Patents

Literature

67results about How to "Reduce the expansion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

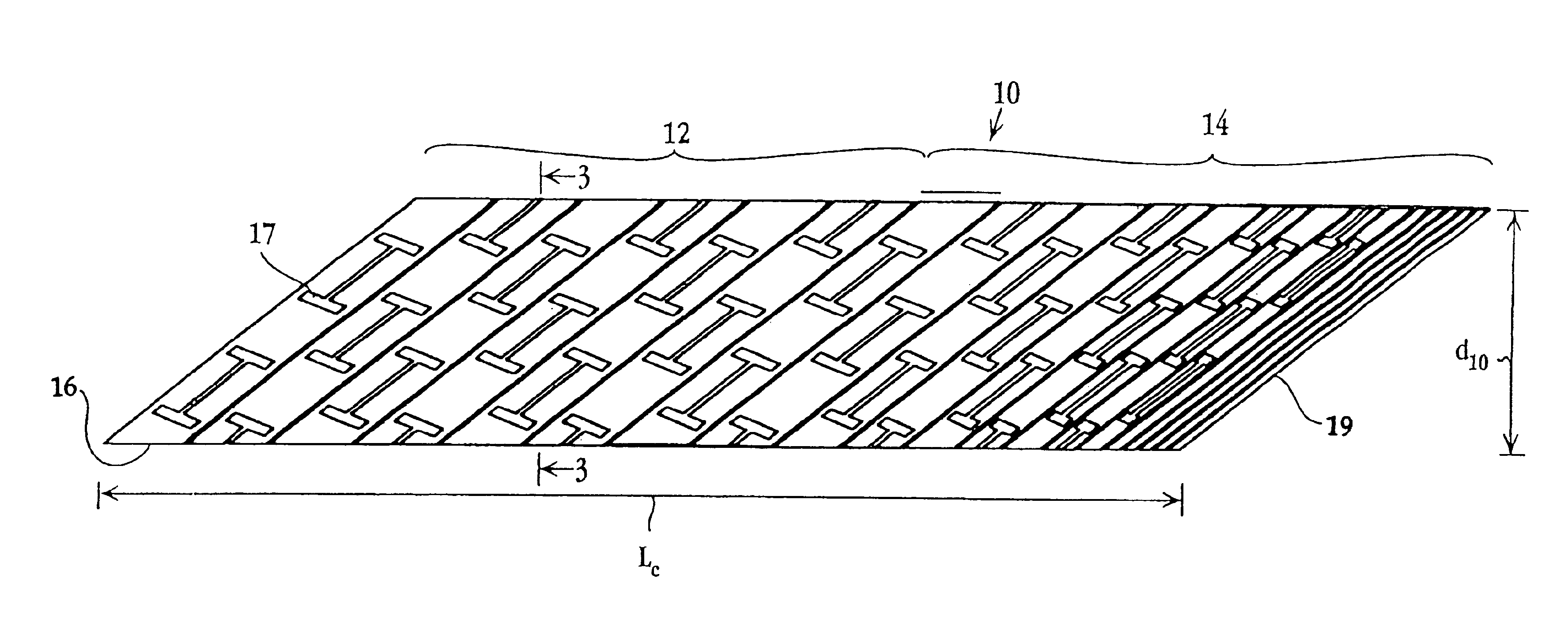

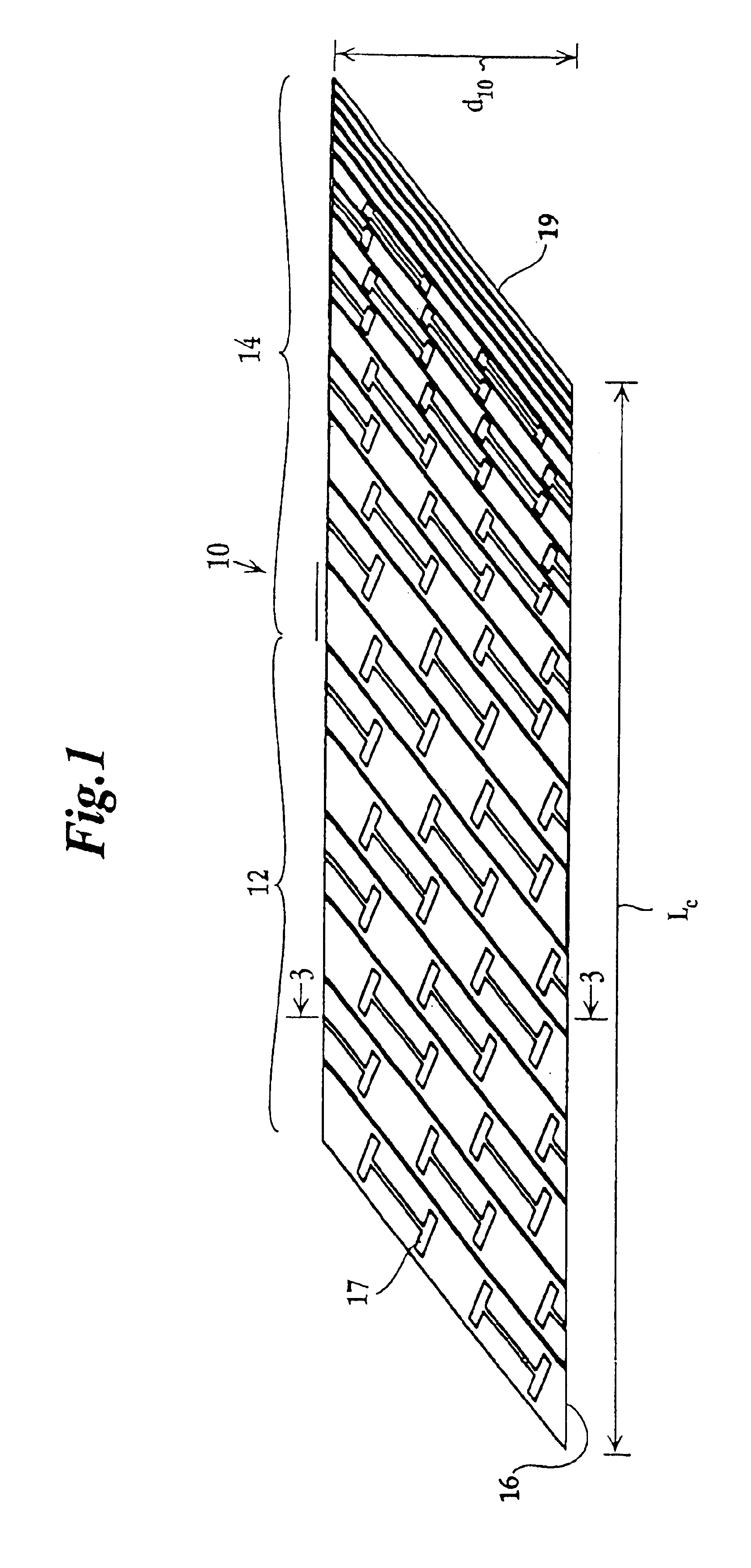

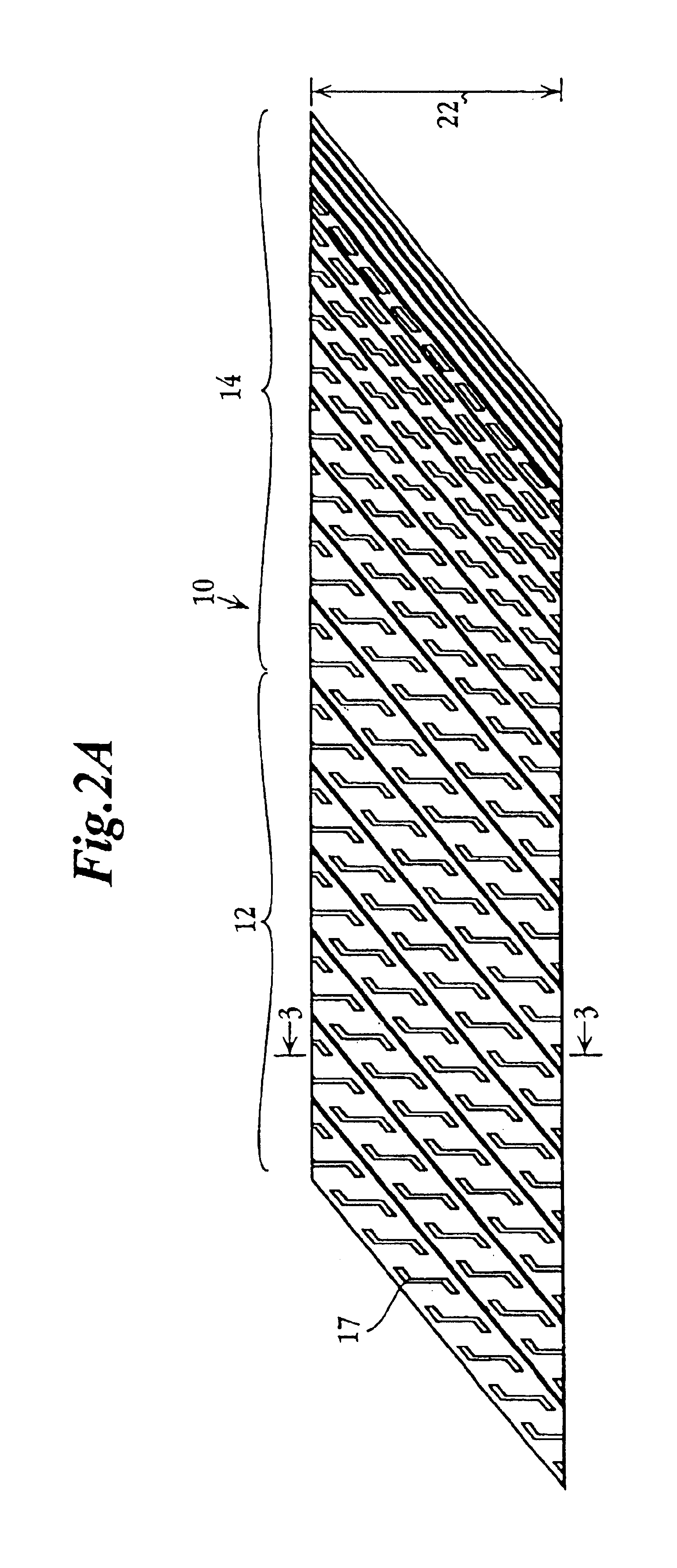

Catheter-stent device

A graftless prosthetic stent for treatment of vascular lesions such as aneurysms and arterio-venous fistulas, especially in neurovascular vessels, comprises a continuous helical ribbon formed of a shape-retaining metal having a transition temperature at which the stent expands from its contracted condition to a radially expanded condition, the stent remaining substantially cylindrical in its contracted and expanded conditions. The helical windings have variable width, thickness, number or size of openings, or combinations of these features, which affect the stiffness, rate of expansion at the transition temperature, and the area of vessel wall covered by the stent. A catheter device which includes the stent, and a method of treatment using the stent are also provided.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

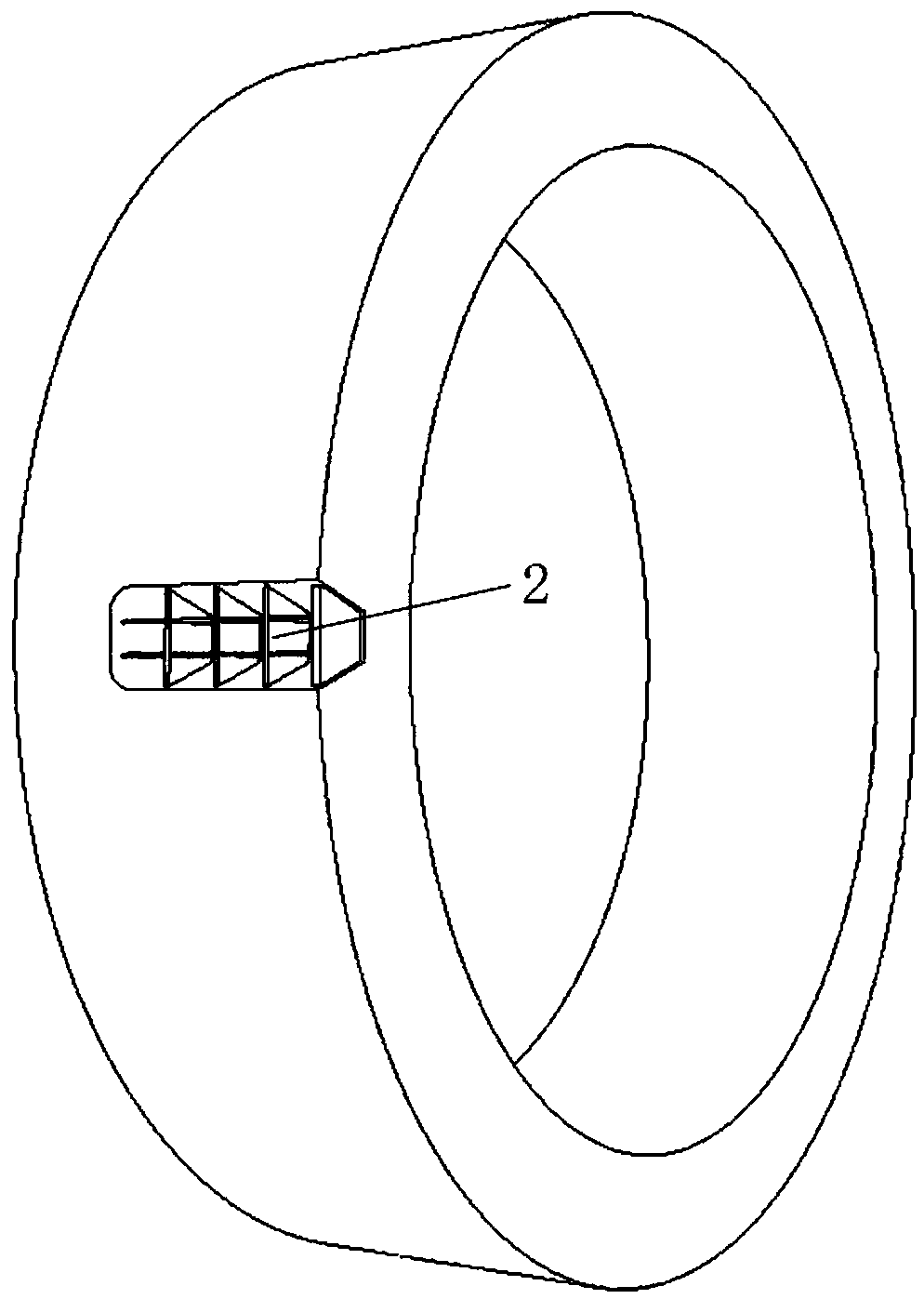

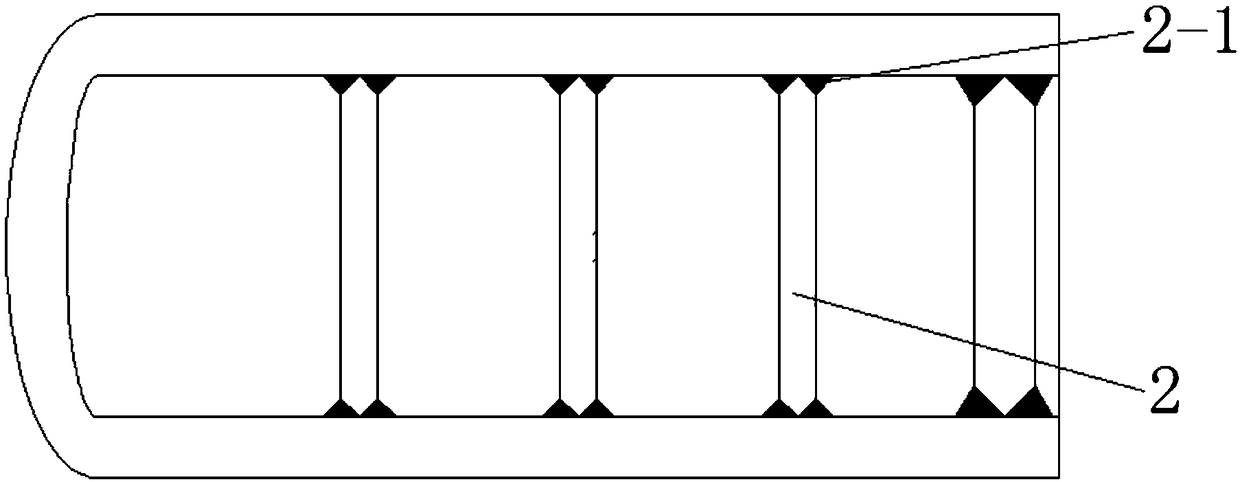

Titanium alloy and annular titanium alloy forge piece forming method

InactiveCN104148554AIncrease contentImprove high temperature strengthMetal rollingTitanium alloyUltimate tensile strength

The invention discloses titanium alloy and an annular titanium alloy forge piece forming method. The chemical element content of the titanium alloy comprises, by weight, 7.50%-7.80% of A1, 1.00%-2.00% of Mo, 2.60%-2.80% of Zr, 2.60%-2.80% of Sn, 0.50%-1.50% of W, 0.10%-0.25% of Si, no more than 0.15% of Fe, no more than 0.10% of Cu, no more than 0.10% of Cr, no more than 0.10% of C, no more than 0.15% of O, no more than 0.04% of N, no more than 0.012% of H, and the balance Ti. The annular titanium alloy forge piece forming method comprises the following steps that after the titanium alloy is fed, and blanking is conducted at the temperature 30 DEG C below the phase transformation point; forming is conducted at the temperature 20 DEG C above the phase transformation point, and water cooling is conducted till the allay reaches the indoor temperature; double annealing is conducted on the materials obtained through the above two steps. The annular titanium alloy forge piece has the high-temperature tensile strength which can meet the use conditions and is large in affluence measure at the temperature ranging from 500 DEG C to 550 DEG C and can replace TC 25 to be used for manufacturing compressor parts and the like.

