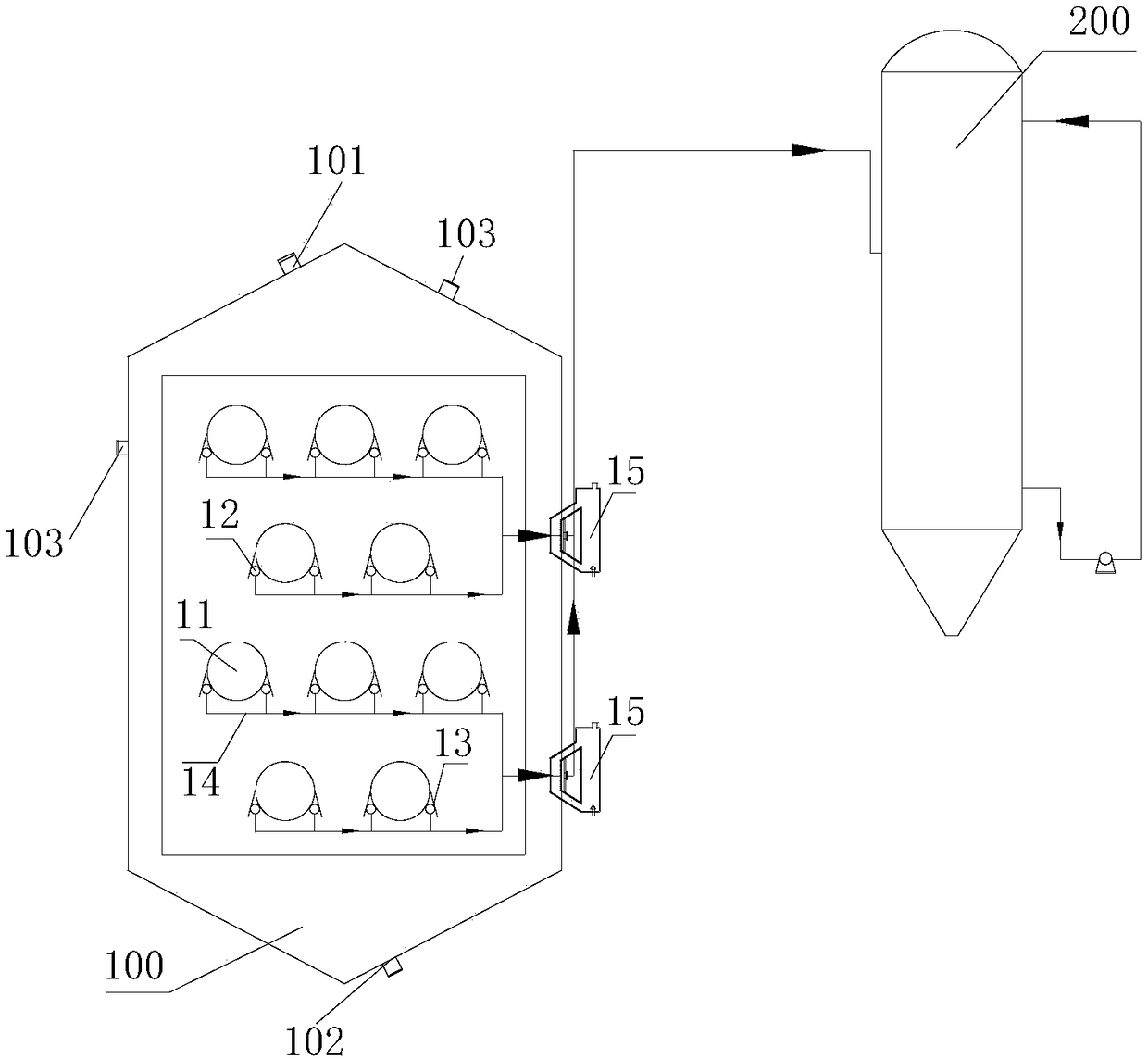

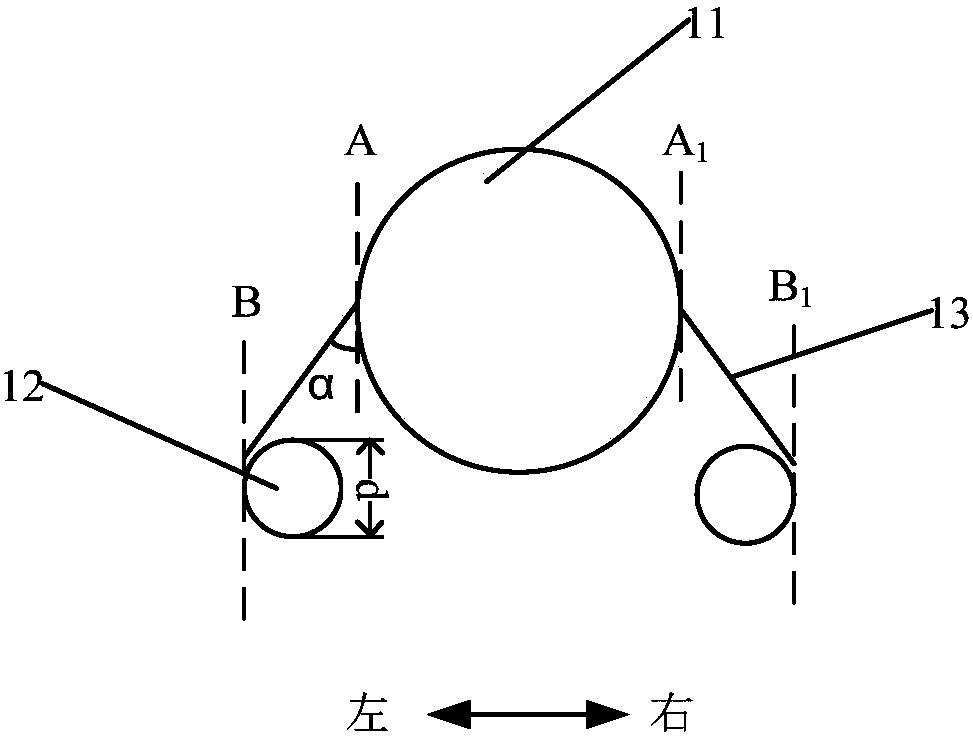

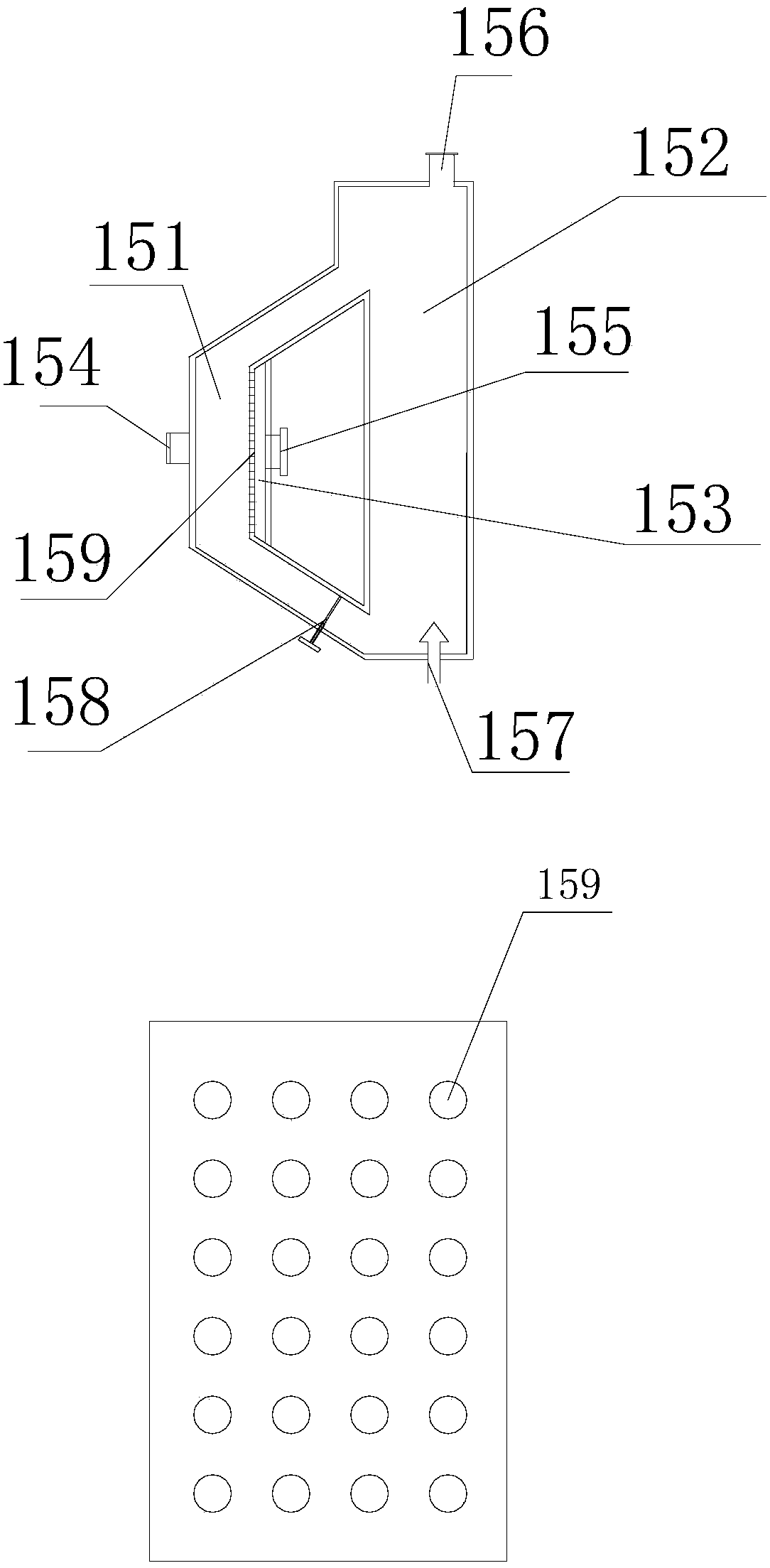

Device and method for pyrolyzing pea coal by utilizing internally heated vertical furnace

ActiveCN103468292AAvoid secondary crackingHigh yieldIndirect and direct heating destructive distillationCycloneRecuperator

The invention relates to a device and method for pyrolyzing pea coal by utilizing an internally heated vertical furnace. The device comprises an internally heated vertical furnace, wherein a feed hopper, a drying section, a first transition section, a pyrolysis section I, a pyrolysis section II, a second transition section, a cooling section, a discharge valve and a discharge hopper are arranged on the internally heated vertical furnace sequentially from top to bottom, wherein the drying section is communicated with a dry steam circulating fan and a high-temperature steam circulating fan; the dry steam circulating fan is communicated with the cooling section; the pyrolysis section I is communicated with a coal gas heat exchanger and a micro-cyclone dust collector; the micro-cyclone dust collector is communicated with a quencher; the quencher is communicated with a raw gas heat exchanger; the raw gas heat exchanger is communicated with a coal gas heat exchanger and a horizontal water-tube cooler; the horizontal water-tube cooler is communicated with an electrical tar precipitator; the pyrolysis section II is communicated with a combustion furnace and the micro-cyclone dust collector; the combustion furnace is communicated with the coal gas heat exchanger. The device and method are easy to operate, high in heat efficiency, environment-friendly and high in carbocoal quality, and the coal gas can be recycled.

Owner:陕西凯德利能源科技有限公司

Blank for mending ceramic paste preforms and preparation method and mending process thereof

The invention relates to a blank for mending ceramic paste preforms and a preparation method and a mending process thereof. The blank for mending ceramic paste preforms is characterized by adding netty reinforcement substrates and auxiliary modified materials to original paste blanks, wherein the weight percentage of the netty reinforcement substrates in the blank for mending ceramic paste preforms is 3-10%, and the weight percentage of the auxiliary modified materials is 3-31%. The blank for mending ceramic paste preforms has the advantages of simple formula, convenient preparation and low cost. The process for mending ceramic paste preforms comprises the following steps of: slightly enlarging the cracking part of a ceramic preform to remove the stress concentration at the cracking part of the preform, and filling the blank for mending ceramic paste preforms in the cracking part to change the spatial connection mode among particles of the preform. The mending process has the advantages of simplicity, convenient operation and excellent mending effect, and achieves the technical effects of thoroughly mending the surface of the ceramic preform and effectively avoiding the second cracking phenomena after sintering.

Owner:LIXIL AS SANITARY MFG (SHANGHAI) CO LTD

Delayed coking method

InactiveCN103087769ASave operating costsSave processHydrocarbon oils treatmentGas phaseFractionation

The invention aims at solving defects such as low light oil yield, high foam layer, and high coke yield of prior arts, and discloses a delayed coking method. The method is characterized in that: a mixed raw material is heated in a heating furnace; the heated hot material flow enters a primary hydrocyclone, such that a gas phase (1) and a mixed liquid phase (1) are obtained; the gas phase (1) is quenched and is delivered into a fractionation column; high-temperature steam is injected into the mixed liquid phase (1), and the mixture is delivered into a secondary hydrocyclone; the secondary hydrocyclone separates the mixed liquid phase (1) into a gas phase (2) and a mixed liquid phase (2). The gas phase (2) is delivered into a fractionation column; high-temperature steam is injected into the mixed liquid phase (2), and the mixture is delivered into a coke column; coke is discharged from the bottom of the coke column, and reaction oil gas is delivered into the fractionation column.

Owner:CHINA PETROLEUM & CHEM CORP +1

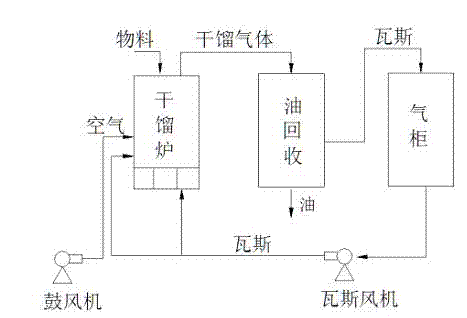

Tire treatment system

The invention discloses a tire treatment system. The tire treatment system comprises a pretreatment device, a revolving bed pyrolyzing furnace, a heat accumulating type fuel gas radiating pipe burner, a direct cooling tower, an oil cooler, an oil storage tank, a purifier, and a gas storage tank, wherein the pretreatment device treats a tire so as to form a pyrolyzing raw material. The revolving bed pyrolyzing furnace receives the pyrolyzing raw material, and a plurality of gas outlets are formed in the side wall of the revolving bed pyrolyzing furnace. The heat accumulating type fuel gas radiating pipe burner heats the pyrolyzing raw material, and a plurality of gas outlets are located below the heat accumulating type fuel gas radiating pipe burner in vertical direction. The direct cooling tower receives an oil-gas product and separates oil from gas. The oil cooler receives and cools the separated pyrolyzing oil, and the cooled pyrolyzing oil is introduced into the direct cooling tower. The oil storage tank and the oil cooler are communicated. The purifier receives the separated pyrolyzing gas. The gas storage tank and the purifier are communicated, and the gas storage tank provides a gas source for the heat accumulating type fuel gas radiating pipe burner. The tire treatment system, pyrolyzing oil is high in yield and good in quality, and the operating cost is low.

Owner:北京节净环保科技有限公司

Rapid rice husk pyrolysis apparatus and matching system thereof

ActiveCN105400528AFast pyrolysisAchieve self-sufficiencyBiofuelsSpecial form destructive distillationScrew conveyorPyrolysis

The present invention discloses a rapid rice husk pyrolysis apparatus. According to the rapid rice husk pyrolysis apparatus, the main body of a reactor is a stainless steel housing, the upper portion is tightly provided with an vacuum material feeder through a material inlet on the upper end, the lower portion, a screw conveyor and two pneumatic gate valves maintain the reactor and outside air isolation state through a material outlet, multiple groups of molten salt heaters are vertically and densely arranged inside the reactor, a fuel gas outlet is arranged above the right side of the main body, the external is connected to a vacuum pump, a condenser and a filter, and separated combustible gas enters a combustor to combust so as to heat high temperature molten salt adopted as a thermal carrier, such that the energy self-sufficiency can be achieved. With the apparatus of the present invention, the rapid rice husk pyrolysis at the temperature of 450-650 DEG C under the total pressure of 5-15 kPa can be achieved, the natural nanometer structure of the silica inside the rice husk is not damaged, and the complete oxidation of the subsequent combustion oxidation unit impurity carbon is easily achieved.

