Friction stir treatment method capable of improving ductility of selective laser melting Ti6Al4V block

A technology of friction stir and laser melting, which is applied in the direction of non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as reduction, and achieve the effects of improving ductility, reducing porosity, and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the above-mentioned optimized process parameters, but the present invention is not limited thereby.

[0027] Titanium powder with an average particle size of 33.8 μm was selected, and a laser power of 280W and a scanning speed of 1200mm / s were used to additively manufacture a 60×40×3mm 3 Ti6Al4V substrate. The surface of the substrate is milled to remove impurities such as surface oxides; then the substrate to be modified is placed in an acetone solution, and the oil on the surface of the substrate is cleaned by ultrasonic waves. Using friction stir processing, the welding forward speed is 75mm / min, the rotation speed is 400rpm, and the SLM Ti6Al4V substrate is post-processed under an argon protective atmosphere.

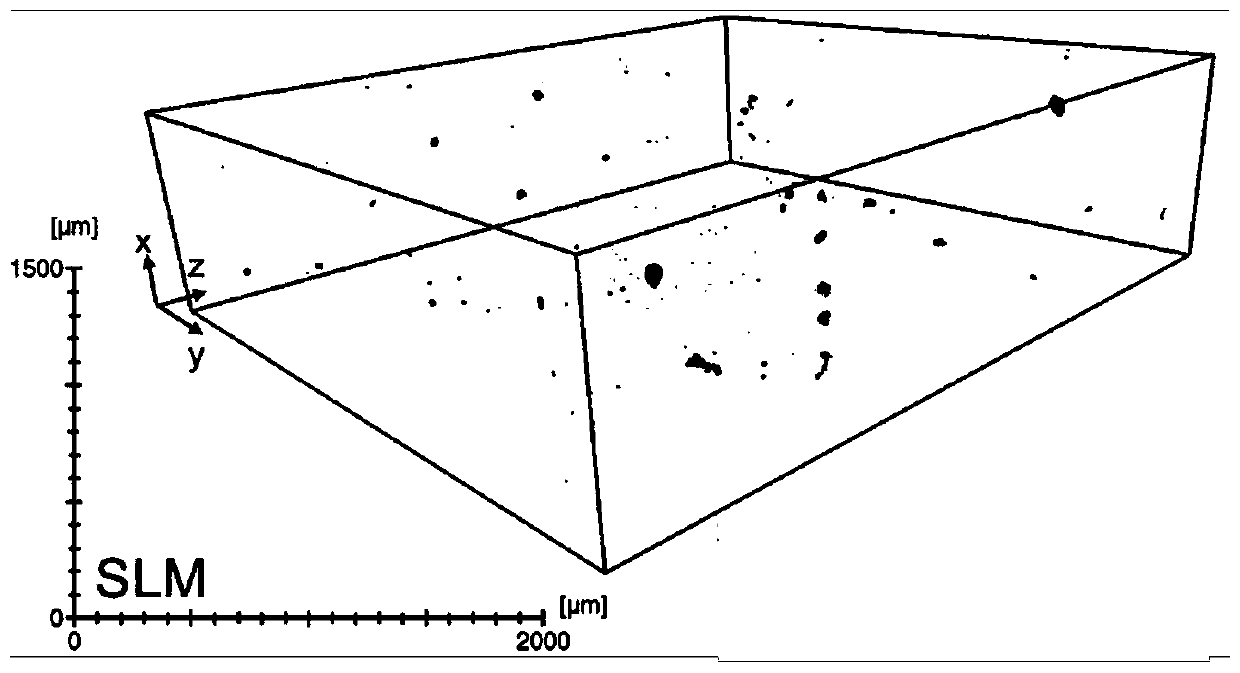

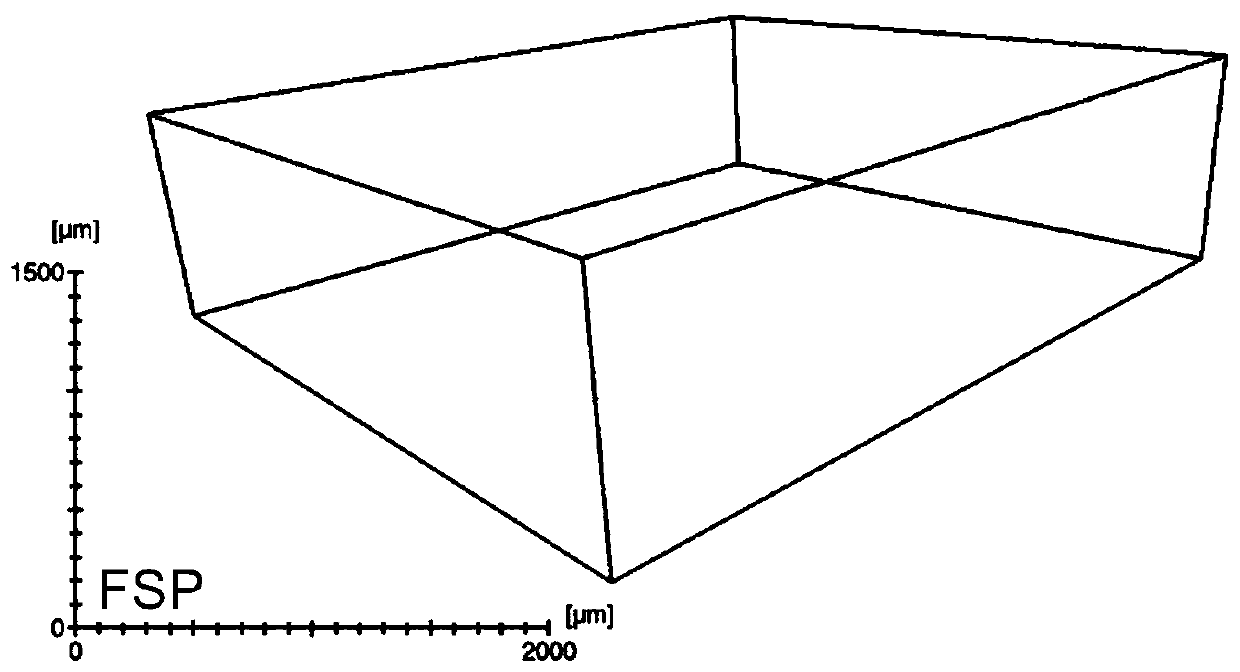

[0028] Utilize the present invention to carry out the porosity of the Ti6Al4V alloy bulk material of SLM material post-treatment to significantly reduce, and structure such as Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com