Owner:GUIZHOU ANDA AVIATION FORGING

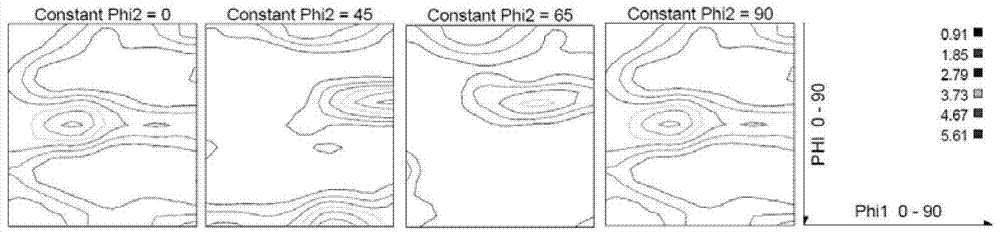

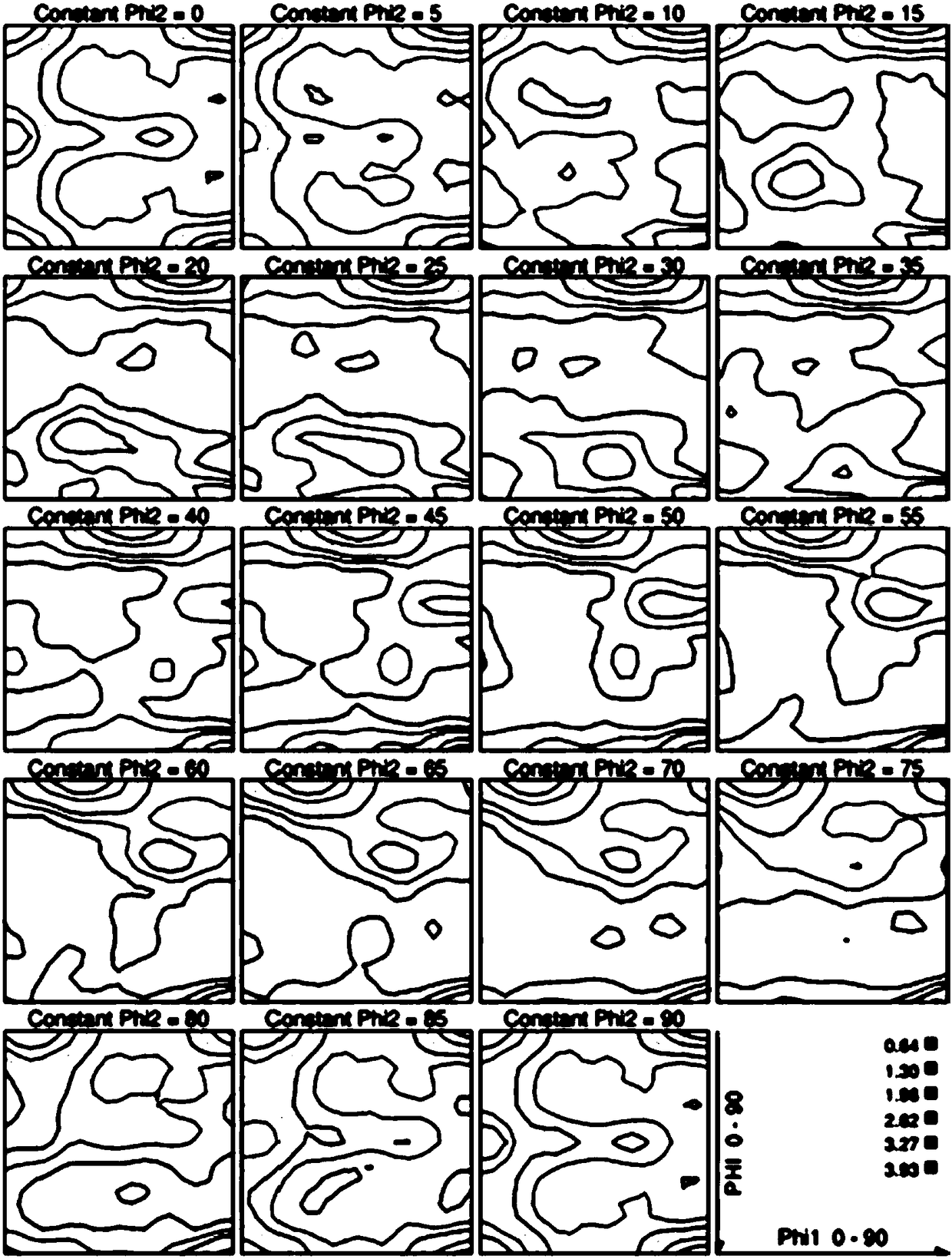

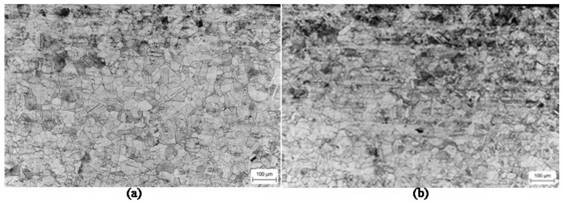

Heat treatment method capable of improving anti-fatigue performance of aluminum alloy

ActiveCN103045976AEliminate entangled dislocation configurationsStress reliefRoom temperatureCorrosion fatigue

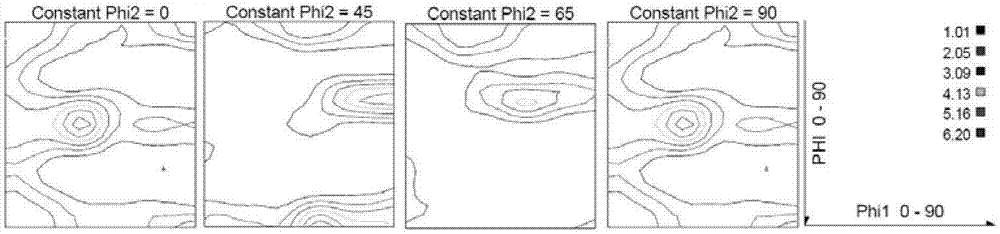

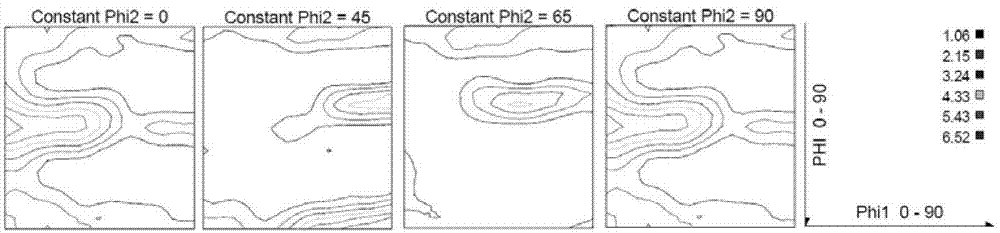

The invention relates to a heat treatment method capable of improving the anti-fatigue performance of Al-Cu-Mg alloy. The method comprises the following steps: performing intermediate annealing on a cold-rolled plate at the temperature of between 300 and 440 DEG C for 20 to 120 minutes; performing solution hardening treatment at the temperature of between 475 and 505 DEG C for 10 to 120 minutes; and naturally ageing at room temperature for at least 100 hours. The Al-Cu-Mg alloy comprises the following components: Cu, Mg, Mn, Ti and Al. The process method is simple and reasonable. By the intermediate annealing heat treatment process, the Gauss texture score of the alloy is increased, and orientation of most of crystal faces {111} of crystal grains of the cold-rolled Al-Cu-Mg alloy is positioned or close to the direction of the maximum external shearing stress, so that reciprocating sliding dislocated under the action of alternating stress is promoted, the closed effect of fatigue crack is improved, the spreading rate of the fatigue crack is reduced, and the alloy has excellent stress corrosion resistance and anti-stripping corrosion fatigue performance and is suitable for industrialized application.

Owner:CENT SOUTH UNIV

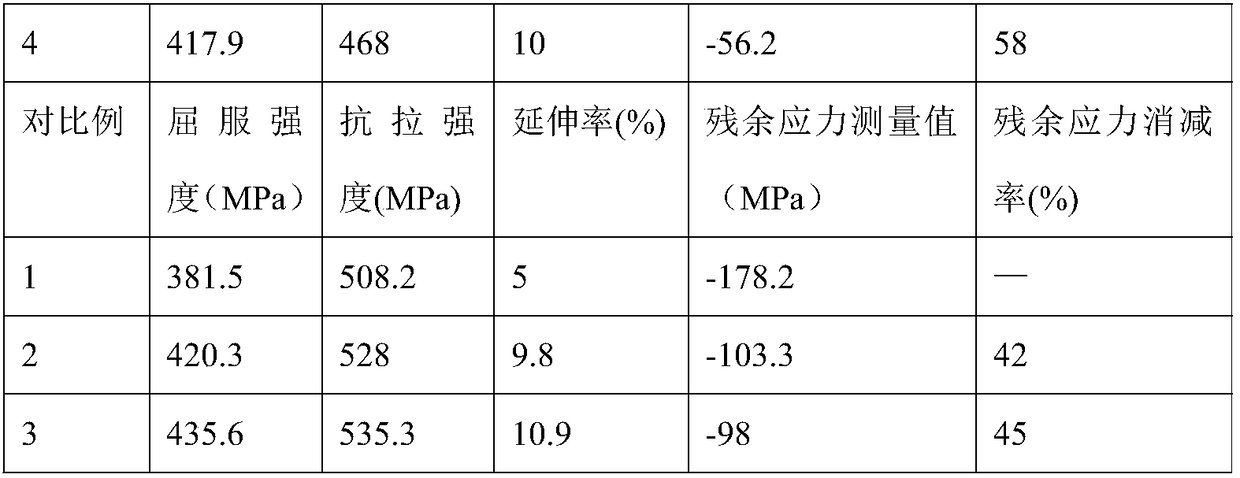

Heat treatment technology for preparing high-performance low-residual stress aluminum alloy

ActiveCN108531836AReduce residual stressHomogenization of dislocation distributionQuenchingSolution treatment

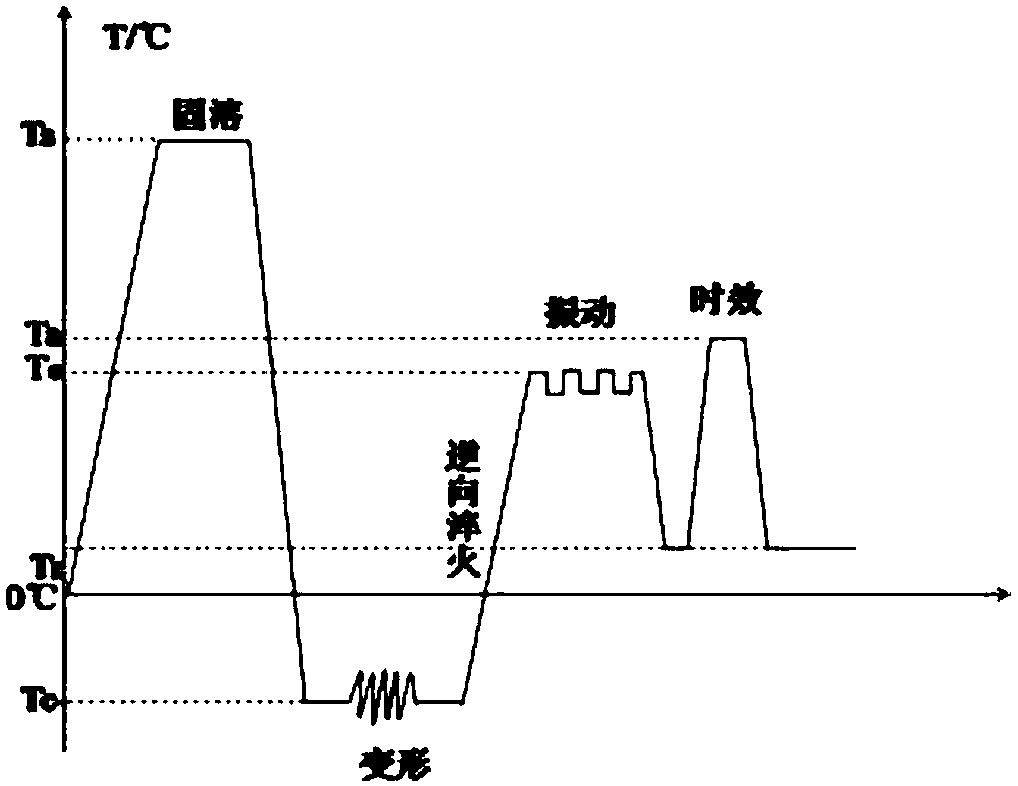

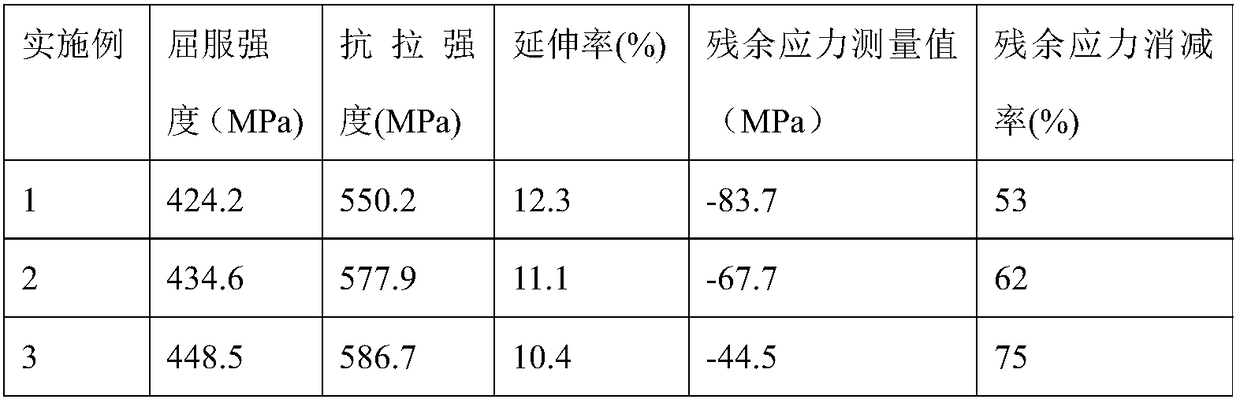

The invention relates to a heat treatment technology for preparing a high-performance low-residual stress aluminum alloy, and belongs to the technical field of aluminum alloy thermomechanical treatment. The method comprises the steps that 1, after an aluminum alloy sample is subjected to solution treatment and heat preservation, then is subjected to low-temperature quenching, and the transfer timedoes not exceed 10 seconds; 2, the sample obtained in the step 1 is subjected to cryogenic deformation to obtain a cryogenic deformation sample, the cryogenic deformation treatment temperature is lower than minus 120 DEG C, and the cryogenic deformation is equal or greater than 5%; 3, the cryogenic deformation sample obtained in the step 2 is put into a hot medium, the cryogenic deformation sample is vibrated by a vibration exciter, heat preservation and vibration maintaining are carried out, and the sample after the vibration reverse quenching treatment is obtained; and 4, the sample after the vibration reverse quenching treatment in the step 3 is subjected to aging treatment, and a finished product is obtained. The aluminum alloy prepared by the heat treatment technology has high comprehensive performance and low residual stress, and the stability of the material in service process is remarkably improved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH +1

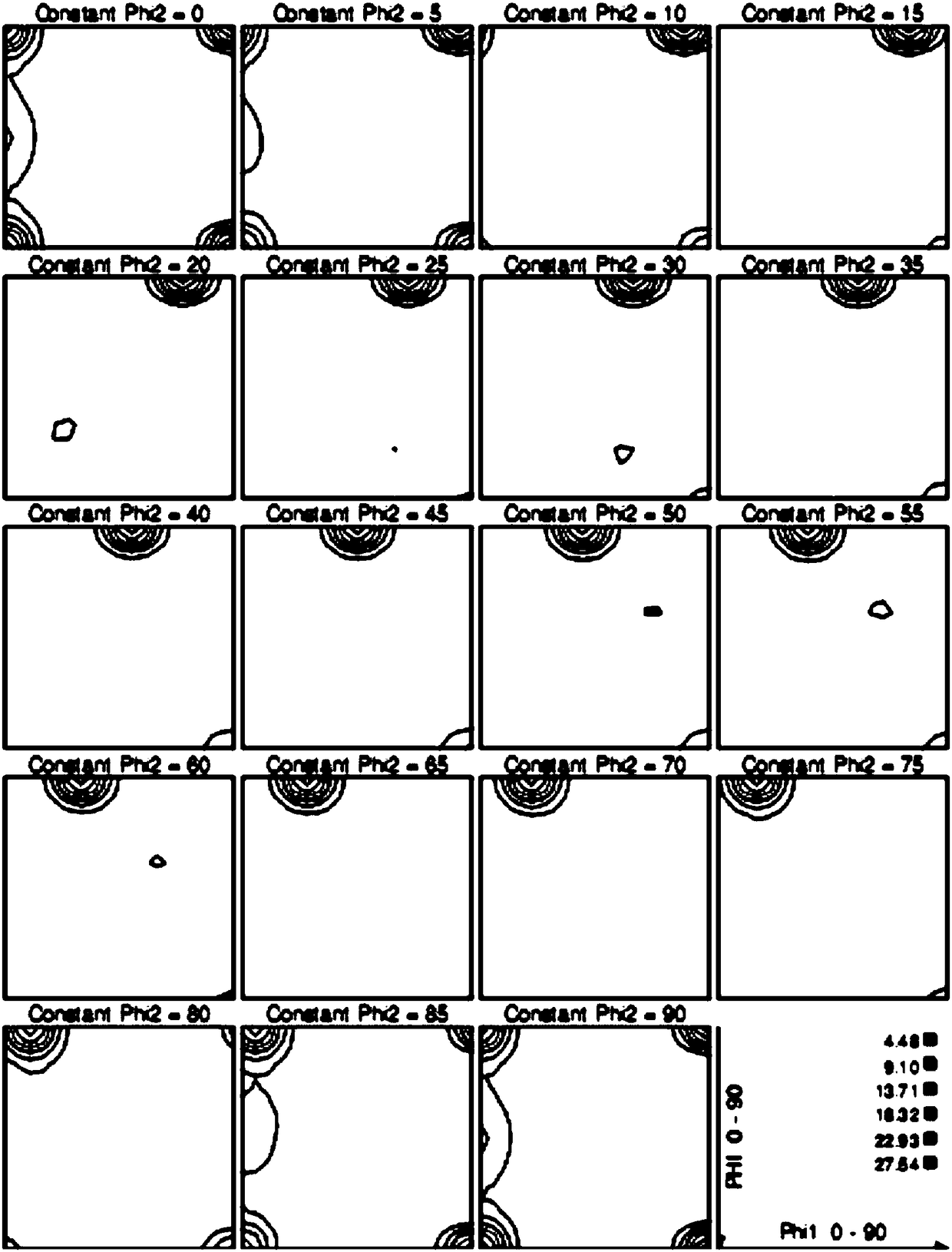

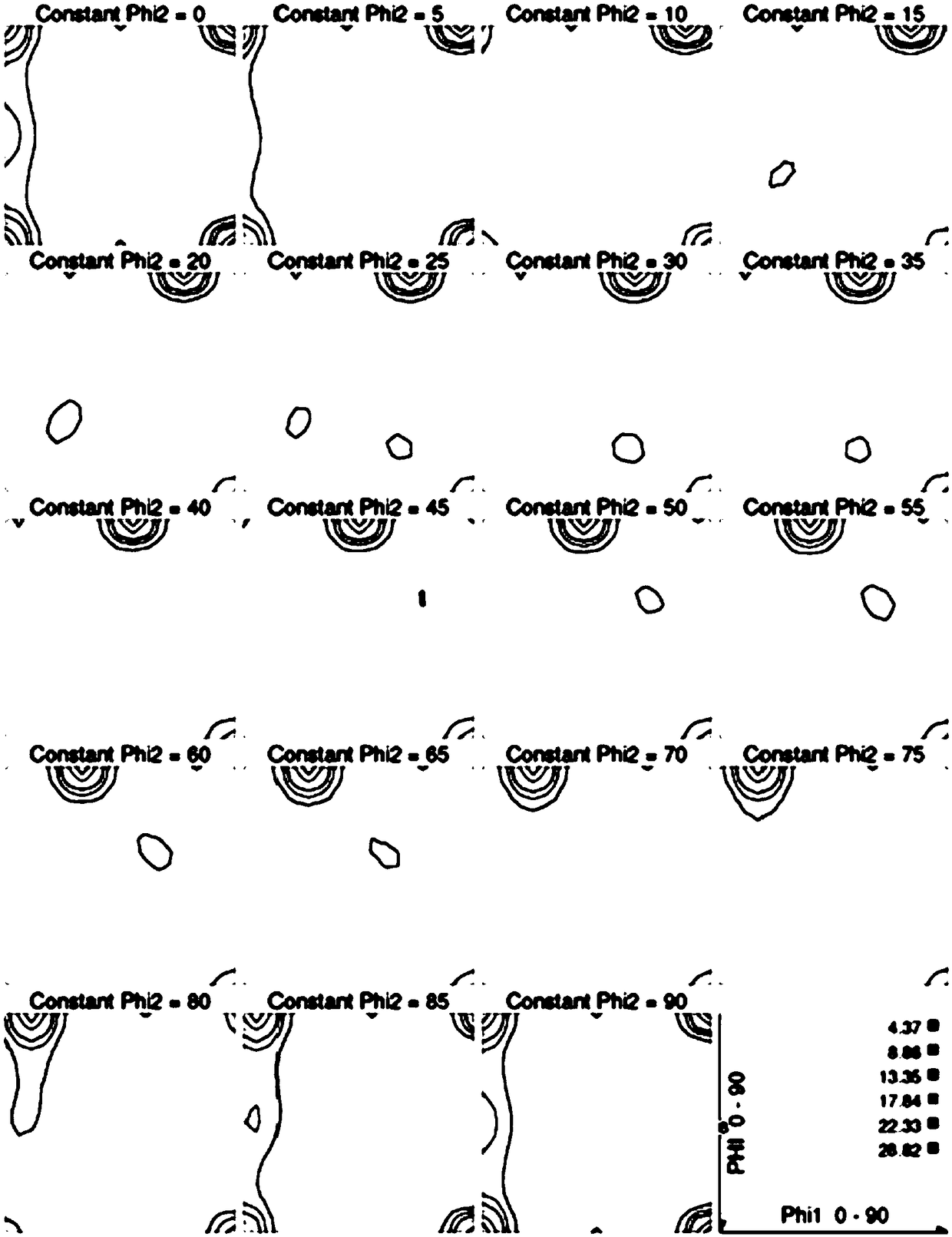

Machining method of fine-grain cubic texture corrosion-fatigue-resistant aluminum alloy plate

The invention relates to a skin material for aviation, in particular to a machining method for preparing corrosion-fatigue-damage-resistant aluminum alloy plates, and belongs to the technical field ofnonferrous metals. The machining method comprises the steps that an aluminum alloy hot rolling material is subjected to solid solution treatment for the first time, then the second time of solid solution treatment is carried out after multi-pass cold rolling with the pass deformation amount being less than or equal to 1.0mm is carried out to achieve the design thickness of the aluminum alloy plate; and in the multi-pass cold rolling process, deep cooling treatment is carried out immediately after each pass of cold rolling, and the temperature of the deep cooling treatment is less than or equal to -100 DEG C. The machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is reasonable in texture design, the preparation process is simple and controllable, obtained products have good performance, and the machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is convenient for large-scale industrial application.