Owner:王开辉

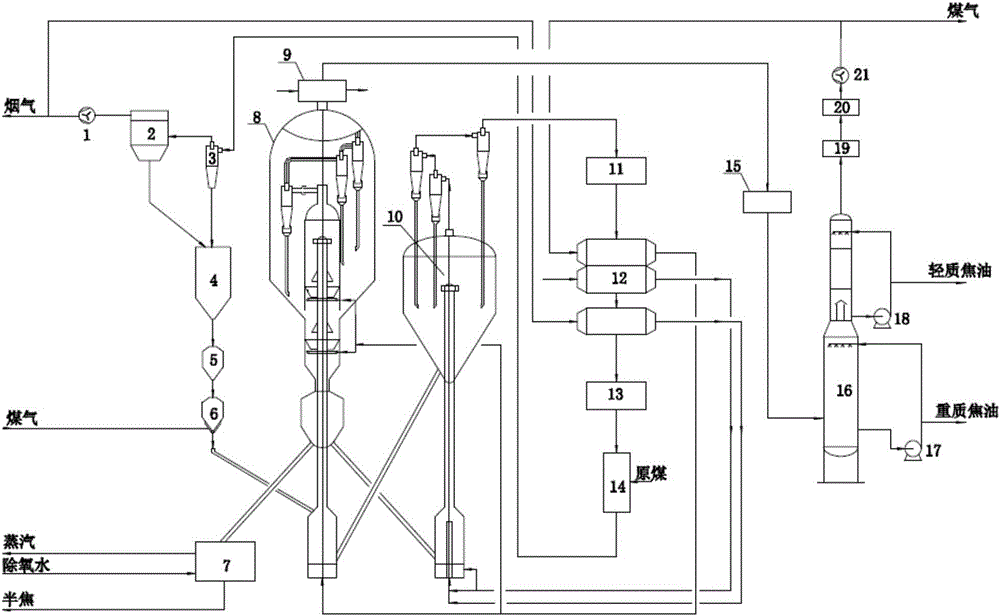

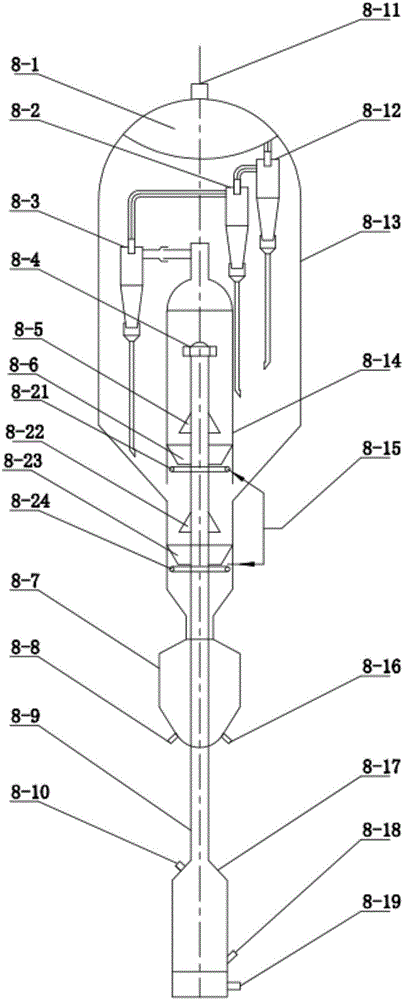

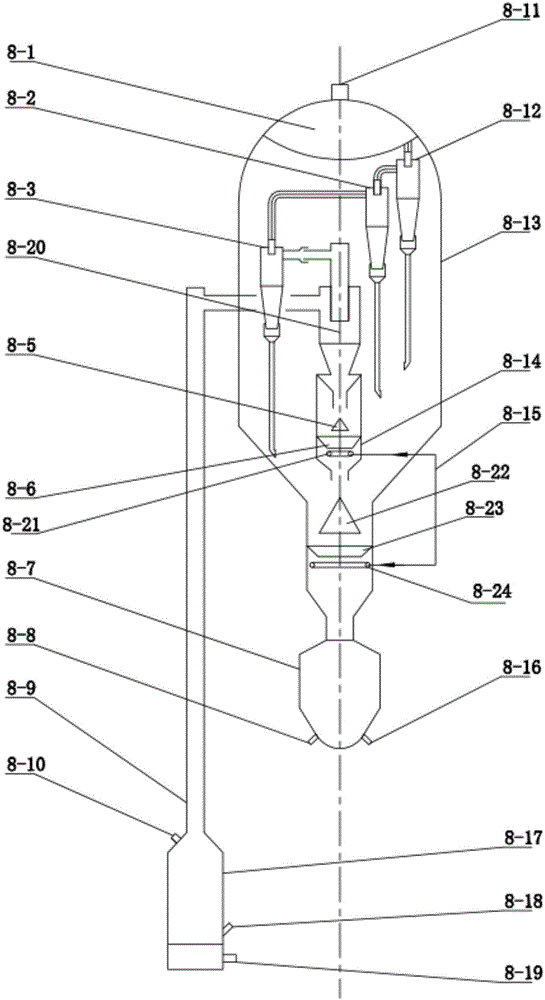

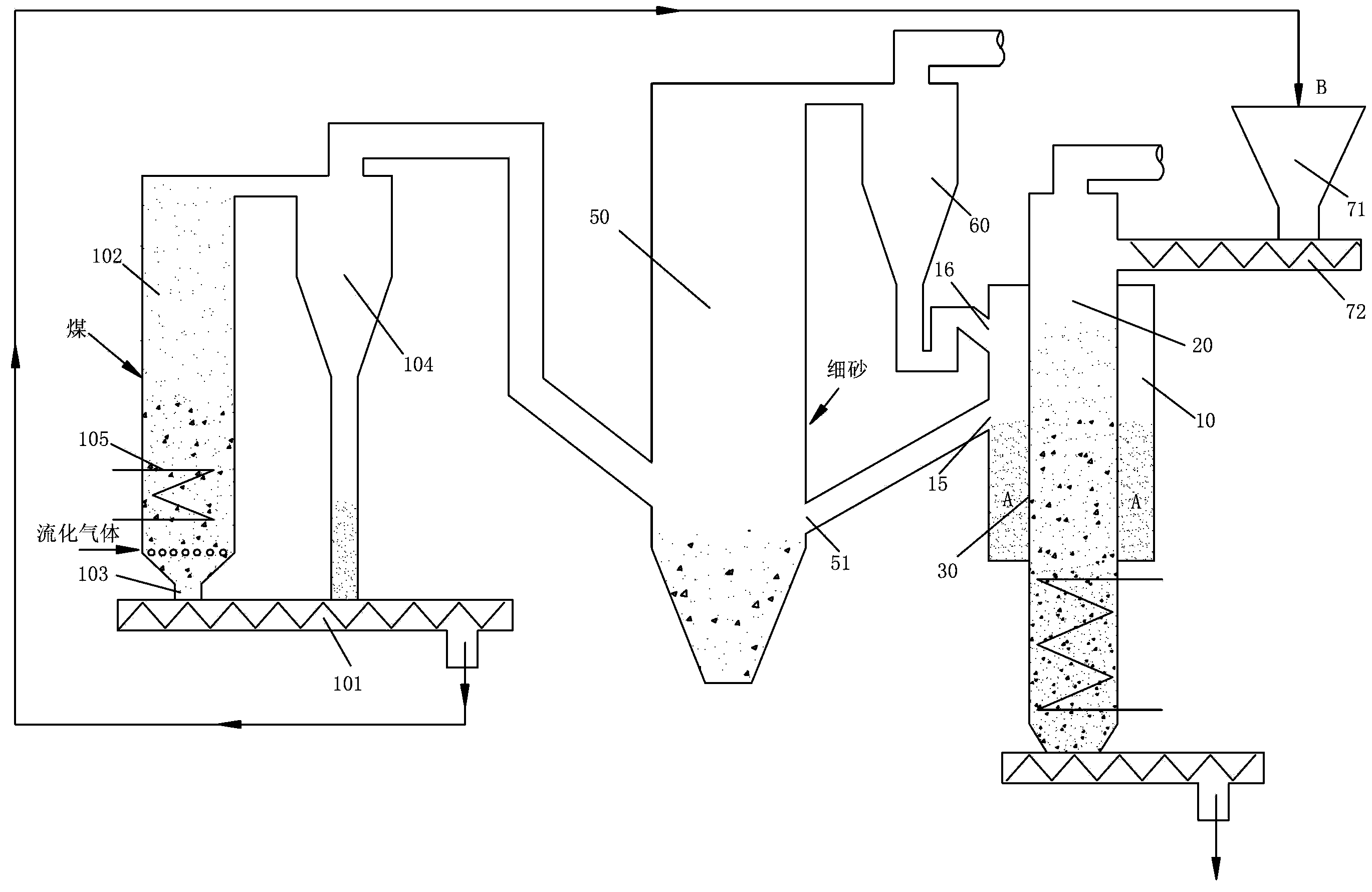

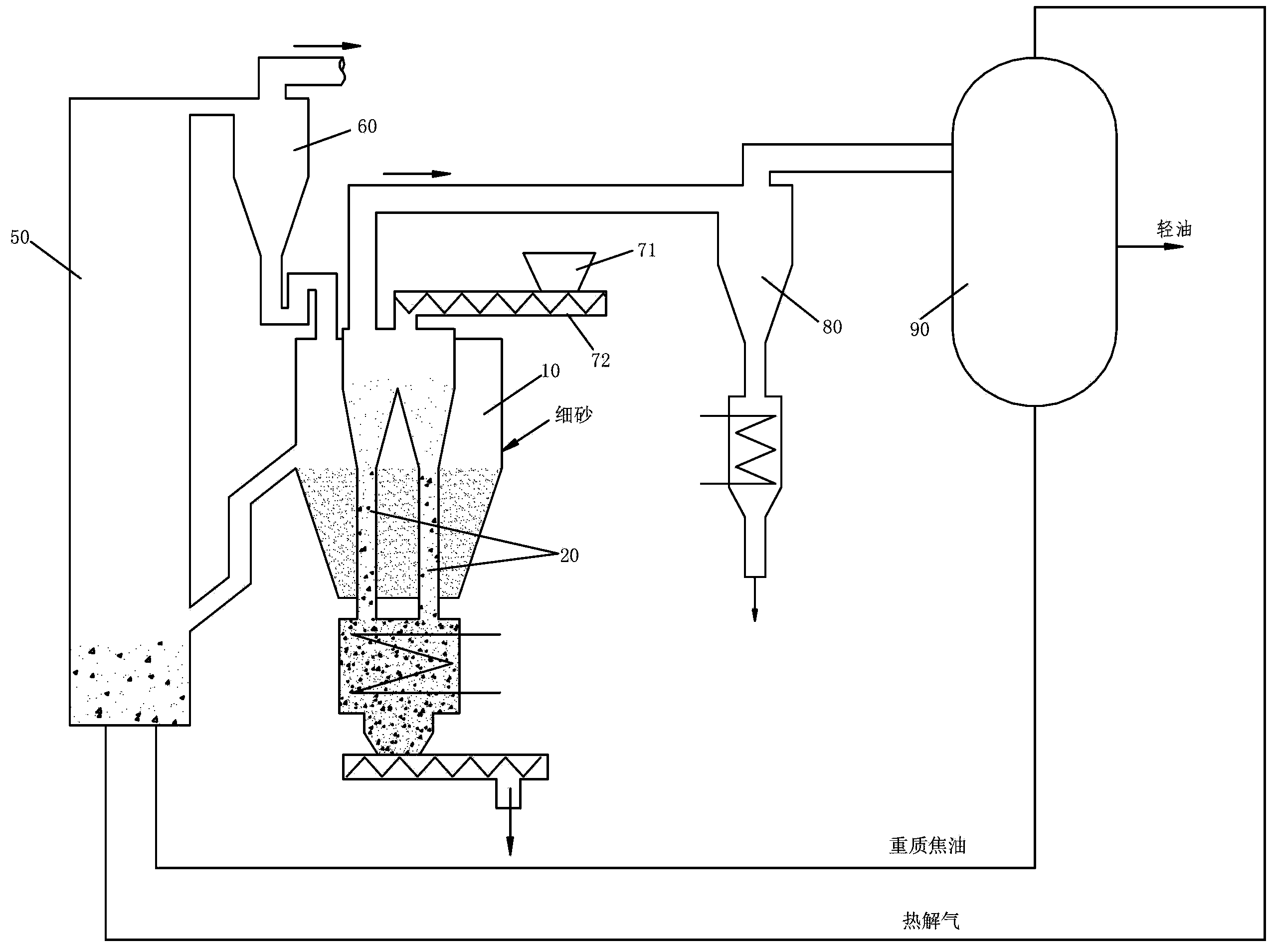

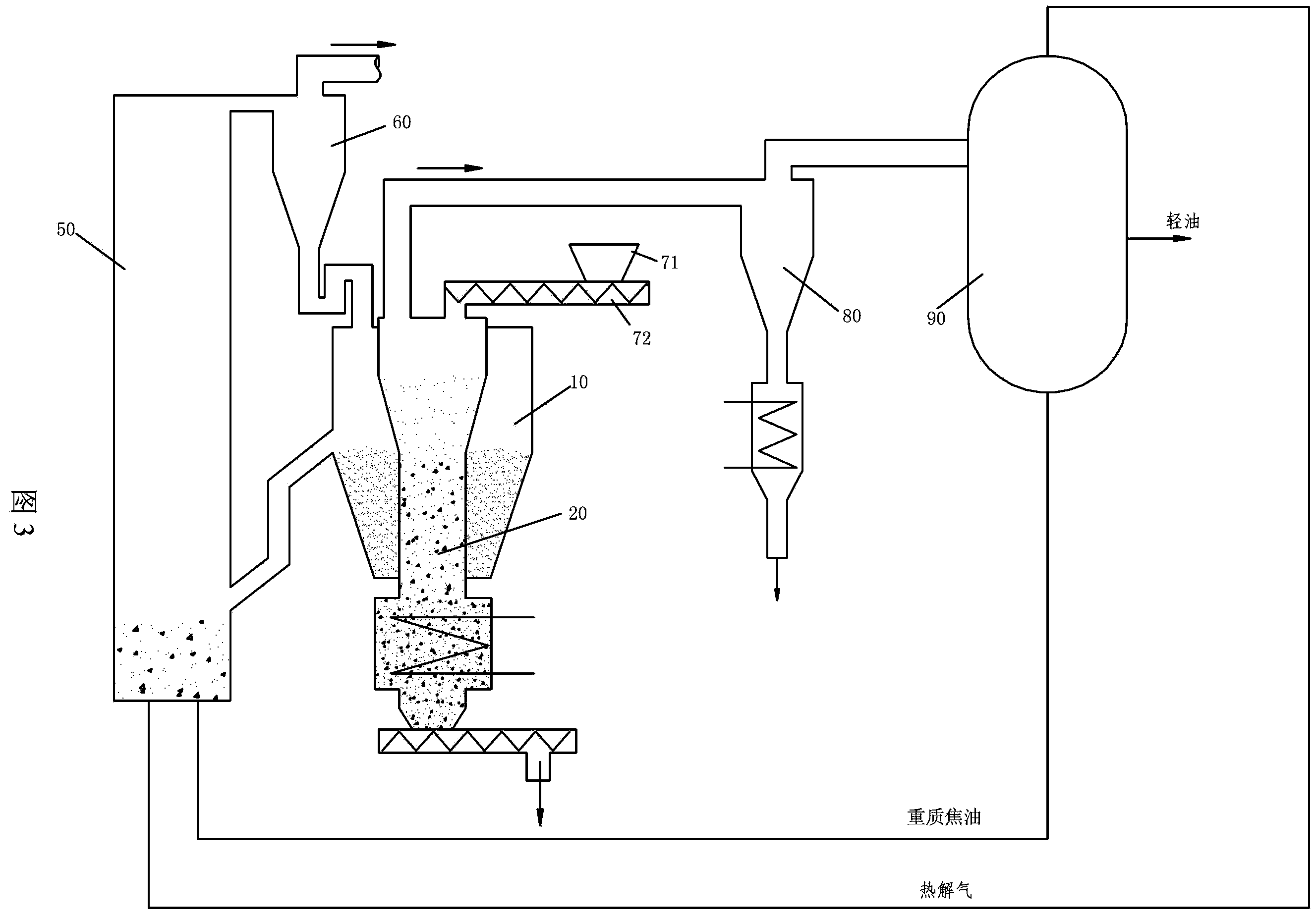

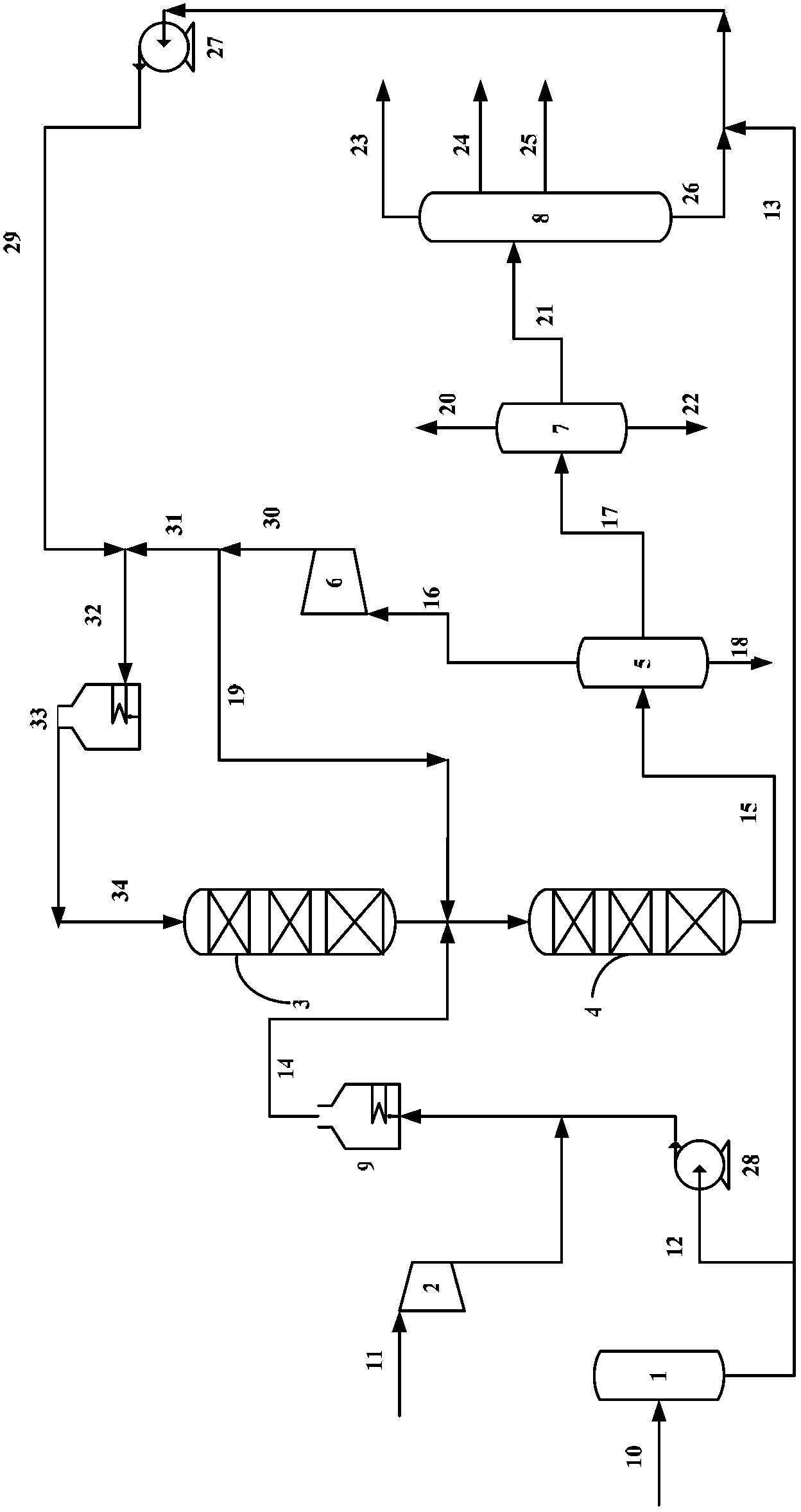

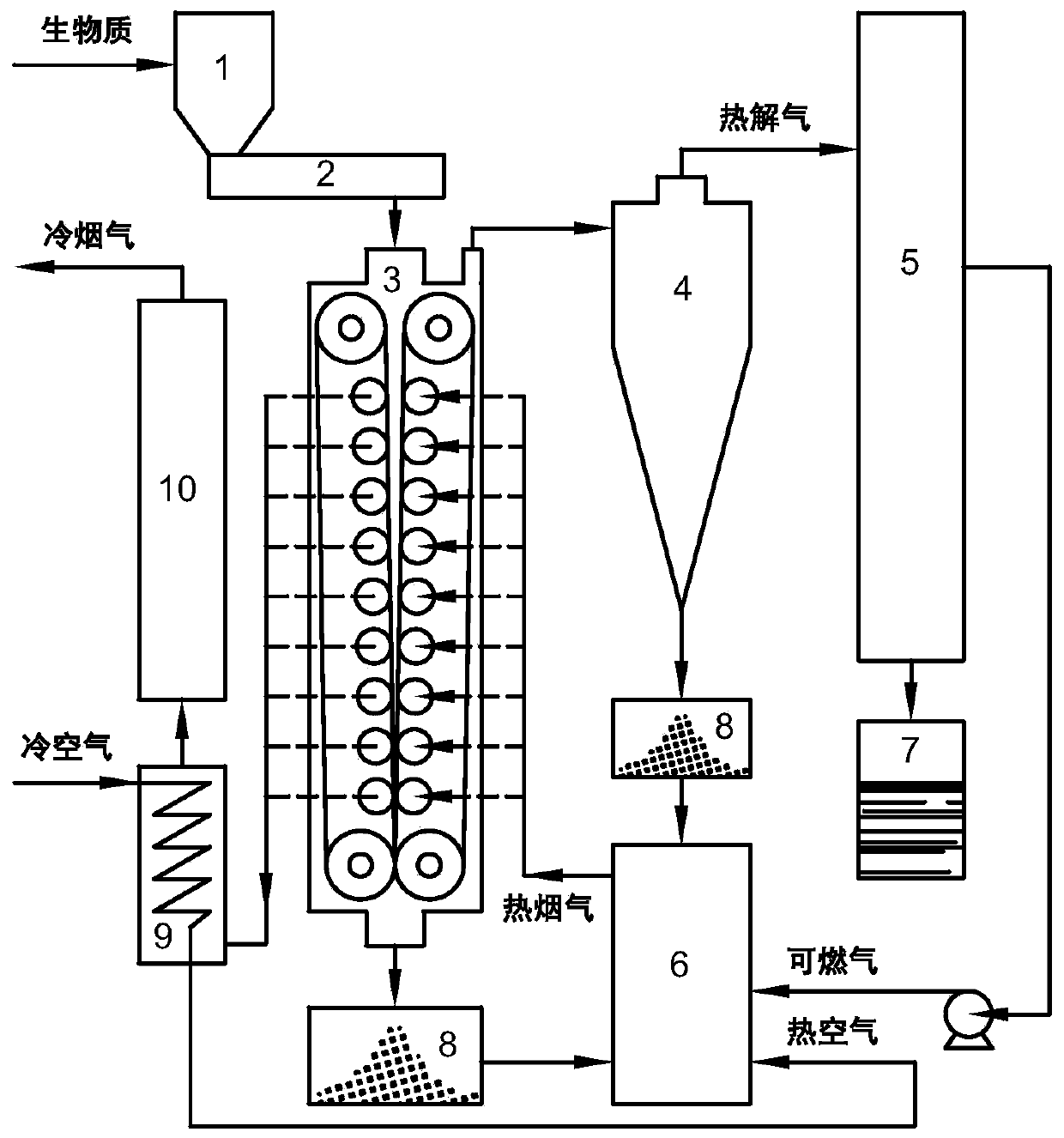

System and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with solid heat carrier

ActiveCN106753491AHigh yieldShort stayDirect heating destructive distillationSpecial form destructive distillationHeat carrierHigh energy

The invention relates to a system and method for preparing coal tar, gas and semi-coke by activating coal gas and flash pyrolysing coal with a solid heat carrier. The system comprises a raw coal primary processing apparatus, a pyrolytic reaction separator, a semi-coke heating separator, a recycling apparatus, a coak tar recovering apparatus and a semi-coke cooling apparatus; a part of semi-coke powder discharged from the pyrolytic