Patents

Literature

66 results about "Ti6al4v alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Ti-6Al-4V alloy is an α–β titanium alloy that exhibits high strength, low density, and good corrosion resistance. It is one of the most commonly used titanium alloys.

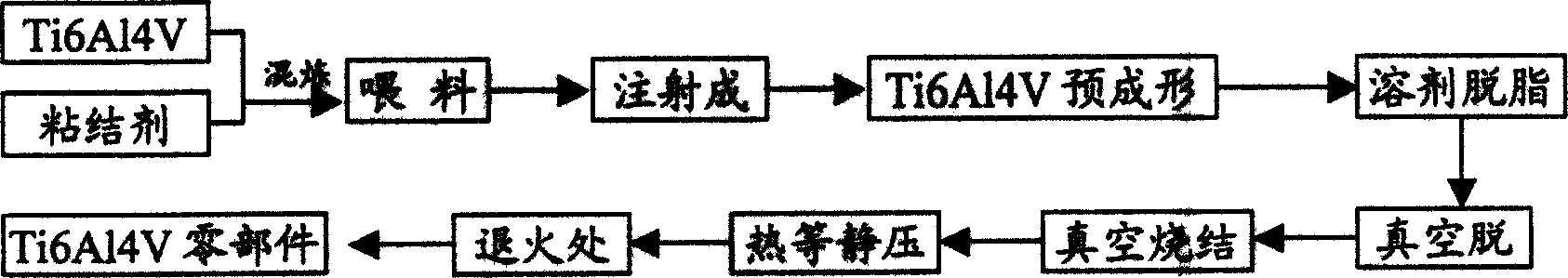

Ti6Al4V alloy injection forming method

An injection moulding technology for the Ti6A14V alloy workpiece includes such steps as steps as providing Ti6A14V powder, proportionally mixing it with adhesive for 1.5-2 hr, granulating, injection moulding, thermal vacuum degreasing in the mixture of absolut alcohol and vinyl trichloride, vacuum sintering, isostatic pressure treating and annealing. Its advantages are high mechanical performance and high size precision.

Owner:UNIV OF SCI & TECH BEIJING

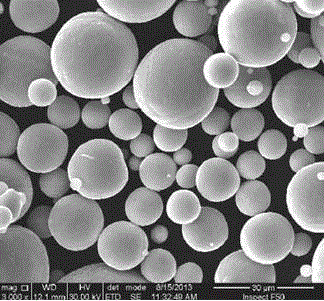

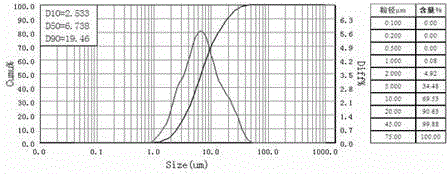

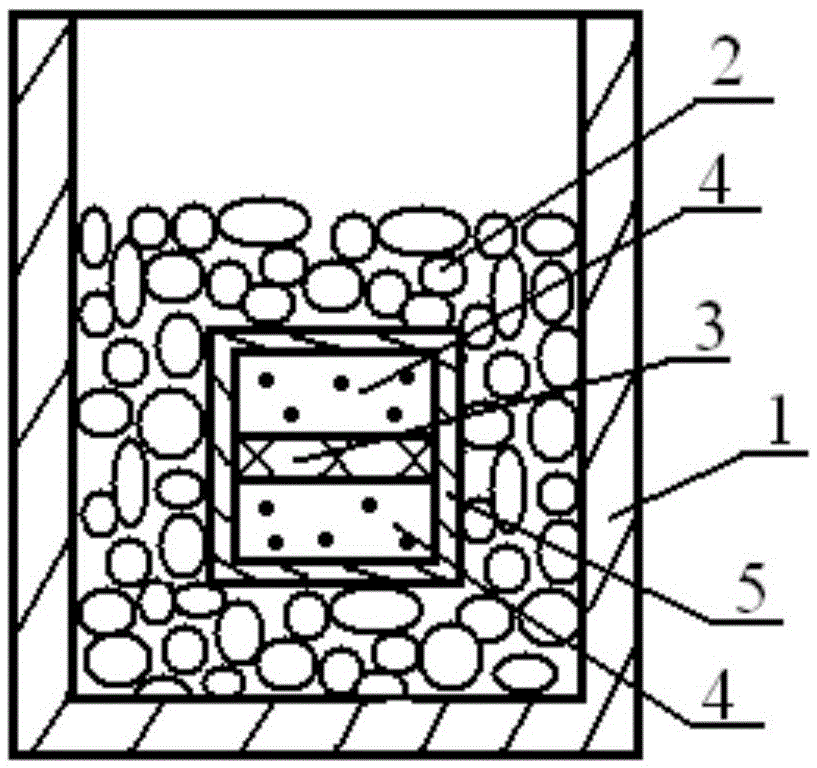

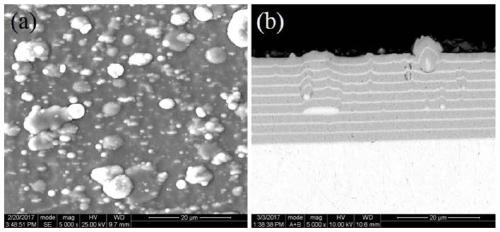

Technique for preparing special Ti6Al4V alloy powder used for material increase manufacturing

The invention discloses a technique for preparing special Ti6Al4V alloy powder used for material increase manufacturing. The technique organically combines vacuumized and water-cooled copper crucible induction smelting with multistage ultrasonic atomization on the basis of ensuring the purity of raw materials, ensures that titanium alloy is not oxidized and metal melt is uniform in temperature and ingredient during smelting to obtain consistent degree of superheat, and can prevent nozzle blockage as well as prevent that liquid drops adhere in the cooling process to from nonspherical particles; powder particles are relatively thinner and uniform and can reach high standards of requirements on particle size distribution, apparent density, oxygen content, liquidity and other performances.

Owner:四川省有色冶金研究院有限公司

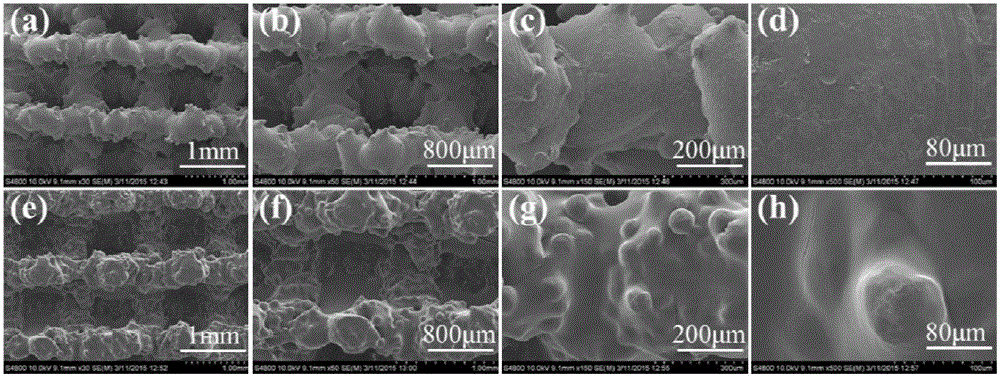

3D (three-dimensional) printing type porous metal scaffold with superficial nanocomposite coatings and preparation of 3D printing type porous metal scaffold

InactiveCN105126167AThickness controllableFast thickness controllabilitySurgeryElectrophoretic coatingsElectrophoretic depositionTi6al4v alloy

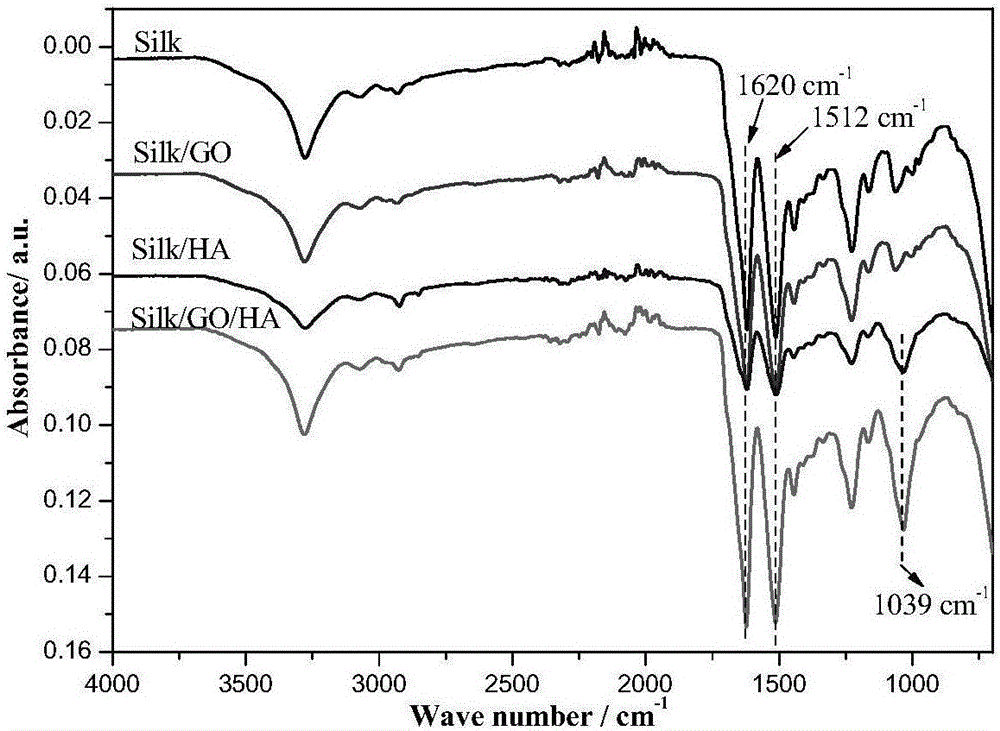

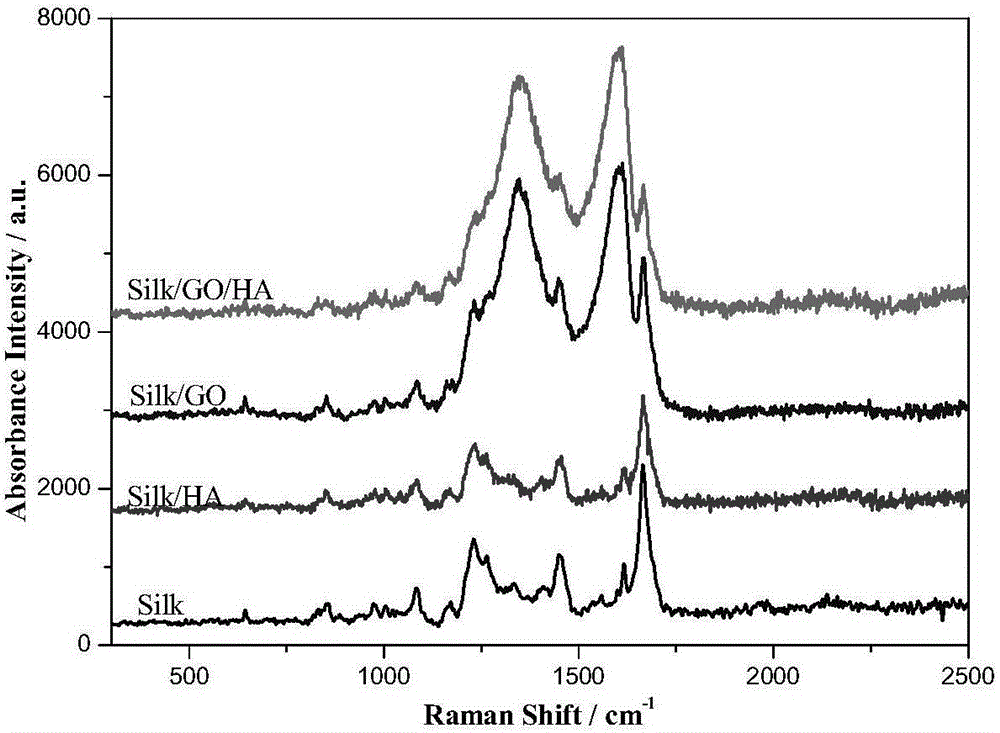

The invention discloses a 3D (three-dimensional) printing type porous metal scaffold with superficial nanocomposite coatings and a preparation method of the 3D printing type porous metal scaffold and relates to the preparation field of functionalized porous scaffolds for bone tissue repair and reconstruction. The silk fibroin-graphene oxide nanocomposite coatings are prepared on nonlinear metal surfaces of a 3D printing type porous Ti6A14V alloy scaffold and the like by an electrophoretic deposition method or a Czochralski method, and the functional coatings uniform in structure and good in binding force are obtained on the inner and outer surfaces of the scaffold at the same time, so that matrix biological activity is improved and matrix corrosion rate is decreased.

Owner:PEKING UNIV

Medical titanium alloy for teeth outer part

InactiveCN1570167AGood biocompatibilityLow elastic modulusImpression capsDentistry preparationsBiocompatibility TestingTitanium

The invention discloses an alloy, especially a bio-medical titanium alloy for teeth. The alloy is used for clinical oral rehabilitation, planting and remedy. The alloy is characterized in that the alloy consists of Ti, Zr, and Pd, wherein the content of the components is as follows (by weight): Zr:5-25%, Pd:0.1-0.2%, Ti: the rest. The alloy has the following advantages: 1. good biocompatibility : selecting Zr and Pd as the alloy elements; 2. Low elastic modulus (80-90Gpa); 3. excellent corrosion-resisting property: containing negative active constituent Pd; 4. good technological formability.