Owner:HUNAN UNIV OF SCI & TECH

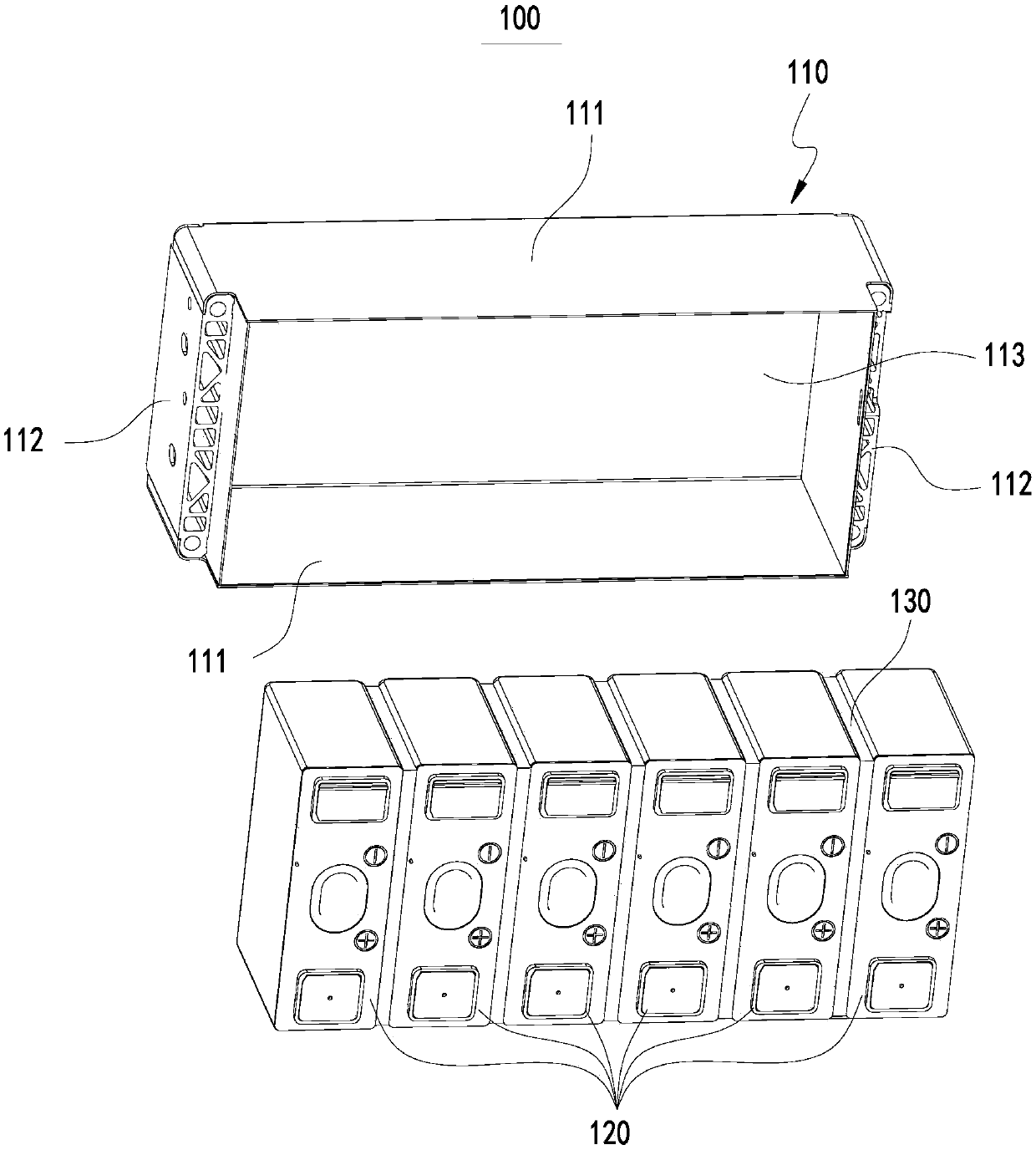

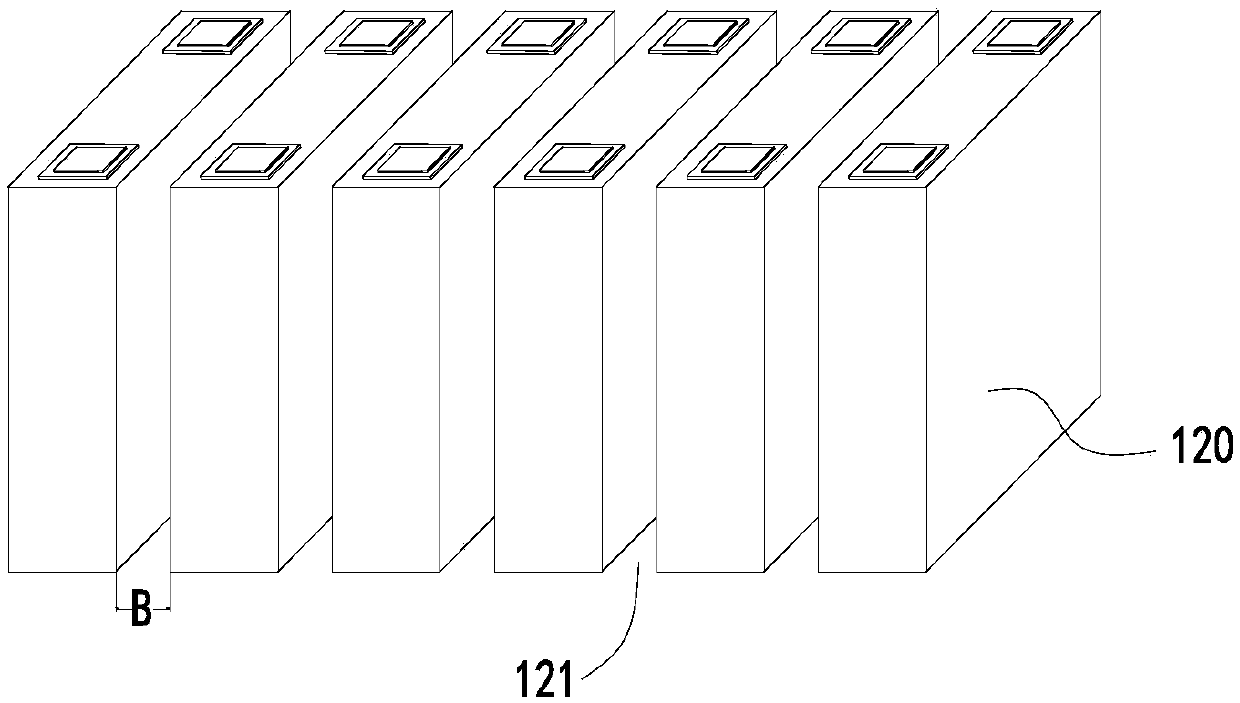

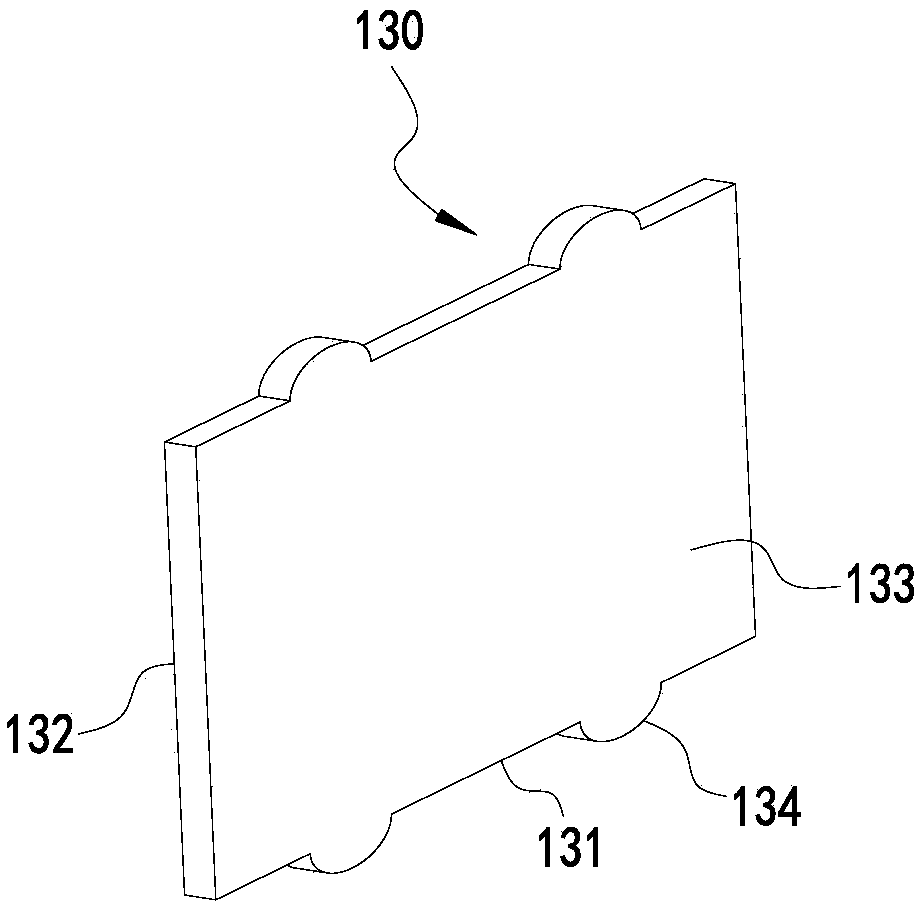

Battery module

ActiveCN110265591APromote circulationCompressibleFinal product manufactureSecondary cellsEngineeringCompressibility

The invention discloses a battery module and belongs to the technical field of energy storage. The battery module includes: a frame having a receiving space; a plurality of battery units which are successively arranged in the receiving space of the frame along the thickness direction of the battery units, wherein separating plates are disposed between adjacent battery units and have compressibility, and a compression ratio [delta]1 of the separating plates at a pressure less than or equal to 2MPa satisfies a condition of C0*[delta]1 <= A0*0.2, wherein C0 is the initial thickness of the separating plates, and A0 is the initial thickness of the battery units. The battery module provided by the invention has excellent cycle performance.

Owner:CONTEMPORARY AMPEREX TECH CO

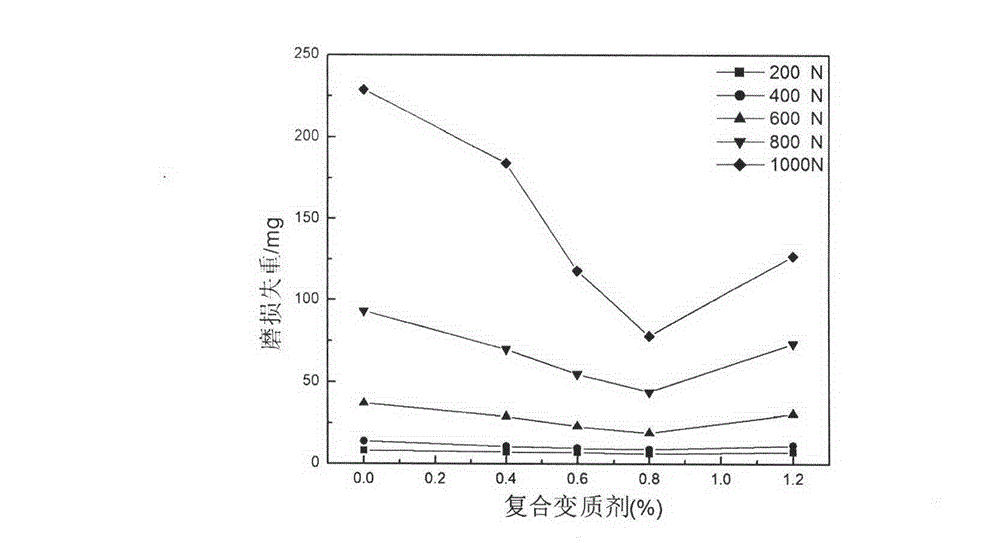

Composite modifier capable of improving overall performance of zinc-aluminum alloy

InactiveCN102719722AExtended service lifeAvoid the shortcomings of insignificant overall performance improvementZincAluminium alloy

The invention relates to a composite modifier capable of improving overall performance of zinc-aluminum alloy, belonging to the technical field of zinc-aluminum alloy preparation. The composite modifier comprises the components in percentage by weight: 20-30% of Ni, 15-25% of Ti, 5-15% of Mn, 5-15% of Cr, 5-10% of Si, 5-10% of Ce, 5-10% of La, 1-6% of Y, 1-6% of Nb, 1-6% of V and the balance of aluminum. The modifier is blocky grey alloy, and has the particle size range of 0.5-40 mm and the melting point range of 800-1200 DEG C. By adopting the composite modifier, the overall performance of the zinc-aluminum alloy is obviously improved.

Owner:东莞市慧淳金属制品有限公司

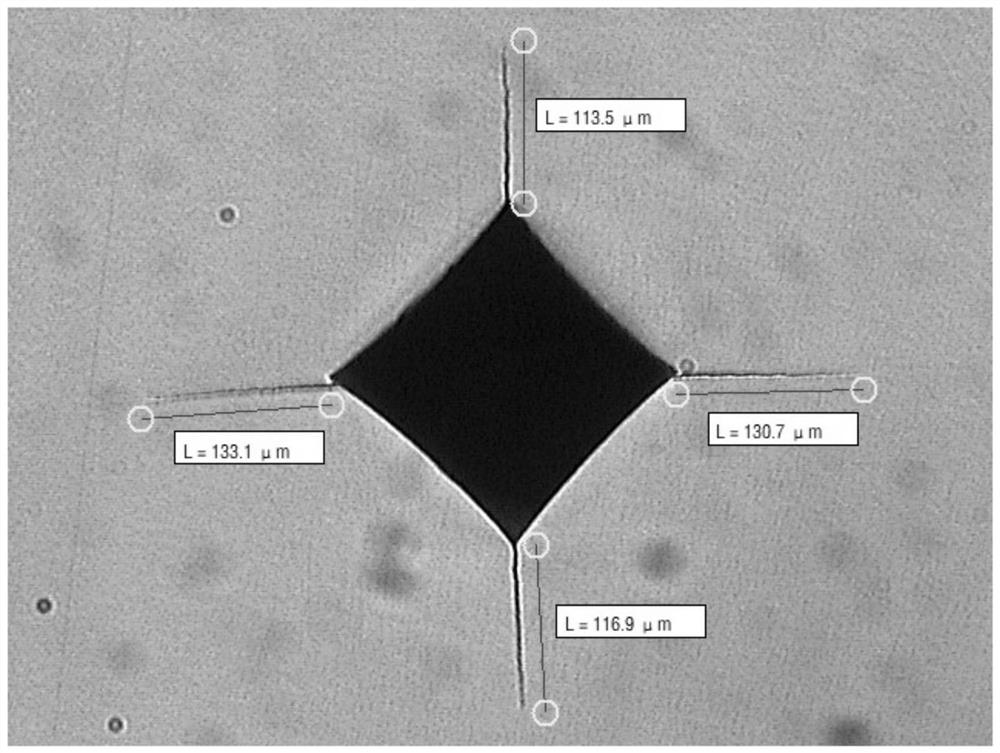

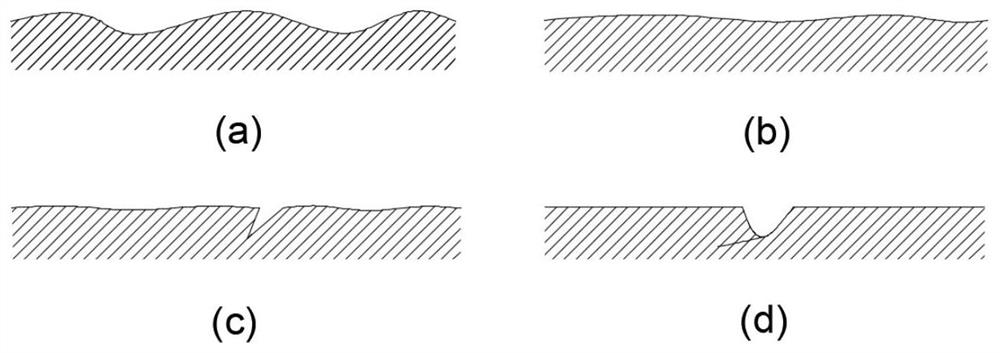

Processing method of alloy surface micro-cracks

InactiveCN102642177AExtended peening timeReduce processing timeAbrasion apparatusSurface finishHardness

The invention relates to a processing method of alloy surface micro-cracks. The aimed micro-crack size range is that the depth is smaller than 0.8 mm, the width is smaller than 0.2 mm, and the length is smaller than 2 mm. A compressive stress layer is formed on the periphery of the alloy surface cracks by using liquid shot-peening repair method, so that micro-cracks with lower depth are eliminated directly, the size of cracks with deeper depth become small, closure effects are produced, spreading rate of the surface micro-cracks is effectively reduced, the surface rigidity and toughness are increased, and components serve continuously; and deformation of alloy after processing is small, and the surface fineness is high. The method is applied in the repair of alloy surface micro-cracks, the operation of the device is flexible, and the process is simple; and limits to workpiece size, operation site and space are small, the processing efficiency is high, energy is saved, and the method is clean and pollution-free.