reaction separator enters the semi-coke heating separator, high-temperature smoke discharged from the semi-coke heating separator enters the recycling apparatus, the coal tar recovering apparatus produces coal tar and coal gas, and the semi-coke cooling apparatus produces semi-coke. In the existing coal tar preparation method, the coal pyrolytic optimization of the coal is not good, so that the existing coat tar preparation method has the technical problems of low oil yield, high investment and high energy consumption. The system for preparing the coal tar, gas and semi-coke by activating the coal gas and flash pyrolysing the coal with the solid heat carrier is rapid in pyrolysis, rapid in output and rapid in cooling.

Owner:陕西凯德利能源科技有限公司

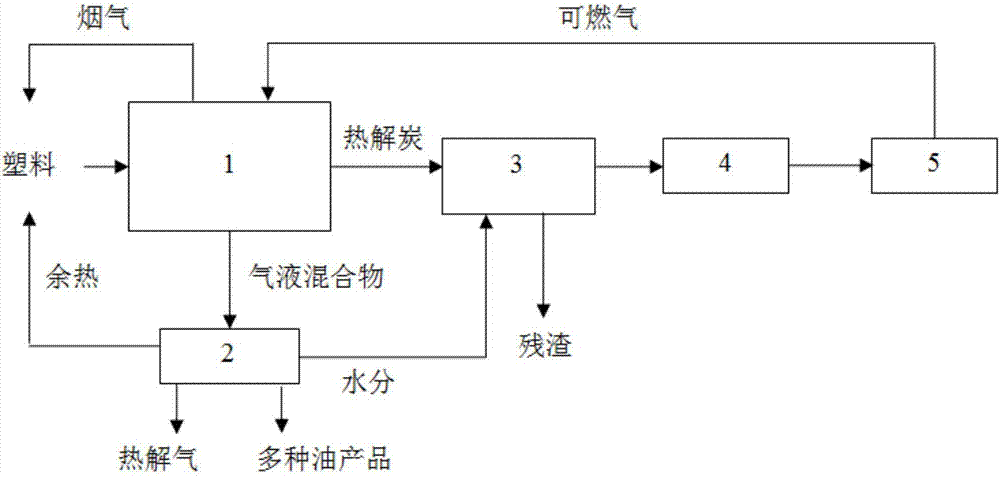

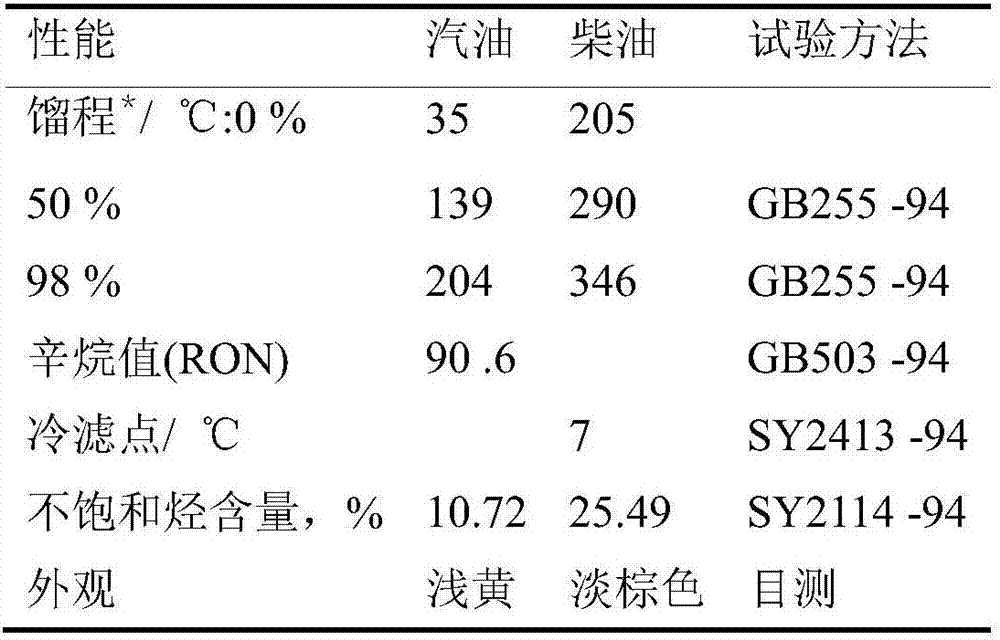

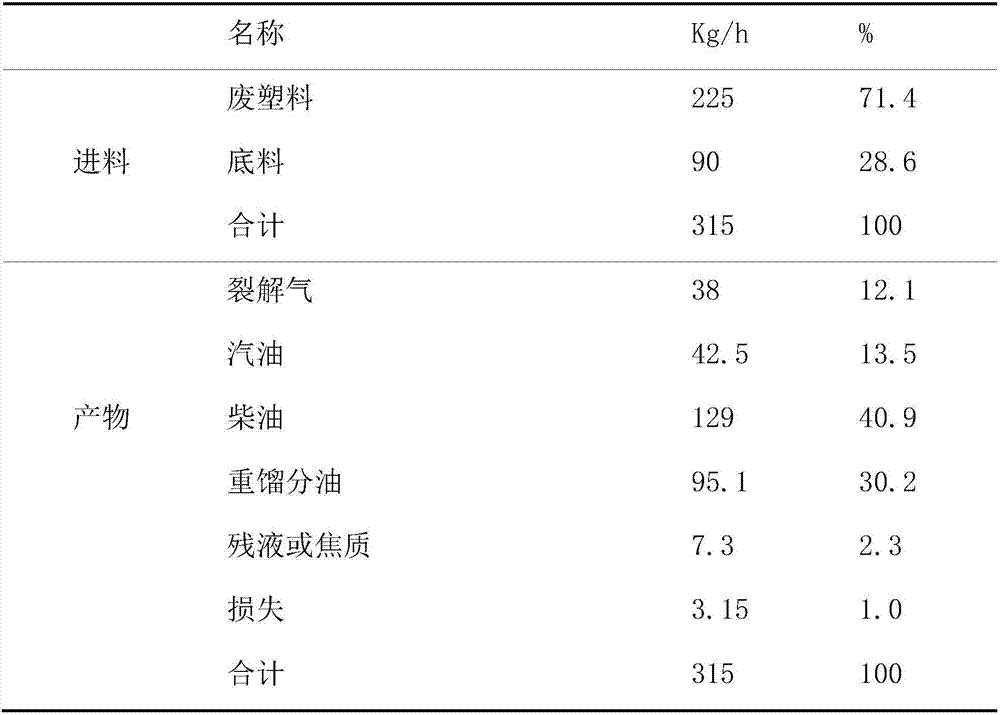

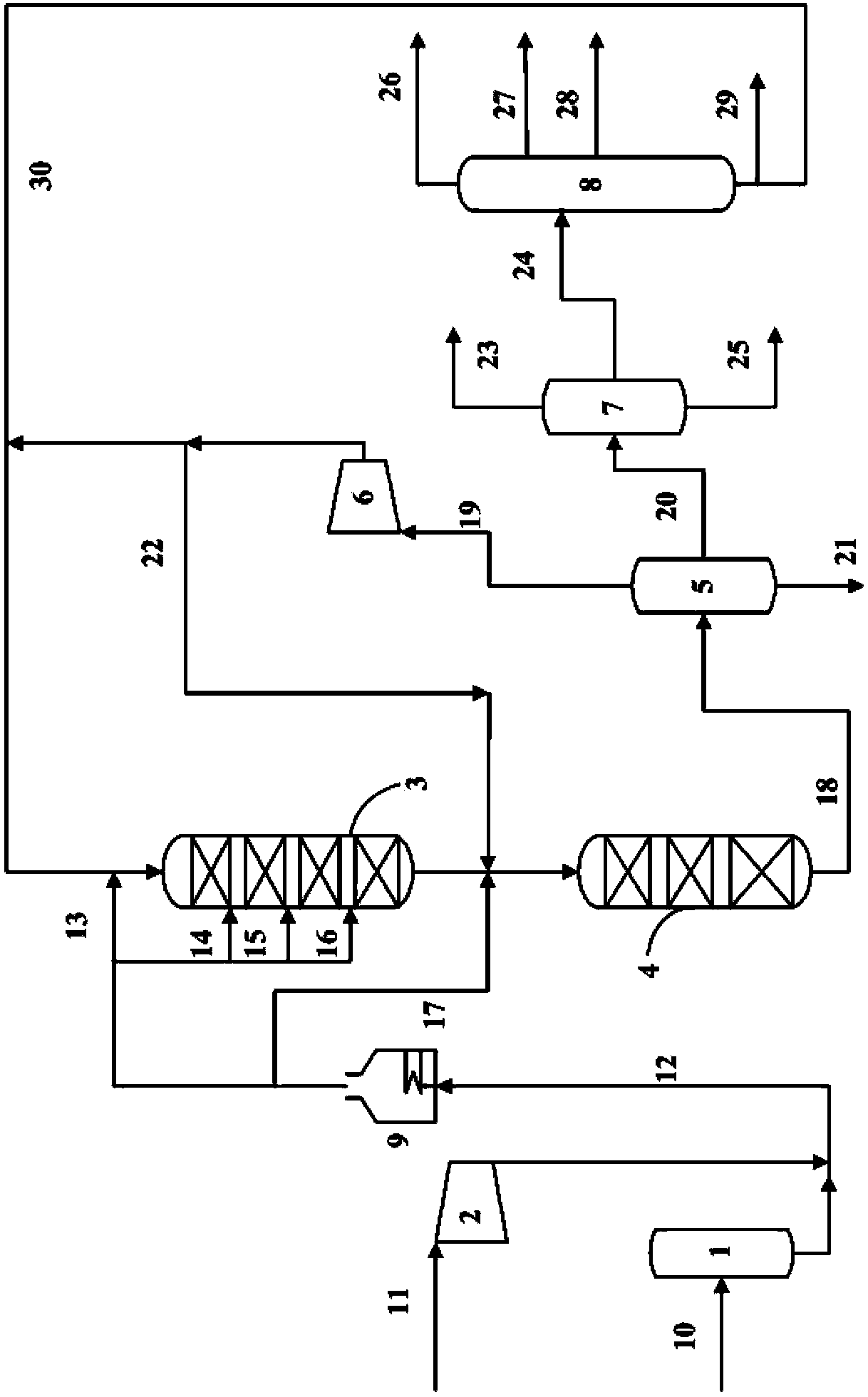

System and method for preparing oil product through pyrolysis and gasification of plastics