Owner:DALIAN SANSHENG SCI & TECH DEV

Method for preparing high-performance Ti6Al4V alloy plate

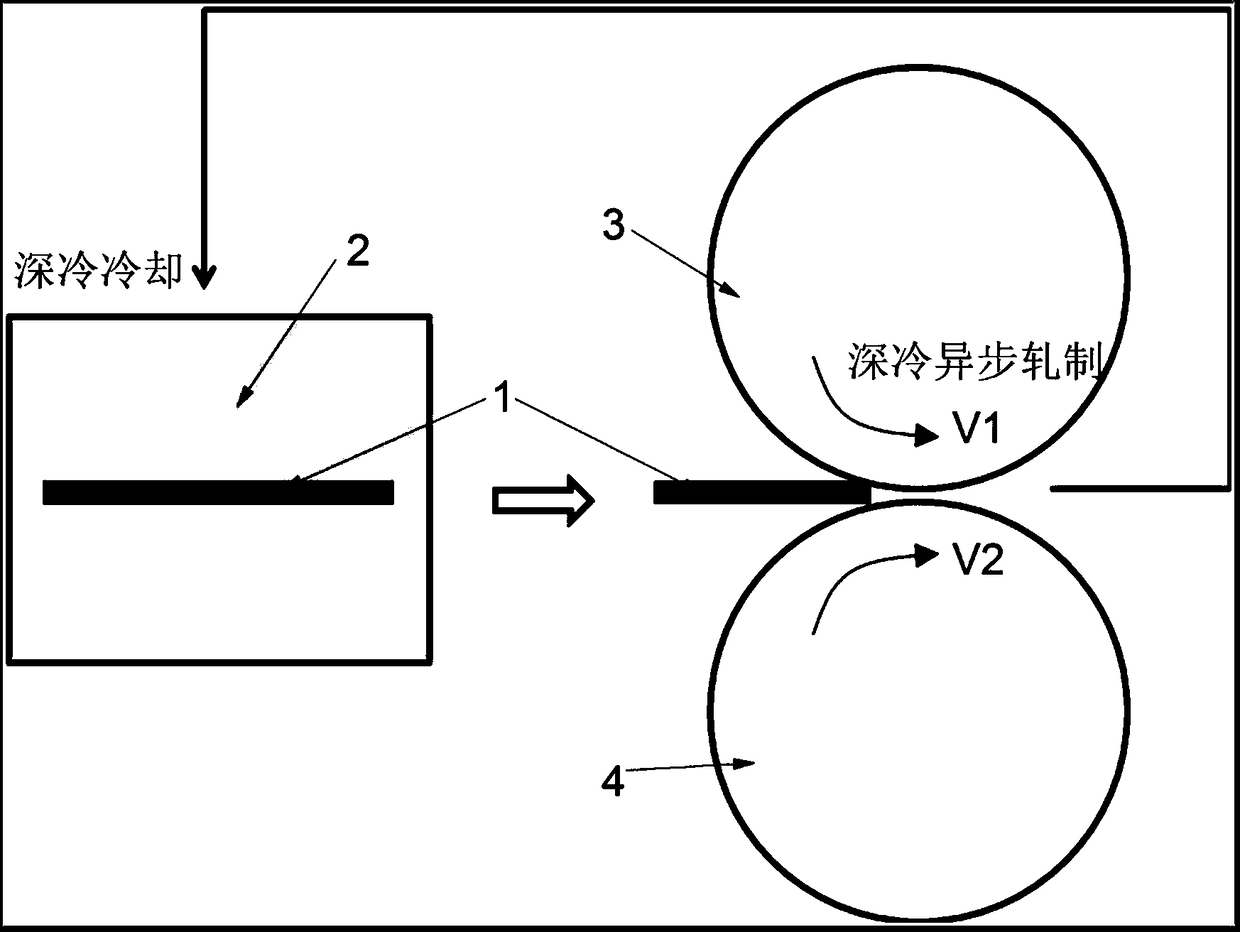

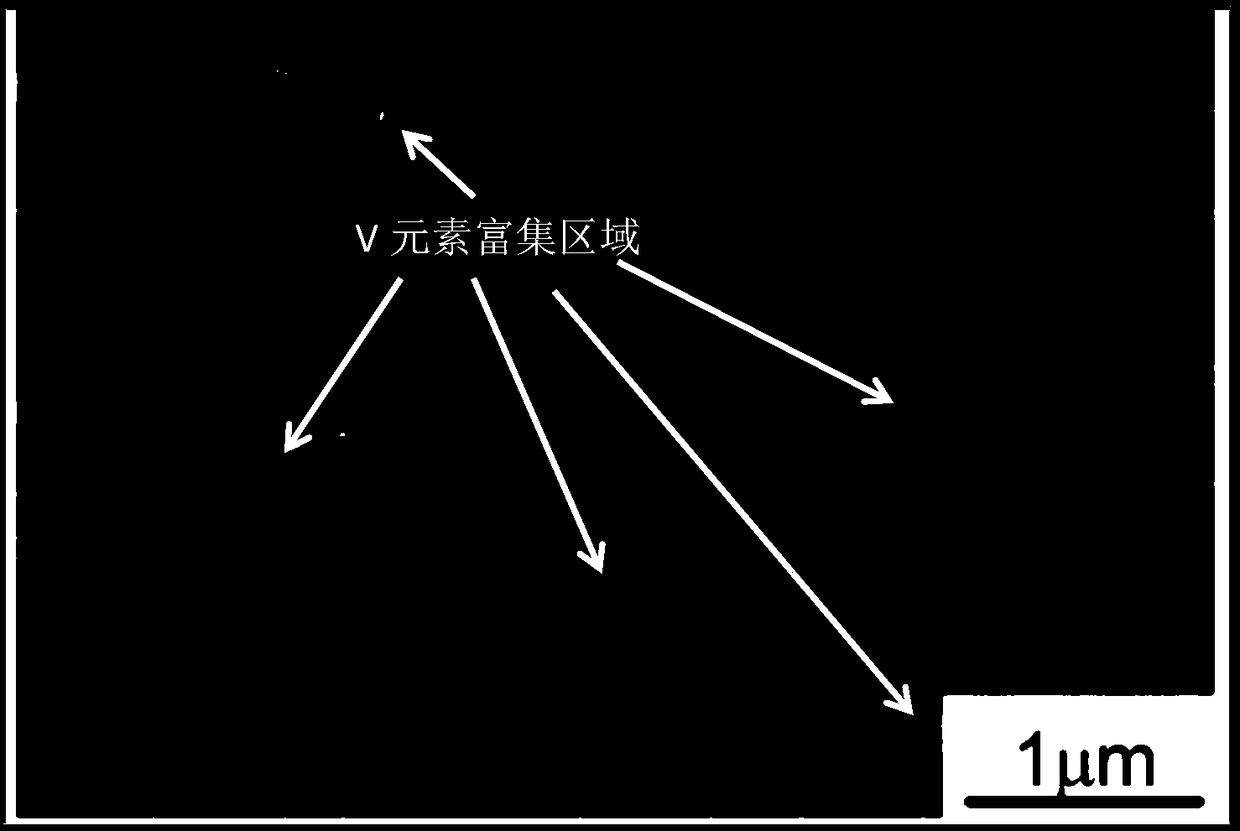

ActiveCN107185963AImprove mechanical propertiesExtended service lifeWork cooling devicesMetal rolling arrangementsReduction rateMechanical property

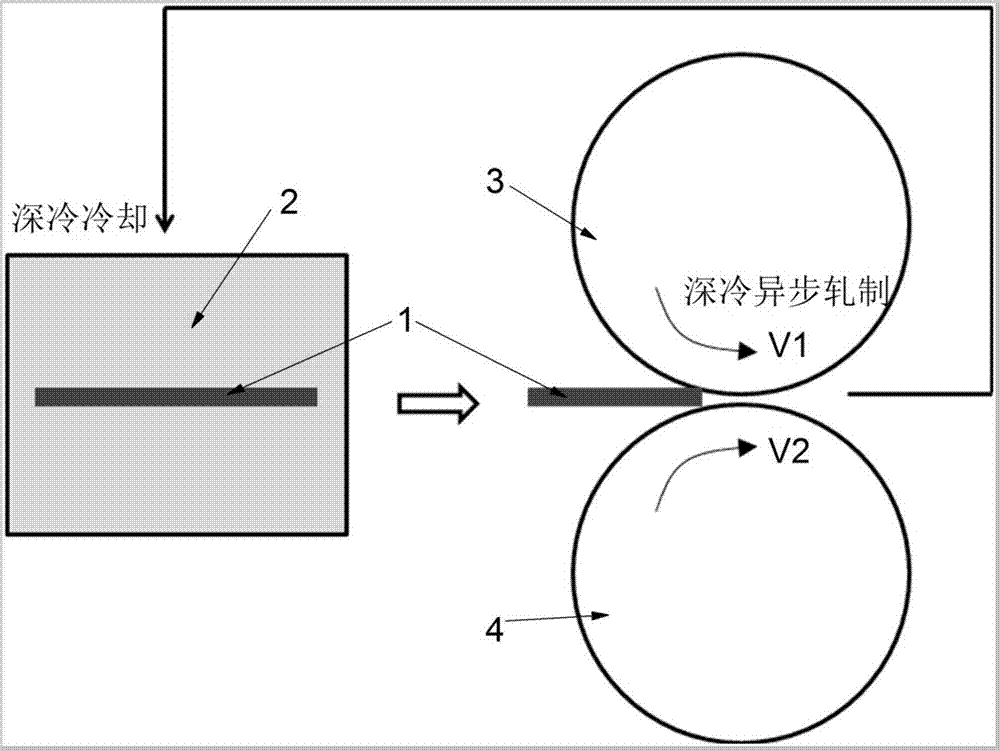

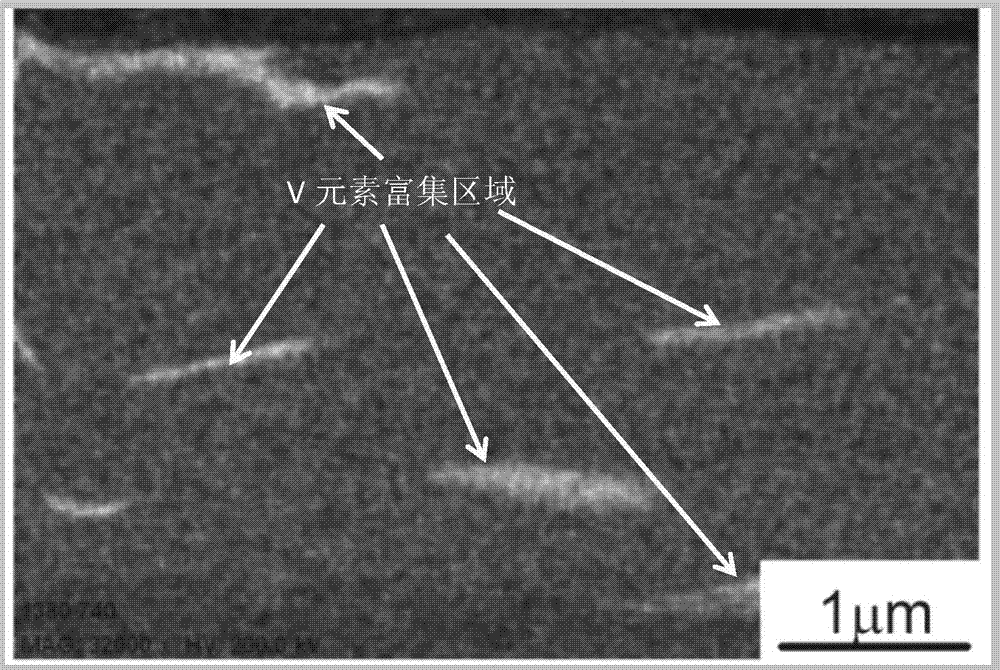

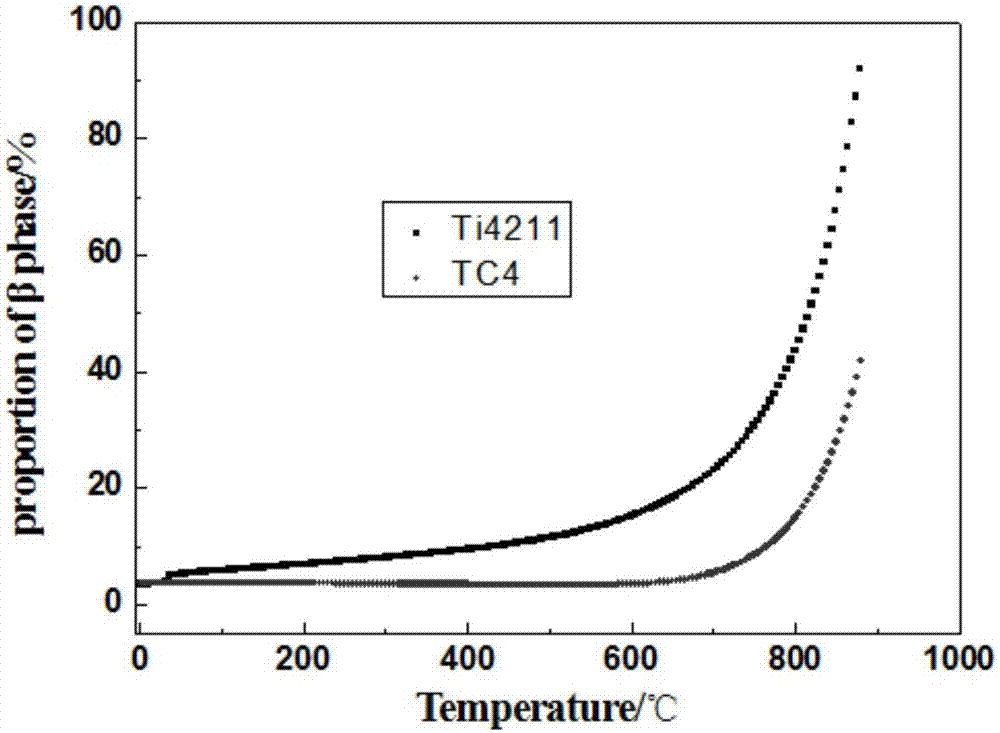

The invention discloses a method for preparing a high-performance Ti6Al4V alloy plate. The method comprises the following steps that 1) a Ti6Al4V hot rolled plate is taken as a raw material, wherein the thickness of the hot rolled plate is 1.5mm-3.5mm; 2) the hot rolled plate is put into a cryogenic tank for cooling, the temperature of the rolled piece is reduced to 190 DEG C, and heat preservation is carried out for 10 minutes; 3) the rolled piece is taken out for cold rolling, wherein the rolling speed of an upper roller is V1, the rolling speed of a lower roller is V2, the ratio of V1 to V2 is controlled to be 1.1 to 1.2, the rolling is carried out, and the rolling reduction rate is 5%-10%; and 4) the rolling is repeatedly carried out on the rolled piece until the total reduction rate reaches 20%-25%, and the high-performance Ti6Al4V alloy plate is obtained. The method adopts the principle that small-sized grains especially small-sized high-V-phase materials can be formed in the deformation process of titanium alloy under the condition of ultralow temperature, so that the mechanical property of the material is improved; and the Ti6Al4V alloy has wide application prospects in the fields of aerospace, life medical science and the like, and the method can effectively prolong the service life of the material.

Owner:CENT SOUTH UNIV

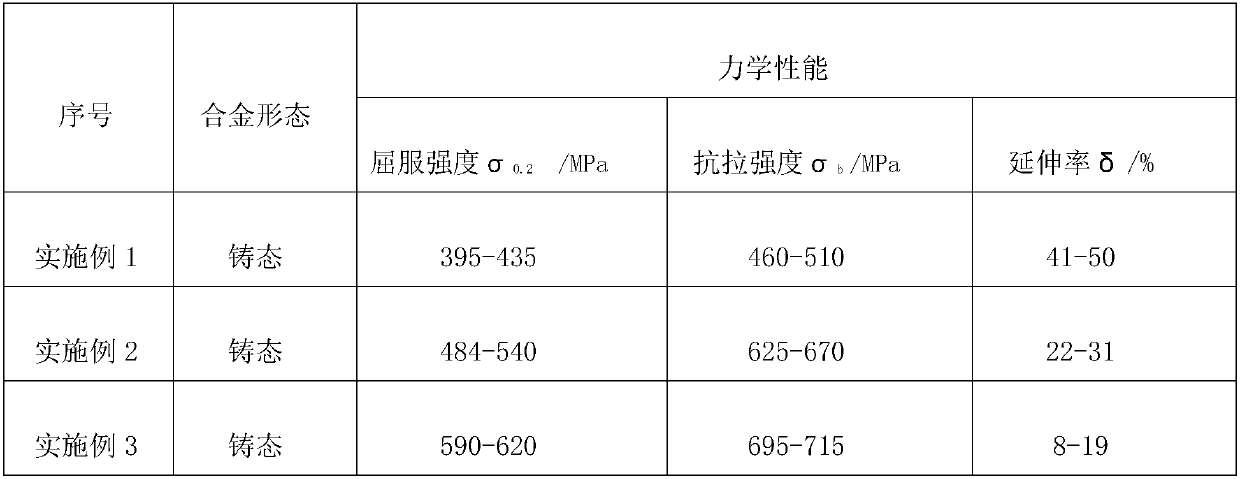

Method for preparing high-performance powder metallurgy Ti6Al4V alloy

ActiveCN111545742AGuaranteed purityRaw materials are easy to getTransportation and packagingMetal-working apparatusAl powderHydrogenation process

The invention provides a method for preparing a high-performance powder metallurgy Ti6Al4V alloy, and belongs to the field of powder metallurgy titanium. The invention proposes that TiCl2, VCl3 and aluminum powder are taken as raw materials and mixed uniformly in a certain proportion, and finally the high-performance Ti6Al4V alloy is obtained after heat treatment-ball grinding-forming-sintering. During the heat treatment of the powder, TiCl2 and VCl3 respectively have redox reaction with the aluminum powder, Cl removes a matrix in the form of gaseous AlCl3, and the generated Ti, V and Al are further reacted and diffused, after being crushed by ball milling, fine Ti6Al4V powder is obtained, and after forming and sintering, the high-performance Ti6Al4V alloy with the oxygen content of 0.12wt.% and the density of more than or equal to 99% is finally obtained. The preparation process of the invention is simple, pressureless sintering can densify Ti6Al4V, the grain size is small, the loss of alloying elements caused by a hydrogenation process is effectively avoided, and high oxygen increment caused by an element powder mixing method is also avoided, thereby providing a new idea for thepreparation of low-oxygen high-performance Ti6Al4V alloys.