Owner:DALIAN UNIV OF TECH

Magnesia-zirconia eutectic side hole material for submersed nozzle

ActiveCN106396711AImprove antioxidant capacityImproved thermal shock stabilityMelt-holding vesselsHigh resistanceSlag

The invention discloses a magnesia-zirconia eutectic side hole material for a submersed nozzle. The magnesia-zirconia eutectic side hole material is prepared from the raw materials of magnesia-zirconia powder, graphite powder, fused silica powder, monatomic silicon powder, silicon carbide powder, boron carbide powder, powdered resin and liquid resin, wherein the granularity of the magnesia-zirconia powder is not greater than 1mm; the magnesia-zirconia powder is prepared from 94 to 98 percent of MgO and 2 to 6 percent of ZrO2; the granularity of the graphite powder is not greater than 100 meshes. The magnesia-zirconia eutectic side hole material provided by the invention has relatively high resistance to oxidation, high thermal shock resistance, high anti-erosion property and resistance to slag corrosion; the submersed nozzle made of the magnesia-zirconia eutectic side hole material has high mechanical strength, the service life of the submersed nozzle can be prolonged greatly, and the continuous steel casting operation efficiency is increased; meanwhile, a tire cord steel billet is prevented from being broken easily in a wire drawing process of a produced tire cord steel billet, and the phenomena of impurity adhesion and blockage on the inner wall of the submersed nozzle can be prevented effectively.

Owner:北京利尔高温材料股份有限公司

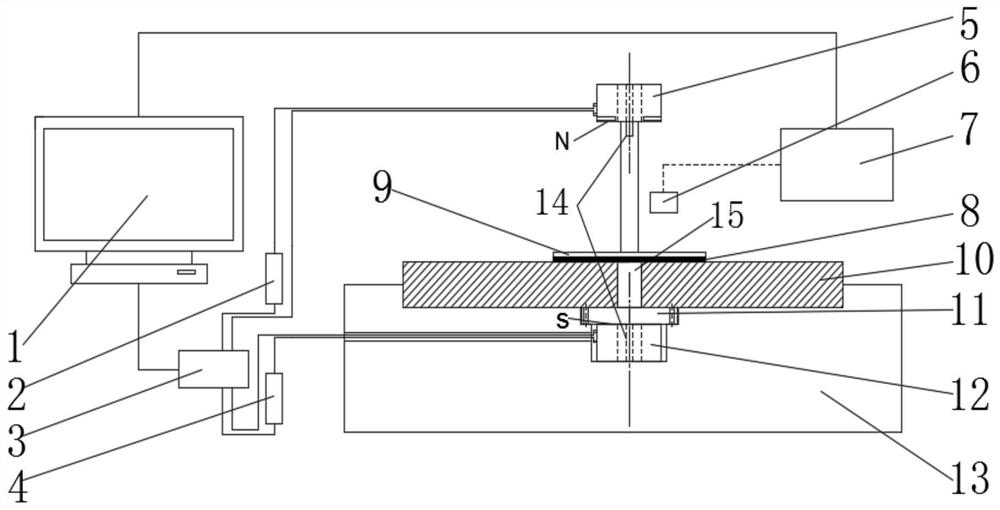

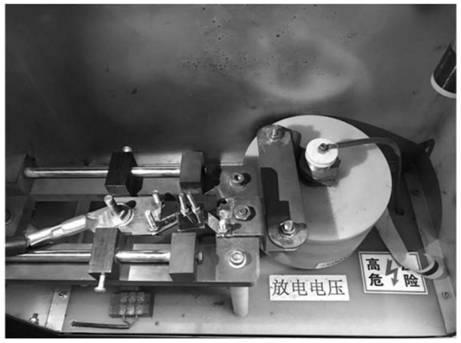

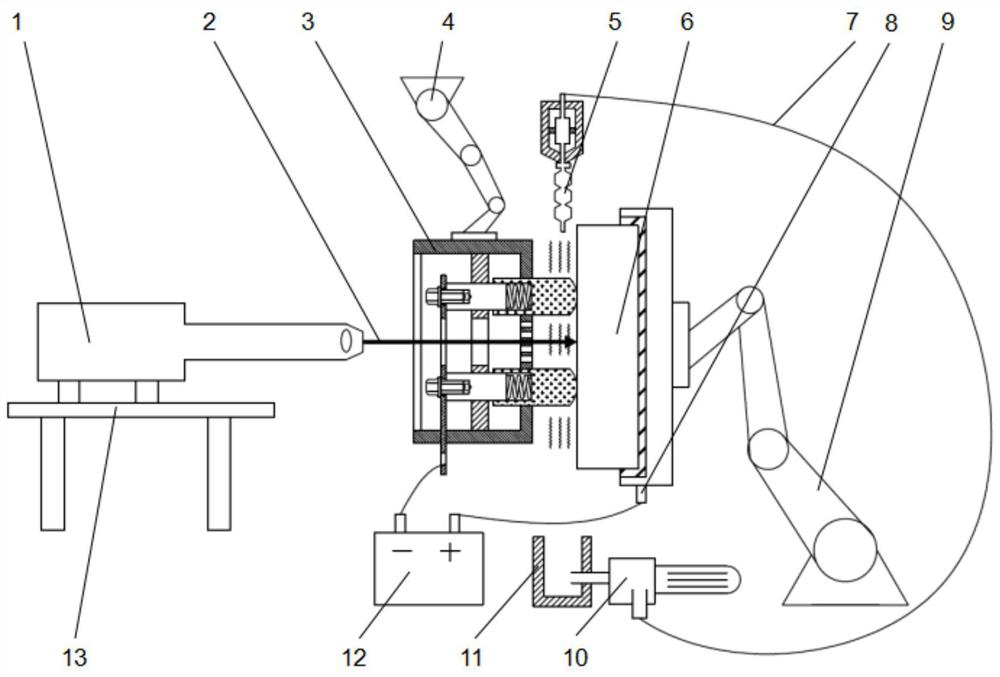

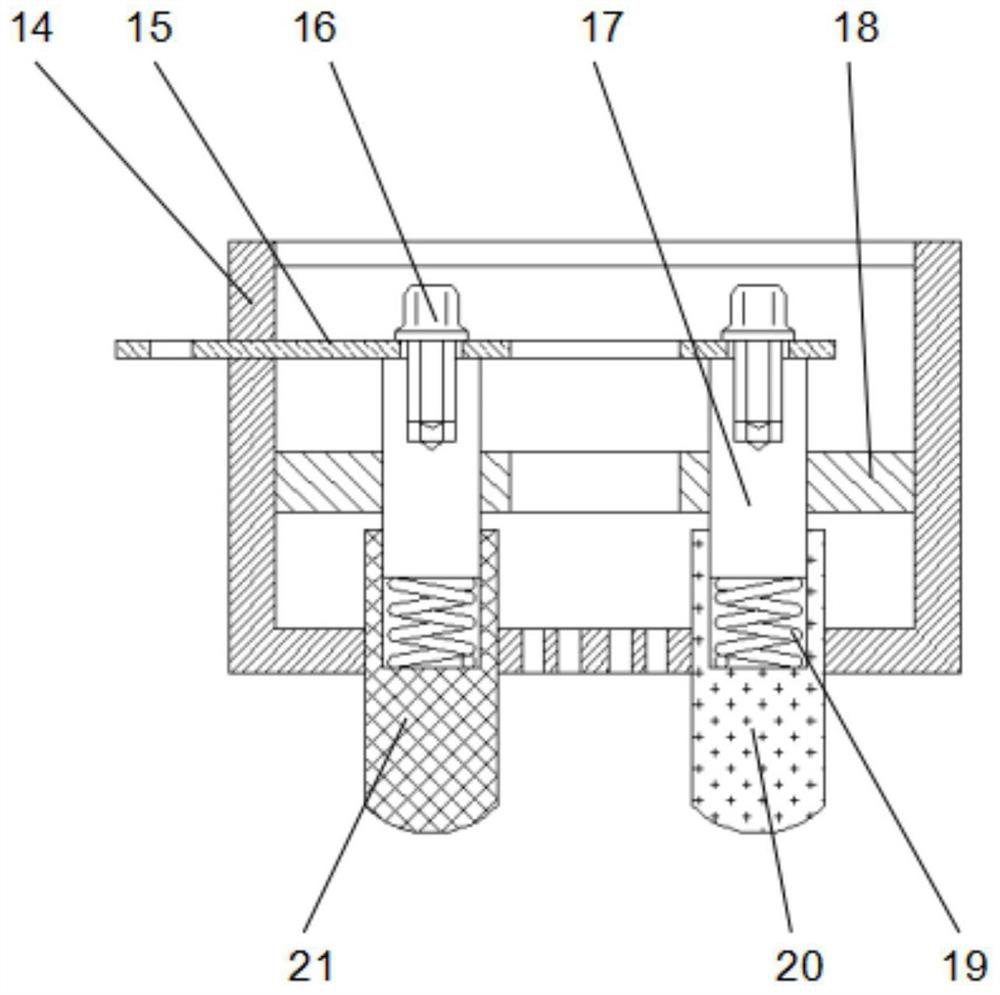

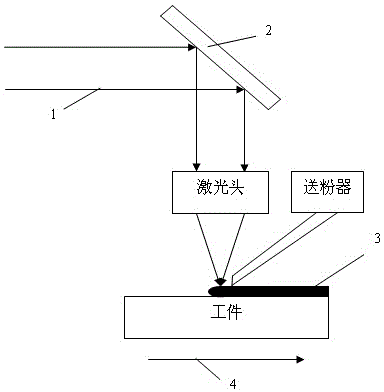

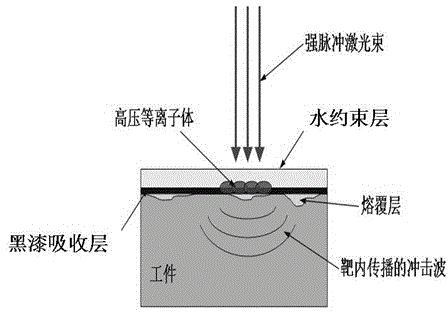

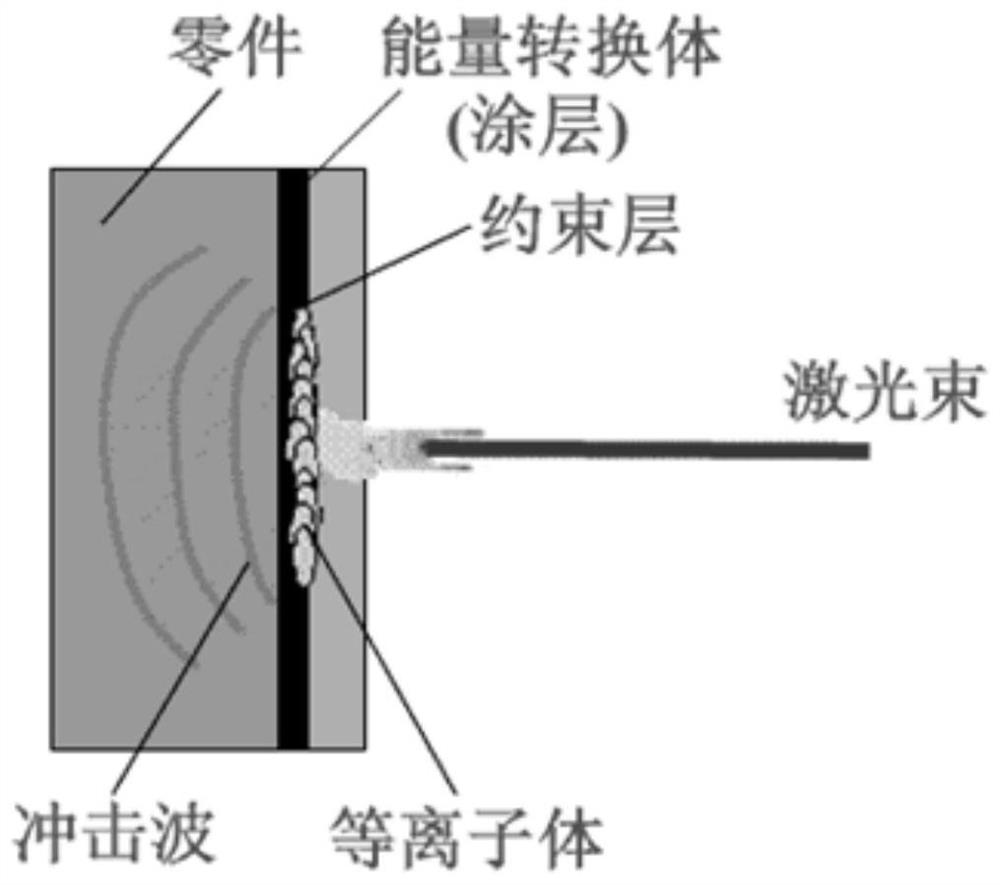

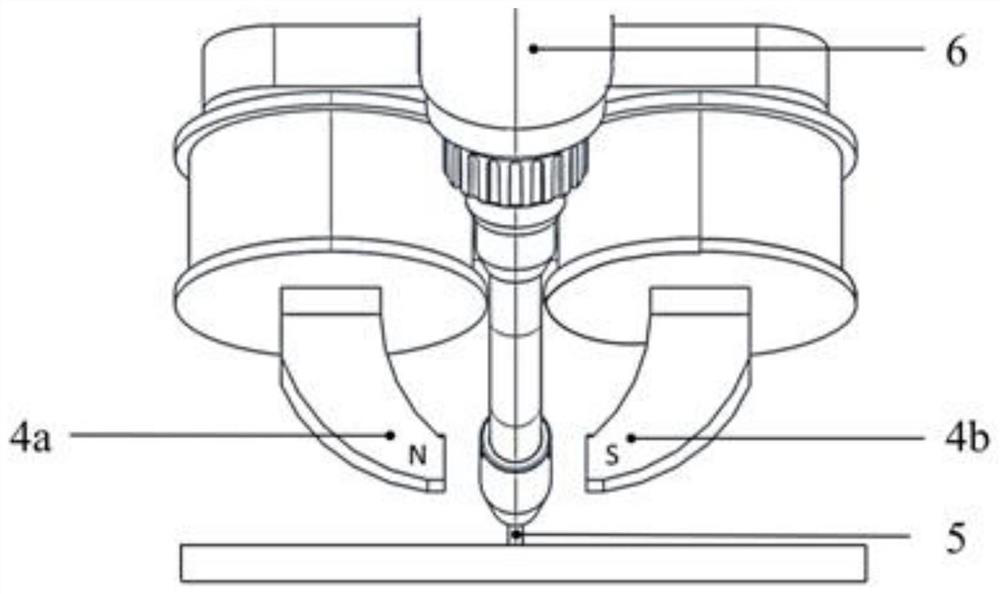

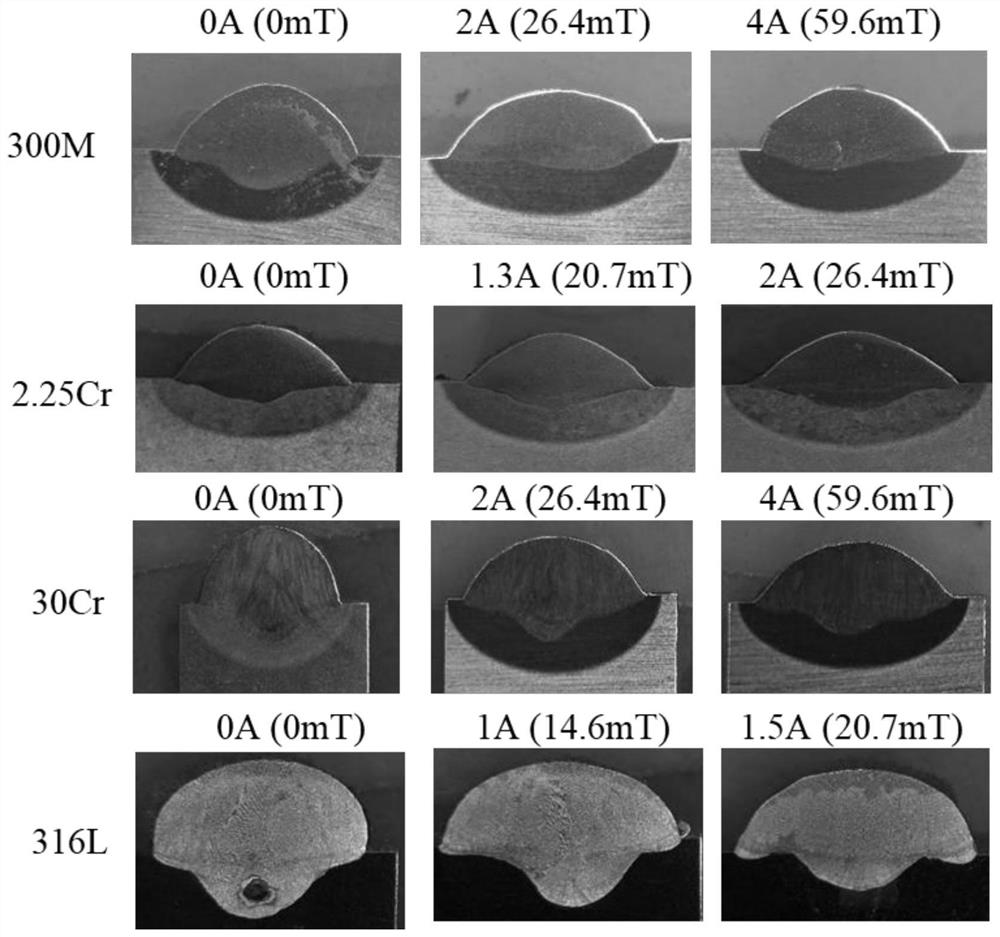

Magnetoplasticity and laser shock combined strengthening device and method

ActiveCN111961836AImprove performanceNice strengthening effectIncreasing energy efficiencyHigh intensityMachining

The invention provides an electromagnet-assisted laser shock combined strengthening device and a method, and relates to the field of laser and magnetic field processing. The device comprises a laser generating device and electromagnets; a to-be-machined workpiece is arranged on a workbench, the two electromagnets are arranged above and below the to-be-machined workpiece, and the to-be-machined workpiece is placed in arc-shaped magnetic fields formed by the electromagnets; and the laser generating device and the electromagnets simultaneously work for conducting combined machining on the to-be-machined workpiece. According to the method, the specific arc-shaped magnetic fields are applied to the workpiece, by means of the magnetoplasticity effect of the high-intensity magnetic fields, the plastic deformation resistance of the surface layer of the metal workpiece is reduced, machining hardening of the surface layer of the workpiece in a laser impact process is weakened, and then the laserimpact is matched, and the influence depth of the laser impact is increased; and particularly, the depth of residual pressure stress is large, and the pressure stress distribution is suitable for therequirement of three-dimensional strengthening of components such as a small hole structure, and is suitable for strengthening of thick workpieces and high-strength materials.

