Heat treatment method capable of improving anti-fatigue performance of aluminum alloy

A heat treatment method and technology of the treatment method, applied in the field of heat treatment of metal materials, can solve the problems of weakening and reducing the fatigue resistance of alloys, and achieve the effects of reducing damage accumulation, eliminating obstacles to reciprocating sliding of dislocations, and excellent fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1(300

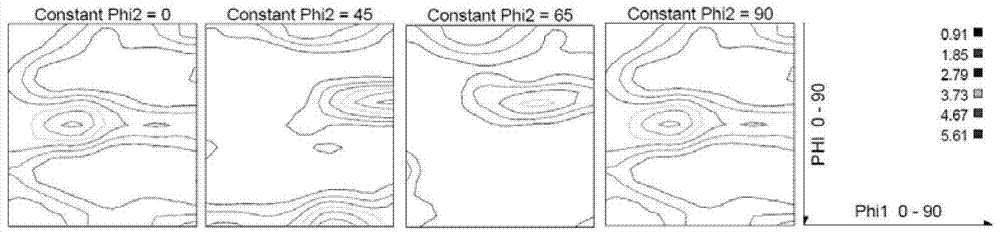

[0025] Example 1 (300 degree annealed state);

[0026] The composition of alloy 1 is: 3.8%Cu, 1.4%Mg, 0.6%Mn, 0.05%Ti, and the balance is aluminum. After the cold-rolled sheet is annealed at 300°C for 120 minutes, it is solution treated at 505°C for 20 minutes and quenched in water. After natural aging at room temperature for more than 100 hours, the mechanical properties at room temperature reach: the tensile strength is 435MPa, yield Strength is 290MPa, elongation is 24.4%; fatigue resistance: ΔK=25MPam 1 / 2 ,da / dN=1.5×10 -3 mm / cycle.

Embodiment 2(350

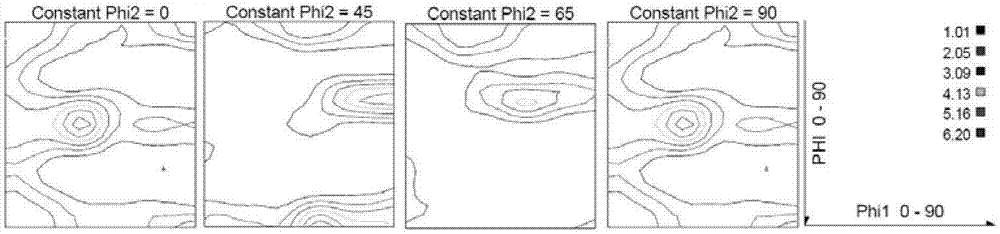

[0027] Example 2 (350 degree annealing state);

[0028] The composition of alloy 2 is: 4.0% Cu, 1.5% Mg, 0.3% Mn, 0.10% Ti, and the balance is aluminum. After the cold-rolled sheet is annealed at 350°C for 90 minutes, it is solution treated at 500°C for 30 minutes and quenched in water. After natural aging at room temperature for more than 100 hours, the mechanical properties at room temperature reach: the tensile strength is 430MPa, yield Strength is 288MPa, elongation is 25.7%; fatigue resistance: ΔK=25MPam 1 / 2 ,da / dN=9.5×10 -4 mm / cycle.

Embodiment 3(400

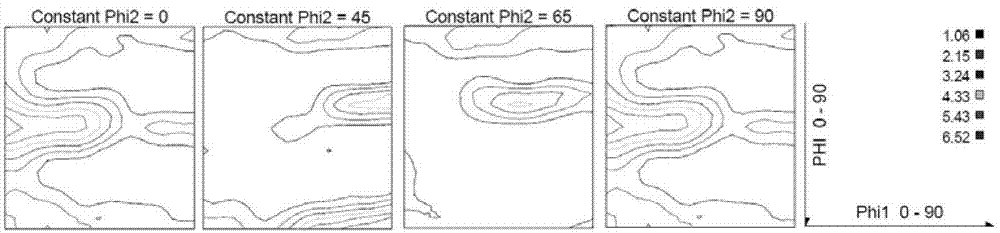

[0029] Example 3 (annealed state at 400 degrees);

[0030] The composition of alloy 3 is: 4.5% Cu, 1.2% Mg, 0.4% Mn, 0.10% Ti, and the balance is aluminum. After the cold-rolled sheet is annealed at 400°C for 40 minutes, it is solution treated at 485°C for 60 minutes and quenched in water. After natural aging at room temperature for more than 100 hours, the mechanical properties at room temperature reach: the tensile strength is 400MPa, yield Strength is 260MPa, elongation is 27.2%; fatigue resistance: ΔK=25MPam 1 / 2 ,da / dN=5.7×10 -4 mm / cycle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com