Owner:UNIV OF SCI & TECH BEIJING

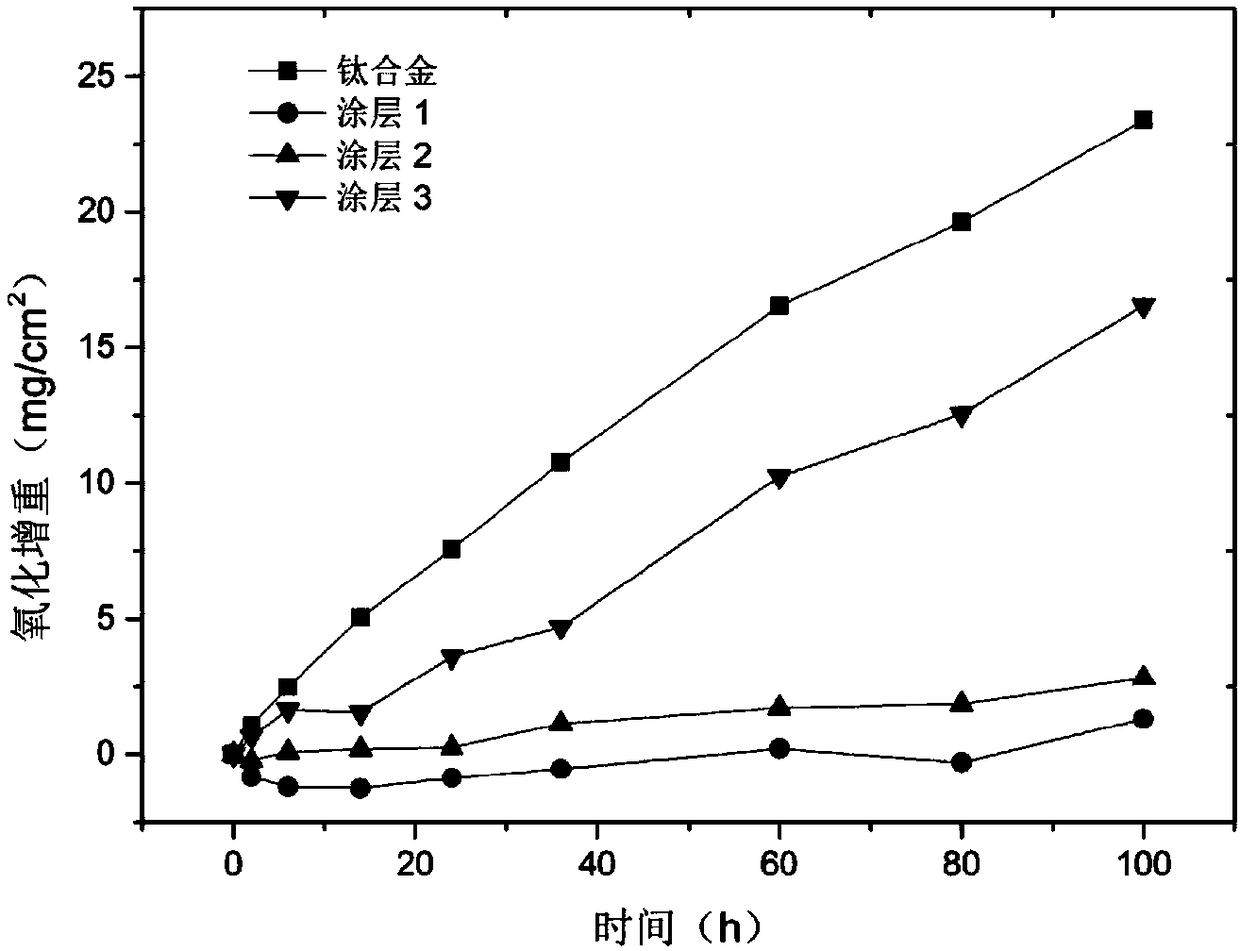

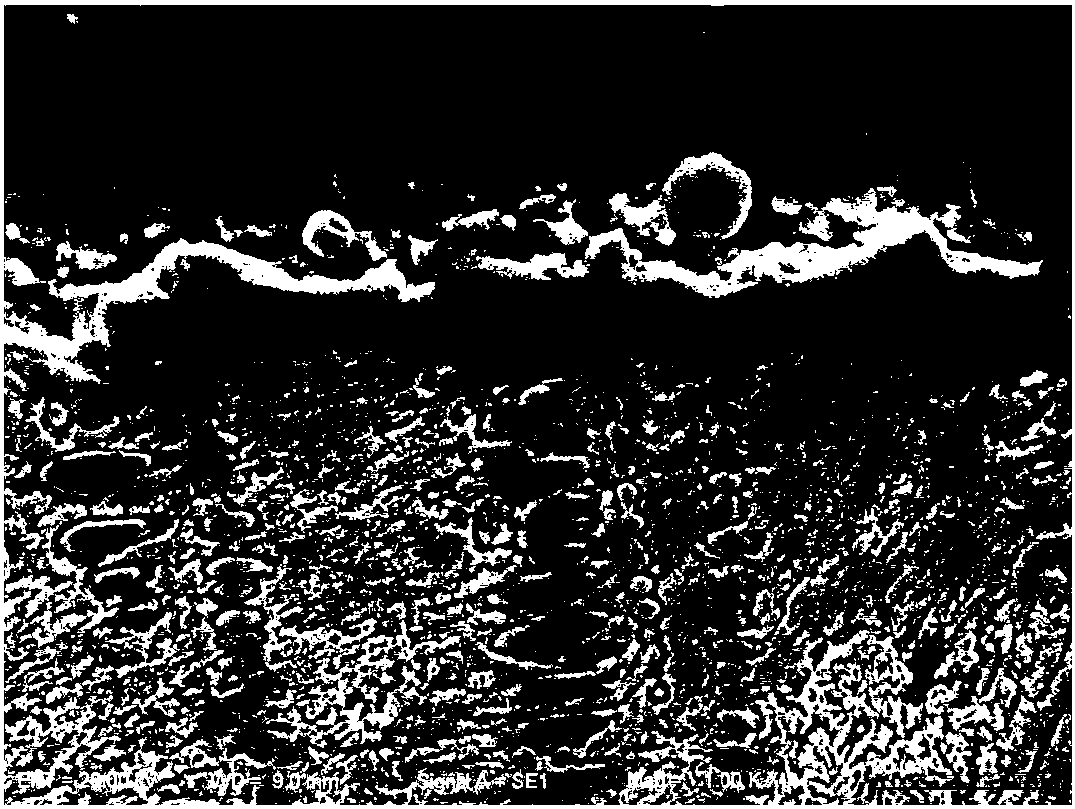

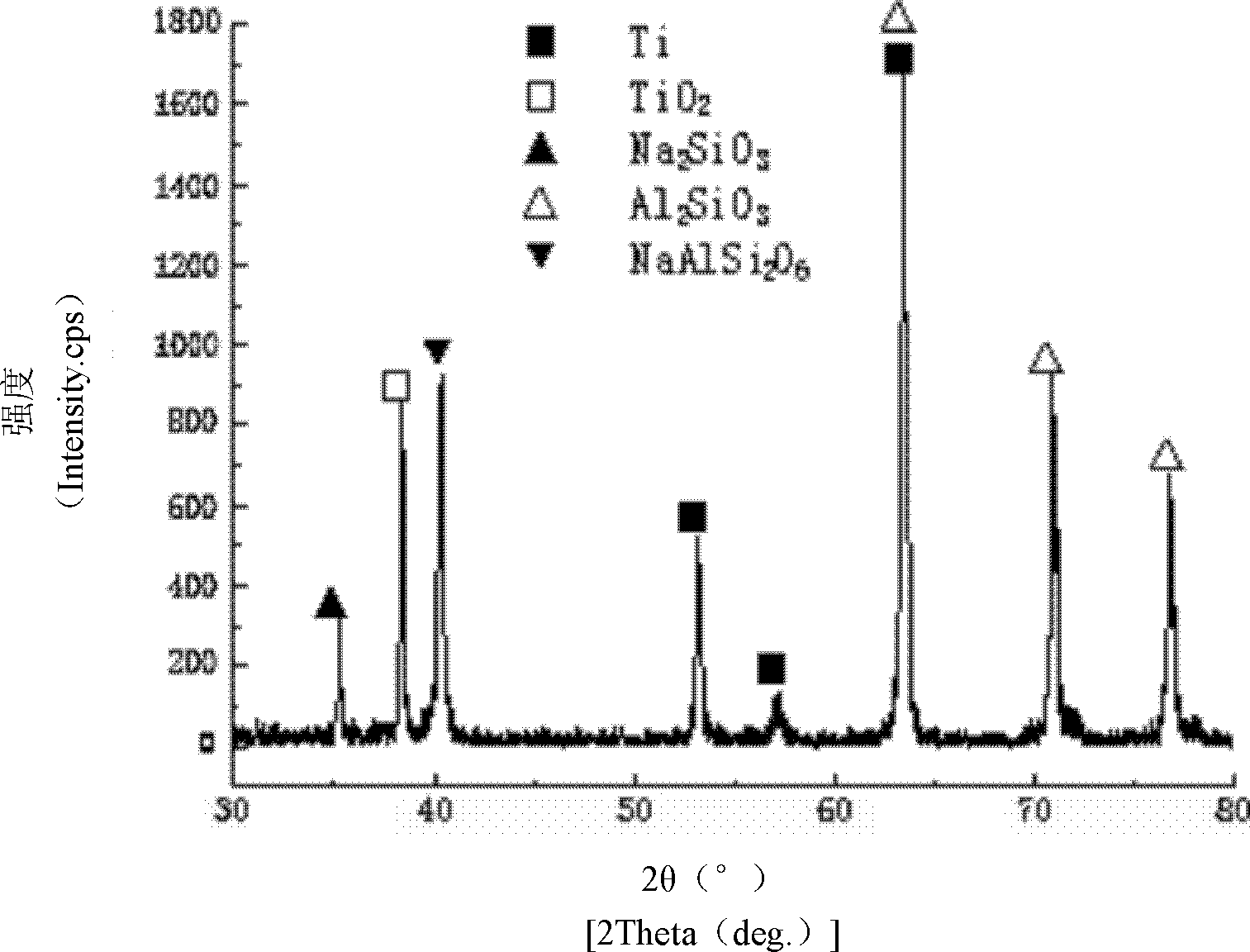

Preparation method of composite coating capable of improving high-temperature anti-oxidization performance of titanium alloy

The invention relates to an alloy material and in particular relates to a preparation method of a composite coating capable of improving the high-temperature anti-oxidization performance of a titaniumalloy. The preparation method comprises the following steps: (1) carrying out ball milling: putting prepared nickel, molybdenum and silicon powder into a ball grinding mill and carrying out the ballmilling to obtain an alloy powder mixture; (2) pre-preparing: taking a methyl cellulose solution as an adhesive; putting the alloy powder mixture into the surface of a titanium alloy TC4 matrix in advance; carrying out heat insulation at 120 DEG C for 2h in a drying furnace; (3) carrying out single-path scanning on the surface of the titanium alloy TC4 with alloy powder by adopting a semiconductorlaser device to prepare the high-temperature anti-oxidization compound coating. According to the preparation method provided by the invention, a laser cladding technology is adopted, and Ni-Mo-Si alloy powder is used as a raw material; the composite coating is prepared on the surface of a Ti6Al4V alloy, and a phase tissue structure, the microscopic rigidity and the high-temperature anti-oxidization performance of the coating are researched.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

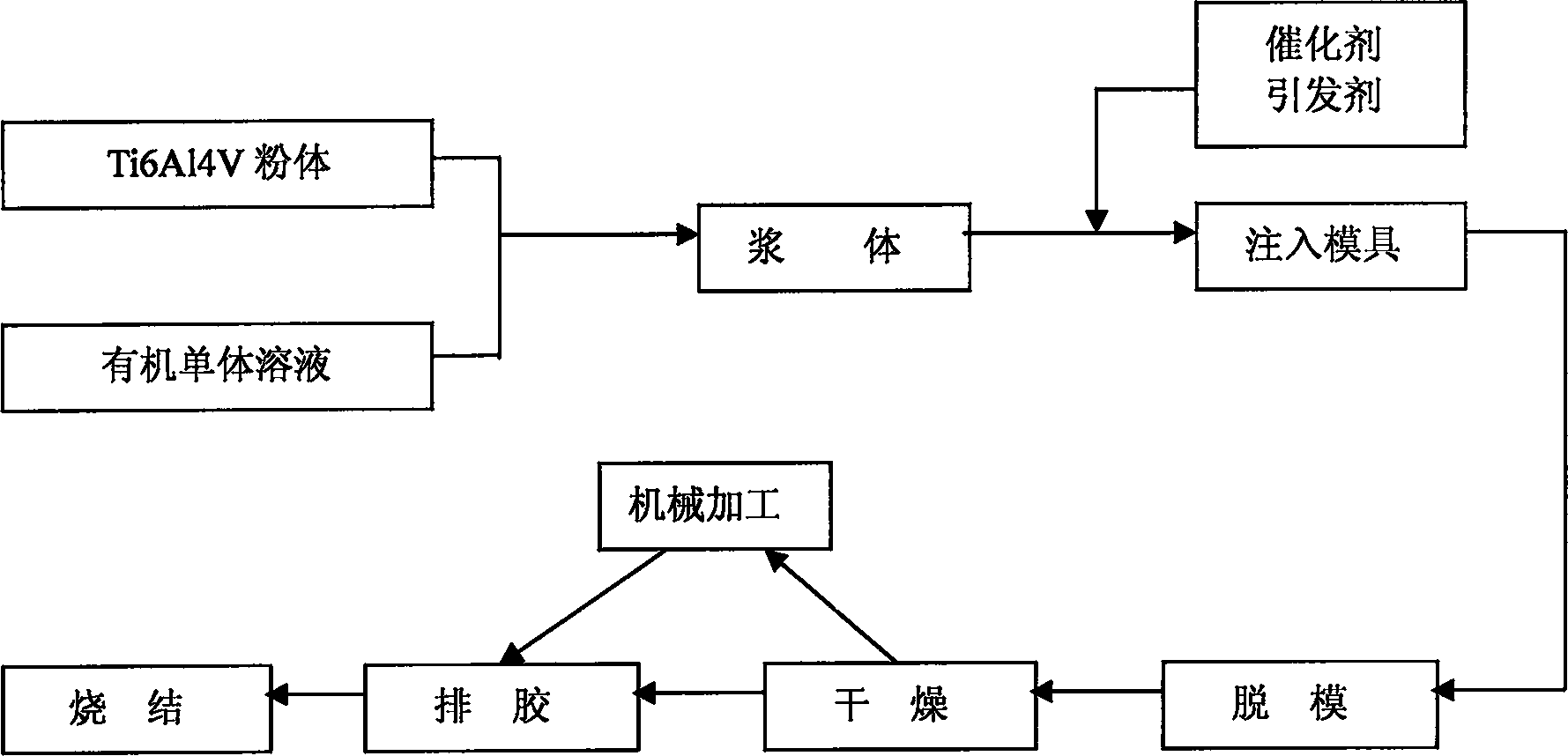

Injection moulding method for Ti6A14V alloy gel

A gel injection moulding method for the Ti6Al4V alloy includes such steps as preparing premixed liquid, preparing slurry, preparing blank, drying while degumming, and sintering. Its advantages are high strength and size precision and complex shape of product, and low cost.