Owner:JIANGSU UNIV

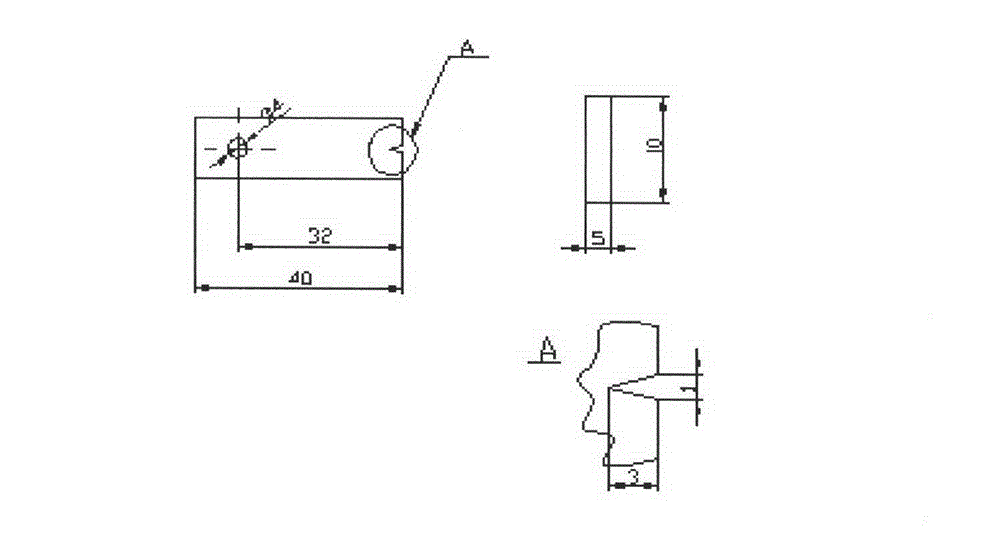

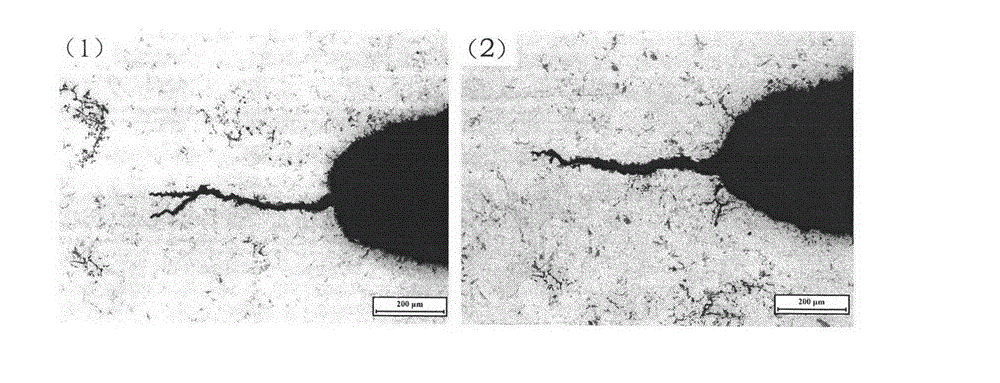

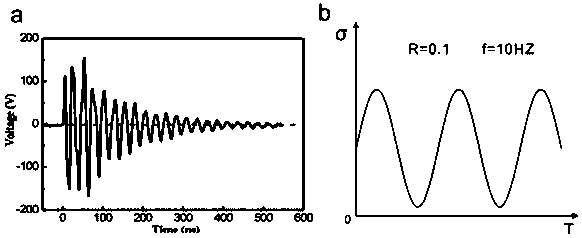

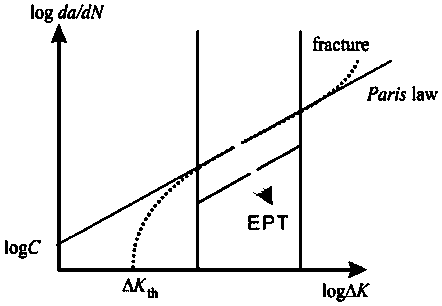

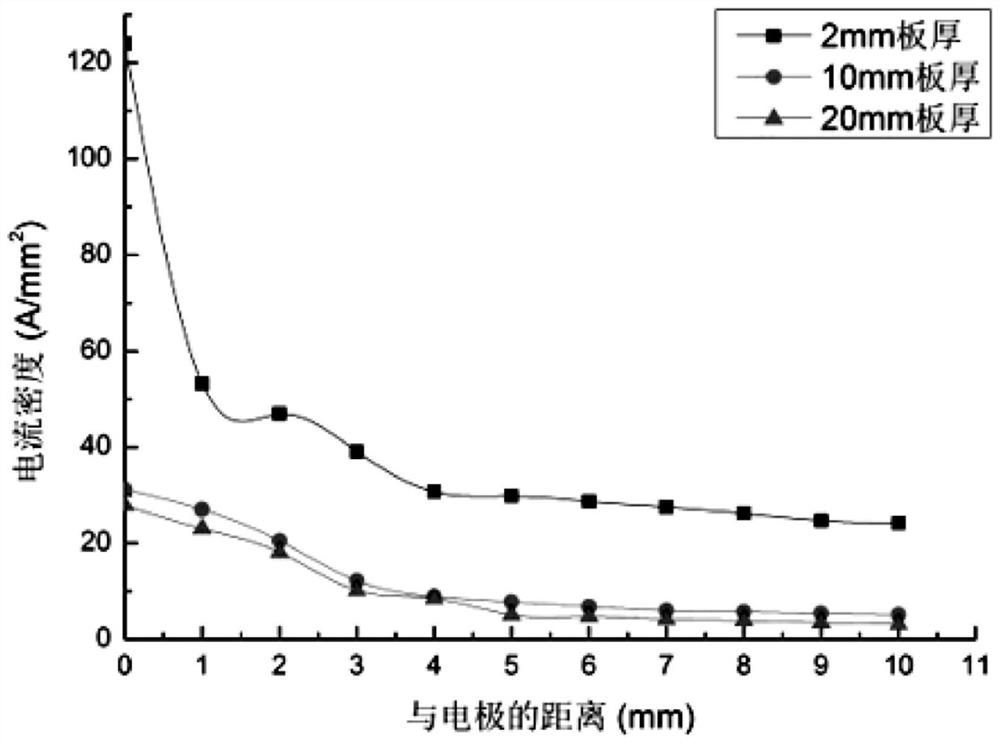

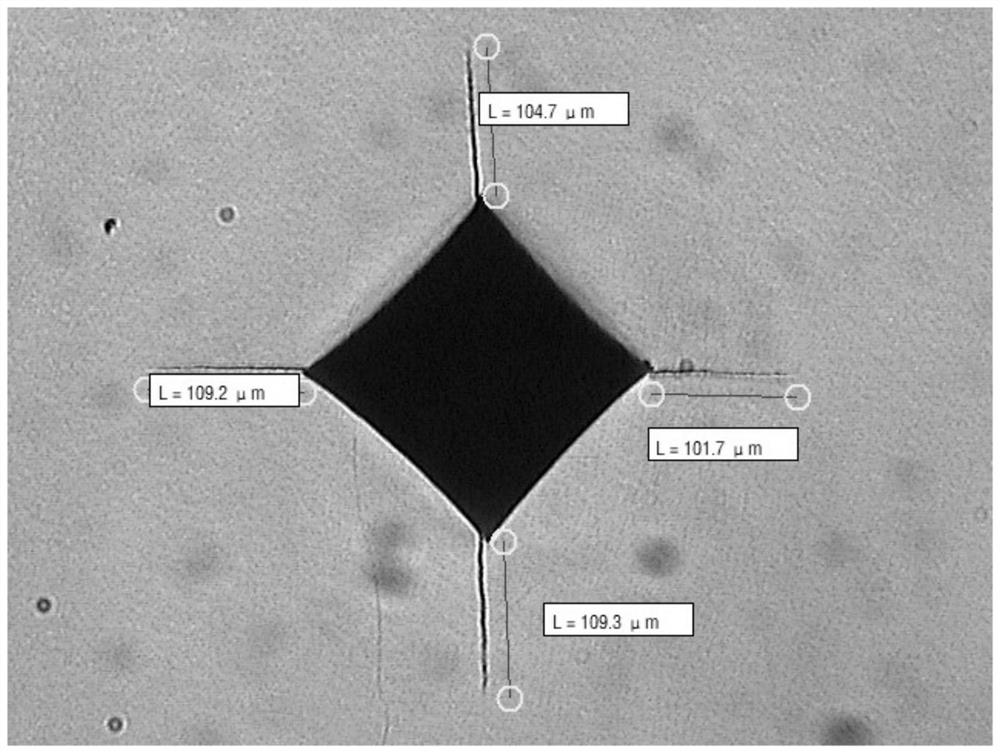

Electric pulse treatment method for lowering fatigue crack spreading rate of steel materials

InactiveCN109338093AReach arrestTo achieve the purpose of crack healingFatigue damageElectrical impulse

The invention discloses an electric pulse treatment method for lowering the fatigue crack spreading rate of steel materials, and belongs to the technical field of fatigue life of high-strength steel materials. Through the method, the steel materials with fatigue cracks are subjected to electric pulse treatment, the fatigue crack spreading rate of the steel materials is lowered, and thus the fatigue life of the materials is prolonged. In the electric pulse treatment process, the electric pulse discharge waveform is in a damped waveform, the discharge period is 400 ns, treatment is conducted twice, the first treatment working voltage is 9-10 kV, and the second treatment working voltage is 10.5-12 kV. The method can be used for research and engineering application of crack arresting, crack healing and fatigue damage repair and fatigue life prolonging of the high-strength steel materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

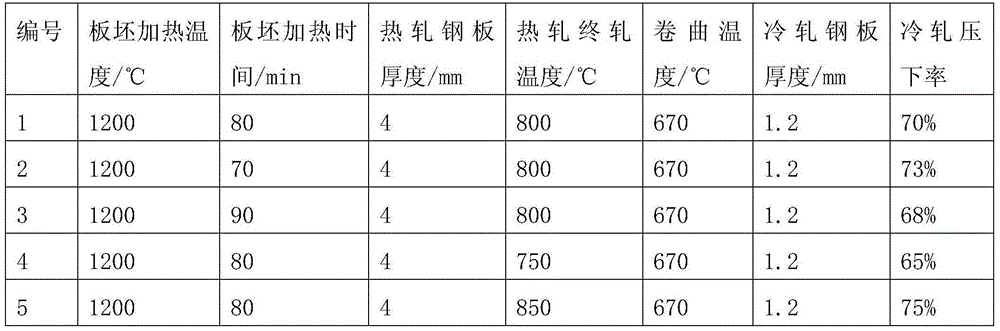

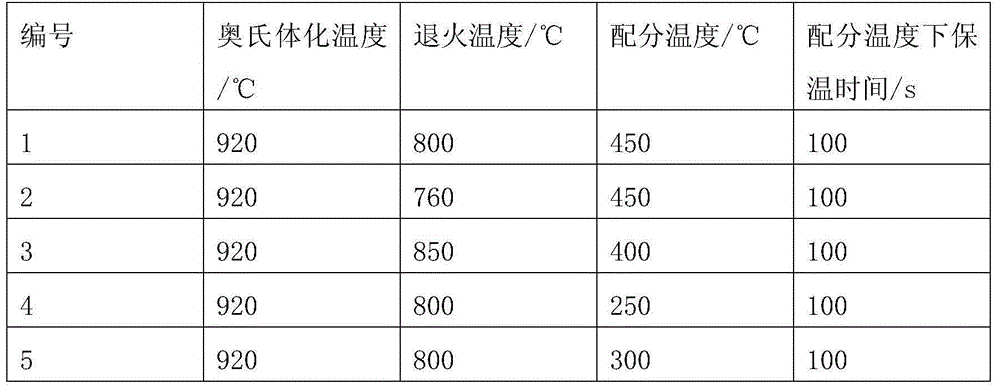

Vanadium alloying TAM steel and preparing method thereof

The invention relates to vanadium alloying TAM steel and a preparing method thereof, and belongs to the technical field of metal component designing and thermal processing. The vanadium alloying TAM steel comprises, by weight percentage, 0.18%-0.21% of C, 1.48%-1.55% of Si, 1.90%-2.20% of Mn, not larger than 0.020% of P, not larger than 0.015% of S, 0.19%-0.21% of V, not larger than 0.04% of Al and the balanced Fe and inevitable impurities. An appropriate amount of vanadium is added in a vanadium alloying manner, the toughness of the TAM steel is improved through precipitation of carbide of vanadium and the like, and therefore the comprehensive mechanical performance of vanadium-containing TAM steel is improved, and a steel plate has high strength and plasticity and especially has the superior hydrogen resisting and induced delaying fracture performance. According to the production of the vanadium-contained TAM steel, the steel organization performance is more stable through the new technology-Q&P technology.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Electroplasticity and laser shock composite strengthening method and device for large workpiece

The invention discloses an electroplasticity and laser shock composite strengthening method and device for a large workpiece. The device comprises a current applying component, a laser component and a water spraying component, wherein the current applying component is used for providing current in order to enable a workpiece to be machined to be electroplastic; the laser component is used for providing laser energy in order to machine the workpiece to be machined; and the water spraying component forms a flat water curtain on the workpiece to be machined to serve as a restraint layer for laser shock treatment. The electroplasticity and the laser shock are combined to reinforce the material, and compared with single laser shock, a series of problems of strain hardening, non-uniform and non-deep stress distribution, cracks, dislocation and the like can be solved. Meanwhile, for the large workpiece, a current collector is provided, the current can be fully led to a machining area, a large amount of loss of the current in the large workpiece is reduced, and the high-density current is formed in a to-be-strengthened area. The method can solve the problem that current energy is small, the machining quality is remarkably improved, and the machining efficiency is improved.

Owner:JIANGSU UNIV

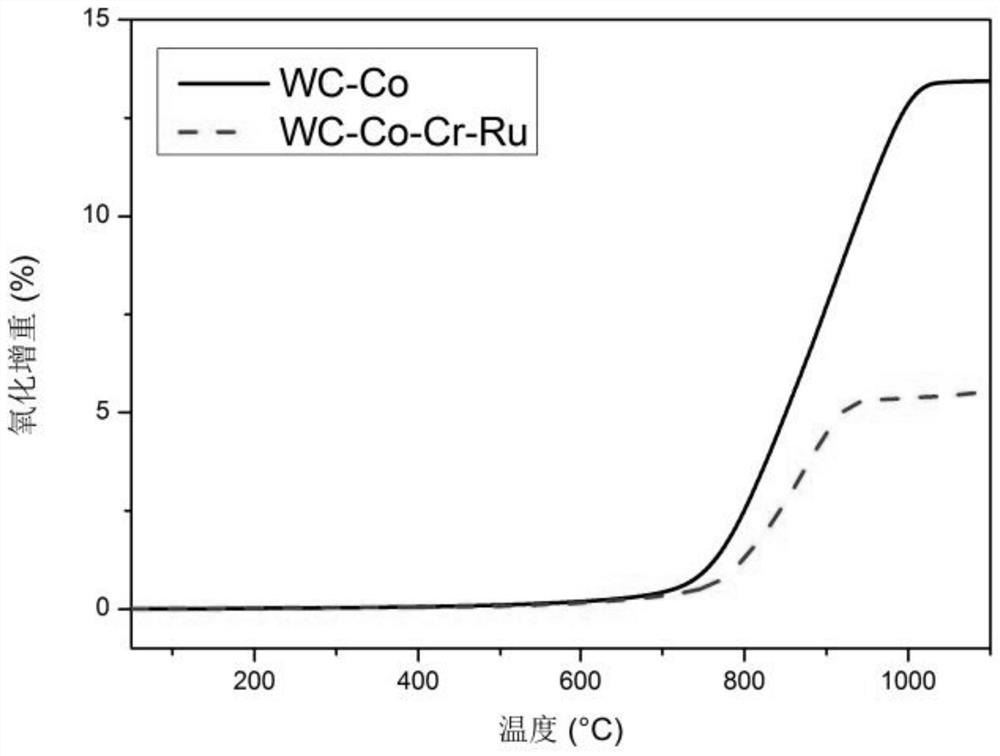

Ultra-fine grain hard alloy and preparation method thereof

The invention discloses an ultra-fine grain hard alloy and a preparation method thereof. The ultra-fine grain hard alloy is mainly prepared from the following raw materials in percentage by mass: 5%-8% of binding phase powder, 0.20%-0.80% of Cr3C2 powder, 0.25%-0.80% of Ru powder and 90.40%-94.55% of ultra-fine WC powder. According to the preparation method, all the raw materials are subjected to batching, ball milling, granulation, pressing and sintering, and the hard alloy is prepared. The Cr3C2 and the Ru are compositely added, so that the hardness of the alloy is ensured, the micromechanical property of a binding phase of the ultra-fine hard alloy is improved, the crack propagation resistance and the high-temperature oxidation resistance of an alloy material are obviously improved, and the binding wear resistance of the hard alloy is obviously improved; and the technical problem that turning machining of common high-temperature alloy materials in the fields of spaceflight, aviation, automobiles, ships and the like is difficult is solved.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Carburizing technique for medium carbon steel cold rolled bearing case loop

InactiveCN101294285AReduce the co-infiltration temperatureFast penetrationSolid state diffusion coatingFurnace typesPunchingCarbon potential

The invention discloses a carburizing process for cold rolling the bearing ring through medium carbon steel, which belongs to the technology field of heat treatment. A circular ring is made of tubes or bar stock through punching or forging into wafer after annealing, and made into a bearing ring through cold rolling; then carburizing heat treatment process is performed; in the carburizing atmosphere of 1.15 percent of carbon potential, direct quenching is performed after carburizing is performed for 10 hours at the temperature of 850 to 870 DEG C; the tempering temperature is 150 to 160 DEG C, and the temper time is 3 to 4 hours. The medium carbon steel bearing ring after being treated through the carburizing process has higher toughness and longer fatigue life; particularly, for the bearing working under the contaminated environment, the service life and the operational reliability can be improved.

Owner:LUOYANG BEARING RES INST CO LTD

Bionic coupling method for processing machinery parts by local laser melting and consolidation

InactiveCN101792906BImprove thermal fatigue resistanceSimple processing technologyMetallic material coating processesBiological bodySurface layer

The invention relates to a manufacture technology of fatigue wear machinery parts used under the working conditions of thermal fatigue and abrasive wear, particularly relating to a bionic coupling method for processing machinery parts by local laser melting and consolidation, which adopts the following technical scheme: a bionic coupling unit is manufactured by simulating a coupling structure of an organism and using laser melting and consolidation to fill in a groove or a pit with various alloys and ceramic powder on the area of a friction surface with a certain thickness on the machinery part. The bionic coupling unit and a workpiece surface form a bionic coupling area simulating the organism surface, namely, a concave pit or a groove is processed on a sample surface according to the organism structure and is filled with various alloys and ceramic powder blended with binder, compacted and dried by air, and is subject to bionic coupling treatment by laser melting and consolidation. By using the method, the problems of fatigue property and abrasion resistance of the machinery part surface layer are effectively solved under the working condition of thermal shock or repeated friction.