The invention relates to a system and a method for preparing an oil product through pyrolysis and gasification of plastics. The system comprises a heatless carrier heat accumulation type rotating bed and a fractionating tower, the heatless carrier heat accumulation type rotating bed comprises a rotating bed pyrolysis furnace, a heat accumulation type gas radiation tube burner, the shell of the rotating bed pyrolysis furnace is provided with a material inlet, a gas and liquid mixture outlet, a material outlet, a combustible gas inlet and a flue gas outlet, the gas and liquid mixture outlet is arranged on the sidewall of the shell, and the bottom furnace of the rotating bed pyrolysis furnace is a rotatable annular furnace bottom; and the heat accumulation type gas radiation tube burner is arranged on the annular furnace wall of the rotating bed pyrolysis furnace, the heat accumulation type gas radiation tube burner comprises an upper heat accumulation type gas radiation tube and a lower heat accumulation type gas radiation tube which are respectively positioned at the upper side and the lower side of the rotatable annular furnace bottom. The heatless carrier heat accumulation type rotating bed adopts radiation tube heating, so air is effectively isolated, generation of dioxins and other harmful gases is reduced, and the stability and the controllability of the oil and gas product are increased.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

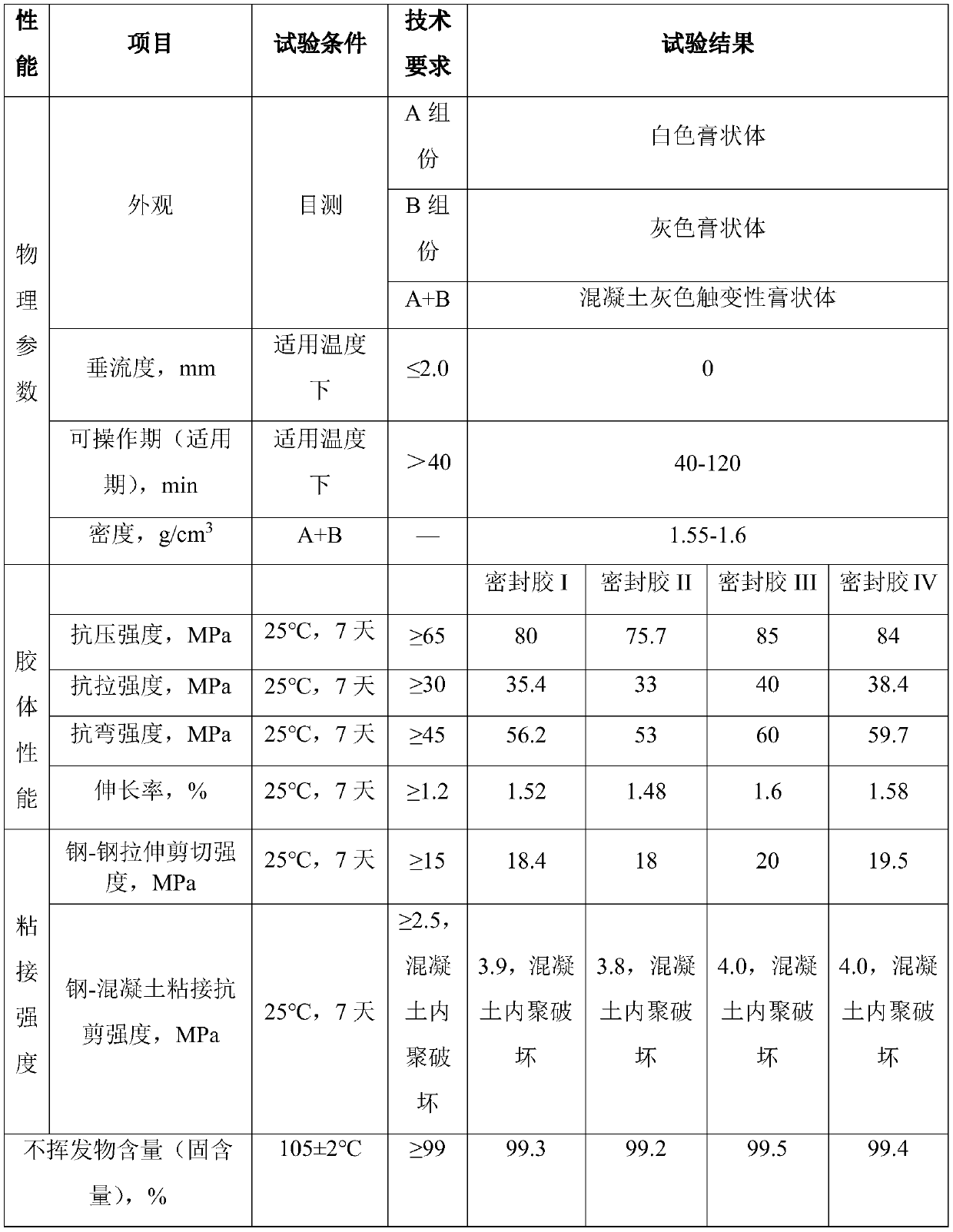

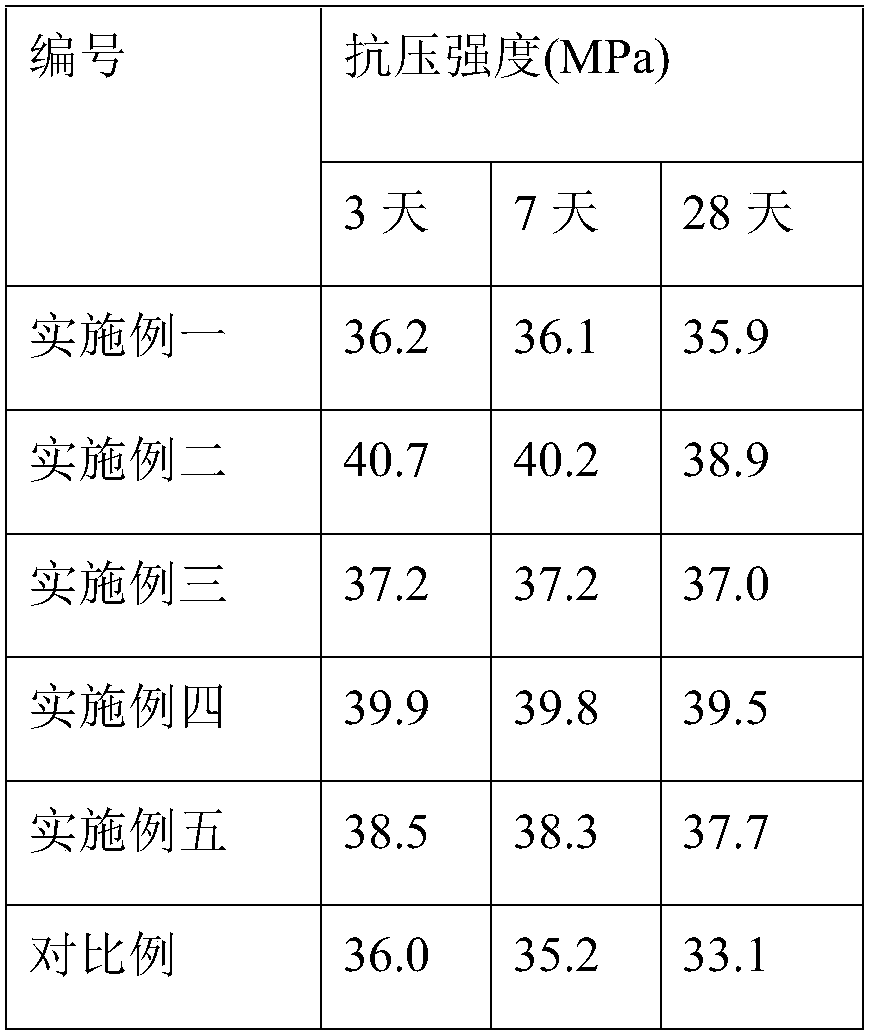

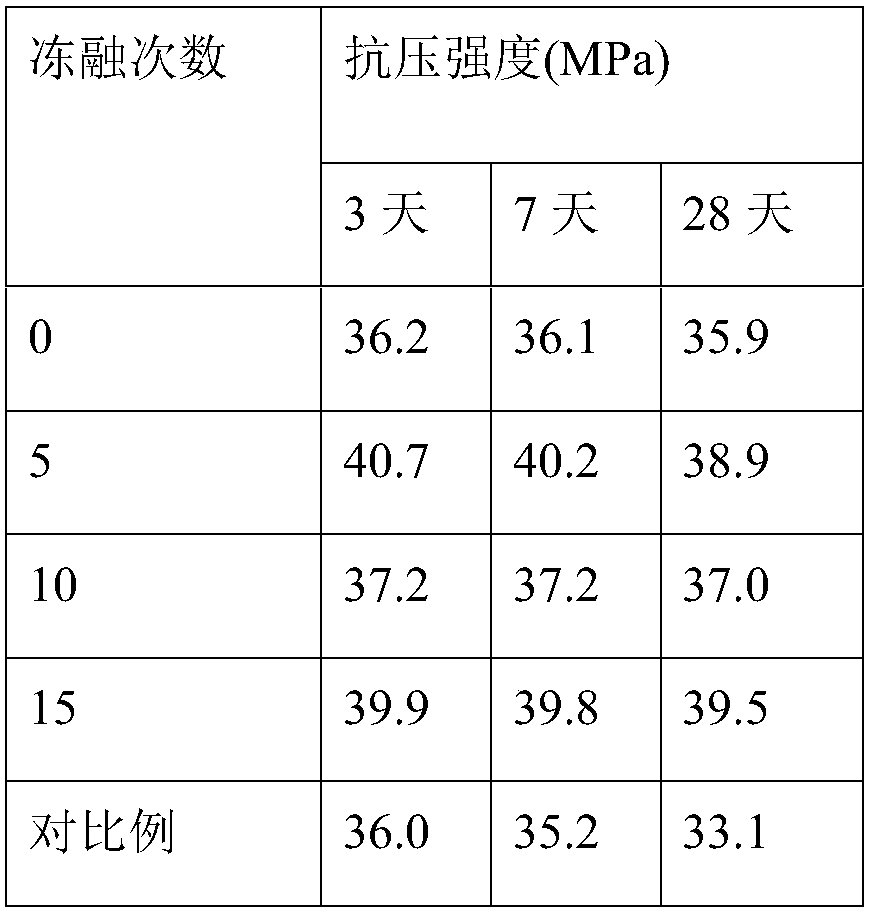

Two-component fabricated building sealant and preparation method thereof

InactiveCN110922927AGood adhesionEasy to prepareNon-macromolecular adhesive additivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention discloses a two-component fabricated building sealant and a preparation method thereof. The sealant is a reactive adhesive. In the curing process, volatile matters are extremely few, theshrinkage rate is low, a modified curing agent with excellent toughness is selected by the formula, and the modified curing agent is a high-toughness low-shrinkage-rate curing agent prepared by modifying polyether amine by using epoxy resin mixed with an active diluent, while the adhesion is excellent, a certain stress relaxation function is achieved. The preparation method and operation of the sealant are relatively simple and convenient, the material utilization rate is high, the concrete-colloid-concrete has high strength after gap sealing, and later secondary cracking can be effectively avoided.

Owner:HUNAN KOSEN NEW MATERIAL

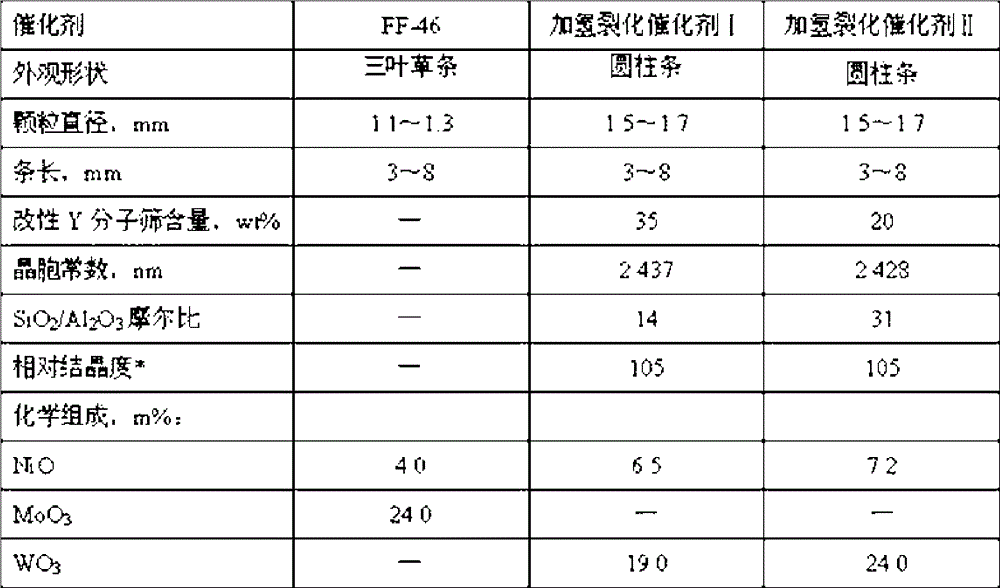

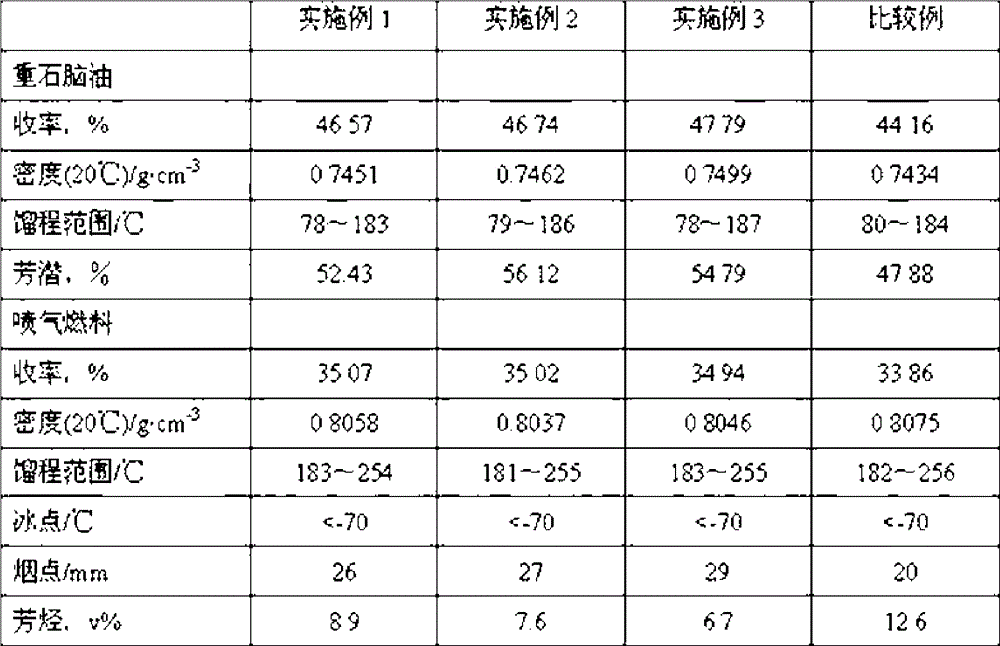

Two-stage hydrocracking method used for producing high-quality jet fuel

ActiveCN103773473AReduce the impactIncrease hydrogen partial pressureTreatment with hydrotreatment processesAlkaneMolecular sieve