Owner:UNIV OF SCI & TECH BEIJING

Novel low-cost and high-performance titanium alloy

The invention relates to a novel low-cost and high-performance titanium alloy which is suitable for production of multiple types of titanium alloy products such as rods, wires, plates, pipe fittings and the like and can be widely applied in the technical fields of aviation, oceans and the like. The alloy is prepared from composition elements in percentage by weight as follows: 3.5%-4.5% of Al, 2.0%-3.0% of V, 0.5%-1.5% of Fe, 0.5%-2.0% of Mo and the balance of Ti and inevitable impurity elements. Compared with a widely-applied Ti6Al4V alloy, the alloy has the characteristics as follows: (1) the raw material cost is relatively low, the hot working cracking tendency is low, and the yield of other product forms such as rods and the like from cast ingots is relatively high, so that the alloy cost is remarkably reduced; (2) the room-temperature tensile strength of the alloy after annealing is equivalent to that of the Ti6Al4V alloy, the room-temperature ductility and toughness of the alloy are higher, and the alloy is suitable for cold working and warm working forming of the plates and pipes.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Liquid state hydrogen-replacing method for smelting Ti-6Al-4V alloy

InactiveCN101225485ASolve the problem that is difficult to apply to the hydrogenation of larger ingotsControl contentTi 6al 4vMicrostructure

The invention discloses a method of melting the Ti6Al4V alloy through the hydrogenation at liquid state, relating to the hydrogenation method during melting casting the Ti6Al4V alloy ingot, solving the problem that the hydrogenation technique at solid state of the titanium alloy is only suitable for the thin-walled members, but can not carry out the hydrogenation for big volume ingot. The melting method is characterized in that: the Ti6Al4V alloy or the alloy material is put into a working chamber; then the working chamber is carried out vacuum pumping; the argon is pumped in the working chamber, so as to enable the air in the air pressure system outside the working chamber to be emptied; the argon and the hydrogen mixed according to certain proportion are pumped in the working chamber through the gas path system; and the hydrogenation melting is carried out when the melting current is 80 to 150 A, so as to obtain the Ti6Al4V alloy after the hydrogenation at liquid state. The method of melting the Ti6Al4V alloy through the hydrogenation at liquid state has the advantages that: the microstructure of the Ti6Al4V alloy after the hydrogenation at liquid state is thinned; the hot workability is improved; the problem that the hydrogenation at solid state is difficult to apply to lager ingot hydrogenation is radically solved; and the content of the hydrogen added in the alloy can be more accurately controlled, so as to apply to mass and continuous production with practical significance.

Owner:HARBIN INST OF TECH

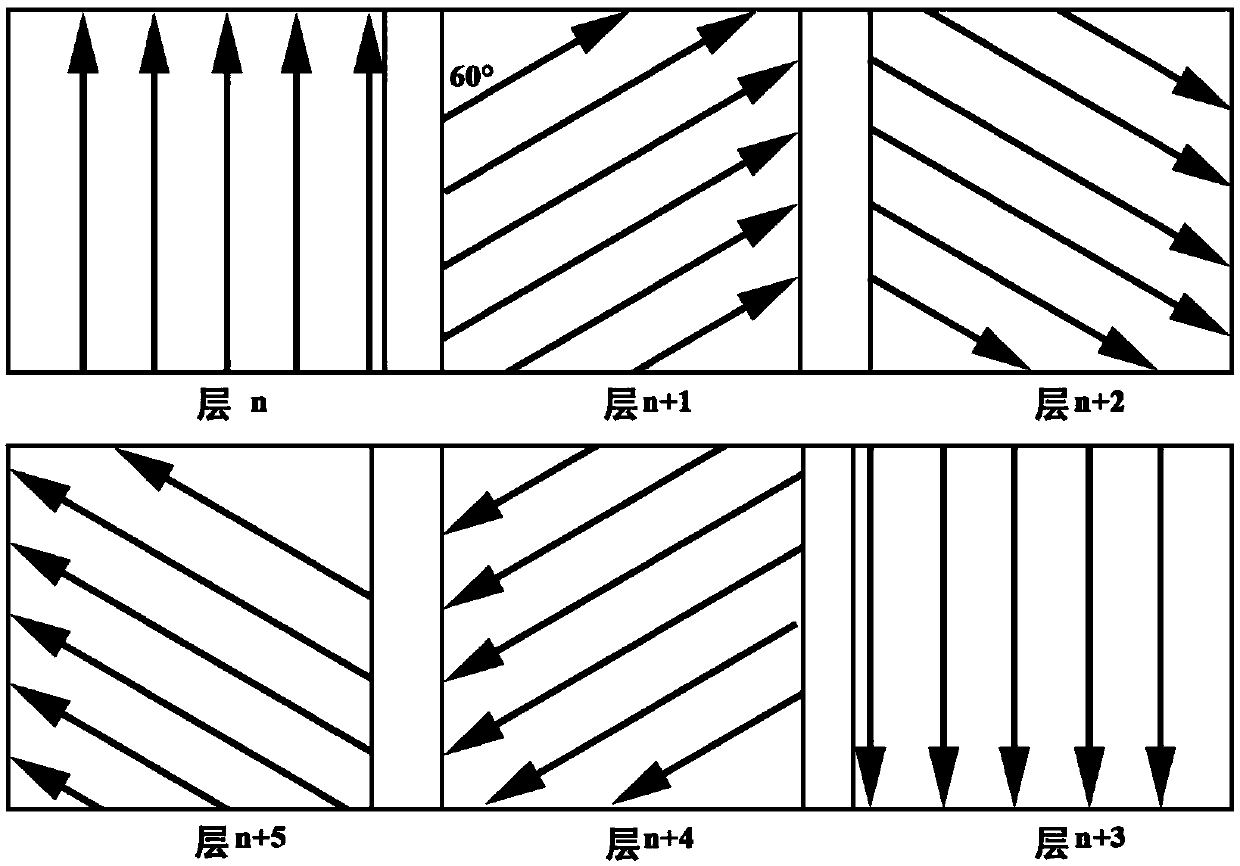

Laser additive manufacturing method for synergistically improving surface precision and strength of titanium alloy

InactiveCN110523984ASynergistically improve surface accuracySynergistically enhance surface strengthAdditive manufacturing apparatusIncreasing energy efficiencyScan lineLaser scanning

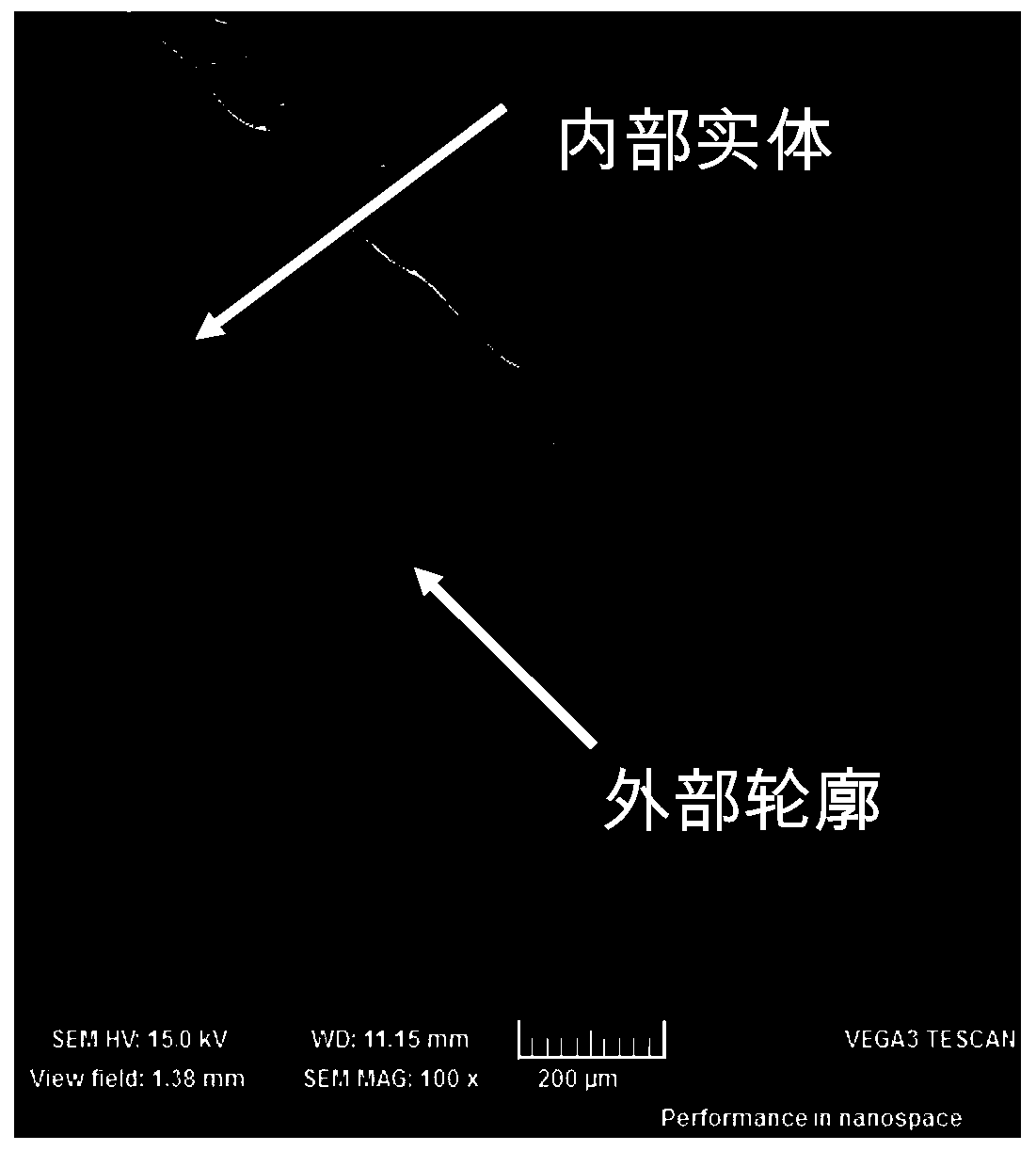

According to the laser additive manufacturing method for synergistically improving the surface precision and strength of the titanium alloy, the forming structure is adjustable, the surface is smoothand clean, the surface is self-strengthened, and extra surface treatment and other procedures are not needed. The method comprises the following steps: uniformly and continuously pre-paving Ti6Al4V alloy powder on a forming cabin substrate of laser additive manufacturing equipment, and printing and forming layer by layer to obtain a Ti6Al4V alloy test piece; when each layer is printed and formed,using laser beams to adjacently scan line by line to form an internal solid plane, after forming the internal solid plane, performing laser scanning of a contour along the edge of the internal solid plane to form an external contour, and finish forming of the printing layer; repeating the forming process of the printing layers until laser additive manufacturing forming of the Ti6Al4V alloy test piece is completed, wherein the laser power for printing internal solid plane is not less than the laser power for printing the external contour, and the scanning speed for printing the internal solid plane is not greater than the scanning speed of the printing external contour.

Owner:SHANGHAI AIRCRAFT DESIGN & RES INST COMML AIRCRAFT OF CHINA +1

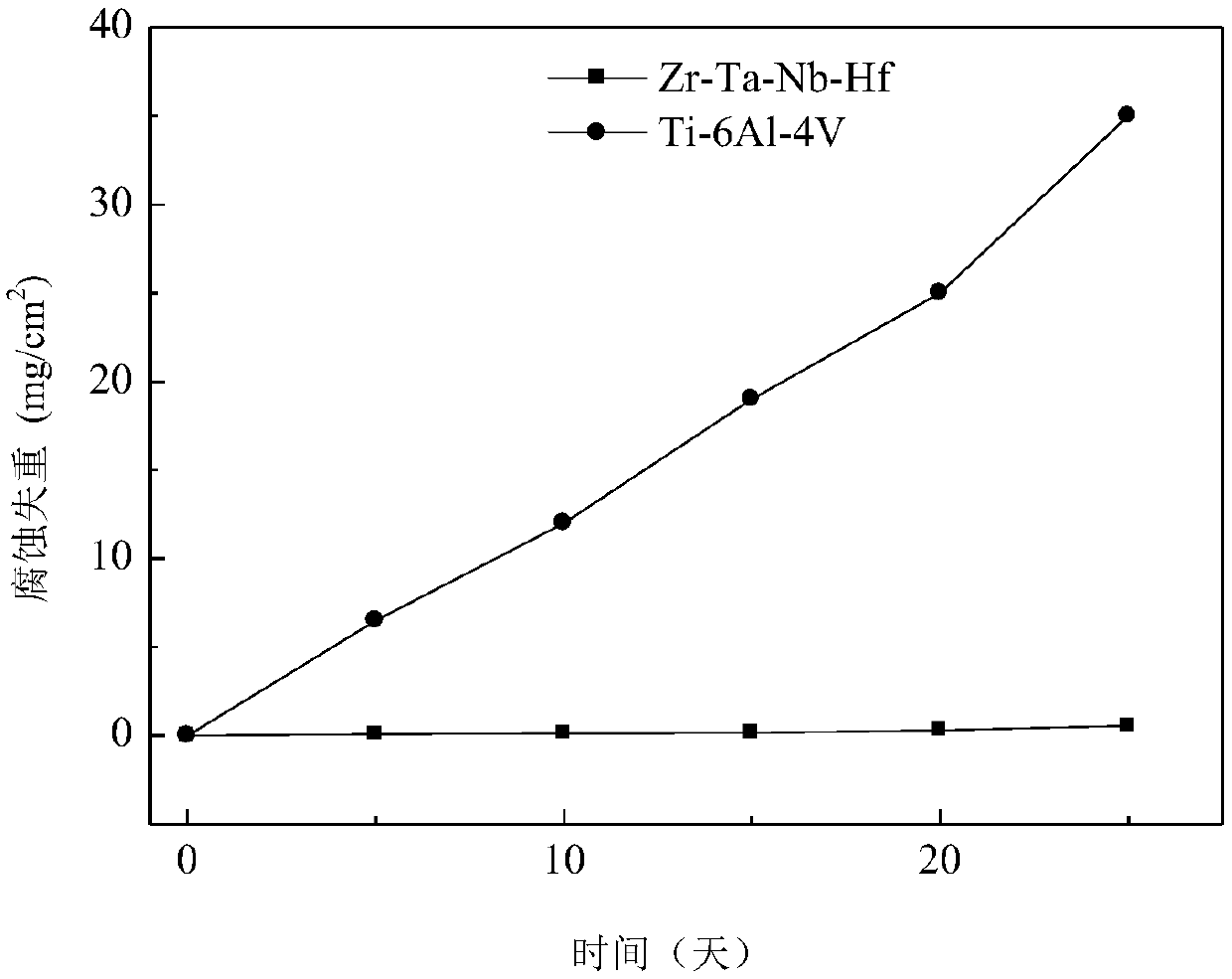

Corrosion-resistant zirconium-tantalum-niobium-hafnium alloy and preparation method thereof

The invention provides a corrosion-resistant zirconium-niobium-tantalum-hafnium alloy. The chemical components of the corrosion-resistant zirconium-niobium-tantalum-hafnium alloy comprises the following compositions of, by weight, 0.1-10% of tantalum, 0.5-3% of niobium, 0.1-5% of hafnium and the balance zirconium. A preparation method of the corrosion-resistant zirconium-tantalum-niobium-hafnium alloy mainly comprises the steps that according to the ratio of zirconium alloy materials, crushed industrial-grade sponge zirconium, a zirconium-tantalum intermediate alloy and a zirconium-niobium intermediate alloy are pressed and molded, and single block electrodes are obtained; the single block electrodes are subjected to combined welding to a consumable electrode; and the consumable electrodeis subjected to vacuum consumable smelting, the voltage of vacuum consumable smelting is 33 V, the vacuum degree of vacuum consumable smelting is 5*10<-3>Pa, the current of vacuum consumable smeltingis 185 A, and the melting coefficient of vacuum consumable smelting is 0.95 kg / (kA.min), and the corrosion-resistant zirconium-niobium-tantalum alloy is obtained after smelting for 2-3 times. The preparation method is easy, the mechanical properties of the prepared corrosion-resistant zirconium-niobium-tantalum-hafnium alloy are obviously higher than a Zr-2.5Nb alloy with the high mechanical properties at present, and the corrosion resistance of the prepared corrosion-resistant zirconium-niobium-tantalum-hafnium alloy is obviously higher than that of a famous Ti6Al4V alloy.