Owner:JILIN UNIV

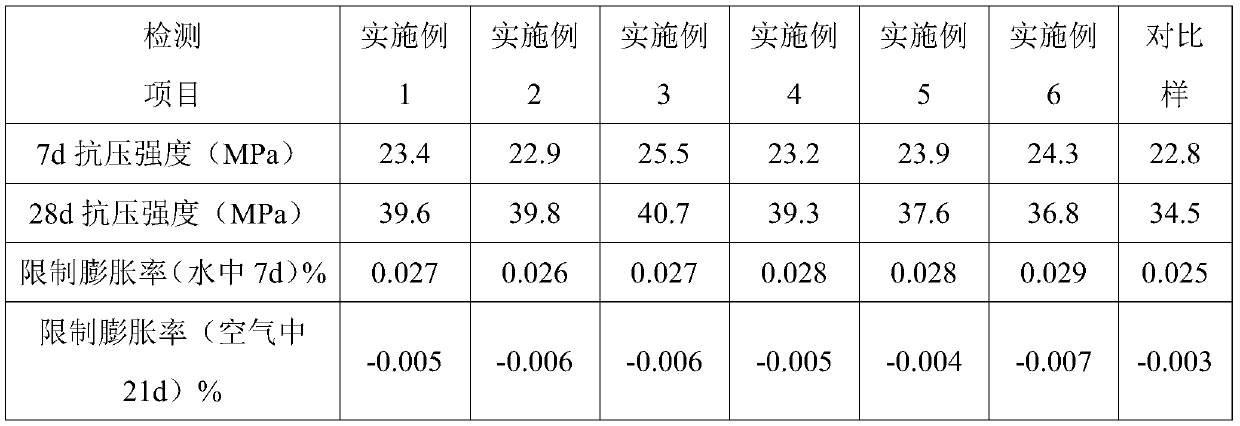

Liquid expanding agent expanding step by step and preparation method thereof

ActiveCN110963744AAvoid large local expansion stressesEvenly dispersedCrack resistancePolypropylene glycol

The invention discloses a liquid expanding agent capable of expanding step by step and a preparation method thereof. The liquid expanding agent is prepared by the following steps: 1, weighing a nano magnesium oxide powder mixture, butanol, span-80 and water, and stirring at a constant temperature of 30-40 DEG C for 1 hour; 2, heating to 50-70 DEG C, sequentially adding polypropylene glycol 400, dimethicone and a shrinkage reducing component, and stirring for 1-2 hours; and 3, adding polyacrylamide, stirring for 1-2 hours, curing at constant temperature for 1 hour, and cooling to room temperature to obtain the liquid expanding agent capable of expanding step by step. An expansion component in the liquid expanding agent is formed by grinding, modifying and mixing magnesium oxide fired at different temperatures of 700 DEG C, 900 DEG C and 1100 DEG C, the magnesium oxide powder is mixed and ground to a nanometer level, the hydration time of the three magnesium oxide powder prepared at different firing temperatures is different, and the step-by-step expansion effect is achieved; by compounding with the shrinkage reducing component and the like, the volume expansion of concrete can be remarkably improved, the concrete volume shrinkage is reduced, and the crack resistance and impermeability of concrete are improved.

Owner:HUBEI UNIV OF TECH

Composite rear earth alterant used for thermal fatigue resisting steel

InactiveCN101168816AQuality improvementAvoid the shortcomings of insignificant overall performance improvementThermal fatigueChemical composition

The invention relates to compound rare earth modification agent used for heat-resistant and anti-fatigue steel, and the agent belongs to addition agent applied to an alloy steel material. The invention is characterized in that the chemical components include the content (mass percentage ratio) that: RE occupies 15 to 17 percent (therein, Y occupies 50 to 71.1 percent of the mass of RE, and La+Ce+Pr+Nb+Sm+Eu+Gd+Tb+Dy+Ho+Er+Tm+Yb+Lu occupies 28.9 to 50 percent of the mass of RE), B occupies 0 to 10 percent, Nb occupies 0 to 17 percent, V occupies 0 to 6 percent, Ca occupies 0.5 to 15 percent, Ba occupies 0 to 15 percent and the residual is iron. The modification agent is block shaped grey alloy, the grain size scope is 0.5 to 50 mm, and the melting point scope is 1200 to 5000 DEG C. The modification agent is used to perform refining modification treatment to the material, and the anti-fatigue performance of the parts can be obviously enhanced, thereby lengthening the service life of the alloy suffering cold and heat alternating load function.

Owner:JIANGSU UNIV

Life extension method of pump shell and blade micro-cracks strengthened by laser

InactiveCN103409758BExtended service lifeImprove fatigue strengthMetallic material coating processesLaser processingHeat-affected zone

The invention discloses a method for prolonging life of pump shells and blades by carrying out laser strengthening, which relates to the technical fields of machinery manufacturing and laser processing application. The method adequately combines the characteristics of laser cladding with laser shock strengthening, i.e., the method comprises the steps of performing laser cladding repair on micro-cracks at first, and then performing laser shock strengthening treatment on a cladding layer, thus effectively solving the problem that the pump shells and blades are easy to generate internal defects such as cracks and air holes in the laser cladding repair process, and avoiding the problems of welding deformation, large heat influence area, easy generation of heat cracks and the like in a conventional processing method; the method disclosed by the invention is capable of generating a high-amplitude residual compressive stress on the surface of a material, effectively improving the fretting fatigue resistance of the material, comprehensively improving the mechanical properties of the material, and greatly prolonging the fatigue life of the material, thus achieving the purposes of prolonging the life and improving the reliability and safety.

Owner:JIANGSU UNIV

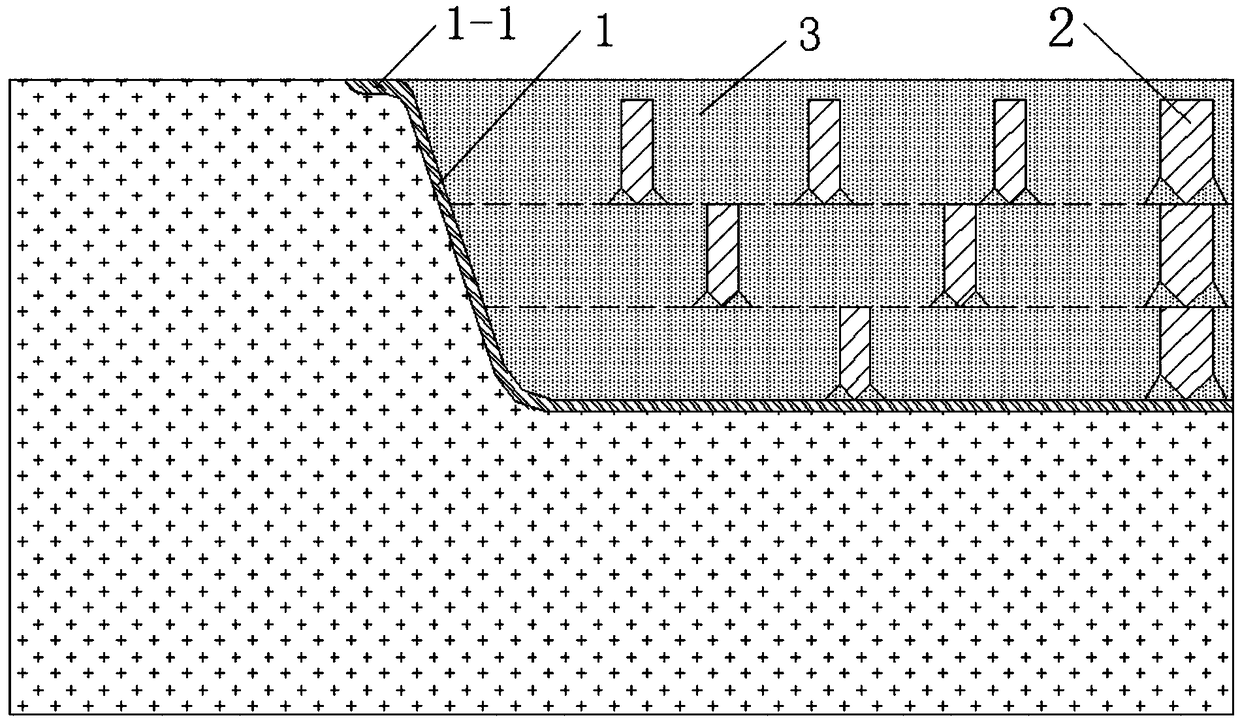

Welding structure of metal defect digging-patching welding groove of steel casting and reinforcing method of welding structure

ActiveCN109014648AImprove thermal field distributionInhibition of harmful effectsWorkpiece edge portionsWelding apparatusStructural stabilityPropagation rate

The invention relates to a welding structure of a metal defect digging-patching welding groove of a steel casting and a reinforcing method of the welding structure. By adoption of the welding structure of the metal defect digging-patching welding groove of the steel casting and the reinforcing method of the welding structure, the technical problems that during digging-patching welding of an existing large cast steel component, deformation of a welding structure is difficult to control, a repair welding area is likely to crack, and the structural stability and fatigue resistance of the weldingstructure cannot be guaranteed easily can be solved. The reinforcing method comprises the steps of first, welding a shell structure; second, arranging a plurality of rows and columns of multi-stage internal steel webs at intervals in the longitudinal and horizontal directions of a weld joint and the depth direction of the groove; third, filling welding deposited metal in a separated space of the welding groove; and fourth, conducting facing welding on the surface of the welding groove. According to the reinforcing method, a shell and rigid framework three-dimensional welding structural systemconstructed through welding can resist and disperse the shrinkage stress of weld joint metal, the welding deformation is effectively controlled, the stability of the welding structure is improved, propagation of fatigue cracks is changed, and accordingly, the propagation rate of the cracks is decreased.

