Systems and methods for pyrolyzing waste tires

A waste tire pyrolysis technology, applied in the chemical industry, can solve the problems of waste tire pyrolysis technology that needs to be improved, low material filling volume ratio, and easy leakage of harmful gases, etc., to inhibit secondary cracking, increase oil yield, Guaranteed uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

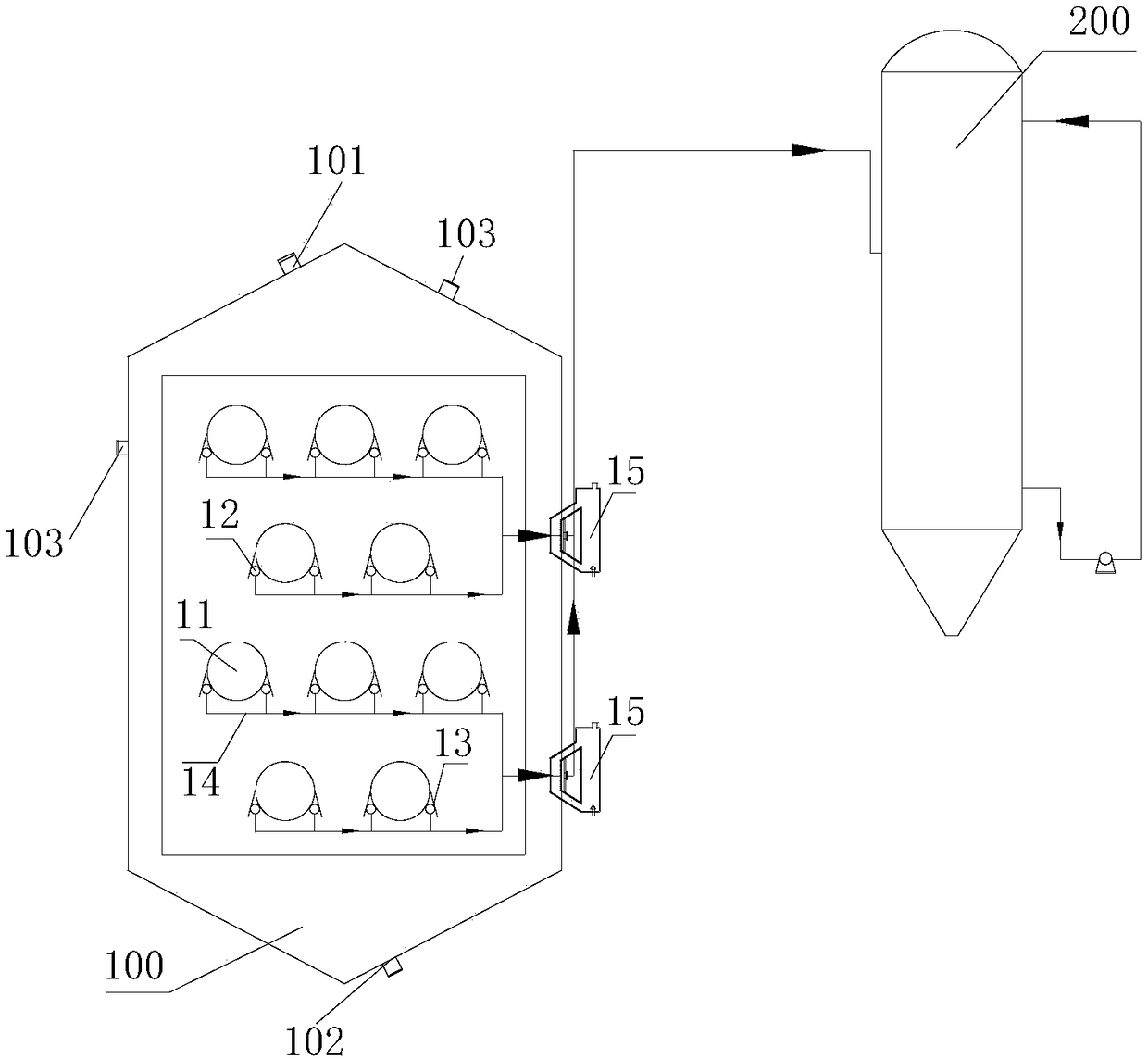

[0157] use Figure 1-4 The waste tires are processed by the pyrolysis waste tire system. Among them, the waste tires are pre-treated in advance: the waste tires are pulled out of the whole steel wire by the steel wire removal device 300 (steel wire drawing machine), and then enter the crushing device 400 (crusher) for crushing, and then pass the undrawn steel wire through the magnetic separation device 500 (magnetic separator) for magnetic separation, and finally screened by particle size screening device 600 (vibrating screen sieving), and finally screened to obtain rubber particles with a particle size of less than 2mm, which are sent into the feeding hopper 700, and passed through the screw feeder 800 into the moving bed pyrolysis reactor 100.

[0158] The analysis data, process operation parameters and material balance of waste tires are shown in Table 1-Table 3.

[0159] Table 1 Analysis data of waste tires

[0160]

[0161] Table 2 Process operation parameters

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com