Owner:YANSHAN UNIV

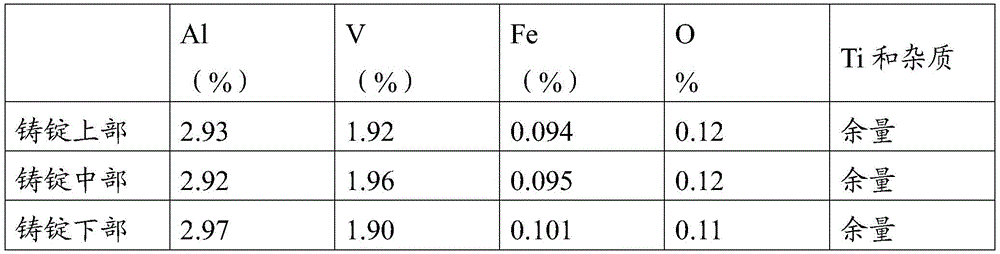

Low cost titanium alloy and homogenization preparation method thereof

The invention discloses a low cost titanium alloy. The low cost titanium alloy comprises, by mass percent, 1.8%-4.0% of Al, 1.2%-2.0% of V, 1.0%-3.0% of Fe, 0.1%-0.2% of O and the balance Ti and unavoidable impurities. According to the low cost titanium alloy, the content of the O element is improved, interstitial solid solutions can be formed in titanium alloy lattices, and the intensity of the titanium alloy is improved. Meanwhile, in order to further improve the material intensity, the content of precious metal V is reduced, and the cost of raw materials is saved; and Fe is added in the alloy blending process and is an alpha phase stable element, the material intensity can be improved through solid solutions, and the effect of reducing cost is achieved while the intensity of the prepared titanium alloy is guaranteed. The content of the low cost titanium alloy is close to a half of the Ti6Al4V alloy content, but the preparing cost is low, the extending rate is high, and the strength of extension is above 796 MPa.

Owner:BAIMTEC MATERIAL CO LTD

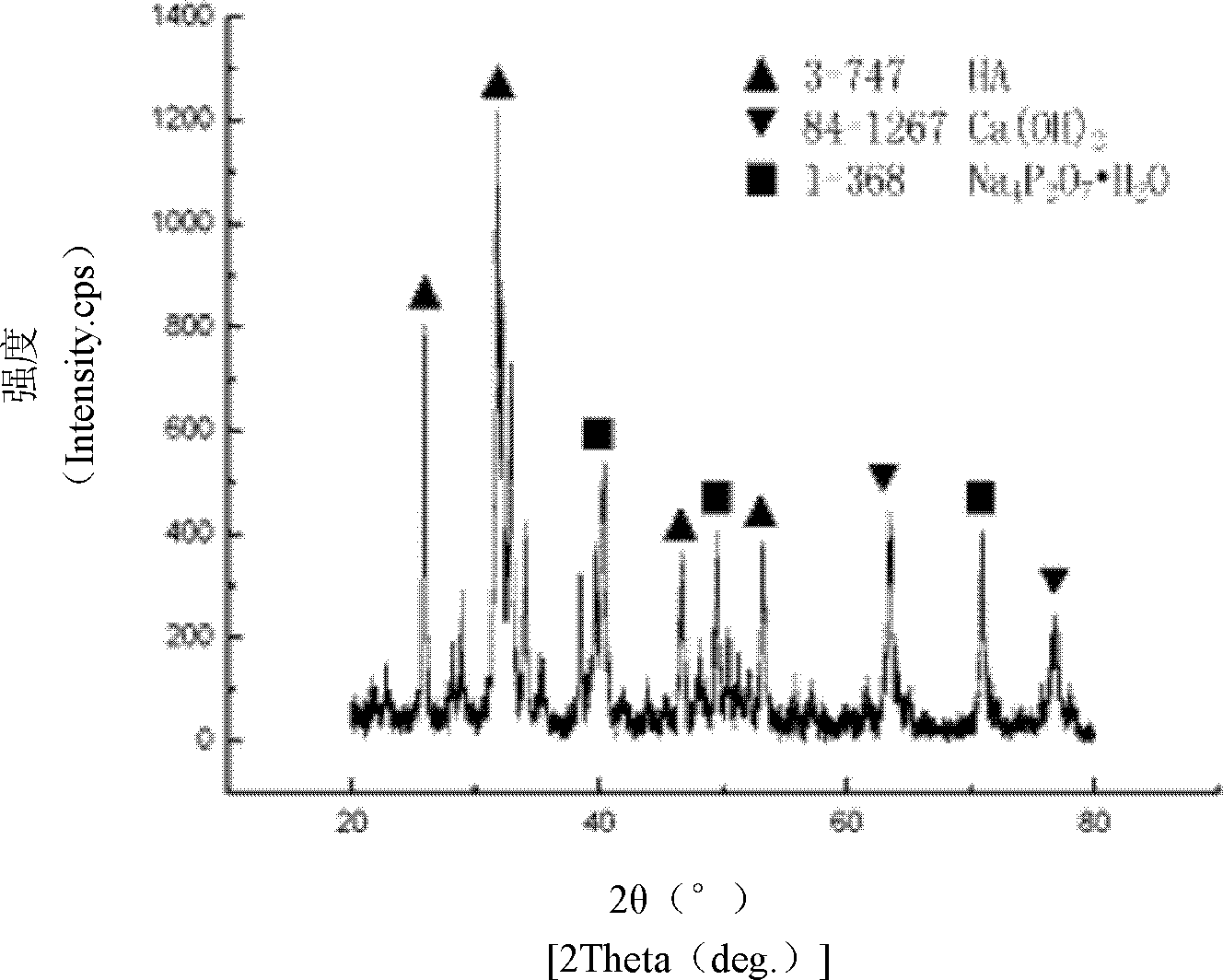

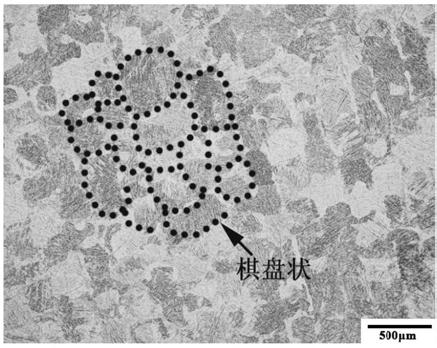

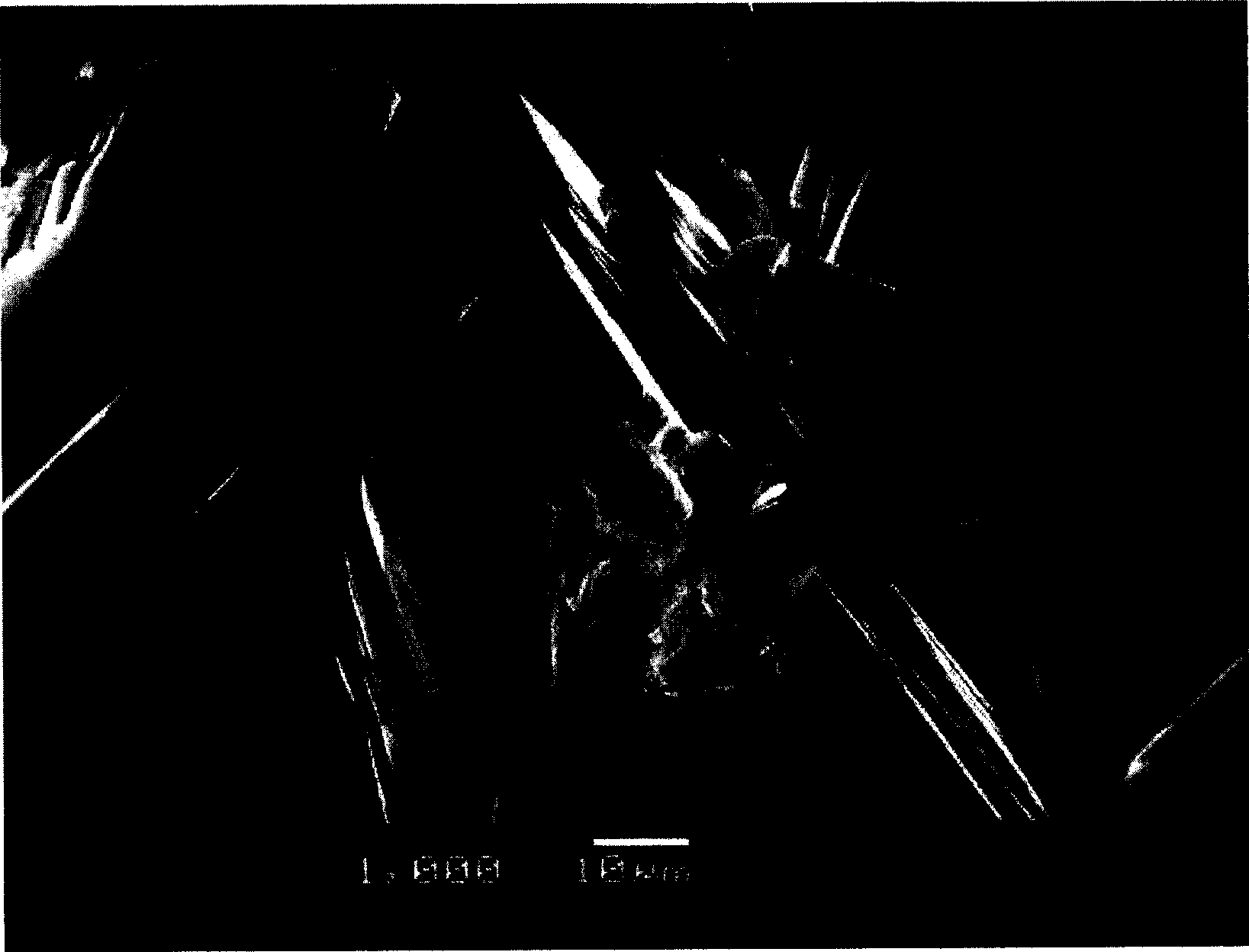

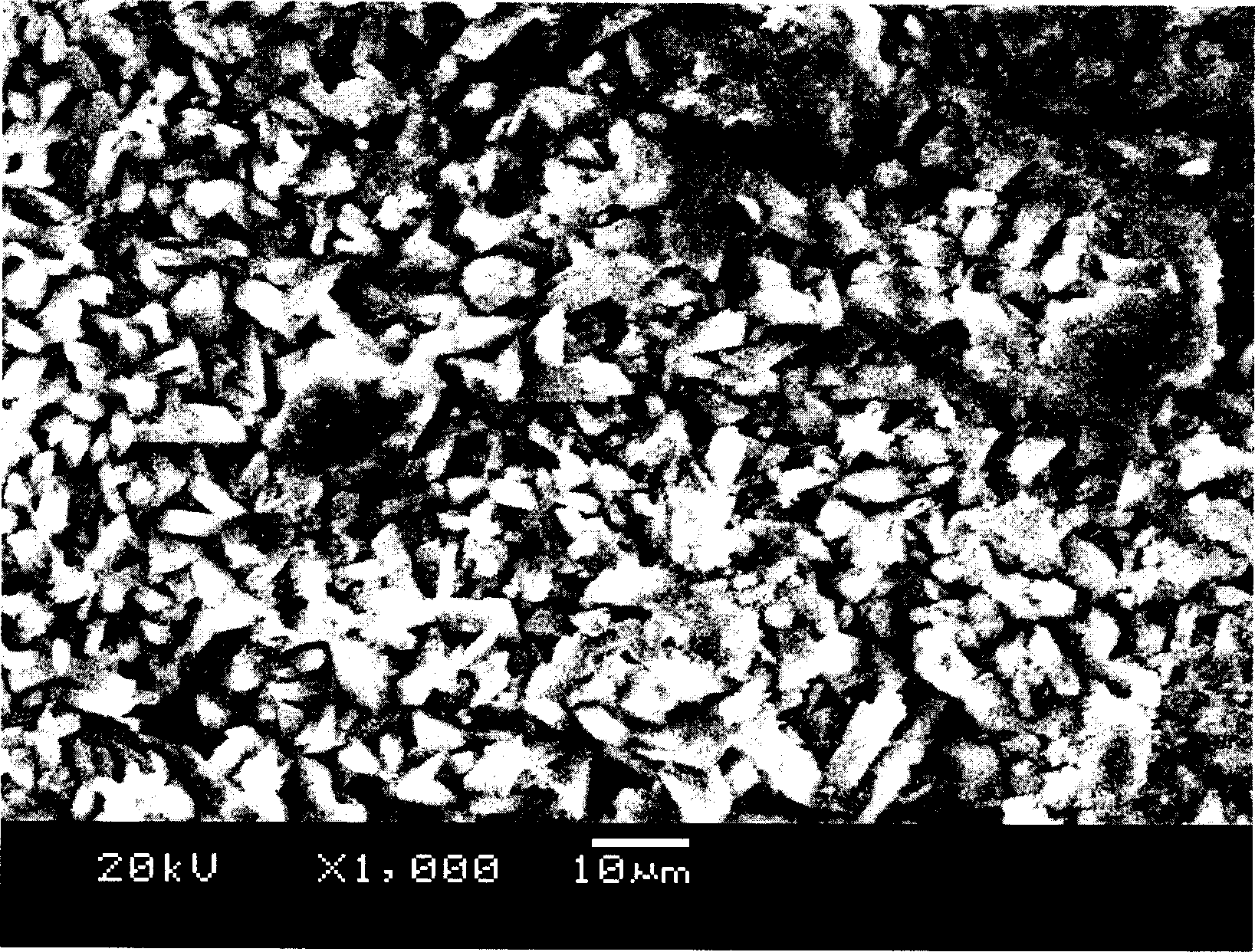

Method for synthesizing hydroxyapatite-titanium oxide composite coating by adopting microarc oxidation method and potentiostatic method

InactiveCN102492973AImprove bindingAffect mechanicsElectrolytic inorganic material coatingSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

A method for synthesizing hydroxyapatite-titanium oxide composite coating by adopting the microarc oxidation method and the potentiostatic method comprises the following steps: preparing a titanium oxide coating with a solution containing silicate by adopting the microarc oxidation method, configuring an electrolyte with raw materials such as calcium ions and phosphate radicals, and preparing a hydroxyapatite coating on the surface of the titanium oxide coating by adopting the potentiostatic method. Through the adoption of the invention, a TiO2 coating with circular micropores is formed on the surface of Ti6Al4V alloy after microarc oxidation; the surface is a composite coating after constant potential and hydrothermal synthesis; HA and titanium oxide in the composite coating are distributed on two layers respectively; the surface is flaky HA crystal and contains a small quantity of Na4P2O7.10H2O and Ca(OH)2; and the Ca / P ratio is 1.669. The method has the advantages that the binding force between the composite coating and a base body is greatly improved; and the influence on the mechanical property and the biocompatibility of a composite material is better.