The invention discloses a hydrocracking method used for producing high-quality jet fuel from inferior raw materials. The hydrocracking method comprises following steps: (1) inferior raw material oil is subjected to hydrofinishing reaction; (2) a hydrofinishing effluent is subjected to gas-liquid separation, and an obtained liquid material is subjected to fractionation; (3) tail oil obtained via fractionation is subjected to hydrocracking reaction, wherein a hydrocracking reaction zone comprises a hydrocracking catalyst I and a hydrocracking catalyst II with different molecular sieve contents; and (4) a hydrocracking effluent is subjected to separation, and an obtained liquid product is subjected to fractionation so as to obtain corresponding products. The upper part of the hydrocracking reaction zone is filled with the hydrocracking catalyst I; the hydrocracking catalyst I possesses relatively high aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw materials into smaller molecules, and distributing the smaller molecules into heavy petroleum and jet fuel fractions; the lower part of the hydrocracking reaction zone is filled with the hydrocracking catalyst II; and the hydrocracking catalyst II possesses relatively high hydrocarbon alkyl cracking capacity. The two catalysts are combined, so thathydrocracking product quality is improved obviously, and especially, smoke point of jet fuel fractions is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

External heating type solid carbon-containing material pyrolysis method and pyrolysis system

ActiveCN103666503AImprove heat transfer coefficientEffective disturbanceDirect heating destructive distillationBiofuelsSolid carbonHeat carrier

The invention relates to a solid carbon-containing material pyrolysis system which comprises a circulating fluid bed hearth and a pyrolysis channel, wherein a solid heat carrier flows in the hearth in a fluidized state; granular solid carbon-containing materials containing volatile compounds are added into the pyrolysis channel from the upper part, pass through the pyrolysis channel in a fluidized state from top to bottom under the action of gravity, and is subjected to pyrolysis reaction; the pyrolysis channel is penetrated through the hearth, and the upper end of the pyrolysis channel and the lower end of the pyrolysis channel are positioned outside the hearth; the pyrolysis channel and the hearth are divided by a heat-conducting dividing wall, the solid heat carrier and the solid carbon-containing materials in the pyrolysis channel perform heat exchange through the heat-conducting dividing wall, and the solid carbon-containing materials are heated and subjected to pyrolysis reaction. The invention also relates to a solid carbon-containing material pyrolysis method.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Air guide brick and air guide wall thereof as well as pulverized coal destructive distillation carbonization chamber applying brick and wall

InactiveCN102634359ASimple structureImprove structural strengthIndirect heating destructive distillationSpecial form destructive distillationBrickCombustion chamber

The invention discloses an air guide brick and an air guide wall thereof as well as a pulverized coal destructive distillation carbonization chamber applying the brick and the wall, wherein the air guide brick is internally provided with air receiving bricks and air exhaust bricks with air channel structures; the air guide wall is composed of at least one longitudinal air channel and at least one horizontal air channel which are formed by a plurality of air receiving bricks and air exhaust bricks in 'T' -shaped structures or 'straight-line'-shaped structures which are communicated with the air receiving bricks; the top end of each longitudinal air channel is provided with an air general channel, and the bottom end of each longitudinal air channel is provided with a tar channel; the carbonization chamber is positioned at the middle line of the carbonization chamber, and the part of the carbonization chamber parallel to a combustion chamber is provided with the air guide wall, and two surfaces of the air guide wall are provided with support walls. The air guide wall of the carbonization chamber provided by the invention internally forms a low-temperature protection region which has the characteristics of rapid guide speed of pyrolysis gaseous products, high comprehensive utilization of pulverized coal, reasonable structure, high intensity and the like.

Owner:TAIYUAN UNIV OF TECH

Integrated gas retort

ActiveCN102827619AReduce consumption costsLow running costEnergy inputIndirect heating destructive distillationCombustion chamberHeat carrier

The invention relates to an integrated gas retort integrating heating of a heat carrier and dry distillation of materials into the same one dry distillation unit. The integrated gas retort is characterized in that smoke gas is used as dry distillation heat carrier for indirectly heating materials; the gas retort is formed by combining a plurality of dry distillation sub units. Each dry distillation sub unit is independent, one combustion chamber corresponds to one dry distillation chamber to form one dry distillation sub unit, the upper parts of retorts comprising a plurality of dry distillation sub units are communicated, the two dry distillation sub units are separated by a smoke gas chamber, and the lower parts share one water seal tank and a tar exhaust device. The actual daily capacity of the gas retort can achieve more than 6000. The integrated gas retort is applicable to low-temperature dry distillation oil refining of materials oil sand, oil shale, coal and the like. The integrated gas retort is applicable to dry distillation and oil refining of small-particle materials, as well as various qualities of materials with low gas content, low fixed carbon content and high moisture content, and the oil recovery rate of the gas retort can achieve about 90%.

Owner:辽宁智越建设有限公司

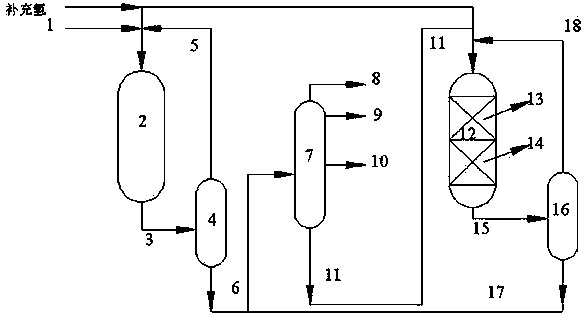

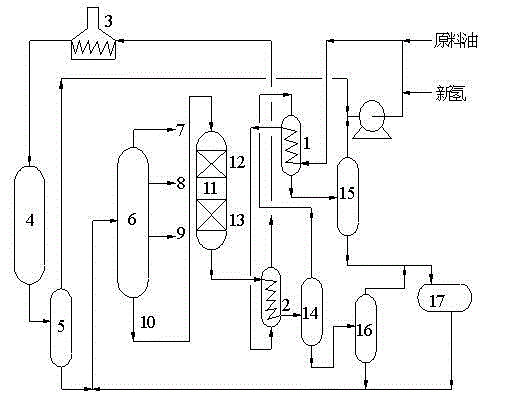

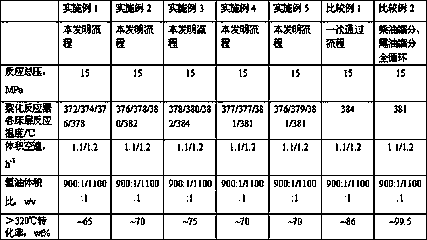

Hydrocracking method

ActiveCN103525461AHigh selectivityAvoid secondary crackingTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a hydrocracking method comprising the steps that raw oil is divided into raw oil I and raw oil II according to a certain proportion; the raw oil I is mixed with hydrogen and is heated by a heating furnace I, and then, the mixture enters a hydrorefining reactor together with an effluent from a hydrocracking reactor and reacts under the action of a hydrorefining catalyst; the raw oil II is mixed with a tail oil distillate and is heated by a heating furnace II after being mixed with a hydrogen-rich gas, and then, the mixture enters the hydrocracking reactor and reacts under the action of a hydrocracking catalyst, wherein the reaction effluent of the hydrorefining reactor is separated and distillated to obtain the hydrogen-rich gas, a light naphtha distillate, a heavy naphtha distillate, middle distillate oil and a tail oil distillate. The method provided by the invention can be used for treating heavy distillate oil and producing the middle distillate oil at the maximum quantity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Parallel-flow hydrogenation method for producing intermediate fraction oil

ActiveCN103509599AHigh selectivityAvoid secondary crackingTreatment with hydrotreatment processesEffluentChemistry

The invention relates to a parallel-flow hydrogenation method for producing intermediate fraction oil, which comprises the following steps: fresh oil raw materials are simultaneously introduced into a hydrofining reactor and a hydrocracking reactor in a parallel-flow mode, wherein the fresh oil raw material entering the hydrocracking reactor is divided into a plurality of streams which are respectively fed among the beds of the hydrocracking reactor; and the reaction effluent of the hydrofining reactor is subjected to tail oil fraction separation and enters the hydrocracking reactor, and the reaction effluent of the hydrocracking reactor enters the hydrofining reactor together with part of the oil raw material. The method provided by the invention can treat heavy fraction oil, and maximally produce the intermediate fraction oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fischer-Tropsch synthesis wax hydrocracking catalyst, preparation method thereof, and Fischer-Tropsch synthesis wax hydrocracking method

PendingCN110433819AGood dispersionAvoid secondary crackingHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsWaxSorbent

The invention belongs to the field of Fischer-Tropsch synthesis catalytic hydrocracking, and discloses a Fischer-Tropsch synthesis wax hydrocracking catalyst, a preparation method thereof, and a Fischer-Tropsch synthesis wax hydrocracking method. The preparation method of the Fischer-Tropsch synthesis wax hydrocracking catalyst comprises following steps: 1, amorphous silicon aluminium and a binderare subjected to mixing kneading, strip extrusion moulding, primary drying, and primary roasting to obtain a catalyst carrier; and 2, the catalyst carrier is immersed in a dipping solution containinghydrogenation active metal elements and a competitive adsorbent, and secondary drying and secondary roasting are carried out to obtain the Fischer-Tropsch synthesis wax hydrocracking catalyst, wherein the hydrogenation active metal elements contain at least one metal element selected from VIII family in the periodic table of elements, and at least one metal element selected from VIB family in theperiodic table of elements at the same time, and the volume amount of the dipping solution containing hydrogenation active metal elements accounts for 65 to 85% of the pile volume of the catalyst carrier. The hydrogenation active metal components of the catalyst are excellent in dispersibility, and intermediate fraction oil selectivity is high.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

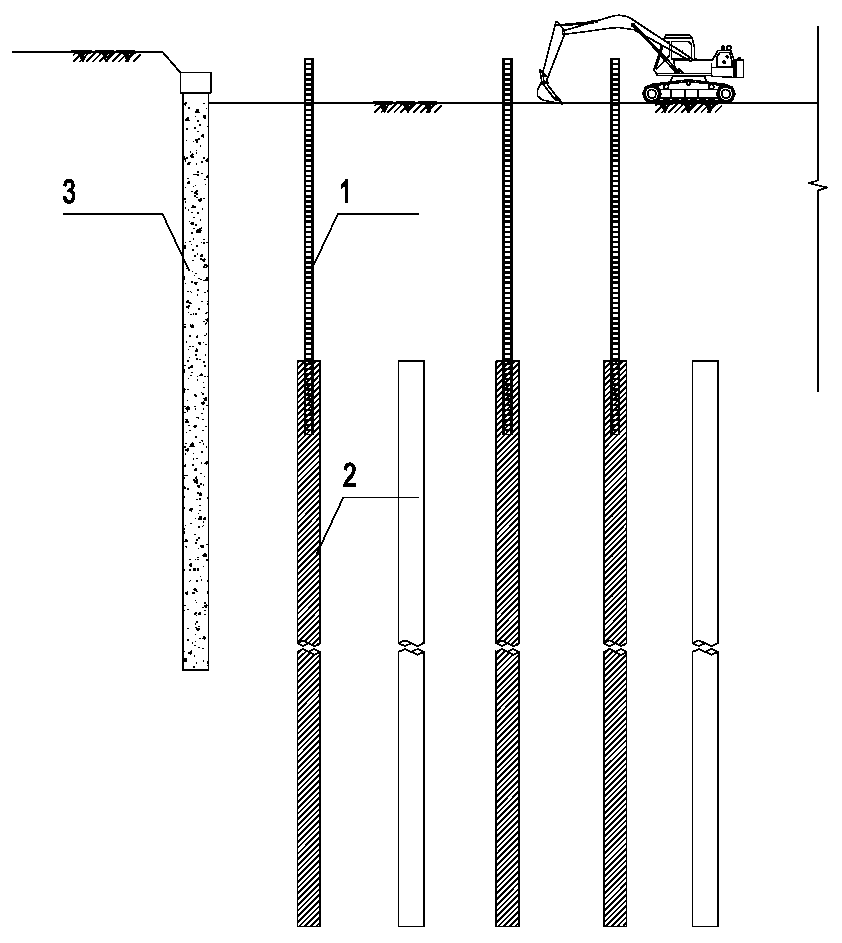

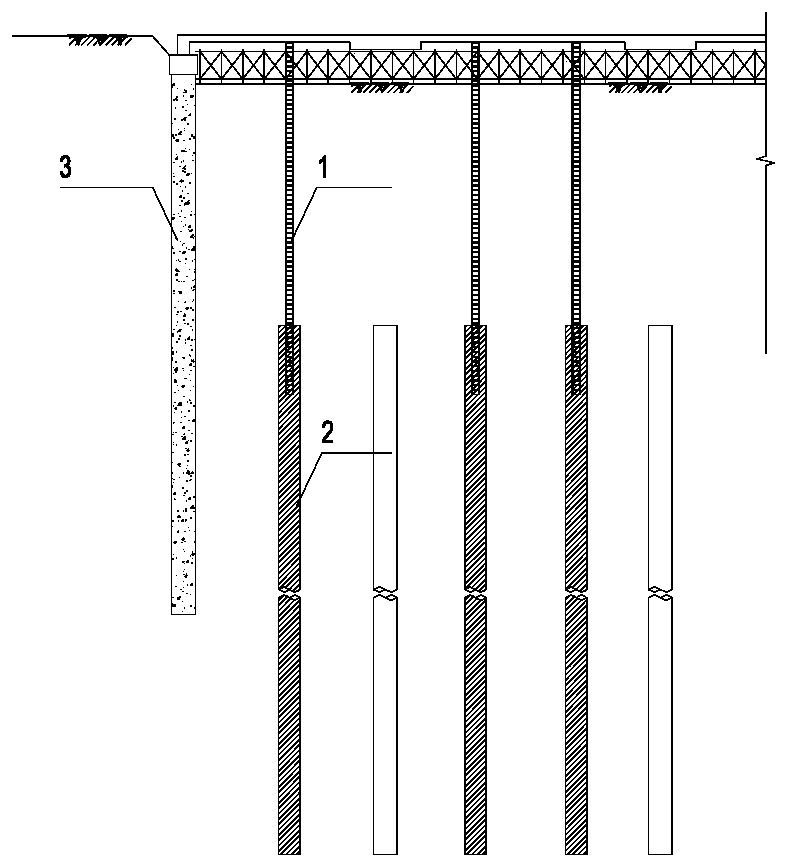

Forward-reverse combined construction method for foundation pit of non-permanent vertical support system

ActiveCN109944250ALow costEffective control of displacement and deformationExcavationsBasementSupporting system

The invention provides a forward-reverse combined construction method for a foundation pit of non-permanent vertical support system, and belongs to the technical field of foundation pit support designand construction, and provides a construction method which has the advantages of a reverse construction method and a forward construction method at the same time. According to the method, a beam plate with a permanent structure is adopted as a horizontal support, and a temporary vertical support member is adopted to bear a vertical force during foundation pit construction. And earthwork is excavated according to the floor from top to bottom, a structural beam plate is poured, a permanent vertical member is poured from bottom to top after bottom plate construction is finished, and finally temporary steel upright posts are disassembled from top to bottom to finish earthwork excavation and structural construction of the whole basement. Namely, when the permanent structural beam plate is adopted to replace a support in the foundation pit, the temporary vertical support member is adopted to bear the vertical force during the construction of the foundation pit, and the excavation of the foundation pit and the construction of the basement structure of the whole basement are achieved through reasonable construction sequence and reliable node connection.

