Technique for preparing special Ti6Al4V alloy powder used for material increase manufacturing

A process method and alloy powder technology, which is applied in the field of preparing Ti6Al4V alloy powder for additive manufacturing, can solve the problems of no formation, influence of forming process, high price, etc., achieve non-oxidized temperature and composition, increase melting rate, and uniform solution composition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Raw material preparation: The high-purity Ti powder and Al-V master alloy powder are ball milled and mixed according to the alloy composition ratio by the mixed element method to obtain a mixed powder, and then the mixed powder is pressed into a bar block by the cold isostatic pressing method. The alloy composition ratio is: Al: 5.5%, V: 3.5%, Fe≤0.3%, C≤0.1%, N≤0.05%, H≤0.015%, O≤0.2%, the balance is Ti, and the purity of Ti is above 99.9%.

[0030] Alloy Melting: Place the bar block from the previous step in a water-cooled copper crucible, vacuumize the melting chamber, and then heat and melt the bar block by electromagnetic induction, and control the superheat of the titanium alloy solution obtained after melting to 190±1°C.

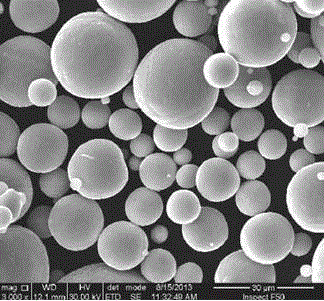

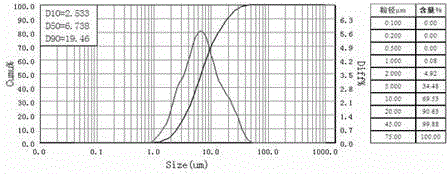

[0031] Atomized powder: The metal melt obtained after smelting titanium alloy powder is atomized into fine droplets through the 99.999% high-purity argon high-pressure airflow sprayed by multi-stage annular holes, and the atomized fine par...

Embodiment 2

[0034] Raw material preparation: The high-purity Ti powder and Al-V master alloy powder are ball milled and mixed according to the alloy composition ratio by the mixed element method to obtain a mixed powder, and then the mixed powder is pressed into a bar block by the cold isostatic pressing method. The alloy composition ratio is: Al: 6.75%, V: 4.5%, Fe ≤ 0.3%, C ≤ 0.1%, N ≤ 0.05%, H ≤ 0.015%, O ≤ 0.2%, the balance is Ti, and the purity of Ti is above 99.9%.

[0035] Alloy Melting: Place the bar block from the previous step in a water-cooled copper crucible, vacuumize the melting chamber, and then heat and melt the bar block by electromagnetic induction, and control the superheat of the titanium alloy solution obtained after melting to 210±1°C.

[0036] Atomized powder: The metal melt obtained after smelting titanium alloy powder is atomized into fine droplets through the 99.999% high-purity argon high-pressure airflow sprayed by multi-stage annular holes, and the atomiz...

Embodiment 3

[0039] Raw material preparation: The high-purity Ti powder and Al-V master alloy powder are ball milled and mixed according to the alloy composition ratio by the mixed element method to obtain a mixed powder, and then the mixed powder is pressed into a bar block by the cold isostatic pressing method. The alloy composition ratio is: Al: 6.0%, V: 4.0%, Fe ≤ 0.3%, C ≤ 0.1%, N ≤ 0.05%, H ≤ 0.015%, O ≤ 0.2%, the balance is Ti, and the purity of Ti is above 99.9%.

[0040] Alloy Melting: Place the bar block from the previous step in a water-cooled copper crucible, vacuumize the melting chamber, and then heat and melt the bar block by electromagnetic induction, and control the superheat of the titanium alloy solution obtained after melting to 200±1°C.

[0041] Atomized powder: The metal melt obtained after smelting titanium alloy powder is atomized into fine droplets through the 99.999% high-purity argon high-pressure airflow sprayed by multi-stage annular holes, and the atomize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com