Owner:DALIAN MARITIME UNIVERSITY

Ti6Al4V alloy and orthopaedic implant prepared from alloy

The invention relates to a Ti6Al4V alloy which comprises the following elements in percentage by mass: 5.5-6.75% of Al, 3.5-4.5% of V, at most 0.3% of Fe, 0.02-0.1% of O, at most 0.08% of C, at most 0.05% of N, at most 0.015% of H and the balance of Ti. The invention also relates to an orthopaedic implant prepared from the alloy. The orthopaedic implant prepared from the Ti6Al4V alloy can effectively lower the infection of the human body.

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

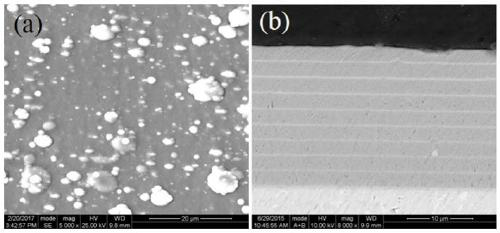

Preparation method of high-compactness, high-hardness and high-abrasion-resistance Ti6Al4V blocky alloys

InactiveCN109536759AControl pressureReduce surface roughnessAdditive manufacturing apparatusIncreasing energy efficiencyHardnessAlloy

The invention provides a preparation method of high-compactness, high-hardness and high-abrasion-resistance Ti6Al4V blocky alloys. The method comprises the steps that a 3D printer layers a three-dimensional mode according to the set layer thickness, builds a support and preheats a Ti6Al4V base board, Ti6Al4V alloy powder is loaded into a printing work cavity of the 3D printer and is spread out, then the Ti6Al4V alloy powder in a remaining powder cavity is sent into the printing work cavity and is spread out according to the layer thickness, after the Ti6Al4V alloy powder is spread out, the Ti6Al4V alloy powder is subjected to laser selective melting, and Ti6Al4V blocky alloy parts are obtained after printing is finished. The compactness of the prepared Ti6Al4V blocky alloy achieves 99.9%,the hardness is improved by 30-50% to achieve 400-440 HV compared with Ti6Al4V alloys in a rolled state, and the abrasion resistance is 1-5 times that of the Ti6Al4V alloys in the rolled state.

Owner:SHANGHAI JIAO TONG UNIV

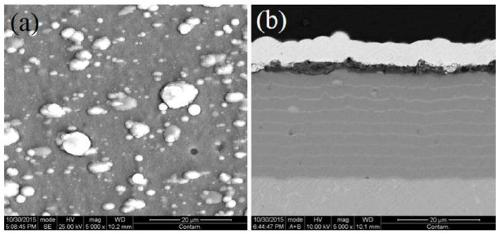

Metal-metal nitride laminated coating resistant to high temperature marine environment corrosion and preparation method thereof

ActiveCN110158035AImprove high temperature corrosion resistanceHigh bonding strengthVacuum evaporation coatingSputtering coatingUltimate tensile strengthHigh-temperature corrosion

The invention relates to the titanium alloy high temperature protection coating field, in particular to a metal-metal nitride laminated coating resistant to high temperature marine environment corrosion and a preparation method thereof. The metal-metal nitride laminated coating resistant to the high temperature marine environment corrosion is formed by alternatively depositing Ti sublayers and TiNsublayers on a substrate, wherein the layer close to the substrate and the uppermost layer are both the TiN layers, and the substrate is Ti6Al4V alloy. In the laminated coating, the thickness of eachTiN sublayer is 1.7-2.0[mu]m, the thickness of each Ti sublayer is 0.1-1.0[mum], and the total number of the Ti sublayers is an odd number from 13 to 21. The preparation method of the laminated coating includes: cleaning the substrate and alternatively depositing the TiN sublayers and the Ti sublayers. According to the preparation method, the thick Ti / TiN laminated coating different in sublayer proportion is prepared on the titanium alloy substrate, the coating of such type has good bonding strength with the substrate, and has large thickness, and furthermore high temperature and corrosion resistance of the titanium alloy substrate is improved by prolonging a diffusion path of a corrosive medium and reducing the number of structure defects.

Owner:HENAN INST OF SCI & TECH

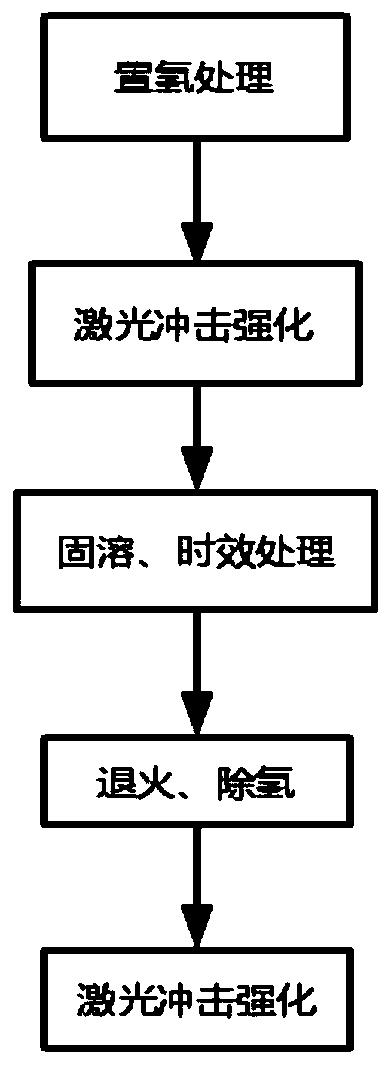

Method for laser shock assisted thermo-hydrogenation treatment of Ti6Al4V alloy

The invention belongs to the technical field of laser assisted thermal treatment, and particularly relates to a method for laser shock assisted thermo-hydrogenation treatment of a Ti6Al4V alloy. According to the method, hydrogenation treatment and laser shocks are combined, defects caused by diffusion of the hydrogen element in the hydrogenation treatment process are reduced by first laser shocks,further refining of grains of the alloy obtained after hydrogenation treatment is promoted through the combination of solid solution aging treatment and second laser shocks, and therefore the tensileproperty of the alloy is improved, the fatigue life of a material is prolonged, and the alloy has an excellent superplastic deformation characteristic.

Owner:JIANGSU UNIV

Pretreatment process capable of prolonging creep rupture life of hot continuous rolled Ti6Al4V alloy

InactiveCN104611612AHigh technology contentEase of industrial productionSolution treatmentThermal treatment

The invention relates to a thermal treatment process of an alloy, in particular to a thermal treatment process method capable of obviously prolonging a creep rupture life of a hot continuous rolled Ti6Al4V alloy under different conditions. The method comprises the methods of carrying out solid solution treatment and carrying out aging treatment on the hot continuous rolled Ti6Al4V alloy; by changing a microstructure of the alloy, the creep rupture life of the alloy is prolonged. Compared with the creep rupture life of an alloy which is not subjected to thermal treatment, the creep rupture life of the hot continuous rolled Ti6Al4V alloy subjected to thermal treatment is prolonged by 4 to 5 times by implementing the thermal treatment process method.

Owner:SHENYANG POLYTECHNIC UNIV

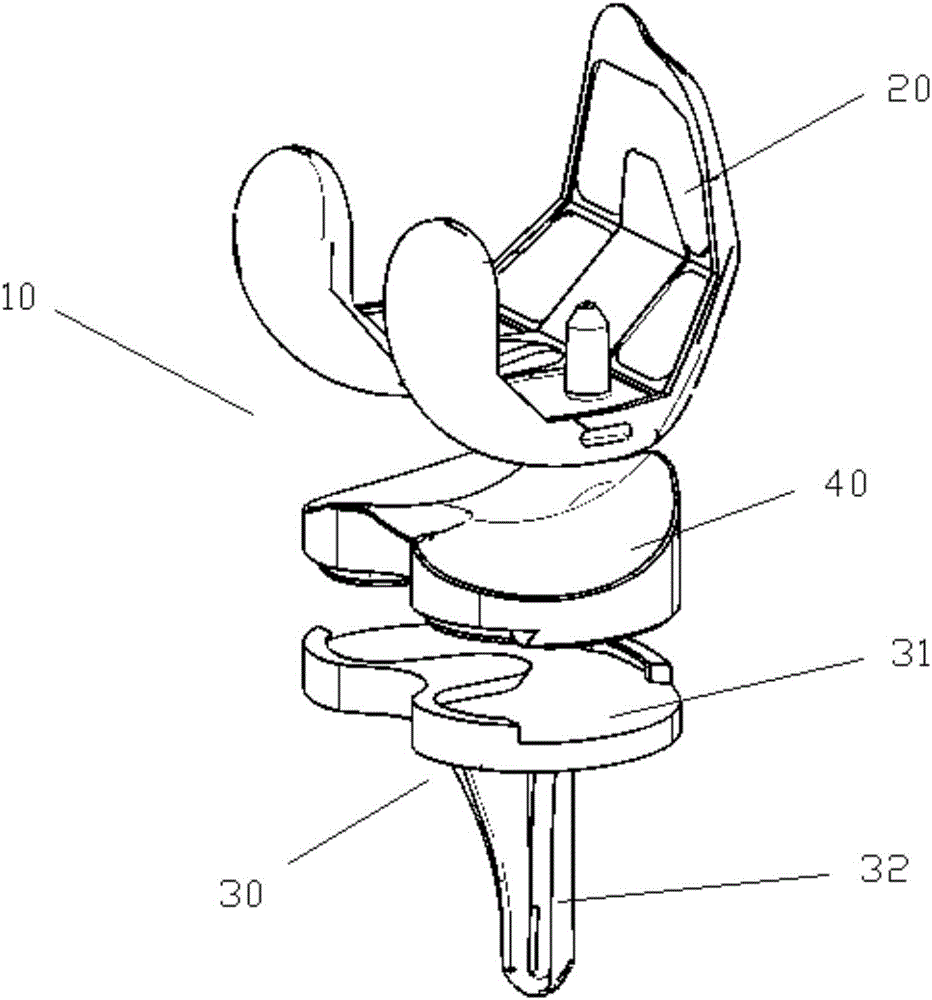

Knee joint prosthesis

InactiveCN106264802ATo prevent aseptic looseningExtend your lifeJoint implantsCoatingsKnee JointAseptic loosening

The invention provides a knee joint prosthesis. The knee joint prosthesis comprises a prosthesis body. The prosthesis structure further comprises a protection coating wrapping the outer surface of the prosthesis body. The knee joint prosthesis comprises the prosthesis body and the protection coating wrapping the prosthesis body, as the outer surface of the prosthesis body is coated with the protection coating, the protection coating can wrap the outer surface of the prosthesis body made of Ti6Al4V alloy, the situation of aseptic loosening of the prosthesis due to separation of Al and V ions can be avoided, and the service life of the prosthesis is prolonged; besides, damage of Al ions and V ions to the human body is avoided, and the use safety and reliability of the prosthesis are improved.

Owner:BEIJING AKEC MEDICAL

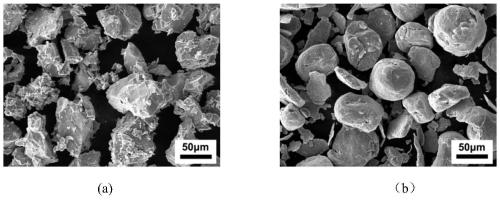

Low elastic modulus Ti6Al4V alloy as well as preparation method and application thereof

The invention discloses a low elastic modulus Ti6Al4V alloy as well as a preparation method and application thereof. The Ti6Al4V alloy comprises the following components of, by mass, 5.5wt.% to 6.2wt.% of Al, 3.8wt.% to 4.5wt.% of V, 0.16wt.% to 0.22wt.% of Fe, 0.01wt.% to 0.1wt.% of Y and the balance Ti. The preparation method comprises the following steps of carrying out hot forging of a Ti6Al4Vtitanium alloy cast ingot, carrying out hot drawing, carrying out double annealing heat treatment, and carrying out machining to obtain the low elastic modulus Ti6Al4V alloy. The Ti6Al4V alloy has the elastic modulus of 80-90 GPa. According to the low elastic modulus Ti6Al4V alloy as well as the preparation method and application thereof, through mutual cooperation between the alloy components and the technology, the content of the beta phase is increased, so that the elastic modulus of the Ti6Al4V alloy is reduced.