Owner:SHANGHAI CONSTRUCTION GROUP +1

Method and device for coal direction liquefaction

ActiveCN108048121AImprove liquefaction conversionExtended stayLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsLiquid productHydrogen

The invention provides a method and device for coal direction liquefaction. The method for the coal direct liquefaction includes the following steps of: S1, performing a first liquefaction reaction ona first raw material which includes coal slurry and hydrogen so as to obtain first liquefied products, and performing oil-gas separation on the first liquefied products to obtain a first liquid-phaseproduct; S2, performing a second liquefaction reaction on a second raw material which comprises the first liquid-phase product, hydrogen and a solvent so as to obtain second liquefied products, and performing oil-gas separation on the second liquefied products to obtain a second liquid-phase product; S3, performing distillation and catalytic hydrogenation treatment on a part of the second liquid-phase product so as to obtain a coal liquefaction product; and S4, performing the steps of S1-S3 repeatedly, wherein the first raw materials and / or the second raw materials also include the rest of the second liquid-phase product during the repeated operation. Through the method for the coal direct liquefaction, the liquefaction conversion rate and liquid product yield of coal can be improved, andthe resource utilization rate can be improved significantly.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Two-stage hydrocracking method for low energy consumption production of high-quality jet fuels

ActiveCN105001909AReduce consumptionSave engineering investmentHydrocarbon oil crackingTreatment with hydrotreatment processesFractionationHigh pressure

The invention discloses a two-stage hydrocracking method for low energy consumption production of high-quality jet fuels. The method comprises the following steps: mixing a raw material with hydrogen, carrying out two-time heat exchange, allowing the obtained material to go through a heating furnace, and carrying out a hydrofining reaction; carrying out gas-liquid separation and fractionation on a refining effluent; allowing obtained tail oil to enter a hydrocracking reaction zone, wherein the cracking reaction zone comprises at least two cracking catalysts, the upstream is a catalyst I, the downstream is a catalyst II, the catalyst I contains 15-50wt% of modified Y molecular sieve, the catalyst II contains 3-30wt% of the modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-25% higher than the content of the modified Y molecular sieve in the catalyst II; and separating and fractioning a hydrocracking effluent to obtain various products. The method organically combines a high temperature and high pressure countercurrent heat transfer technology with a hydrocracking catalyst grading technology, comprehensively utilizes hydrocracking reaction heat, maintains the catalyst selectivity, improves the quality of target products, and reduces the engineering investment and the operation energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

SBS (Styrene Butadiene Styrene) emulsive modified bitumen road cold sealant and preparation method thereof

InactiveCN103725255AImprove maintenance efficiencyReduce maintenance costsNon-macromolecular adhesive additivesOther chemical processesPolymer scienceSodium Bentonite

The invention discloses an SBS (Styrene Butadiene Styrene) emulsive modified bitumen road cold sealant and a preparation method thereof. Materials A and B are mixed according to a weight ratio of (30-40%):(60-70%) and sheared by a colloid mill to form the SBS emulsive modified bitumen road cold sealant, wherein the material A is prepared from the following raw materials in parts by weight: 3-5 parts of furfural extract oil, 3-4 parts of styrene-butadiene-styrene block copolymer and 91-94 parts of bitumen; the material B is prepared from the following raw materials in parts by weight: 1.5-2 parts of hexadecyl trimethyl ammonium bromide, 88-92.5 parts of water and 8-10 parts of Na-bentonite. The invention has the advantages that the SBS emulsive modified bitumen road cold sealant can be adhered to cracks for a long time when being used in the road engineering treatment process of road damage such as crack and surface void, is short in forming time and slight in shrinkage during preparation, and can prevent the secondary cranking in repaired positions.

Owner:河南金欧特实业集团股份有限公司

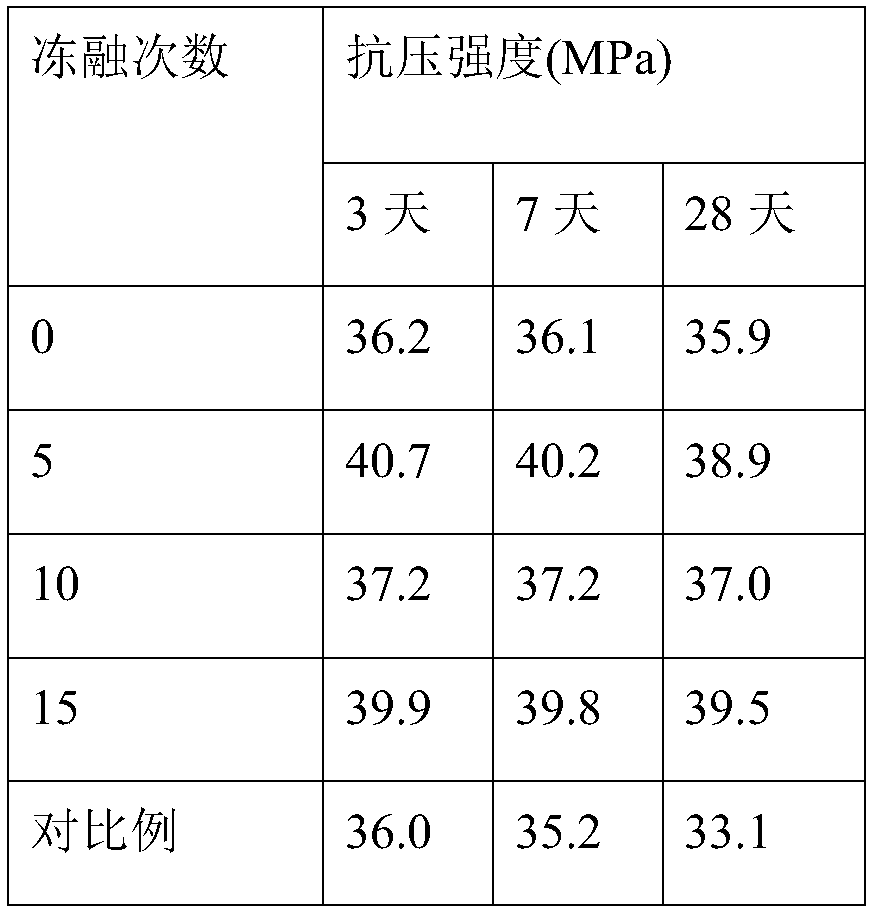

Marine environment concrete crack repair material and preparation method thereof

The invention discloses a marine environment concrete crack repair material which is prepared from the following components in parts by weight: 30-50 parts of Portland cement, 10-30 parts of desaltedsea sand, 5-15 parts of abandoned sea fish, 10-30 parts of crustacean exoskeleton, 4-10 parts of silica fume, 2-5 parts of a corrosion inhibitor, 0.5-2 parts of an early strength agent, 5-10 parts ofan expanding agent and 0.1-0.5 part of polypropylene fiber. The above materials are suitable for marine environment concrete crack repair and can ensure the long-term marine environmental concrete service after being filled.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

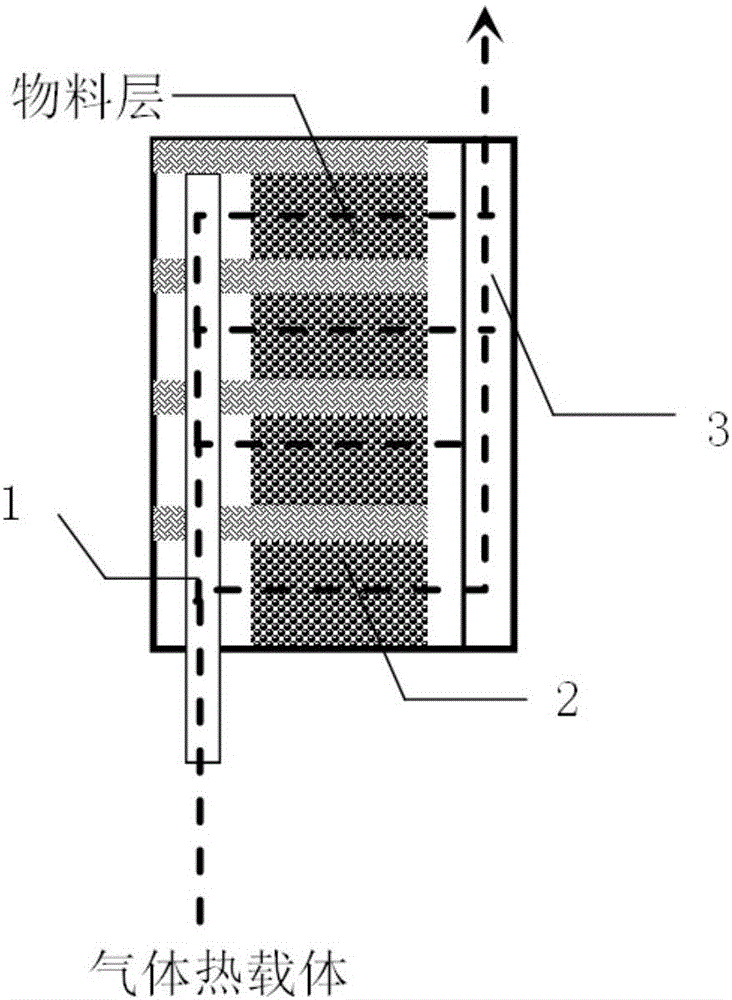

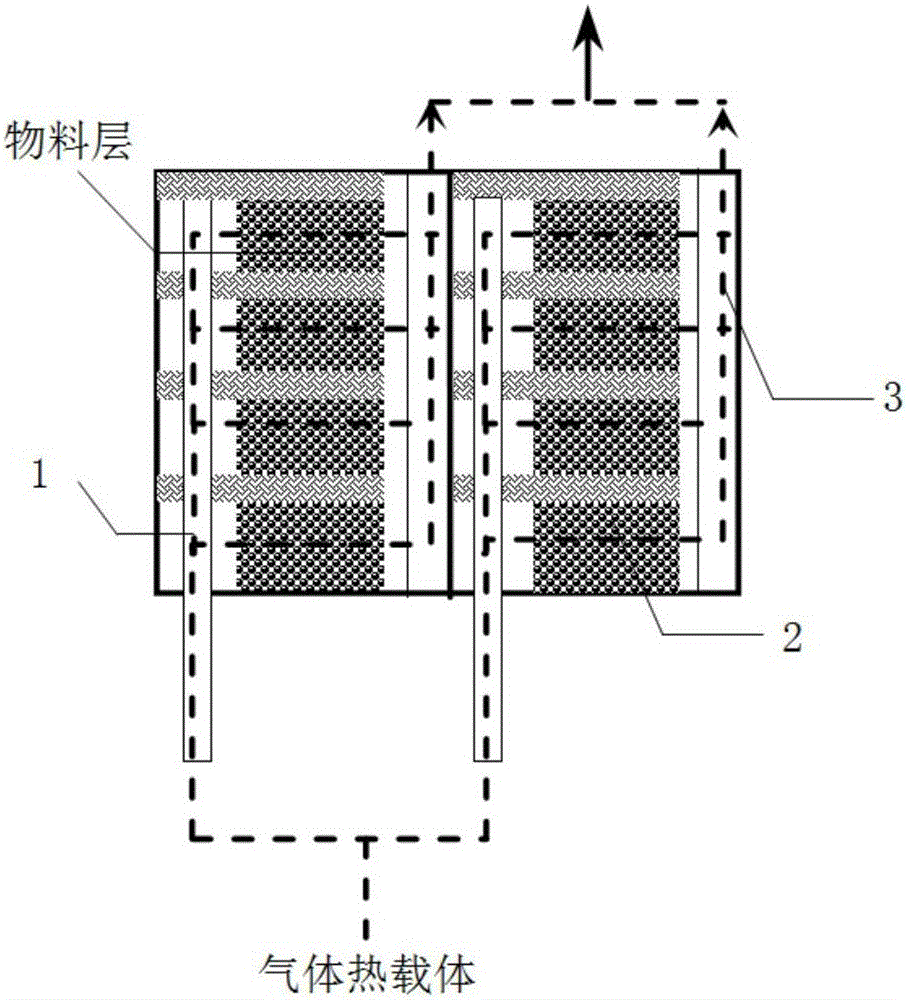

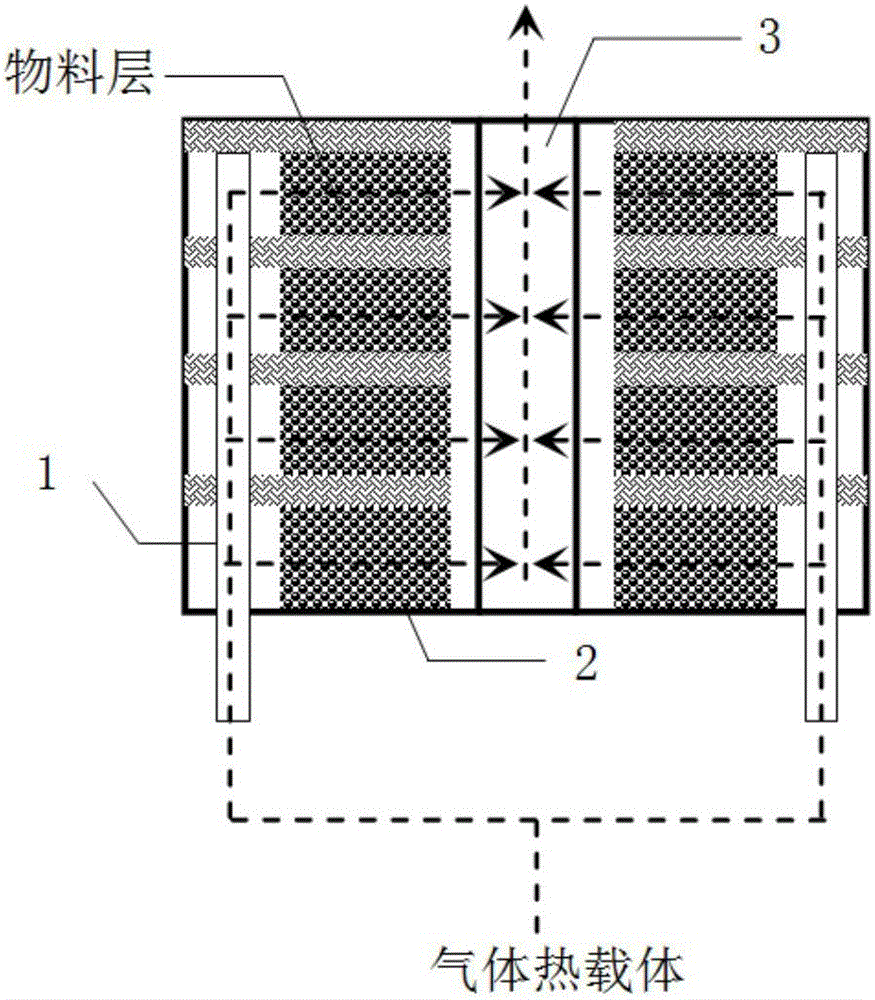

Pyrolysis method for low-rank coal or oil shale with higher tar yield

InactiveCN105018116AHigh yieldReduce resistanceDirect heating destructive distillationSpecial form destructive distillationHeat carrierCombustion chamber

The invention relates to a pyrolysis method for low-rank coal or oil shale with higher tar yield, and is suitable for a heat upgrading process of a low-rank coal moving bed with the purpose of obtaining high-yield tar. The method is a gas heat carrier technology, high-temperature gas flows to the cold end of a collection chamber from a combustion chamber at the hot end of a carbonization chamber by traversing a coal material, quick gas-solid heat exchange between hot carrier gas and the coal material is performed, and the coal material is heated to perform low-temperature pyrolysis. A gas-oil mixture generated by pyrolysis, together with the hot carrier gas, is introduced by the collection chamber at the cold end of the carbonization chamber. The pyrolysis method is characterized in that oil gas and a hot carrier generated by pyrolysis quickly pass through the coal material with the average radial temperature gradient of 600 DEG C / m, and flow to a low-temperature area from a high-temperature area, so that obvious secondary splitting is avoided in time. On the other hand, the method adopts the gas hot carrier to radially penetrate a coal layer, and heat is transferred to the internal coal material at a short transverse distance by the hot carrier, so that the material layer resistance can be obviously reduced, pulverization and semi-coke bringing is reduced, and the heat transfer efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

