Subzero treatment technology of AerMet100 steel

A technology of cryogenic treatment and process, which is applied in the field of cryogenic treatment of AerMet100 steel, can solve problems such as failure to consider the comprehensive impact of cryogenic treatment, brittle fracture, material thermal shock, etc., to prolong crack initiation life, prevent cracking, and improve fatigue performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

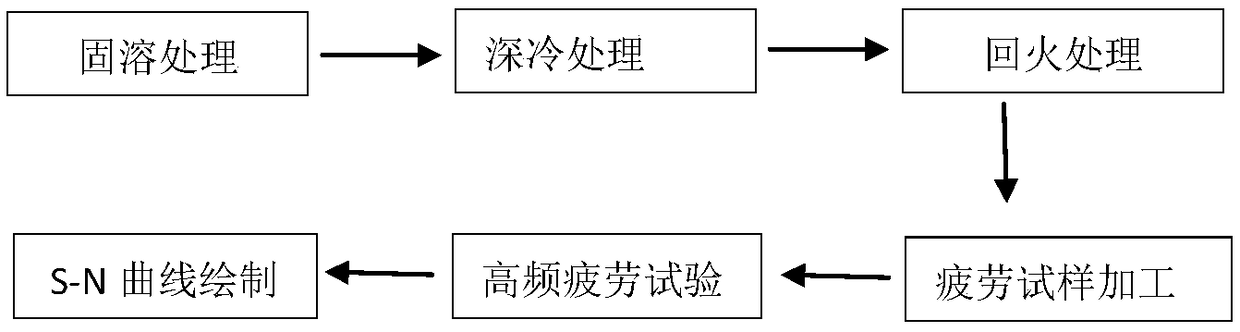

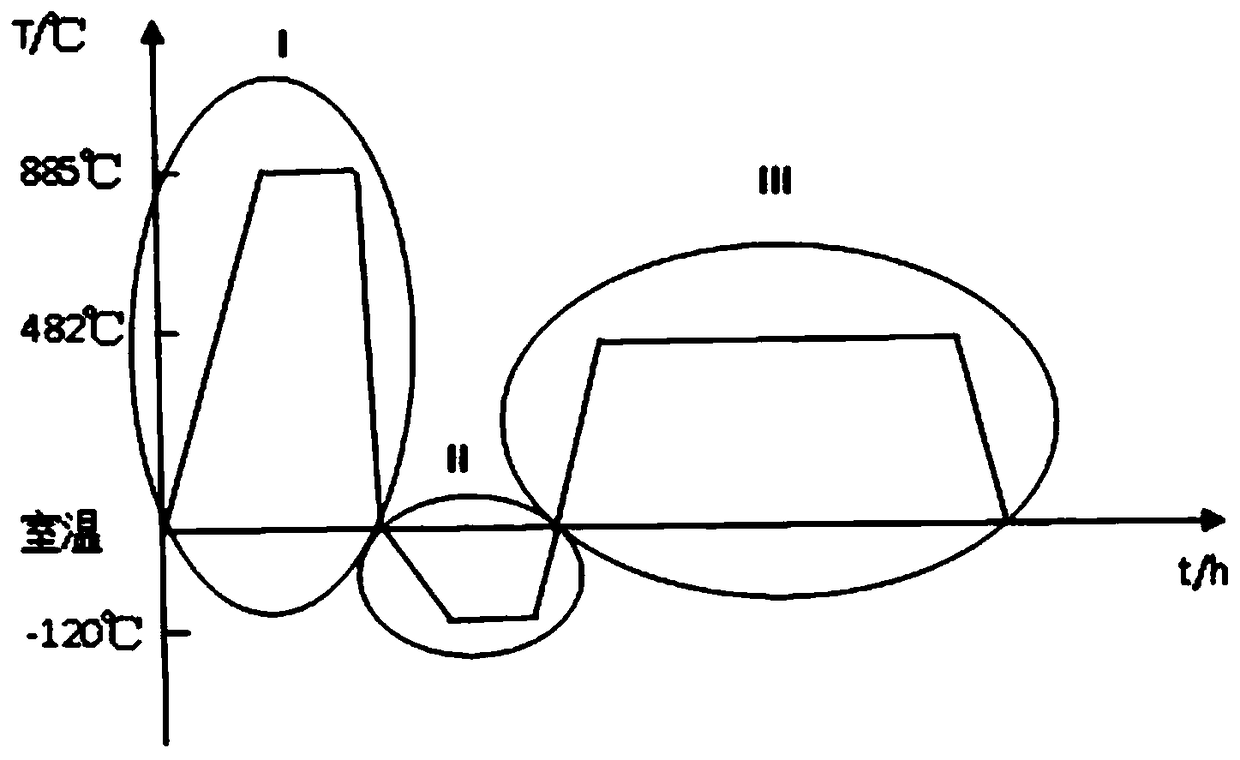

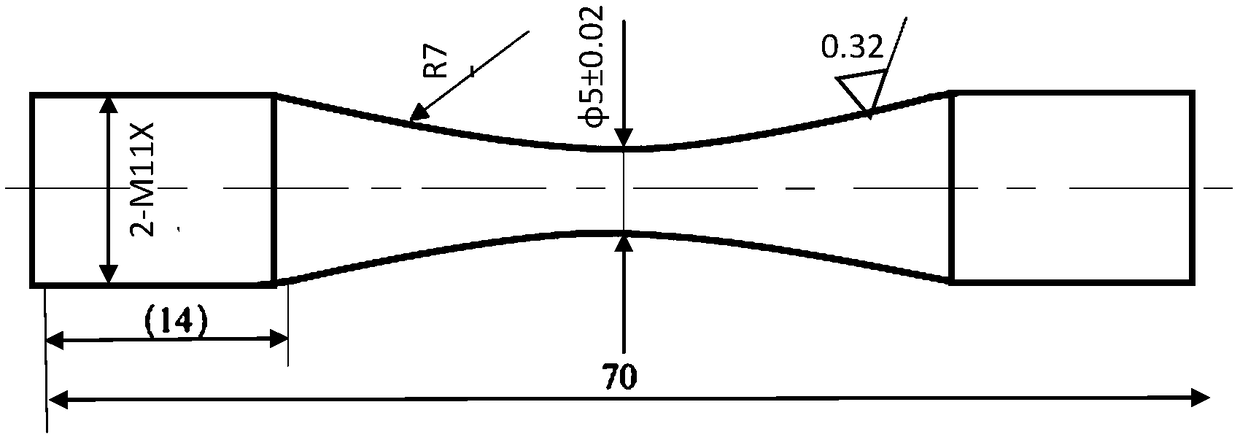

[0050] refer to Figure 1-2 , a cryogenic treatment process for AerMet100 steel, comprising the following steps:

[0051] Heat AerMet100 steel at a heating rate of 10min / °C to 885°C, keep it warm for 1h, and then cool it to room temperature with oil quenching; within 8h after quenching, perform cryogenic treatment, cool it to -115°C at a cooling rate of 3°C / min, and keep it warm for 1h. Take it out from the cryogenic box and air-cool to room temperature; temper within 4 hours, then heat to 482°C at a rate of 10min / °C for tempering, hold for 5 hours, and air-cool to room temperature to prepare the sample

[0052] The standard GB / T228.1 metal room temperature tensile test method was used to carry out the tensile test on the sample, and the test results are listed in Table 1.

Embodiment 2

[0054] A cryogenic treatment process for AerMet100 steel, comprising the following steps:

[0055] Heat the AerMet100 steel to 885°C at a heating rate of 10min / °C, keep it warm for 1h, and then cool it to room temperature with oil quenching; within 8h after quenching, perform cryogenic treatment, cool it to -120°C at a cooling rate of 4°C / min, and keep it warm for 1h. Take it out from the cryogenic box and air-cool to room temperature; temper within 4 hours, then heat to 482°C at a rate of 10min / °C for tempering, hold for 5 hours, and air-cool to room temperature to prepare the sample

[0056] The standard GB / T228.1 metal room temperature tensile test method was used to carry out the tensile test on the sample, and the test results are listed in Table 1.

Embodiment 3

[0058] A cryogenic treatment process for AerMet100 steel, comprising the following steps:

[0059] Heat AerMet100 steel to 885°C at a heating rate of 10min / °C, keep it warm for 1h, and then cool it to room temperature with oil quenching; within 8h after quenching, perform cryogenic treatment, cool it to -125°C at a cooling rate of 5°C / min, and keep it warm for 1h. Take it out from the cryogenic box and air-cool to room temperature; temper within 4 hours, then heat to 482°C at a rate of 10min / °C for tempering, hold for 5 hours, and air-cool to room temperature to prepare the sample.

[0060] The standard GB / T228.1 metal room temperature tensile test method was used to carry out the tensile test on the sample, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com