Owner:HUNAN HANDLIKE MINIMALLY INVASIVE SURGERY CO LTD

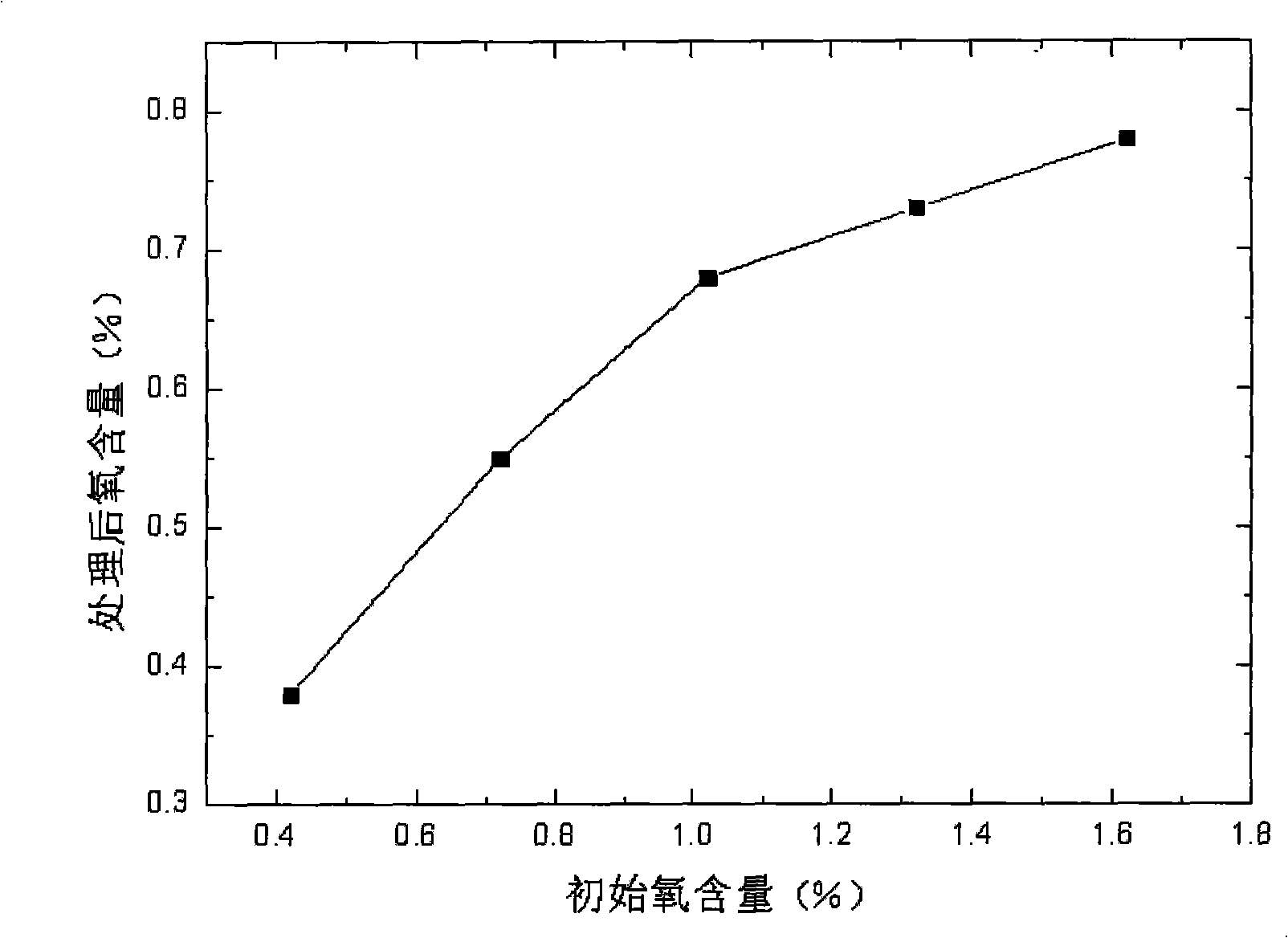

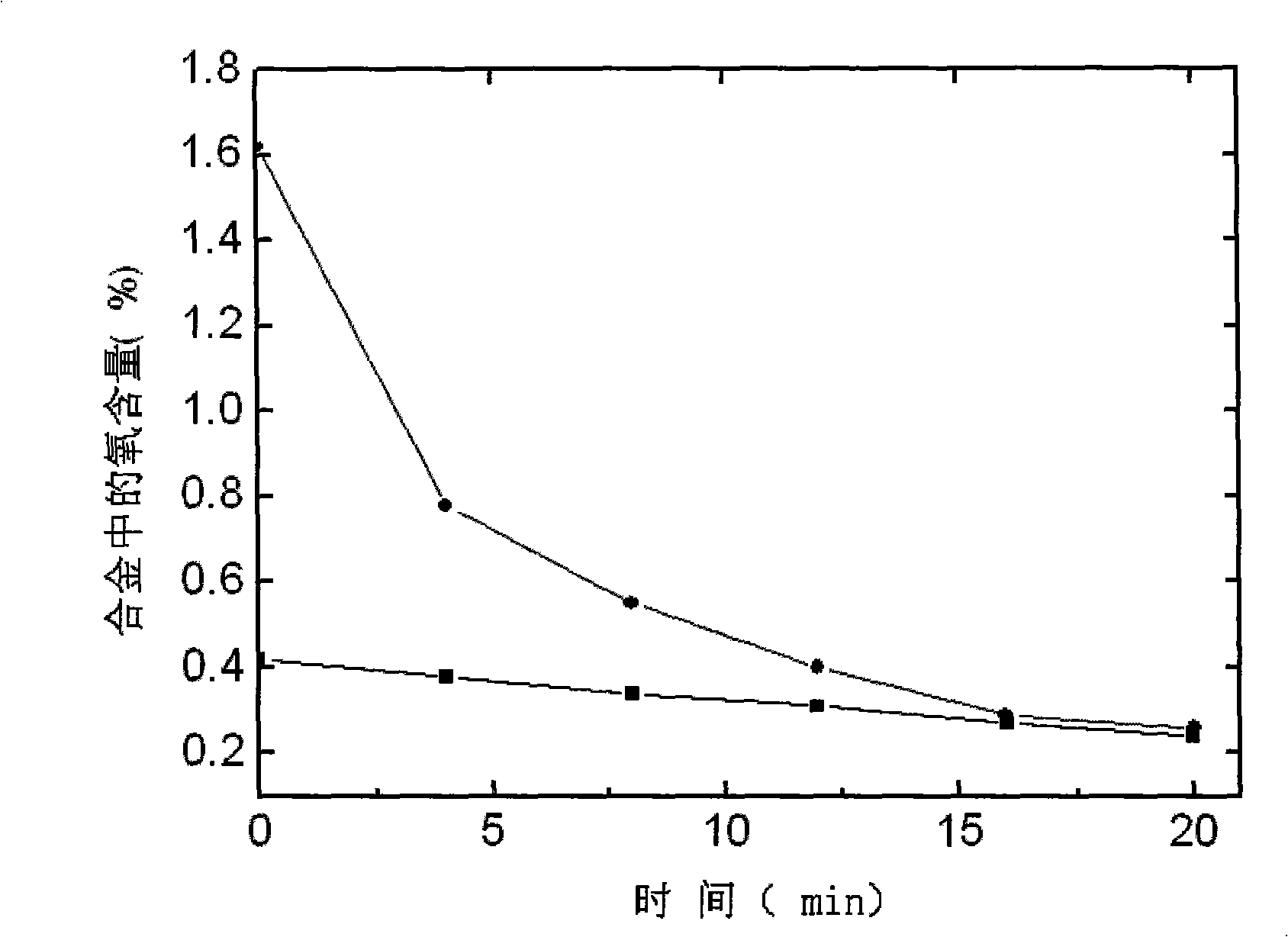

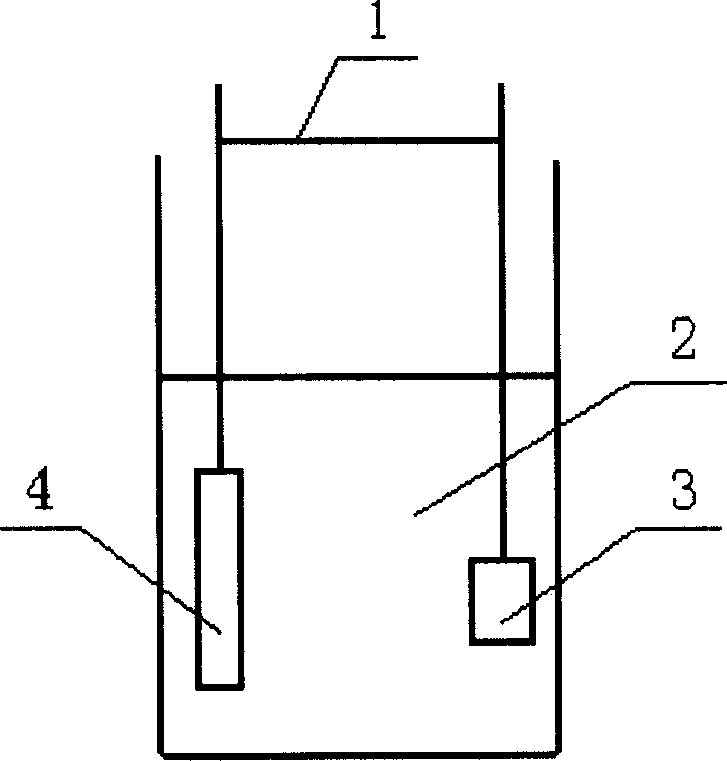

Method for reducing oxygen content in Ti6Al4V alloy by non-consumable arc melting in hydrogen-argon-mixed atmosphere

The invention relates to a method for reducing oxygen content in a Ti6Al4V alloy by non-consumable arc melting in hydrogen-argon-mixed atmosphere. The invention solves the problem that the utilization rate of a titanium alloy waster material is reduced due to high oxygen content. The inventive method comprises the following steps: putting the Ti6Al4V alloy in a water-cooled copper crucible, vacuumizing and then feeding in argon and hydrogen, and striking-melting for 2min-20min. The inventive method has the advantages of reducing the oxygen content in the alloy and improving the utilization rate of the titanium alloy waster material. As proved by tests, the oxygen content of the Ti6Al4V alloy with initial oxygen content of 0.42%, 1.62% (mass) is reduced to about 0.25% (mass) after the melting by the method by means of regulating the admission amount of the oxygen and the melting time. The invention has simply technologies, easily-set parameters and easy control, and can be applied to massive and continuous production and has realistic meaning.

Owner:HARBIN INST OF TECH

Titanium metal ceramic preparation process

InactiveCN104694870AAvoid brittlenessAvoid associativitySolid state diffusion coatingTitanium metalTitanium carbide

The invention discloses a titanium metal ceramic preparation process. According to a technical scheme: an hierarchical carburizing technology is employed to conduct surface high temperature carburizing on Ti6Al4V alloy to prepare titanium carbide ceramics on the surface and form a thick carburized layer, thus preparing the titanium alloy metal ceramic with superior biological friction performance and affinity performance. The process provided by the invention is characterized in that: the hierarchical carburizing technology is employed to conduct surface high temperature carburizing on Ti6Al4V alloy to prepare titanium carbide ceramics on the surface and form the thick carburized layer, thus preparing titanium metal ceramics.

Owner:QINGDAO PINGDU JIUDIAN GOLD MINE

Method for preparing carboxyl apatite coating by single-chamber sacrificial anode hydrothermal synthesis

The invention relates to single room sacrificial anode-water heat compounding hydroxyapatite coating. The process includes making primary coating and water heating process. The primary coating has no magnesium element existing. The interface binding power could reach to 7MPa by adjusting the time to making primary coating, the thickness of the coating. The invention is simple technology, easy to operate and has wide application range.