Owner:哈尔滨中正焊接技术开发有限公司 +6

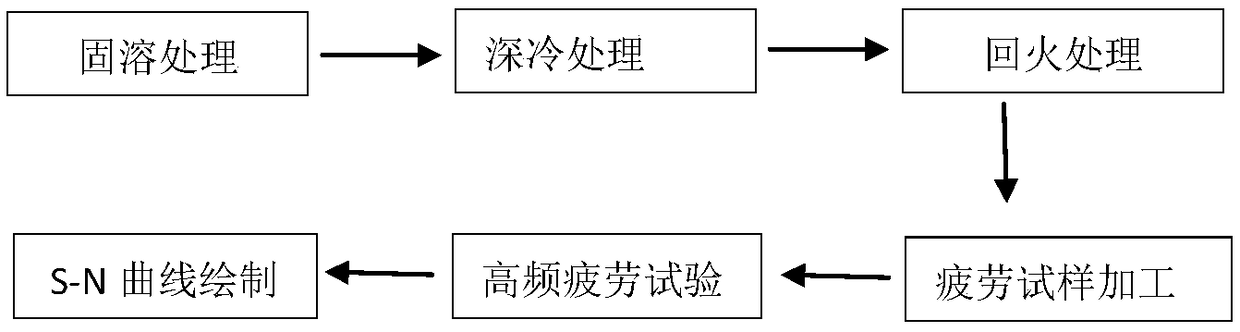

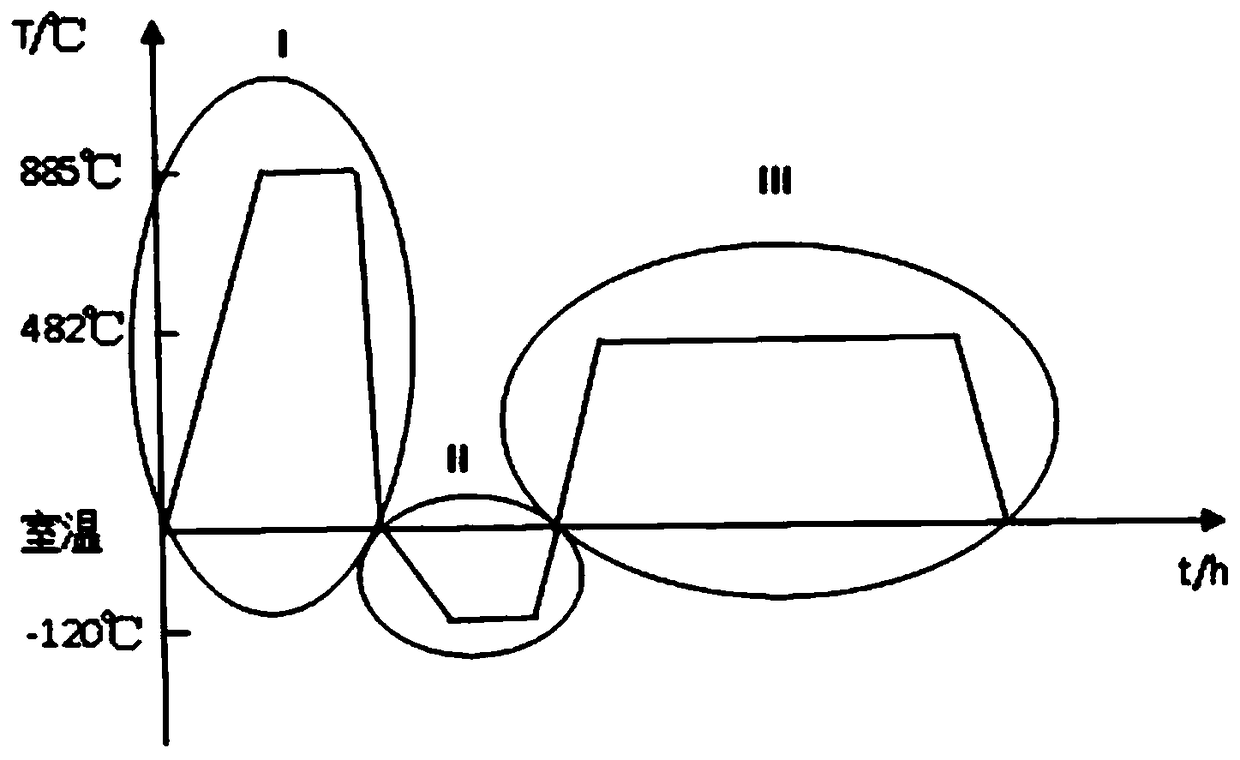

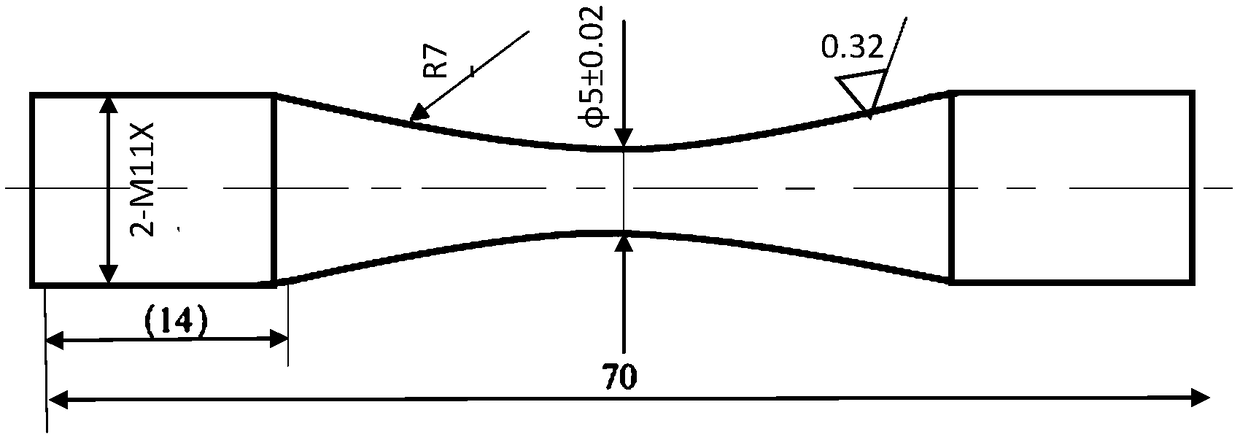

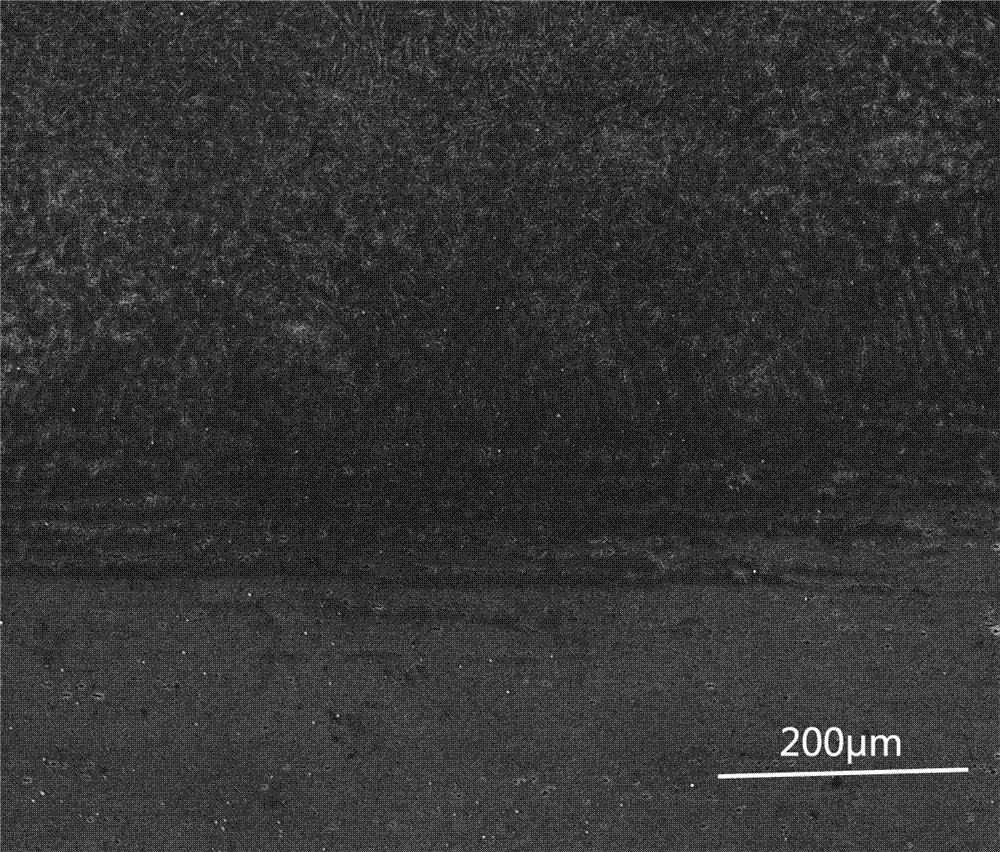

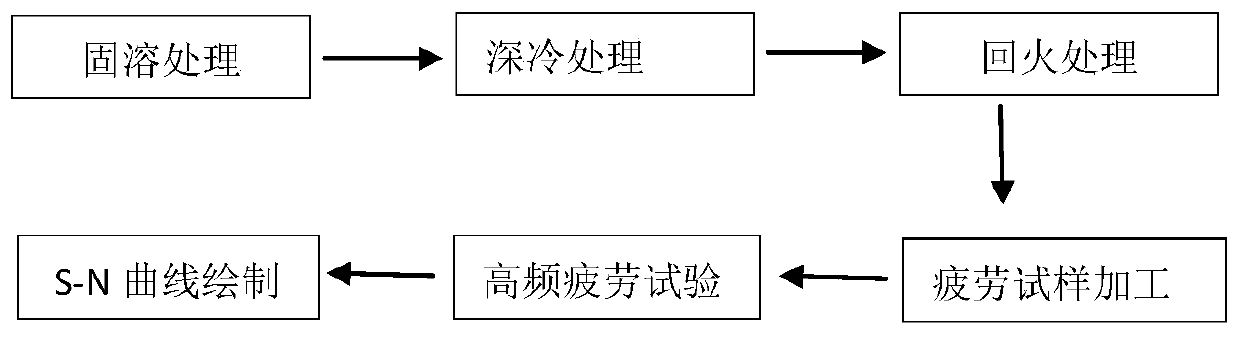

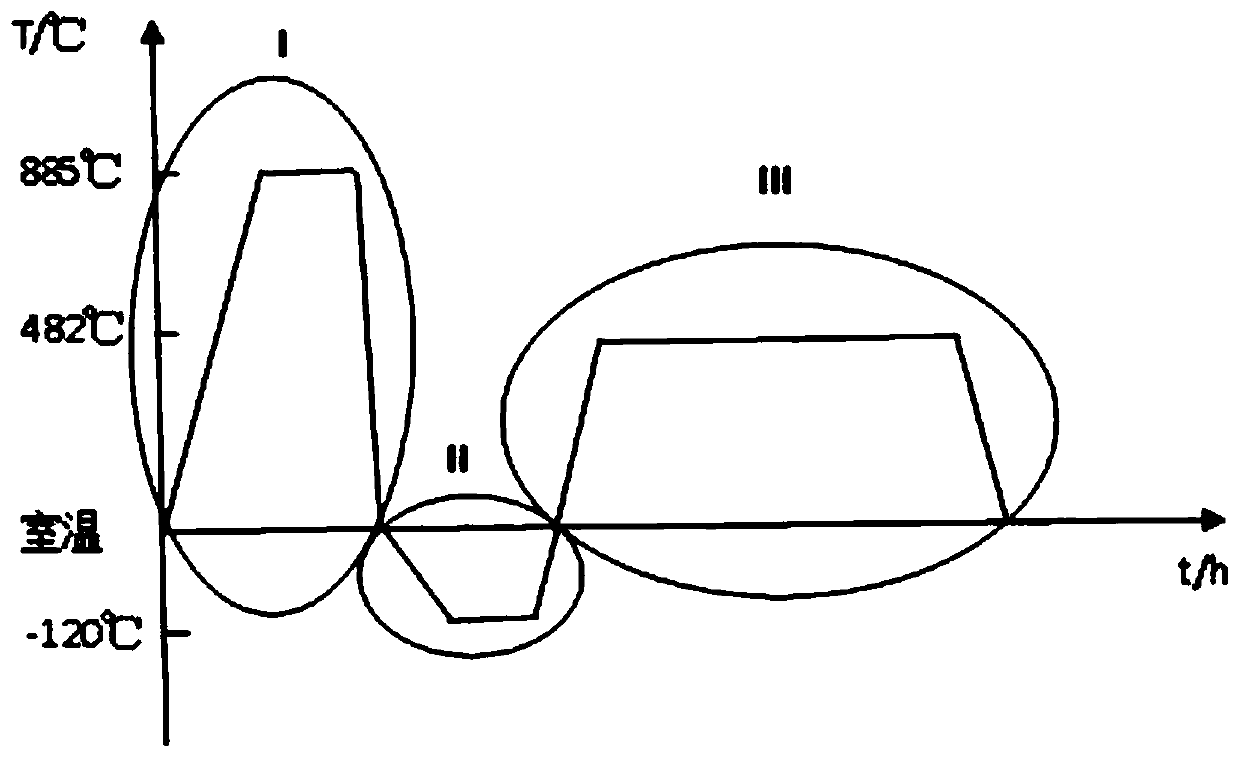

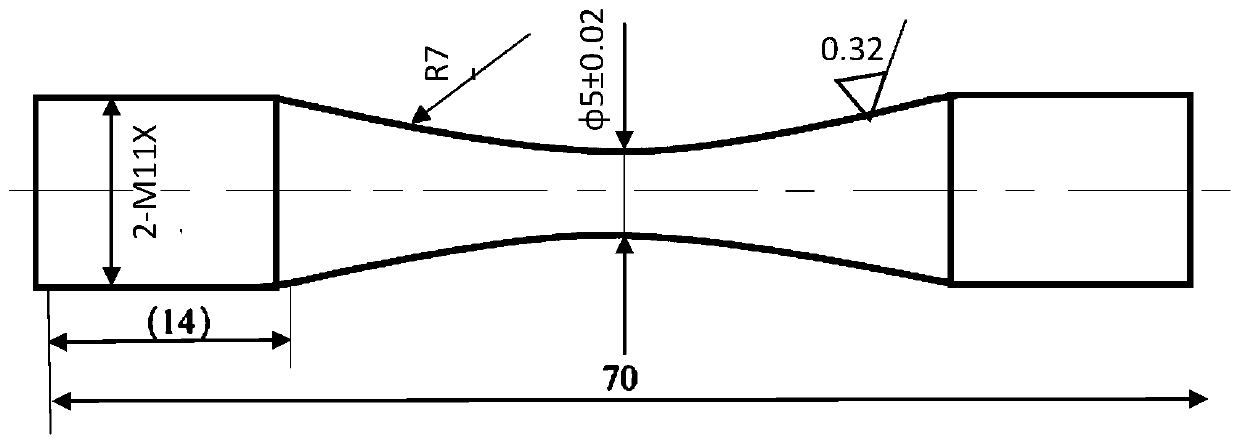

Subzero treatment technology of AerMet100 steel

The invention discloses a subzero treatment technology of AerMet100 steel. The subzero treatment technology comprises the following steps that solid solution treatment is carried out, concretely, theAerMet100 steel is subjected to the solid solution treatment, is subjected to heat preservation, is put into quenching oil for quenching, and is cooled to the room temperature; subzero treatment is carried out, concretely, the AerMet100 steel after being subjected to the solid solution treatment is subjected to the subzero treatment, the cooling rate is 3-5 DEG C / min, the subzero temperature is set as (-115) DEG C to (-125) DEG C, and after being subjected to the heat preservation, the AerMet100 steel is taken out and is subjected to air cooling until the temperature is recovered to the room temperature; and tempering treatment is carried out, concretely, the AerMet100 steel after being subjected to the subzero treatment is subjected to the tempering treatment, then is subjected to heat preservation, and is subjected to the air cooling to the room temperature. After the solid solution treatment, oil quenching is carried out in advance, the air cooling to the room temperature is carriedout, and then the subzero treatment is carried out, so that damage of rapid cooling and rapid heating on materials is avoided. In the subzero treatment process, a sample is cooled below -100 DEG C, so that the fatigue property of the AerMet100 steel is improved substantially.

Owner:CENT OF EXCELLENCE FOR ADVANCED MATERIALS

Processing technology for prolonging service life of thermal barrier coating of gas engine blade

InactiveCN112376014AMake up for interface weakeningReduce the phenomenon of easy crack formationMolten spray coatingCrazingThermal growth

The invention discloses a processing technology for prolonging the service life of a thermal barrier coating of a gas engine blade, and relates to the technical field of machining. The processing technology comprises the following specific steps: (1) processing and preparing mixed micro powder A; (2) processing and preparing mixed micro powder B; (3) processing to obtain nano composite particles with a layered structure; and (4) performing sand blasting roughening treatment on a high-temperature alloy matrix after ultrasonic cleaning, evenly mixing the mixed micro powder A, the mixed micro powder B, the nano composite particles and metal bonding layer powder, spraying the surface of the alloy matrix by a plasma spraying technology to form a bottom layer, and then spraying the bottom layerwith nano ceramic powder. According to the processing technology, various micro-powder particles are introduced into a metal bonding layer, so that the generation and expansion of cracks in a thermalgrowth oxide layer are reduced, the integrity of a microstructure of the thermal growth oxide layer is improved, the peeling failure of a ceramic layer is slowed down, and the service life of the thermal barrier coating is prolonged.

Owner:HANSHAN RONGSHENG MACHINERY CASTING

Method for recovering hammer of refined forging machine through laser cladding

The invention discloses a method for recovering a hammer of a refined forging machine through laser cladding. The method comprises the following steps: carrying out laser cladding on a transitional alloy layer which is prepared from 17.5 to 19% of Cr, 10 to 12.8% of Co, 6.3 to 7.5% of Mo, 1 to 2.6% of W, 1.6 to 2.5% of Al, 0.23 to 0.29% of C, 2.1 to 2.9% of Ti, 0.23 to 0.38% of B and the balance of Ni on the surface of the hammer of the refined forging machine; and then carrying out laser cladding on a surface alloy layer which is prepared from 13 to 16.8% of Mo, 14 to 18% of Cr, 4 to 5.62% of W, 4.3 to 5.8% of Si, 8.2 to 9% of Fe, the maximum 0.15% of C, the maximum 1.2% of Mn, the maximum 0.028% of S, the maximum 0.019% of P, the maximum 2.7% of Co, and the balance of Ni. According to the recovering method disclosed by the invention, the abrasion quantity of the hammer of the refined forging machine under high temperature and strong abrasion of forging can be reduced, extension velocity of cracks of a cladding layer is delayed, and the service life of the hammer of the refined forging machine is prolonged.

Owner:ZHONGBEI UNIV

Welding rod and its preparation method

InactiveCN101148005AHigh hardnessImprove wear resistanceLiquid surface applicatorsWelding/cutting media/materialsHigh carbonWhite powder

The present invention belongs to the field of welding material technology, and is especially one welding rod with high toughness. The welding rod includes one core wire and one welding rod coating comprising ferrovanadium 30-36 wt%, marble 27-35 wt%, titanium white powder 3-6 wt%, high carbon ferromanganese 8-12 wt%, fluorite 2-4 wt%, high carbon ferrochrome 14-18 wt%, nickel 1.5-2.5 wt%, and ferrotitanium 1-2 wt%. The welding rod has high hardness, high wear resistance and high impact strength.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

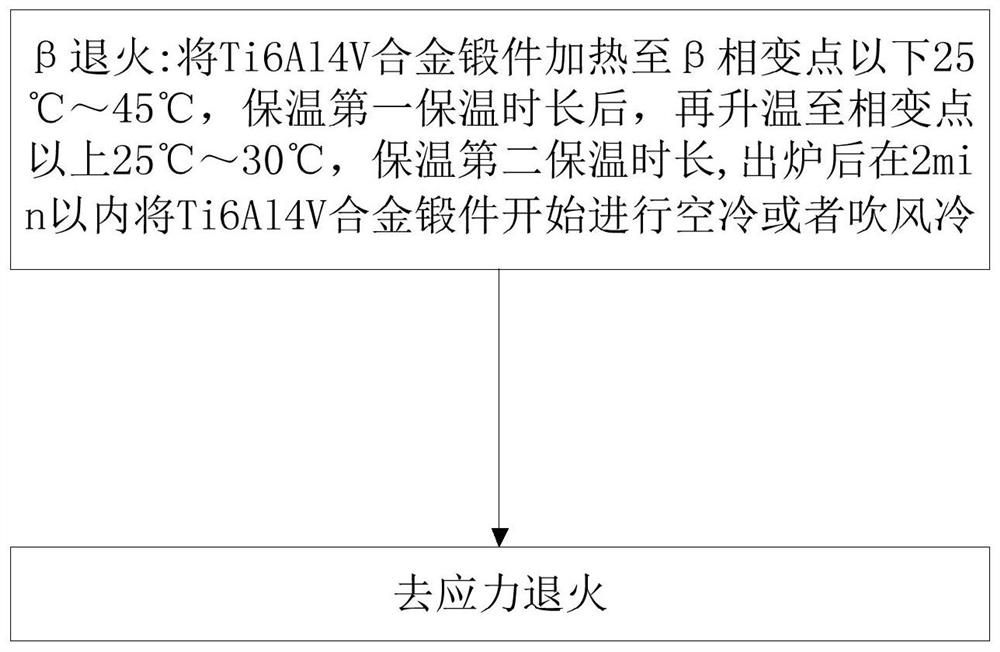

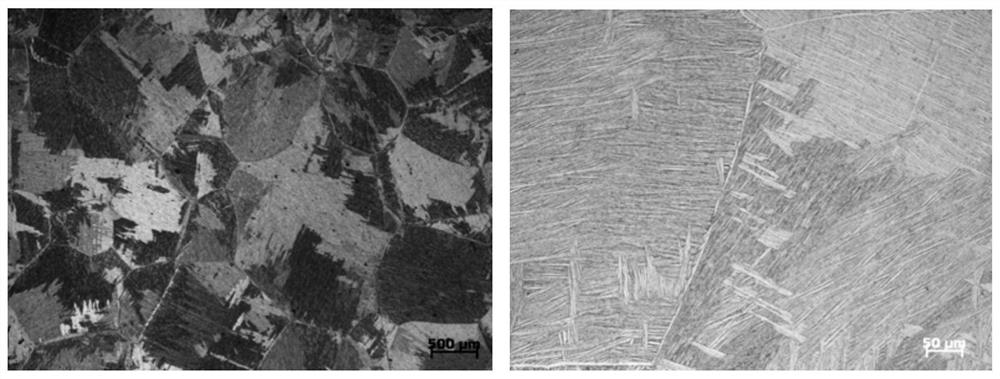

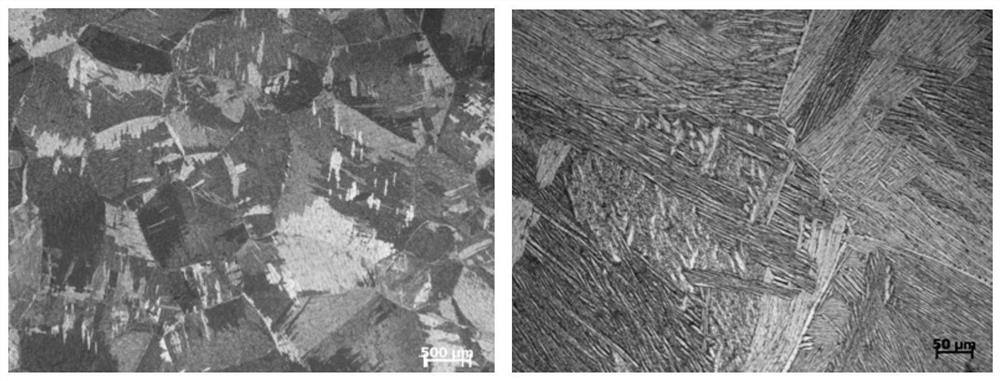

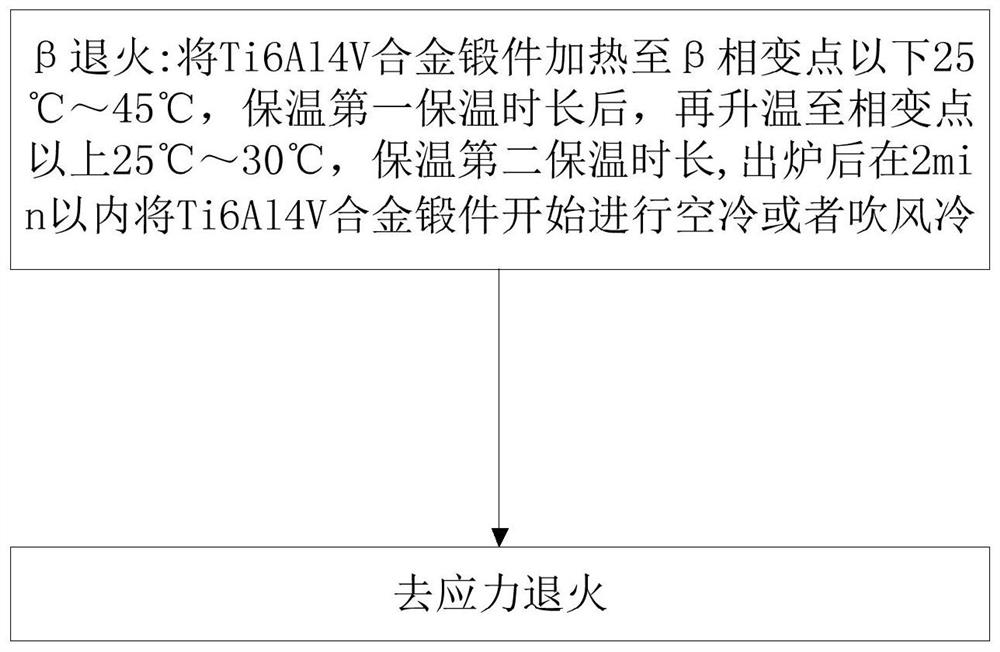

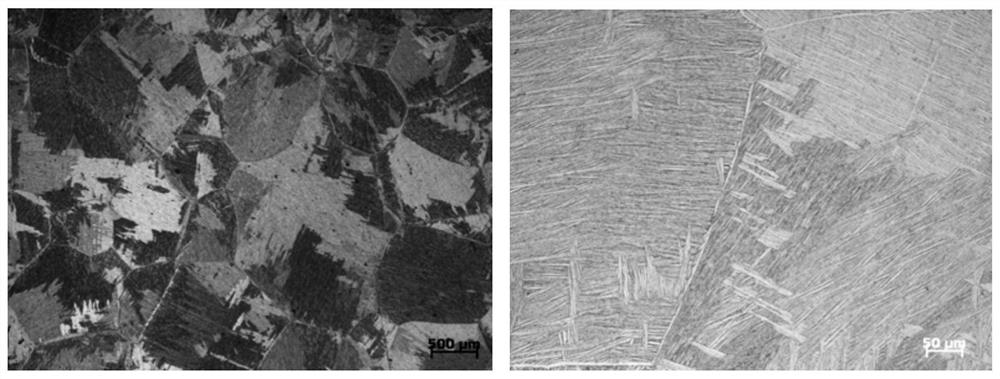

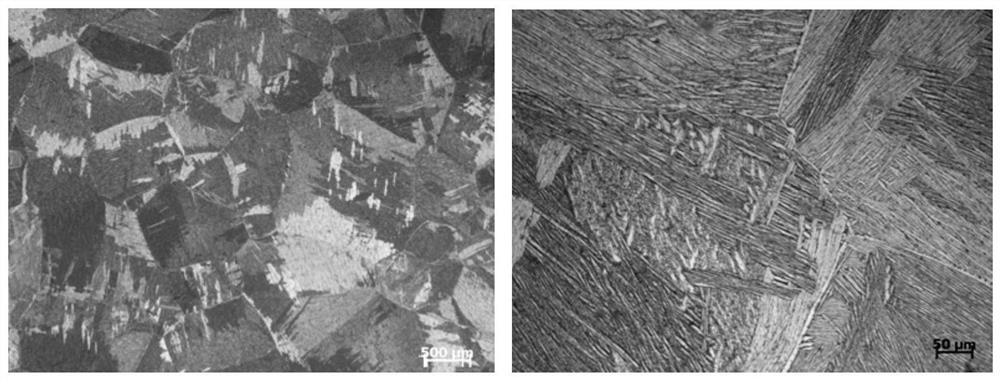

Beta annealing heat treatment method for Ti6Al4V alloy forge piece

The invention provides a beta annealing heat treatment method for a Ti6Al4V alloy forge piece. The beta annealing heat treatment method comprises the following steps of 1, beta annealing, specifically, heating the Ti6Al4V alloy forge piece to 25-45 DEG C below a beta phase transformation point, keeping the temperature for a first heat preservation duration, heating to 25-30 DEG C above the phase transformation point, keeping the temperature for a second heat preservation duration, and starting air cooling or air cooling on the Ti6Al4V alloy forge piece within 2 minutes after furnace discharging; and 2, stress relief annealing. By means of the beta annealing heat treatment method for the Ti6Al4V alloy forge piece, the high strength, plasticity and fracture toughness and the low fatigue crack propagation rate which meet the specification requirements can be obtained, the process is simple and stable, operation is convenient, and the beta annealing heat treatment method is suitable for industrial production.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Method for repairing micro-contact fatigue damage of tooth surface and repairing device

ActiveCN113523708AImprove mechanical propertiesAddress process complexityProcess efficiency improvementLaser beam welding apparatusControl systemMonitoring system

The invention discloses a method for repairing micro-contact fatigue damage of a tooth surface and a repairing device. The method comprises the following steps that a to-be-repaired gear is fixed on a motion platform through a clamp; geometrical morphology characteristics of a to-be-repaired area are measured by using a three-dimensional morphology instrument, collected information is input to a comprehensive control and monitoring system, and material and mechanical characteristics of the to-be-repaired gear are compared through a database to determine optimal laser shock repair process parameters; the optimal process parameters are imported into a pulse laser generator, the laser generator emits laser according to the optimal process parameter scheme, and laser beams are exported through a light path regulation and control system and a light path system; meanwhile, a water restraint layer system controls a water nozzle to form a water restraint layer on the tooth surface; and the laser acts on the to-be-repaired area on the tooth surface, so that the gear generates the required reinforced repair effect, and the purpose of repairing the tooth surface damage is achieved. The problems that in a traditional repairing mode, the process is complex, roughness is high, abrasion resistance is poor, and the gear can be repaired only after obvious defects or faults occur to the gear are solved.