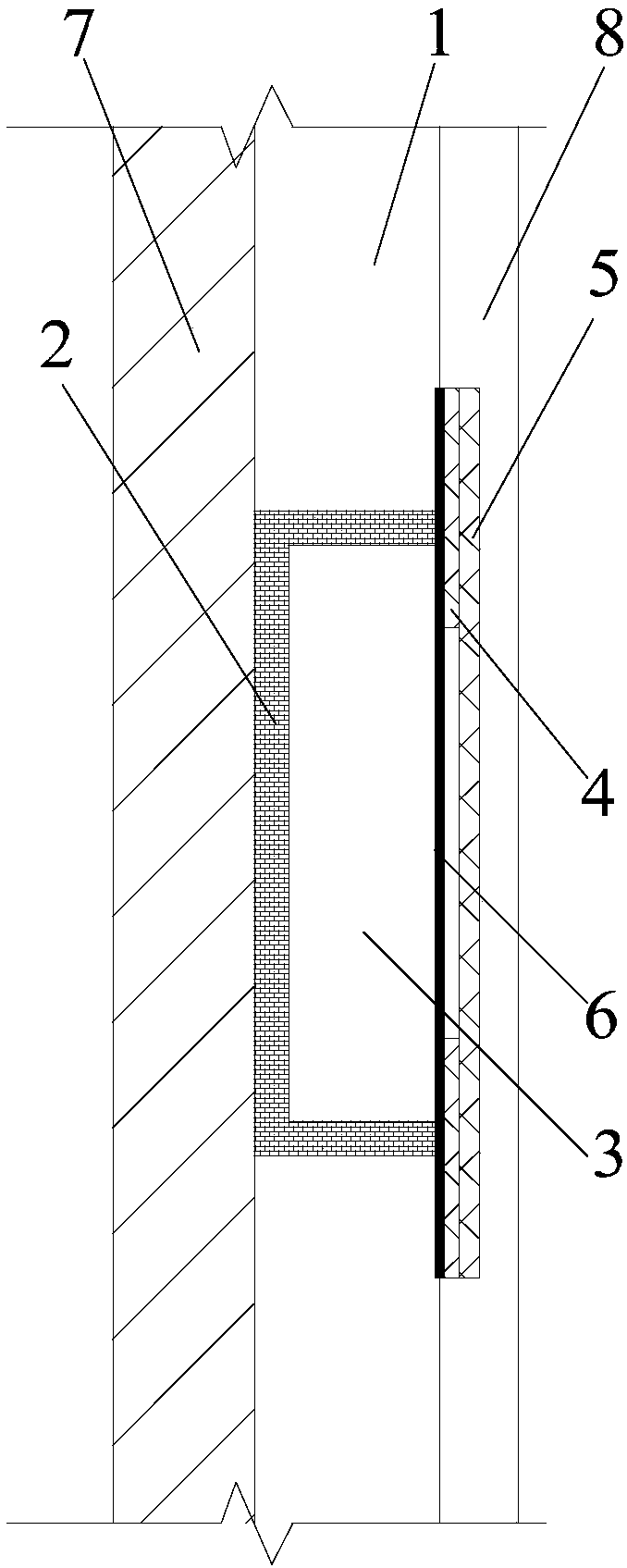

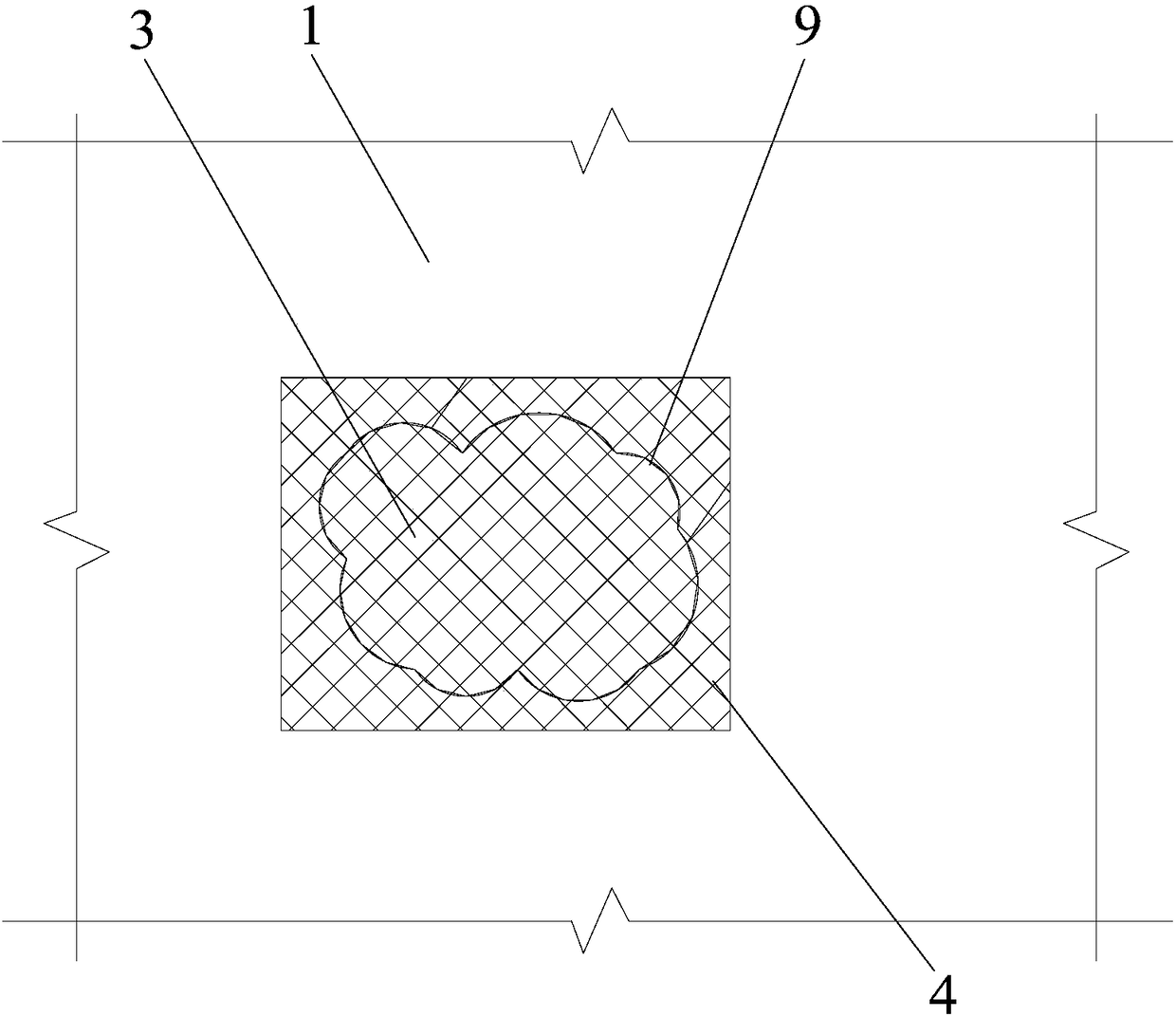

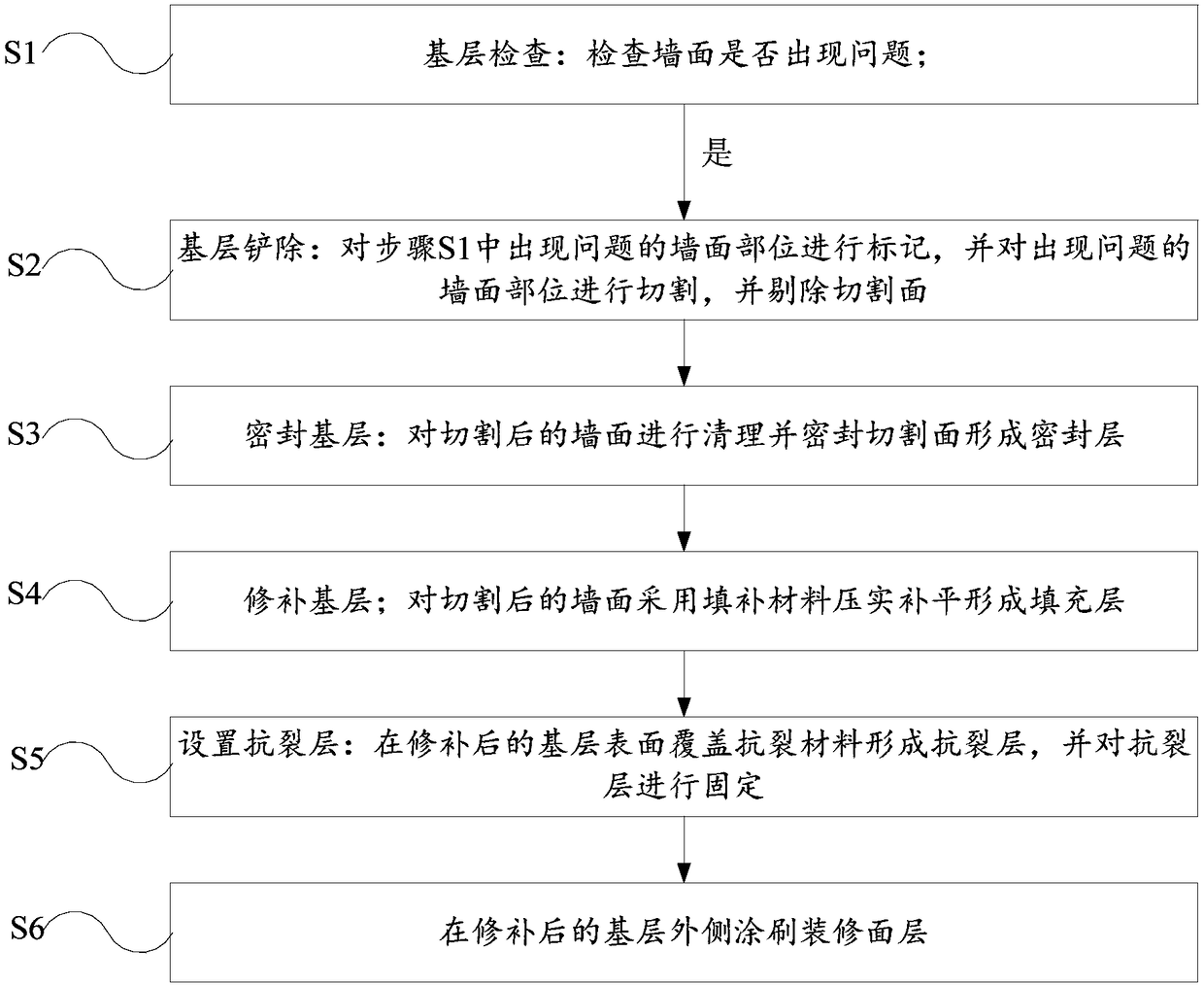

Plastering wall surface repairing process

InactiveCN108131022AAvoid crackingSolve the problem of bonding hollowingBuilding repairsSurface layerStructural engineering

The invention relates to the technical field of building, in particular to a plastering wall surface repairing process. The provided plastering wall surface repairing process comprises the following steps of inspecting a base layer, erasing the base layer, sealing the base layer, repairing the base layer, arranging a crack-resistant layer, covering a repairing wall surface with a crack-resistant material and fixing the crack-resistant layer. According to the plastering wall surface repairing process, since the steps of sealing the base layer and arranging the crack-resistant layer are added onthe basis of a conventional repairing method, the sealing layer can reduce the reoccurring chance of previous problems before repairing, the crack-resistant layer can prevent a repaired part and anoriginal wall surface layer from cracking, correspondingly the problems previously happening to the repaired part of the wall surface is permanently prevented from reoccurring, and secondary crackingof the repairing part and the original wall surface layer is prevented. Therefore, by adopting the process, the treated wall surface can be effectively bonded to the original wall surface base layerto prevent the junction form cracking and prevent problems such as empty bumps on the treated wall surface from reoccurring, and defects caused by manual techniques are overcome in the technical link.

Owner:DONG YI RI SHENG HOME DECORATION GRP

Hydrocracking method for increasing production of high-quality middle distillates

ActiveCN102807898AHigh selectivityAvoid secondary crackingTreatment with hydrotreatment processesNaphthaChemistry

The invention relates to a hydrocracking method for increasing production of high-quality middle distillates. The method comprises the following steps that: fresh feedstock oils are simultaneously introduced into a hydrofining reactor and a hydrocracking reactor in a co-current flow way; the hydrofining reactor is sequentially filled with a hydrofining catalyst and an amorphous hydrocracking catalyst; the hydrocracking reactor is sequentially filled with a hydrofining catalyst and a zeolite hydrocracking catalyst; a reaction effluent from the hydrofining reactor is separated to obtain light naphtha fractions and tail oil fractions; and all or part of the tail oil fractions are introduced into the hydrocracking reactor, and a reaction effluent from the hydrocracking reactor and part of the feedstock oils are introduced into the hydrofining reactor together. According to the method provided by the invention, the heavy distillates can be treated, and the maximum production of the middle distillates can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

