Liquid expanding agent expanding step by step and preparation method thereof

A technology for liquid expansion and powder mixing, applied in the field of building materials, can solve the problems of shrinkage and cracking of concrete, large amount of finely ground fly ash and slag powder, and troublesome concrete, so as to avoid excessive expansion stress, The effect of slowing the expansion rate and controlling the rate of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

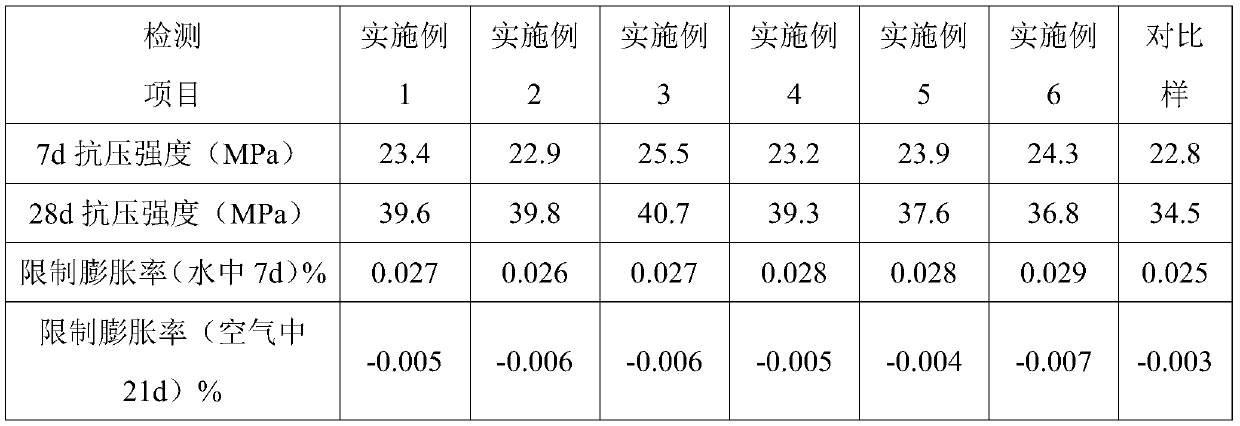

Examples

Embodiment 2

[0055] A method for preparing a step-by-step expansion liquid expansion agent, the total mass of raw materials is 100 parts, the solid content is about 10%, and it is mainly prepared from the following components:

[0056] 700 ℃ nano magnesium oxide powder: 1.0 parts

[0057] 900°C nano-magnesia powder: 0.8 parts

[0058] 1100°C nano-magnesia powder: 0.5 parts

[0059] Butanol: 0.2 parts

[0060] Simethicone oil: 0.3 parts

[0061] Span 80: 0.3 servings

[0062] Polypropylene alcohol 400: 0.6 parts

[0063] Lauryl polyoxyethylene ether: 2.6 parts

[0064] Propylene glycol methyl ether: 2.6 parts

[0065] Polyacrylamide: 1.2 parts

[0066] Step 1: Weigh 1.0 parts of 700°C nano-magnesia powder, 0.8 parts of 900°C nano-magnesia powder, 0.5 parts of 1100°C nano-magnesia powder, 0.2 parts of butanol, 0.3 parts of simethicone, and 0.3 parts of Si Place 80 parts of pan and 90 parts of water in the reaction kettle, control the temperature of the water bath at 40°C, and stir at...

Embodiment 3

[0070] A method for preparing a step-by-step expansion liquid expansion agent, the total mass of raw materials is 100 parts, the solid content is about 10%, and it is mainly prepared from the following components:

[0071] 700°C nano-magnesia powder: 1.4 parts

[0072] 900°C nano-magnesia powder: 0.8 parts

[0073] 1100°C nano-magnesia powder: 0.5 parts

[0074] Butanol: 0.3 parts

[0075] Simethicone oil: 0.2 parts

[0076] Span 80: 0.4 servings

[0077] Polypropylene alcohol 400: 0.7 parts

[0078] Lauryl polyoxyethylene ether: 2.5 parts

[0079] Propylene glycol methyl ether: 2.5 parts

[0080] Polyacrylamide: 1.0 parts

[0081] Step 1: Weigh 1.4 parts of 700°C nano-magnesia powder, 0.8 parts of 900°C nano-magnesia powder, 0.5 parts of 1100°C nano-magnesia powder, 0.3 parts of butanol, 0.2 parts of simethicone, 0.4 parts of Si Place 80 parts of pan and 90 parts of water in the reaction kettle, control the temperature of the water bath at 35°C, and stir at constant t...

Embodiment 4

[0085] A method for preparing a step-by-step expansion liquid expansion agent, the total mass of raw materials is 100 parts, the solid content is about 10%, and it is mainly prepared from the following components:

[0086] 700 ℃ nano magnesium oxide powder: 1.3 parts

[0087] 900°C nano-magnesia powder: 0.9 parts

[0088] 1100°C nano-magnesia powder: 0.8 parts

[0089] Butanol: 0.3 parts

[0090] Simethicone oil: 0.2 parts

[0091] Span 80: 0.4 servings

[0092] Polypropylene alcohol 400: 0.8 parts

[0093] Lauryl polyoxyethylene ether: 2.4 parts

[0094] Propylene glycol methyl ether: 2.4 parts

[0095] Polyacrylamide: 0.8 parts

[0096] Step 1: Weigh 1.3 parts of 700°C nano-magnesia powder, 0.9 parts of 900°C nano-magnesia powder, 0.8 parts of 1100°C nano-magnesia powder, 0.3 parts of butanol, 0.2 parts of simethicone, 0.4 parts of Si Place 80 parts of the pan and 90 parts of water in the reaction kettle, control the temperature of the water bath at 30°C, and stir at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com