Owner:NANTONG UNIVERSITY

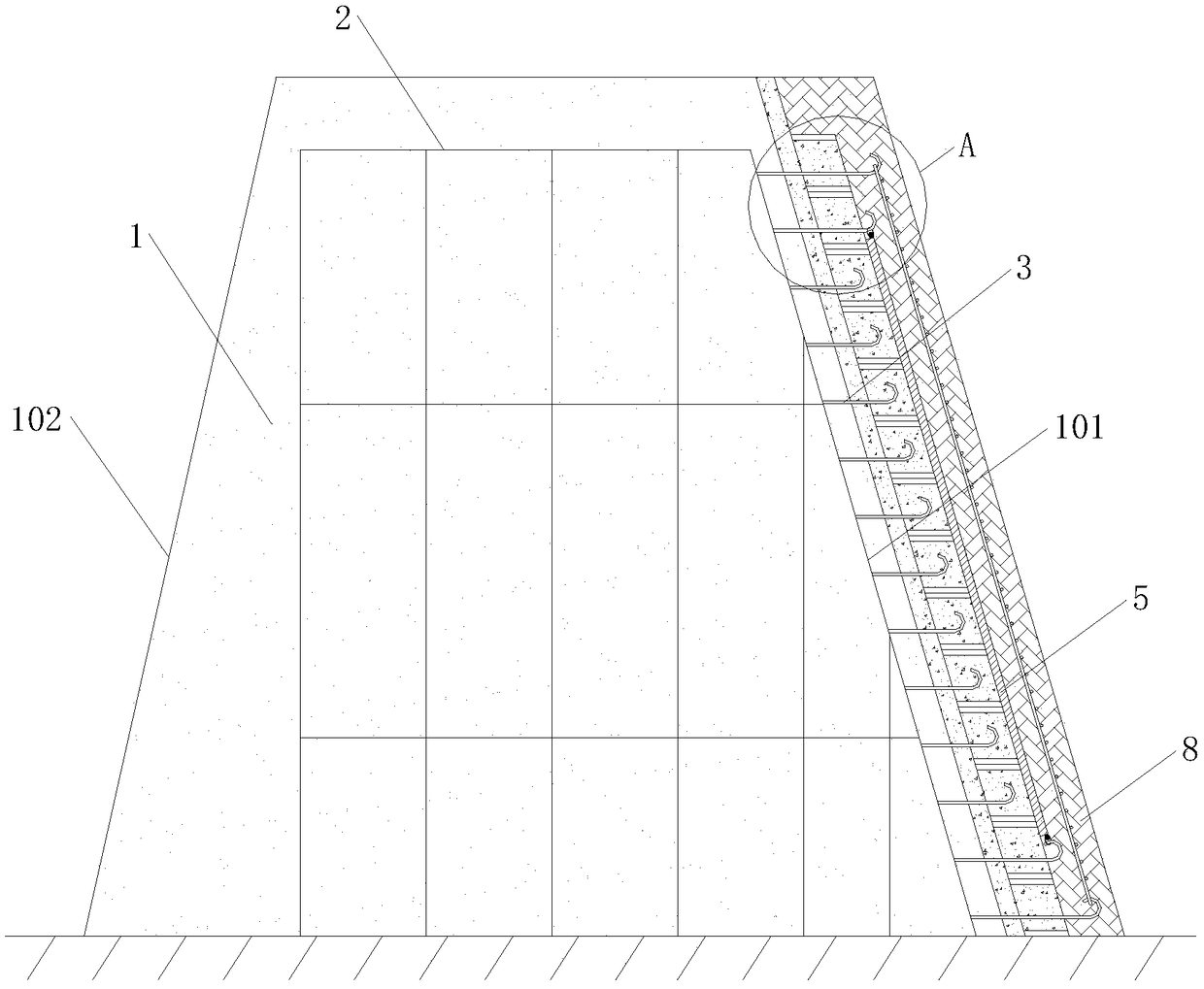

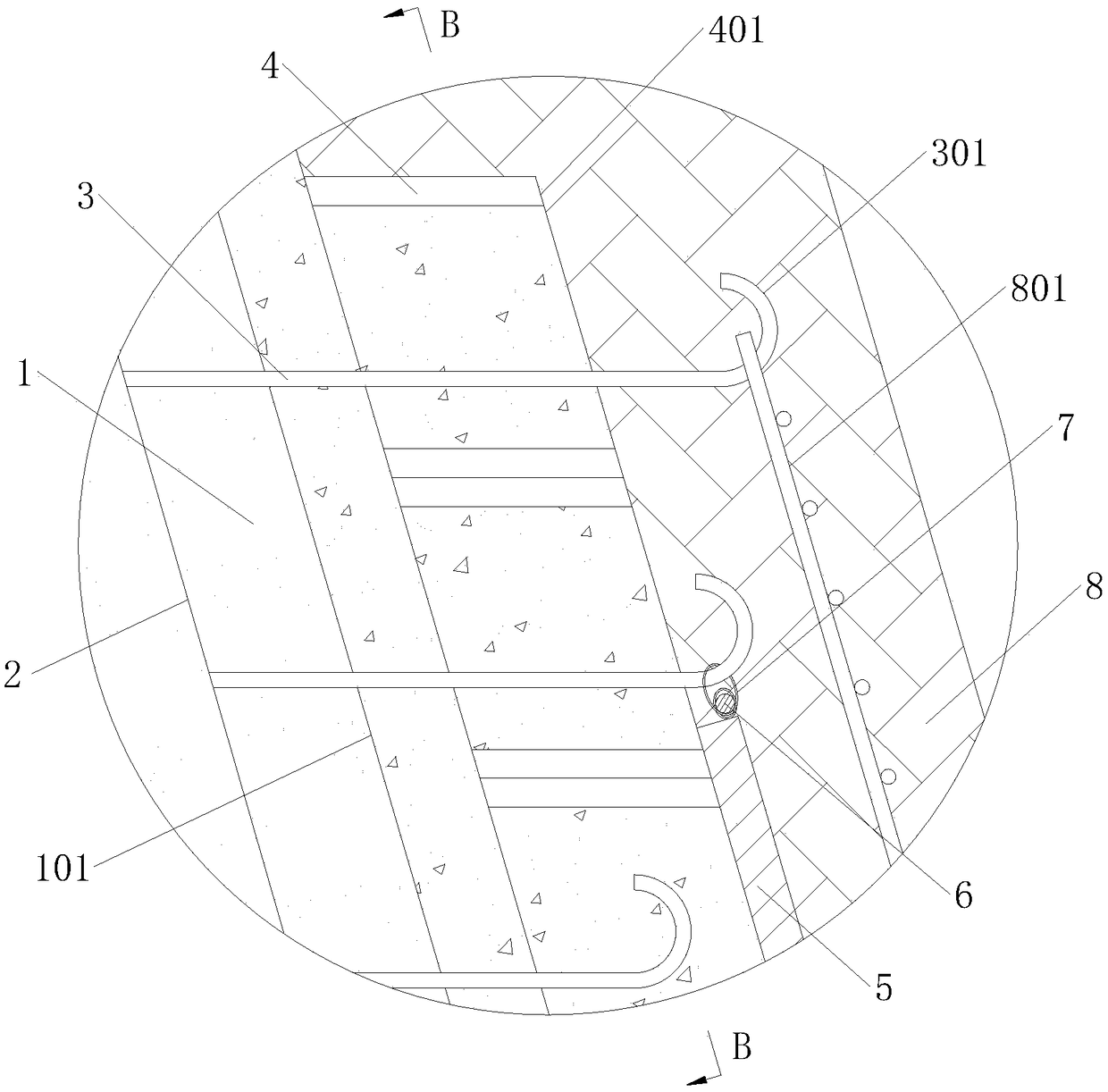

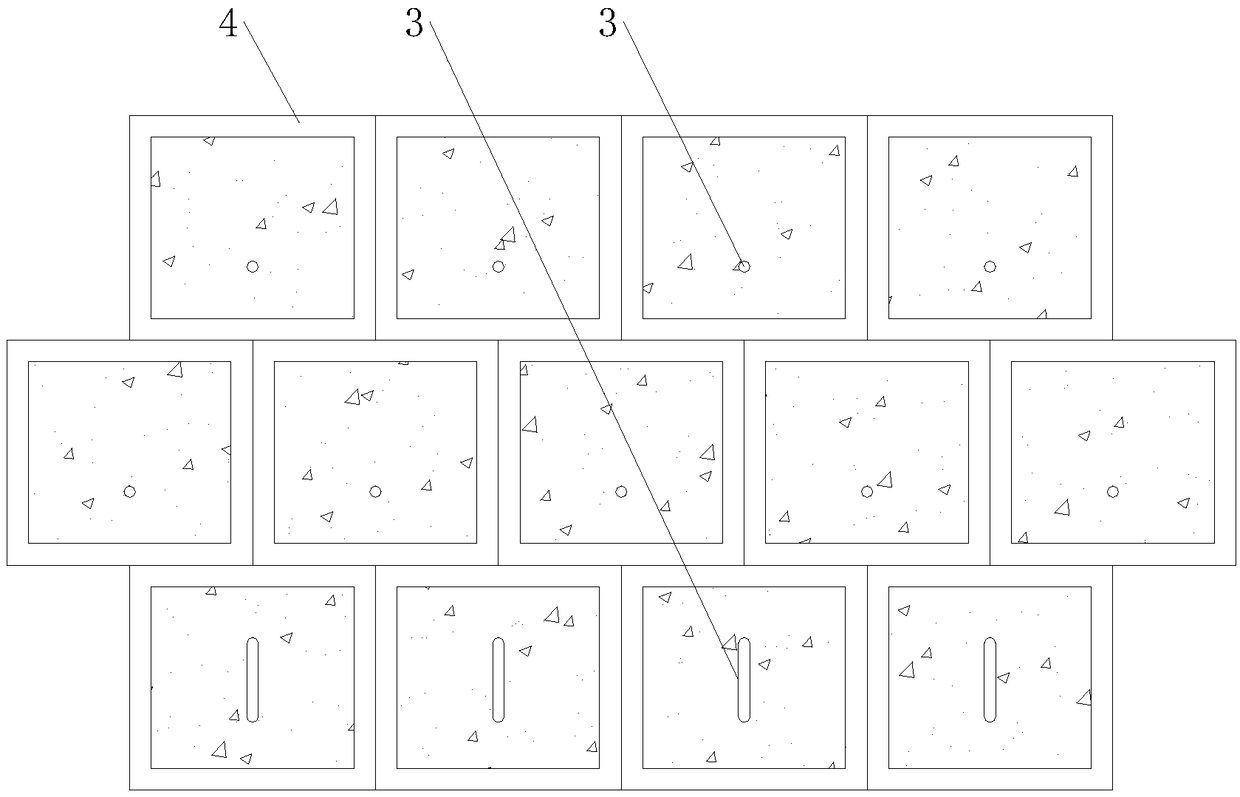

Seepage-proofing type water conservancy dam and building method

ActiveCN108999148AImprove structural strengthImprove impact resistanceDamsClimate change adaptationSurface layerEngineering

The invention discloses a seepage-proofing type water conservancy dam and a building method. The seepage-proofing type water conservancy dam comprises a dam body. A reinforcing steel bar support is arranged on the inner side of the dam body. A tilted front side slope and a tilted rear side slope are arranged on the two sides of the dam body correspondingly. A reinforcing layer, a seepage-proofinglayer and a surface layer are sequentially arranged on the outer side of the front slope. The reinforcing layer comprises a plurality of J-shaped hooked claw sets. Each J-shaped hooked claw set comprises a plurality of J-shaped hooked claws which are horizontally arrayed. One end of each J-shaped hooked claw is connected with the reinforcing steel bar support, and the other end of each J-shaped hooked claw is provided with a cement supporting frame of the rectangle structure. The inner side of each cement supporting frame is filled with concrete. The seepage-proofing layer comprises a waterproof cloth. Four annular woven belts are arranged on the periphery of the waterproof cloth. Each annular woven belt is internally provided with a steel wire rope in a penetrating mode, and the two endsof each steel wire rope are connected with the J-shaped hooked claws on the outer side of the waterproof cloth. Each steel wire rope is sleeved with a plurality of positioning rings at intervals. Theseepage-proofing type water conservancy dam has the beneficial effect that impact resistance and seepage capability are good.

Owner:STATE GRID CORP OF CHINA +2

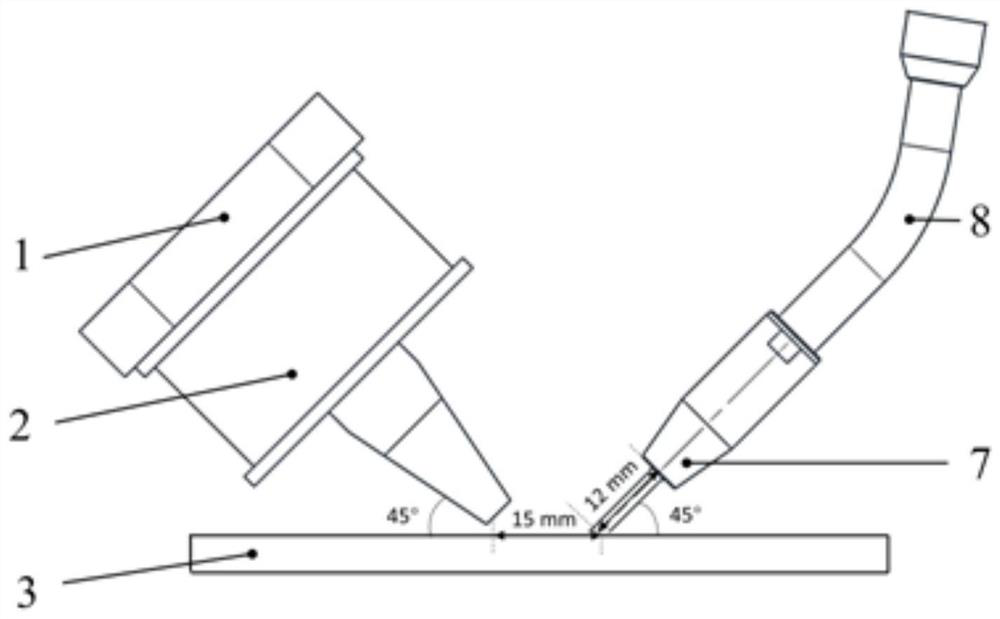

Forming method for electric arc fuse wire additive manufacturing

ActiveCN113798632ARealize real-time regulationReduce or eliminate internal porosityIncreasing energy efficiencyWelding accessoriesEngineeringTransverse magnetic field

The invention discloses a forming method for electric arc fuse wire additive manufacturing. The method comprises the steps that a clamp type electromagnet and an electric arc welding gun are fixed to a robot, different inclination angles exist between the clamp type electromagnet and a workpiece substrate and between the electric arc welding gun and the workpiece substrate, and electric arc fuse wire additive manufacturing is conducted under a steady transverse magnetic field generated by the clamp type electromagnet; wherein the magnetic field intensity of the transverse magnetic field is adjusted according to the magnetism of a finally-formed product, so that welding seam forming is improved, the internal air hole defect is reduced, internal crystal grains are refined, and element segregation is restrained; and the optimal magnetic field intensity of the transverse magnetic field is positively correlated with the magnetism of the finally-formed product. Residual stress distribution is optimized, the micro air hole defect is reduced or eliminated, heat dissipation of a molten pool is promoted, a welding seam structure is refined, element segregation is inhibited, and the mechanical property and corrosion resistance of an electric arc additive component are comprehensively improved. The magnetic field intensity of the transverse magnetic field is adjusted according to the magnetism of the finally-formed product, and the research blank in the aspect is filled up.

Owner:HUAZHONG UNIV OF SCI & TECH

A β-annealing heat treatment method for ti6al4v alloy forgings

The invention provides a β-annealing heat treatment method for Ti6Al4V alloy forgings, which includes the following steps: the first step: β-annealing: heating the Ti6Al4V alloy forgings to 25°C-45°C below the β-transition point, keeping the temperature for the first time, and then raising the temperature To 25 ℃ ~ 30 ℃ above the phase transition point, heat preservation for the second heat preservation time, and start air cooling or blowing cooling of the Ti6Al4V alloy forging within 2 minutes after being out of the furnace; the second step: stress relief annealing. The β-annealing heat treatment method for Ti6Al4V alloy forgings provided by the invention can obtain higher strength, plasticity and fracture toughness meeting specification requirements, lower fatigue crack growth rate, simple and stable process, convenient operation, and is suitable for industrial production.

Owner:SHAANXI HONGYUAN AVIATION FORGING

A cryogenic treatment process for aermet100 steel

The invention discloses a subzero treatment technology of AerMet100 steel. The subzero treatment technology comprises the following steps that solid solution treatment is carried out, concretely, theAerMet100 steel is subjected to the solid solution treatment, is subjected to heat preservation, is put into quenching oil for quenching, and is cooled to the room temperature; subzero treatment is carried out, concretely, the AerMet100 steel after being subjected to the solid solution treatment is subjected to the subzero treatment, the cooling rate is 3-5 DEG C / min, the subzero temperature is set as (-115) DEG C to (-125) DEG C, and after being subjected to the heat preservation, the AerMet100 steel is taken out and is subjected to air cooling until the temperature is recovered to the room temperature; and tempering treatment is carried out, concretely, the AerMet100 steel after being subjected to the subzero treatment is subjected to the tempering treatment, then is subjected to heat preservation, and is subjected to the air cooling to the room temperature. After the solid solution treatment, oil quenching is carried out in advance, the air cooling to the room temperature is carriedout, and then the subzero treatment is carried out, so that damage of rapid cooling and rapid heating on materials is avoided. In the subzero treatment process, a sample is cooled below -100 DEG C, so that the fatigue property of the AerMet100 steel is improved substantially.

Owner:CENT OF EXCELLENCE FOR ADVANCED MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com