Method for reducing oxygen content in Ti6Al4V alloy by non-consumable arc melting in hydrogen-argon-mixed atmosphere

An electric arc melting, non-consumable technology, applied in the field of material processing, can solve the problems of limiting the utilization rate of titanium alloy waste, and achieve the effect of improving utilization rate, simple process and easy parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

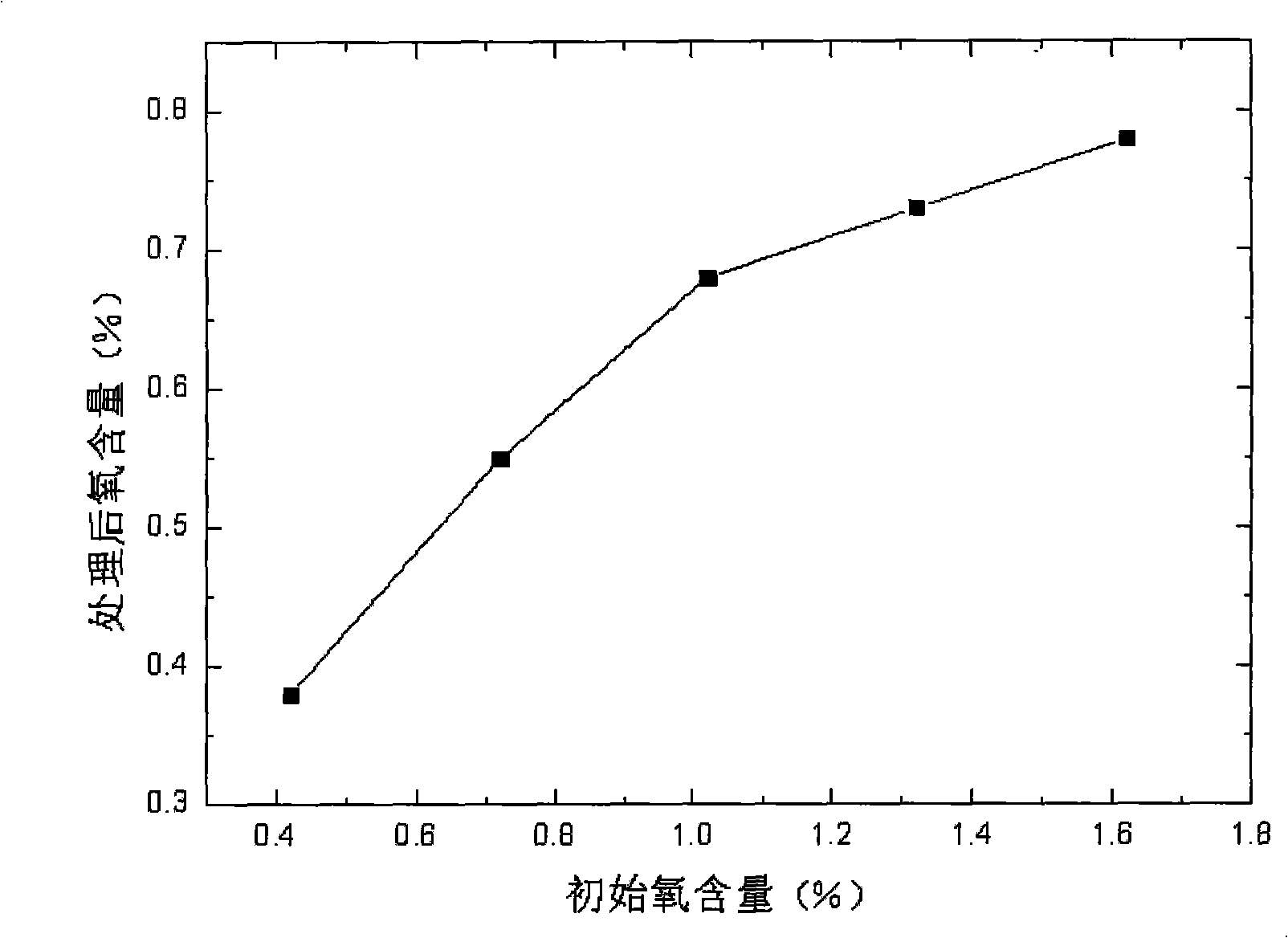

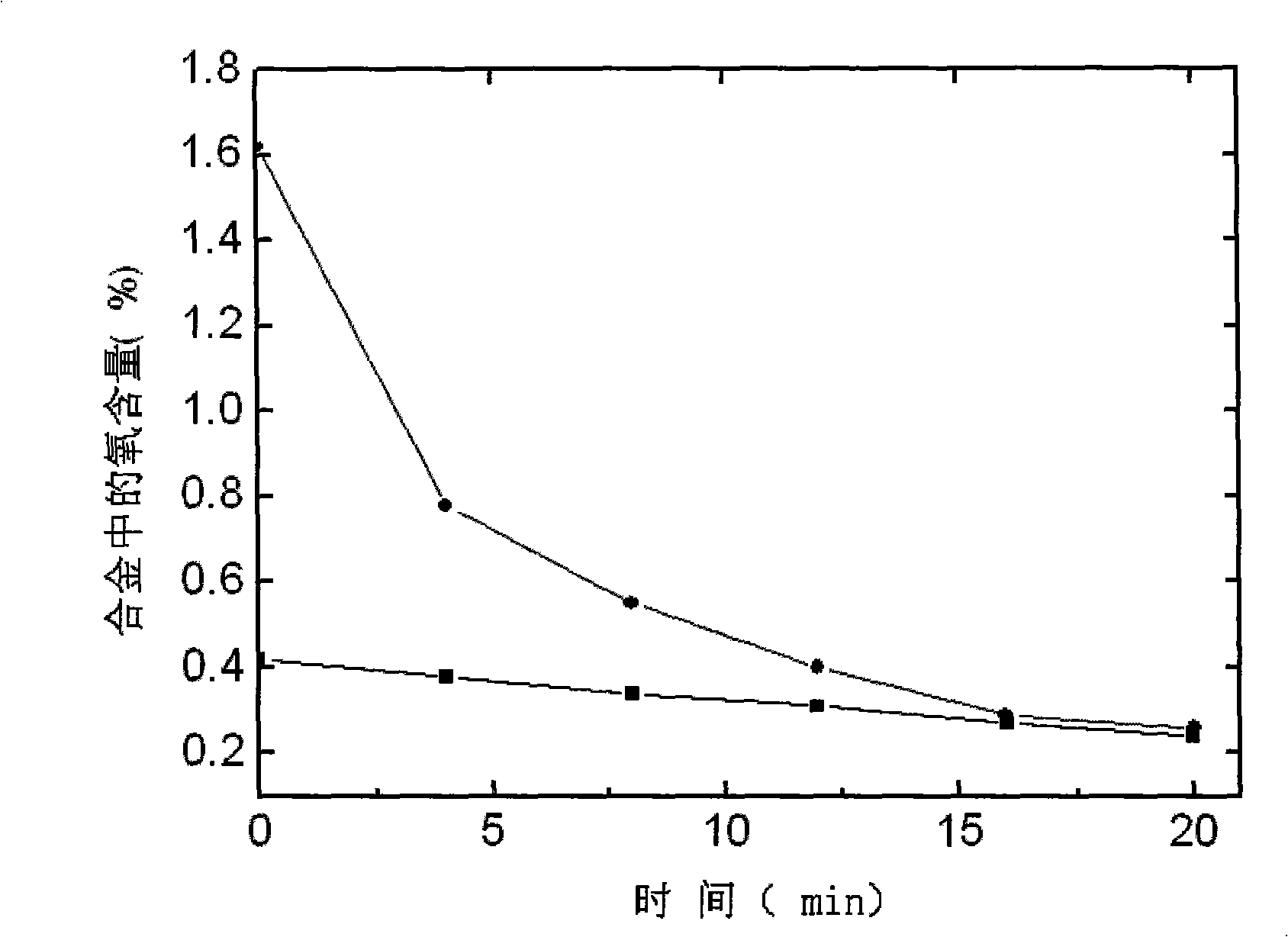

[0010] Specific Embodiment 1: In this embodiment, the method for reducing the oxygen content in Ti6Al4V alloy by non-consumable arc melting in a hydrogen-argon mixed atmosphere is realized by the following steps: Put the Ti6Al4V alloy into the melting chamber of a vacuum non-consumable electrode electric arc furnace In a water-cooled copper crucible, first evacuate the melting chamber to 1×10 -2 ~1×10 -4 Pa, then filled with argon with a purity of 99.999% (volume) and hydrogen with a purity of 99.999% (volume), wherein the pressure in the melting chamber is 3 × 10 4 ~10×10 4 Pa, hydrogen accounted for 5% to 30% of the total volume of argon and hydrogen, and then arc smelting for 2 minutes to 20 minutes; that is, the oxygen content in the Ti6Al4V alloy was reduced.

[0011] In this embodiment, after smelting, it is cooled and solidified in a crucible, or cast into castings or ingots.

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment is different from Embodiment 1 in that the current is 150-250A during the smelting process. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment is different from Embodiment 1 in that the current is 200A during the smelting process. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com