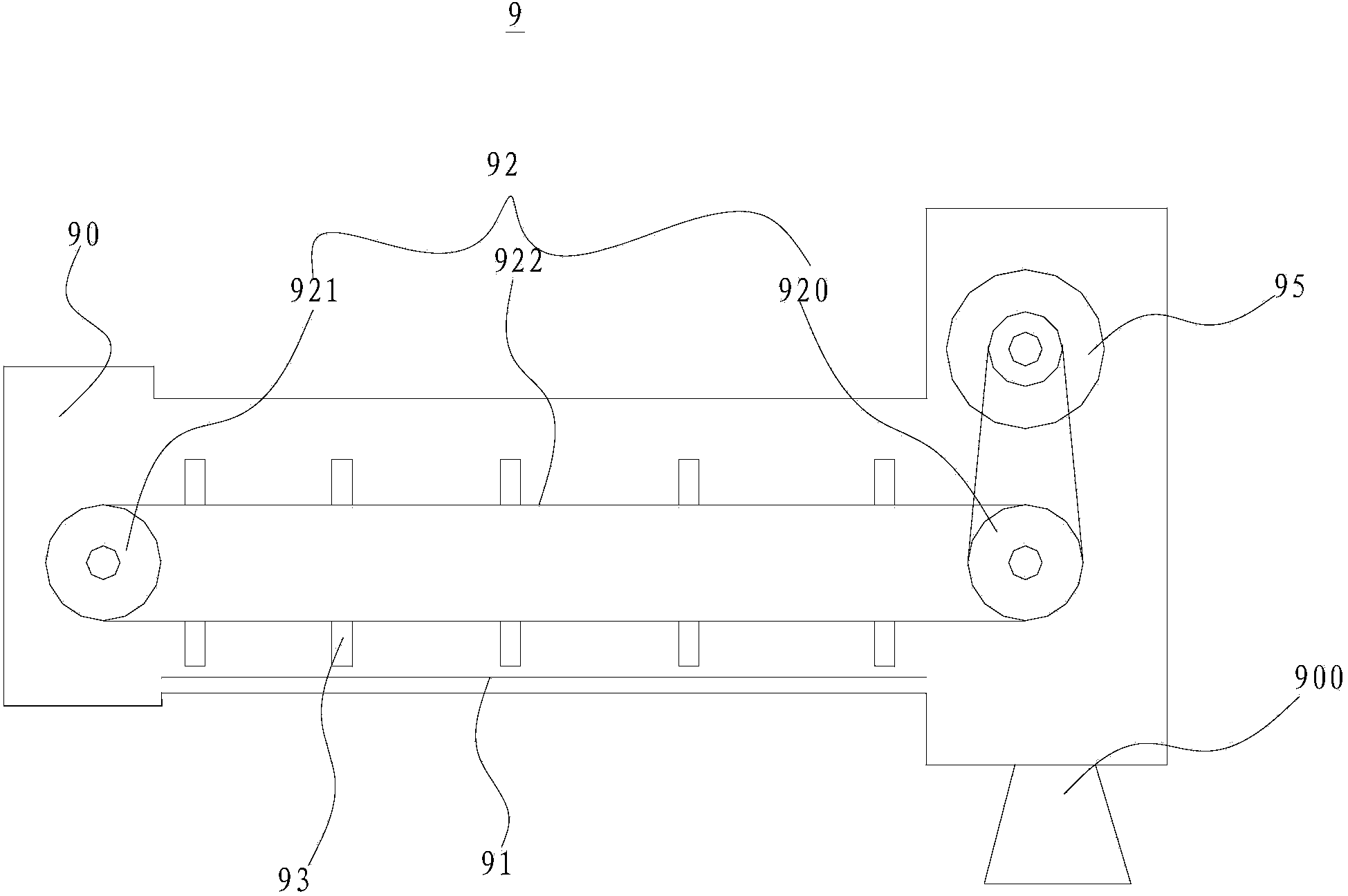

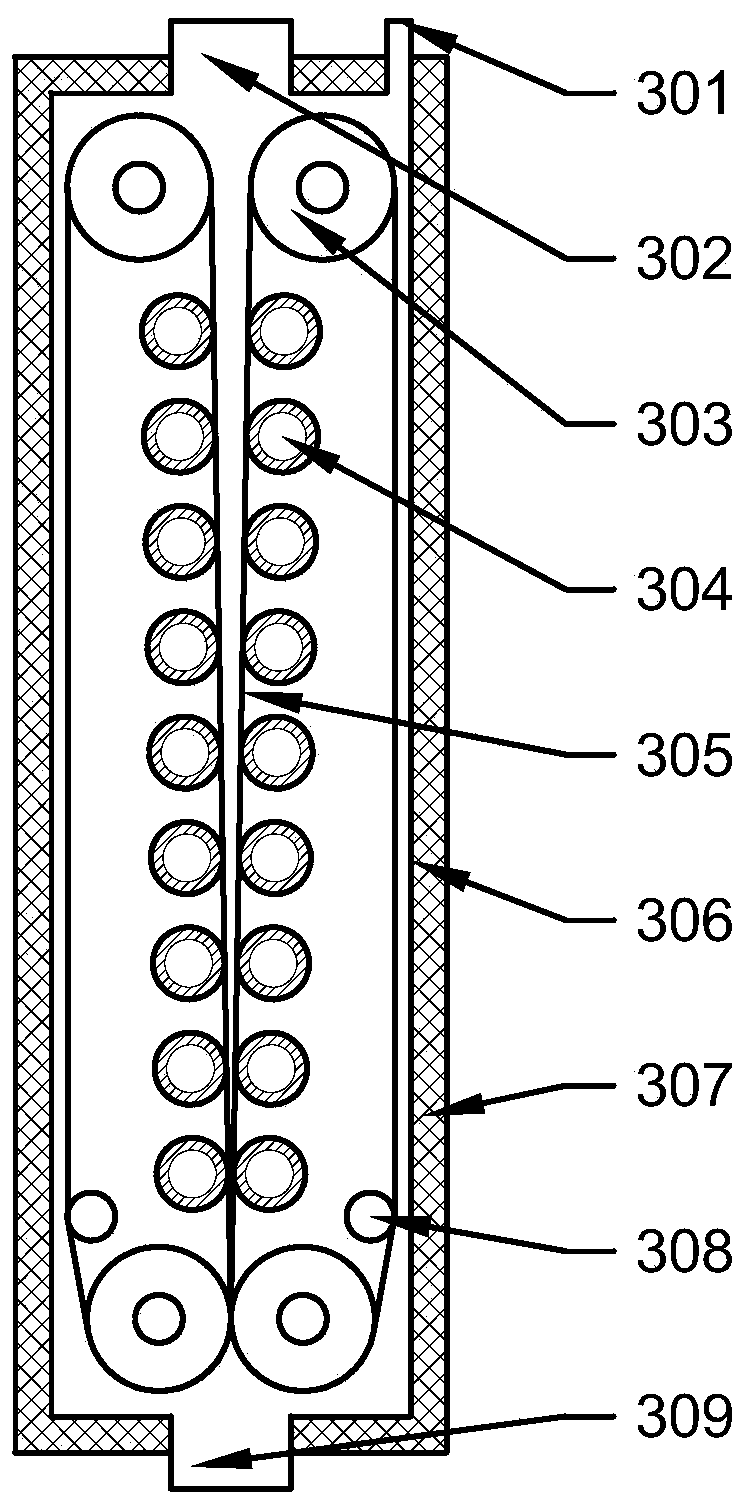

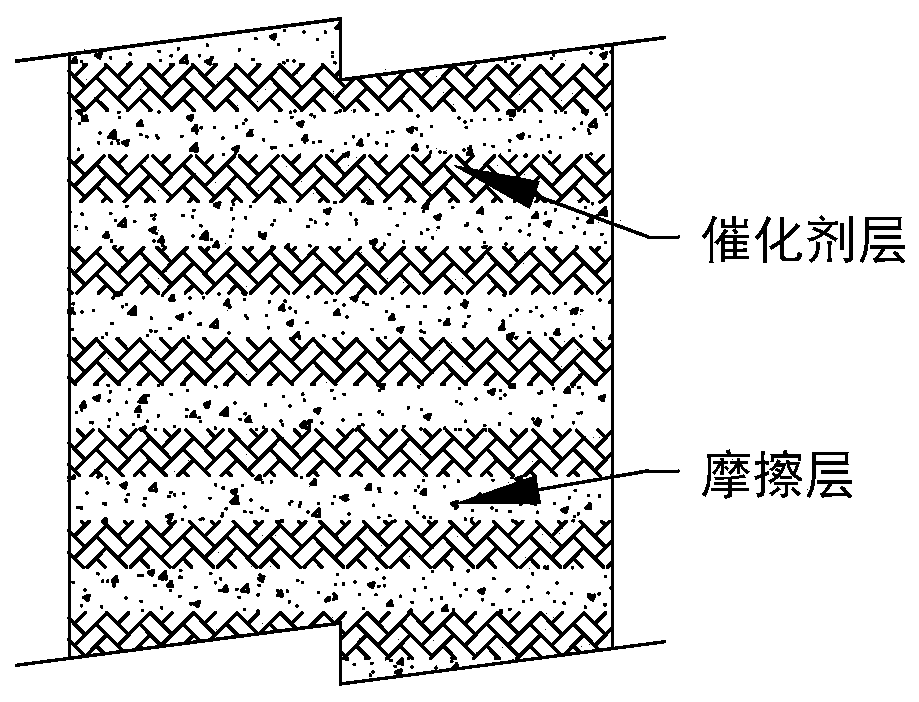

Grinding belt-type device for rapid catalytic pyrolysis of biomass and method

ActiveCN110003927ARapid condensationFully condensedBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisCombustion system

The invention belongs to the field of biomass energy utilization, and relates to a grinding belt-type device for rapid catalytic pyrolysis of biomass and a method. The device comprises a hopper, a feed system, a grinding belt-type pyrolysis reactor, a gas-solid separation system, a pyrolysis gas condensation system, a combustion system, a bio-oil collection tank, a charcoal collection tank, an airpreheating system and a flue gas purification system, wherein the grinding belt-type pyrolysis reactor comprises grinding belts, heating tubes, driving drums, tensioning devices, a sealed casing, a feed inlet, a discharge opening and a gas outlet. Pretreated material particles are continuously sheared and rubbed by the grinding belts with speed difference on two sides, and are heated by the multi-layer heating tubes to continuously pyrolyze on the surface while stripping the residual charcoal, so that a catalyst and heat can be fully fed inside the particles; the pyrolysis gas is rapidly condensed by gas-solid separation to obtain high-grade bio-oil fuel or bio-oil rich in specific high value-added products; combustible gas and coke produced by combustion generate high-temperature flue gas for heating the heating tubes, so as to achieve an autothermal pyrolysis process.

Owner:北京博霖环境科技有限公司

Hydrocracking method for improving yield of heavy naphtha

The invention discloses a hydrocracking method for improving the yield of heavy naphtha. The method comprises the following components: (1), raw oil and hydrogen are mixed and then enter a hydrorefining reactor, and are in contact with a hydrorefining catalyst, so that refining reaction, such as hydrodesulfurization, hydrodenitrogenation and aromatic saturation, occurs; (2), generated oil obtainedin the step (1) and hydrogenation tail oil are mixed and enter a hydrocracking reactor to be subjected to hydrocracking reaction, and are mixed with circulation oil among different beds to be reactedcontinuously; (3), generated oil obtained in the step (2) enters a separation system, obtained hydrogen is recycled, obtained generated distillate oil enters a fractionating system, so as to obtain gas, light naphtha, heavy naphtha, middle distillate and hydrogenation tail oil, the hydrogenation tail oil and the generated oil obtained in the step (1) are mixed and then circulated to the inlet ofthe hydrocracking reactor, and the middle distillate returns the positions among catalyst beds of the hydrocracking reactor. The method can produce more heavy naphtha and improve the product quality of the heavy naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

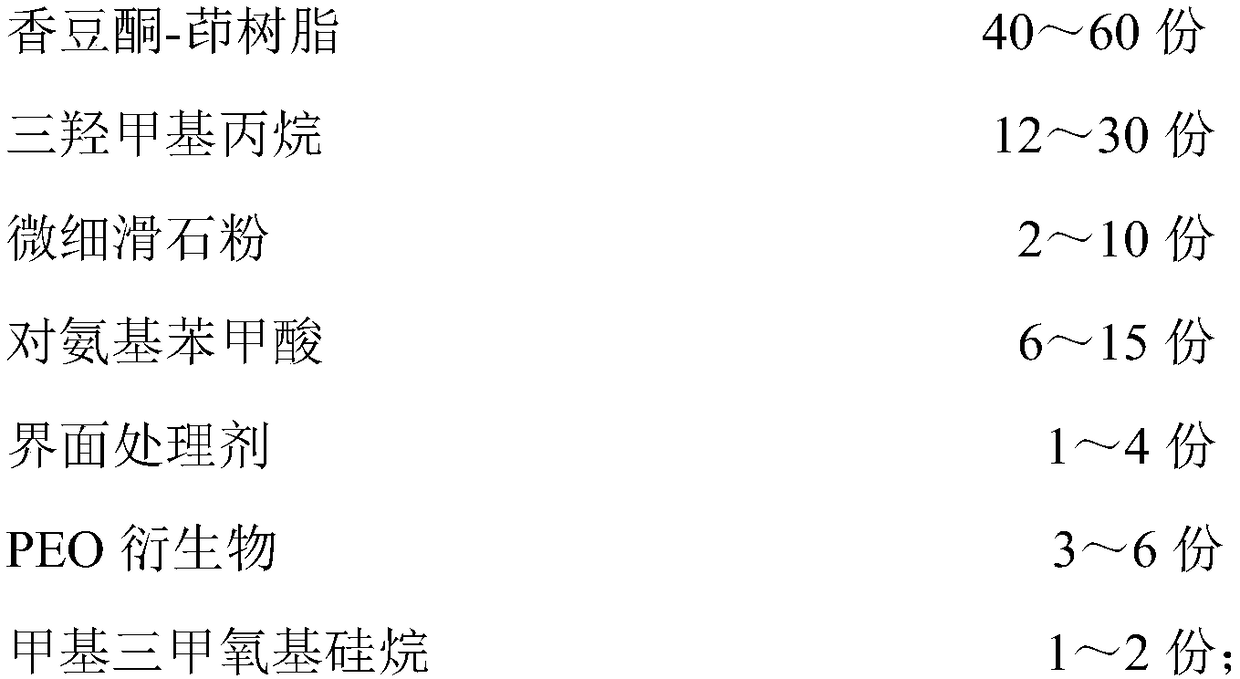

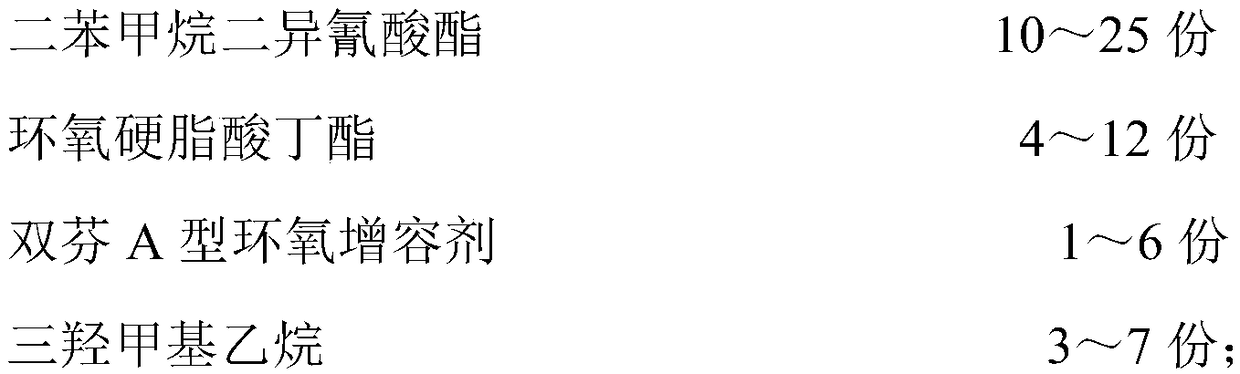

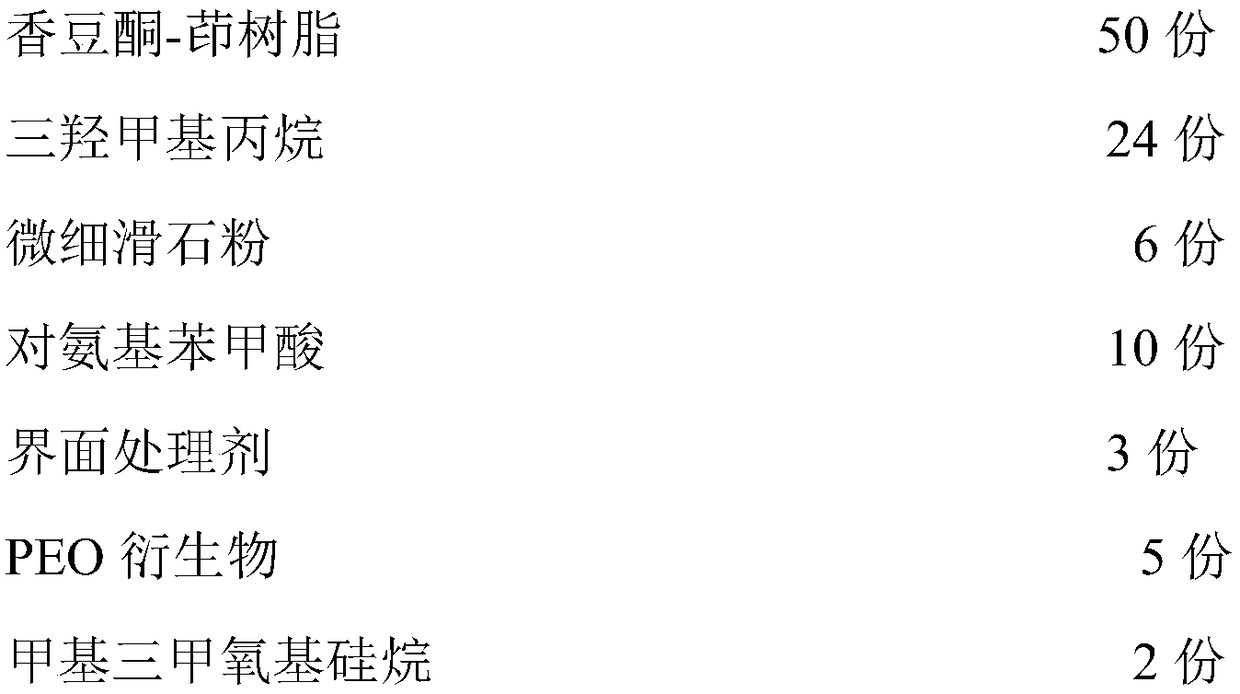

Compound multifunctional asphalt pavement sealant and preparation process thereof

ActiveCN108913093AImprove adhesionIncreased durabilityNon-macromolecular adhesive additivesBituminous material adhesivesSodium BentonitePolymer science

The invention discloses a compound multifunctional asphalt pavement sealant and a preparation process thereof. The main components of the sealant include: 100 parts of mixed modifier-modified asphaltwith 35 percent of 40-mesh rubber powder, 45 percent of 60-mesh rubber powder and 20 percent of 80-mesh rubber powder; 15 to 30 parts of functional component agent A; 10 to 35 parts of functional component agent B; and 5 to 25 parts of functional component agent C. The main components of the functional component agent A are coumarone-indene resin, trimethylolpropane, fine talcum powder, p-aminobenzoic acid and the like. The main components of the functional component agent B are diphenylmethane diisocyanate, butyl epoxy stearate, bisphenol-A epoxy compatibilizer, trimethylolethane and the like. The main components of the functional component agent C are microcapsules, vinyl glass flake mortar, polyvinyl alcohol-modified high-sodium bentonite particles and the like. According to the invention, after the functional component agents A, B and C are prepared, proportion is designed to carry out compounding, and the compounded sealant not only can fill cracks, but also can seal the cracks. The invention is applicable to different types of cracks, and according to causes of crack formation, different amounts of functional component agents A, B and C can be added. The sealant compounded bythe invention has high bonding strength, good sealing property and waterproofness and excellent high-temperature stability and low-temperature bonding property, having high application and popularization values.

Owner:CHONGQING JIAOTONG UNIVERSITY

Systems and methods for pyrolyzing waste tires

ActiveCN105950201BHeating evenlyImprove pyrolysis efficiencyProductsReagentsGas collecting tubeFiltration

The invention discloses a waste tire pyrolysis system and method. The waste tire pyrolysis system comprises a moving bed pyrolysis reactor, a spray tower, heat accumulating type radiant tubes, oil gas output pipelines and dust removing devices, wherein the moving bed pyrolysis reactor comprises a pyrolysis feeding port, a pyrolysis oil gas outlet, a semi-coke outlet and a catalyst inlet. Multiple layers of heat accumulating type radiant tubes are arranged in the moving bed pyrolysis reactor in the height direction of the reactor, and each layer includes multiple heat accumulating type radiant tubes mutually parallel in horizontal direction. Through holes are formed in the walls of the oil gas output pipelines. Each dust removing device is partially embedded into the reactor and communicated with a gas collecting tube through the oil gas output pipelines and comprises a dust filtration chamber, a lifting tube and a gas collecting chamber. The system can effectively inhibit secondary splitting decomposition of oil gas and improve the oil yield of a waste tire material. In addition, the heat efficiency of the system is improved, and a system process is simplified.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com