Owner:DALIAN UNIV OF TECH

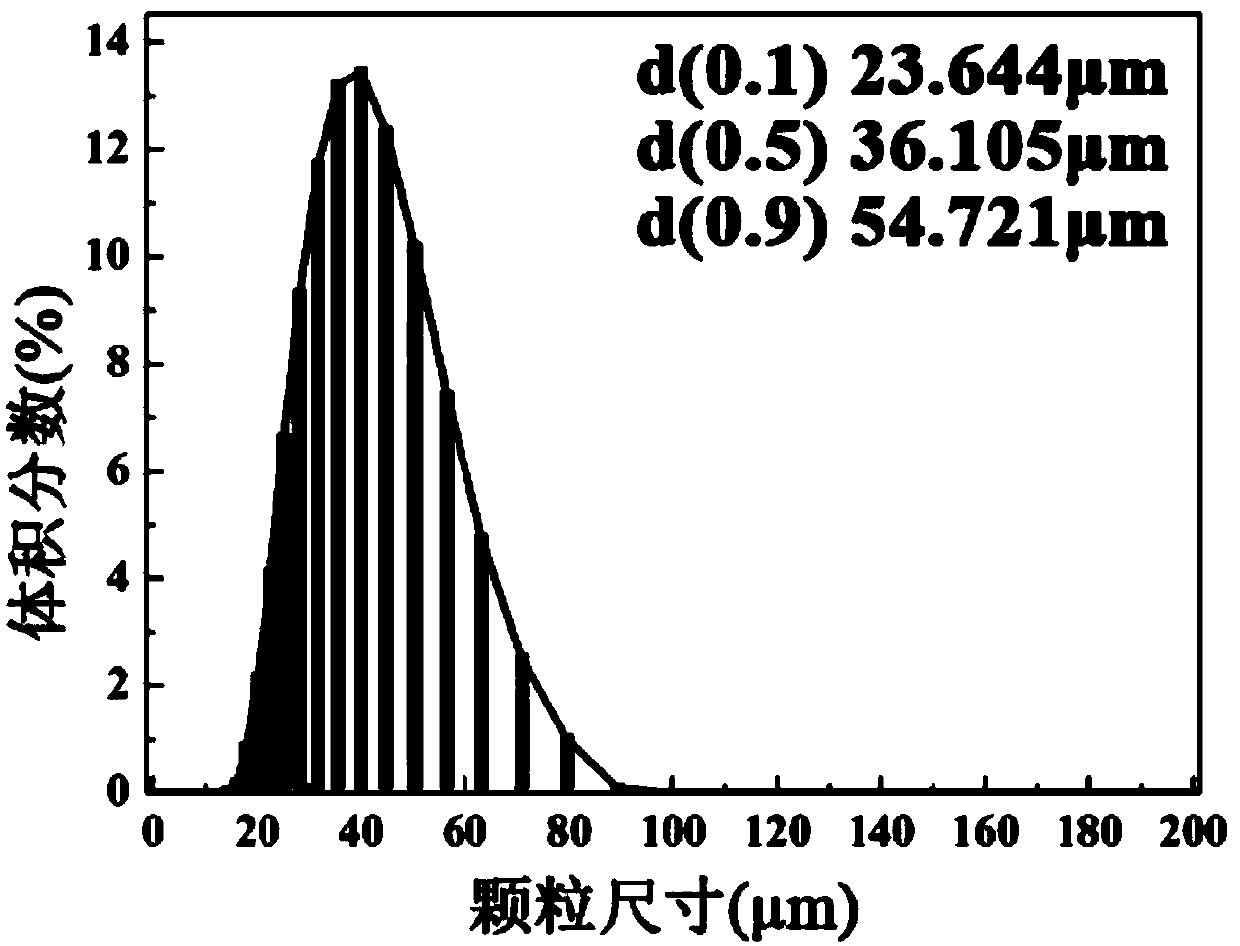

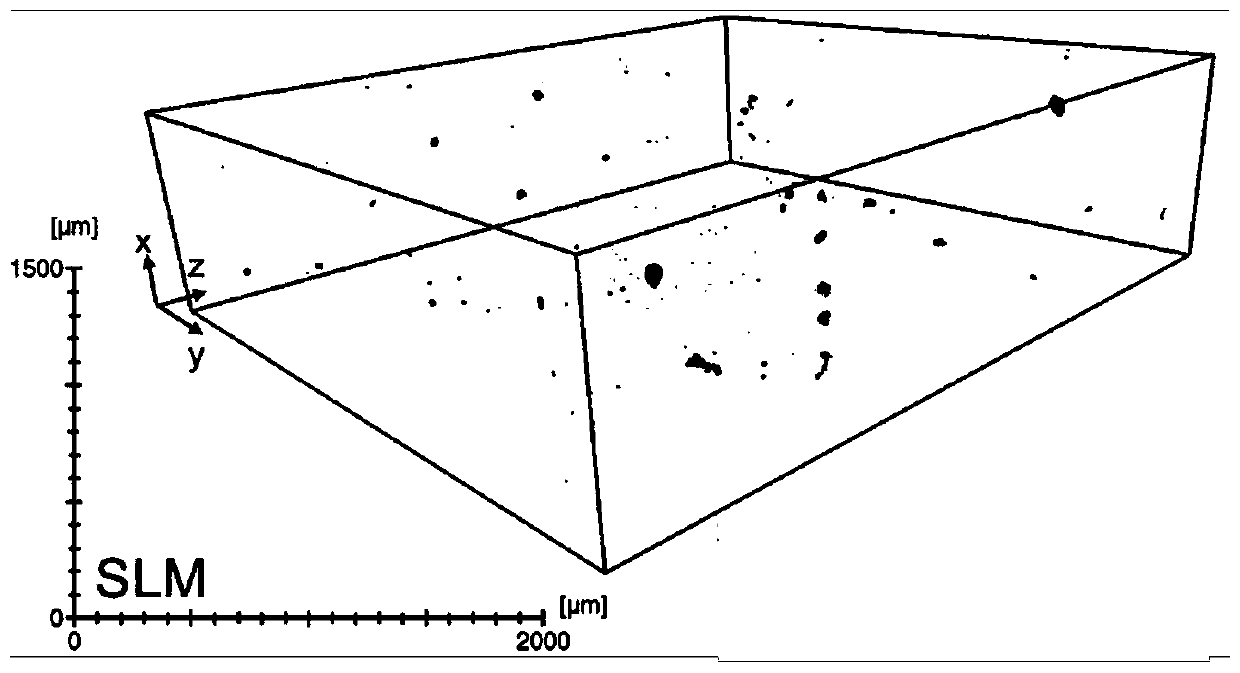

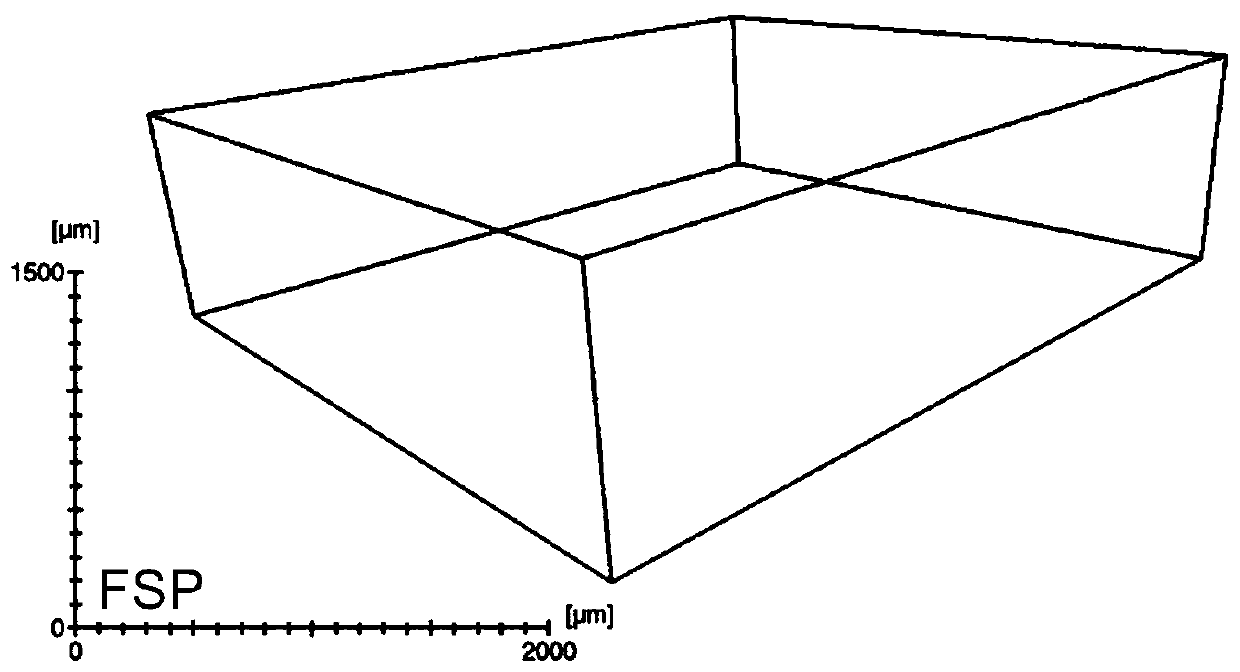

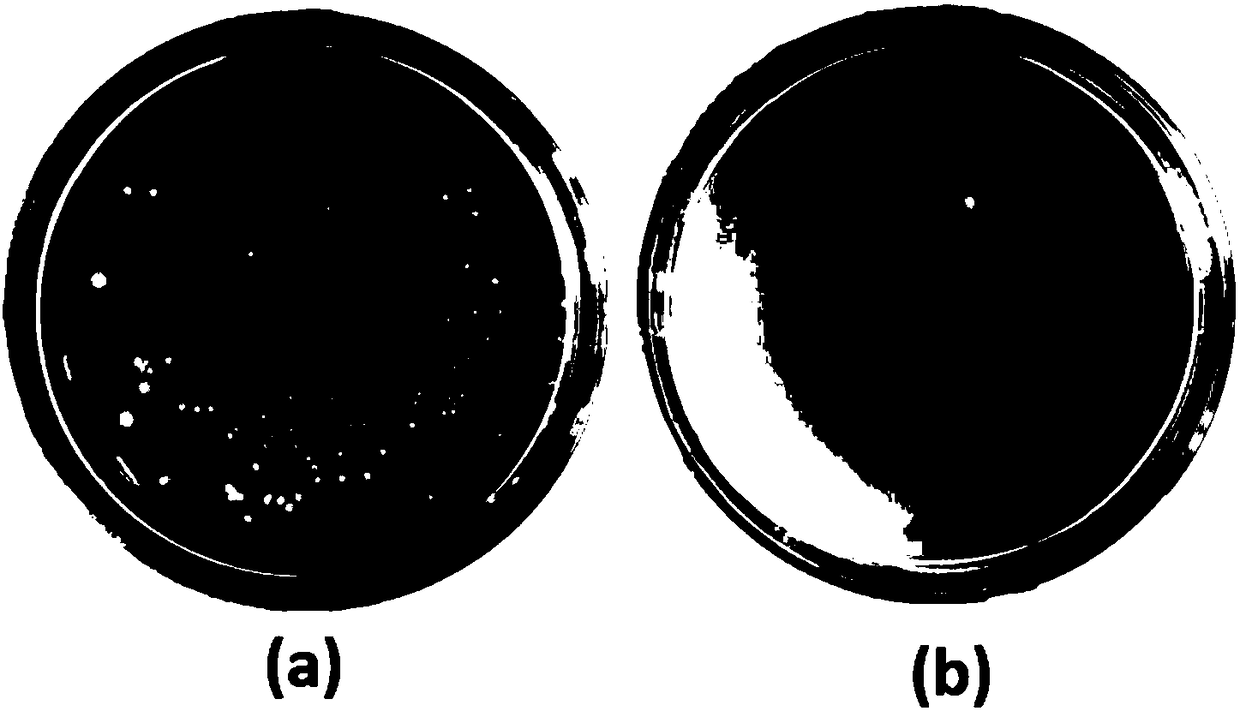

Friction stir treatment method capable of improving ductility of selective laser melting Ti6Al4V block

InactiveCN109746567AChange structureReduce intensityNon-electric welding apparatusPorositySelective laser melting

The invention relates to an aftertreatment process of the selective laser melting Ti6Al4V block, in particular to a friction stir treatment method capable of improving ductility of a selective laser melting Ti6Al4V block. Atomized titanium powder with the average grain size being 33.8 micrometers is selected, an EOS M290 device is adopted for additive manufacturing of a Ti6Al4V base plate, and thesize is 60*40*3 mm<3>. During the test, optimized SLM parameters are selected; the printed SLM Ti6Al4V base plate surface is subjected to oxide, impurity and oil stain clearing; friction stir processing modified post-treatment is carried out, a friction stir welding device is adopted for carrying out local friction stir processing modification treatment on the Ti6Al4V base plate. The porosity ofthe original SLM block can be obviously reduced, the microscopic structure in the material is changed, the ductility of the SLM Ti6Al4V alloy is greatly improved, and the material strength cannot be greatly reduced.

Owner:SICHUAN UNIV

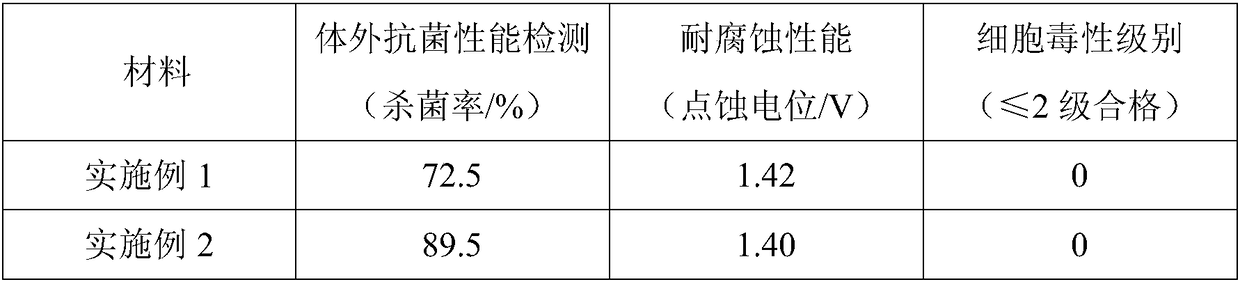

Anti-infection medical material titanium alloy

ActiveCN108728692AImprove the bactericidal effectImprove antibacterial propertiesProsthesisChemical compositionOrthopedic department

The invention relates to the field of medical titanium alloy materials, in particular to an anti-infection medical titanium alloy. The medical titanium alloy comprises chemical components including, by weight percent, 5.5%-6.5% of Al, 3.5%-4.5% of V, 0.2%-4.0% of Ga and the balance Ti and other inevitable impurity elements. The proper amount of Ga element is added in a medical Ti6Al4V alloy matrix, and accordingly the Ti6Al4V medical titanium alloy is endowed with the excellent bacterium infection resisting function. The alloy can be widely applied to various medical titanium alloy medical instruments used in the orthopedics department, the stomatology department and other clinic fields, and bacterium infection risks caused during usage of existing implanted material titanium alloy instruments can be further obviously reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

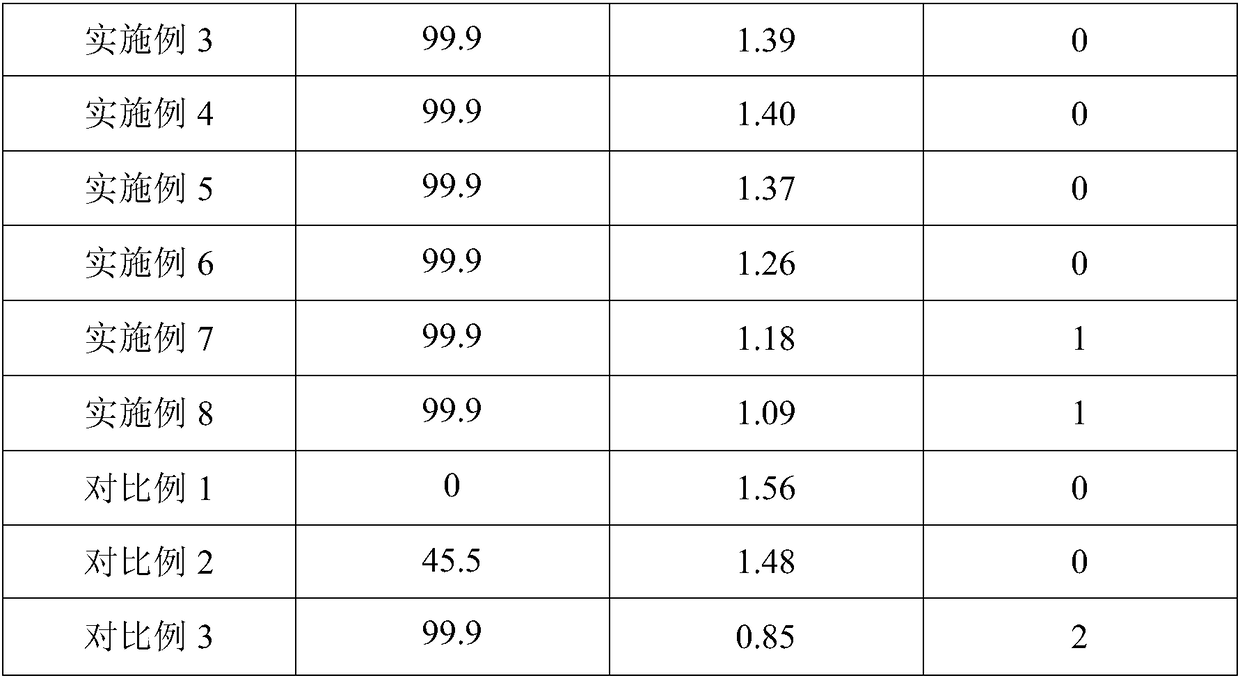

Ti6Al4V alloy powder, preparation method of Ti6Al4V alloy powder and 3D printed product

InactiveCN111318684ARounded surfaceGood mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyAl powderMetallurgy

The invention discloses Ti6Al4V alloy powder, a preparation method of the Ti6Al4V alloy powder and a 3D printed product. The preparation method includes the following steps that hydrogenated dehydrogenated titanium powder is put into a ball milling device, ethanol is added, and ball milling treatment is performed to obtain spherical titanium powder; and then, the spherical titanium powder is takenand mixed with aluminum powder and vanadium powder to obtain the Ti6Al4V alloy powder. According to the preparation method of the Ti6Al4V alloy powder, the production process is simple, the production cycle is short, required equipment is simple, adopted raw materials are low in cost and easy to get, and the production cost is low; and the obtained Ti6Al4V alloy powder is high in sphericity, uniform in particle size, good in fluidity and suitable for 3D printing forming, the formability is good, and a formed Ti6Al4V alloy has outstanding mechanical properties.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

A method for preparing high-performance ti6al4v alloy plate

ActiveCN107185963BImprove mechanical propertiesExtended service lifeWork cooling devicesMetal rolling arrangementsReduction rateMechanical property

The invention discloses a method for preparing a high-performance Ti6Al4V alloy plate. The method comprises the following steps that 1) a Ti6Al4V hot rolled plate is taken as a raw material, wherein the thickness of the hot rolled plate is 1.5mm-3.5mm; 2) the hot rolled plate is put into a cryogenic tank for cooling, the temperature of the rolled piece is reduced to 190 DEG C, and heat preservation is carried out for 10 minutes; 3) the rolled piece is taken out for cold rolling, wherein the rolling speed of an upper roller is V1, the rolling speed of a lower roller is V2, the ratio of V1 to V2 is controlled to be 1.1 to 1.2, the rolling is carried out, and the rolling reduction rate is 5%-10%; and 4) the rolling is repeatedly carried out on the rolled piece until the total reduction rate reaches 20%-25%, and the high-performance Ti6Al4V alloy plate is obtained. The method adopts the principle that small-sized grains especially small-sized high-V-phase materials can be formed in the deformation process of titanium alloy under the condition of ultralow temperature, so that the mechanical property of the material is improved; and the Ti6Al4V alloy has wide application prospects in the fields of aerospace, life medical science and the like, and the method can effectively prolong the service life of the material.

Owner:CENT SOUTH UNIV

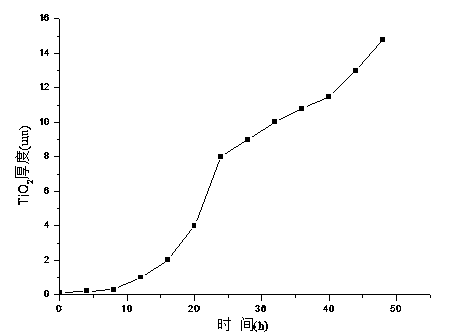

Preparation method of titanium dioxide thin film coating on surface of titanium alloy microporous bone

InactiveCN103628052AThin film method is simpleLow costSolid/suspension decomposition chemical coatingTitaniumArtificial bone

The invention relates to a preparation method of a titanium dioxide thin film coating on the surface of a titanium alloy microporous bone. A titanium dioxide thin film with defense and protection effects, formed on a Ti6Al4V alloy artificial bone in a human body fluid environment, is poor in stability and durability, resulting in separation of toxic elements Al and V in the Ti6Al4V alloy. According to the preparation method provided by the invention, TiPT (Titanium Isopropoxy), C3H8O (anhydrous isopropanol), HCL (Hydrochloric Acid) and H2O (water) are uniformly mixed in a certain molar ratio and aged to obtain a titanium dioxide (TiO2) sol. The titanium dioxide thin film coating is synthesized on the surface of the titanium alloy microporous bone by a dipping extraction method. The produced TiO2 can provide effective anti-corrosive protection to a substrate, enhance the corrosion resistance of the material and well prevent the surface of the Ti6Al4V alloy from being peeled. The TiO2 thin film prepared by the method is simple in method and low in cost and has a potential application value in the biomedical field.

Owner:南京捷科生物科技有限公司

Preparation method of medical Ti6Al4V artificial implant

ActiveCN109550077AHigh hardnessImprove structural stabilityAdditive manufacturing apparatusTissue regenerationStress protectionAlloy

The invention relates to a preparation method of a medical Ti6Al4V artificial implant. The preparation method comprises the following steps of with Ti6Al4 alloy powder as a raw material, preparing theraw material into block-shaped Ti6Al4V alloy by an electron beam melting deposit method; and performing heat treatment on the block-shaped Ti6Al4V alloy to obtain the implant. The tensile strength achieves 960-990MPa, the yield strength can achieve 940-970MPa, the modulus of elasticity can achieve 30-40GPa and is close to the modulus of bones of human bodies, and the stress shielding and the stress protection are reduced.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com