3D (three-dimensional) printing type porous metal scaffold with superficial nanocomposite coatings and preparation of 3D printing type porous metal scaffold

A nano-composite coating, porous stent technology, applied in coatings, electrolytic coatings, prostheses, etc., can solve the problems of increased contact area, low biological activity on the alloy surface, implantation failure, etc., and achieves low cost, film layer Good morphology uniformity and improved biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Cut silkworm cocoon (Bombyxmoricocoon) into pieces, weigh 5g, and place in 2L0.02MNa 2 CO 3 Boil in the solution for 30 minutes to remove sericin on the surface of silk. After boiling, wash the degummed silk fibroin several times with deionized water and dry it naturally. Then dissolve the silk fibroin in 9MLiBr at 60°C until the silk fibroin is completely dissolved Afterwards (about 4h), dialyze with a dialysis membrane for 3 days to obtain a silk fibroin aqueous solution with a mass volume fraction of 6-9w / v% (g / mL), which is stored in a refrigerator at 4°C until use.

Embodiment 2

[0037] Put the 8w / v% silk fibroin (silk) solution freshly prepared in Example 1 in a 50ml centrifuge tube, tighten the cap and place it in a 60°C water bath for overnight treatment. Prepare the deposition solution according to the composition ratio in Table 1. Among them, in order to ensure that graphene oxide (GO) is fully dispersed in the silk fibroin solution, 200 μL GO solution can be mixed with 4.9 mL deionized water first, and then added to the silk fibroin solution. Hydroxyapatite (HA) nanoparticles (about 40nm in diameter) need to be dispersed in 4.9mL deionized water and 1.1mL ethanol solution, after ultrasonic dispersion for 30min, add HA / deionized water / ethanol solution to silk fibroin solution , stir well. After the deposition solution is prepared, it can be deposited after standing for 20-30 minutes.

[0038] Table 1 The composition of silk fibroin / GO / HA deposition solution

[0039]

Embodiment 3

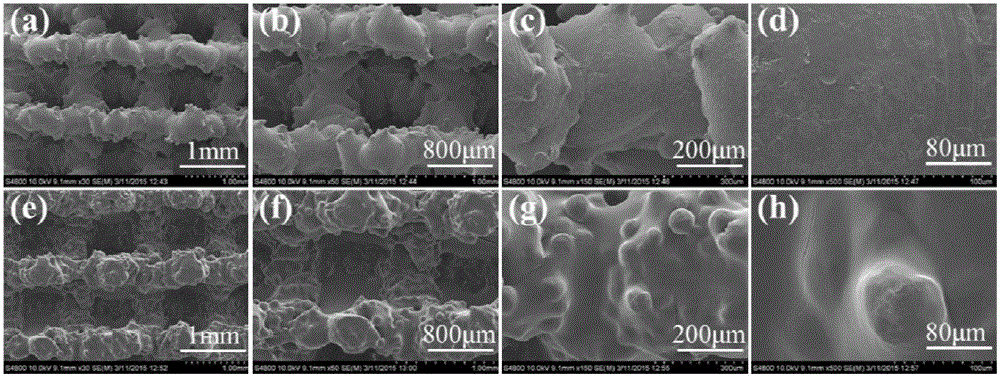

[0041] The 3D printed porous Ti6Al4V scaffolds were ultrasonically cleaned in acetone, 75% ethanol and deionized water for 15 min each, and dried at 60 °C for 1 h. Activate with acid solution at room temperature for 3 minutes. The formula of acid solution is nitric acid: hydrofluoric acid: water = 28.8: 2.4: 70 (volume ratio). The deposition solution in Example 3 was used as the deposition solution, 316L stainless steel as the cathode, and the porous Ti6Al4V support as the anode, the cathode and the anode were placed at a distance of 10mm, a DC voltage of 10V was applied between the two stages, and the deposition time was 30-45s. After the deposition, the samples were soaked in 90% methanol solution for 2 h, and then dried naturally. The surface morphology of the bare stent and the electrophoretic deposition pure silk fibroin coating surface SEM morphology are as follows: figure 1 shown.

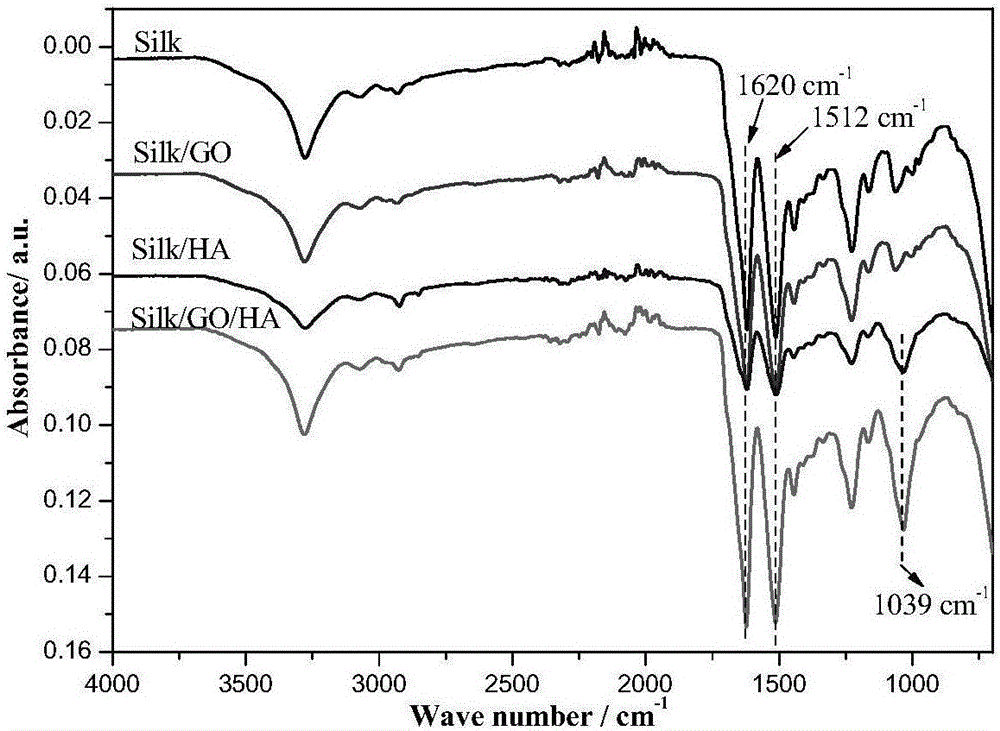

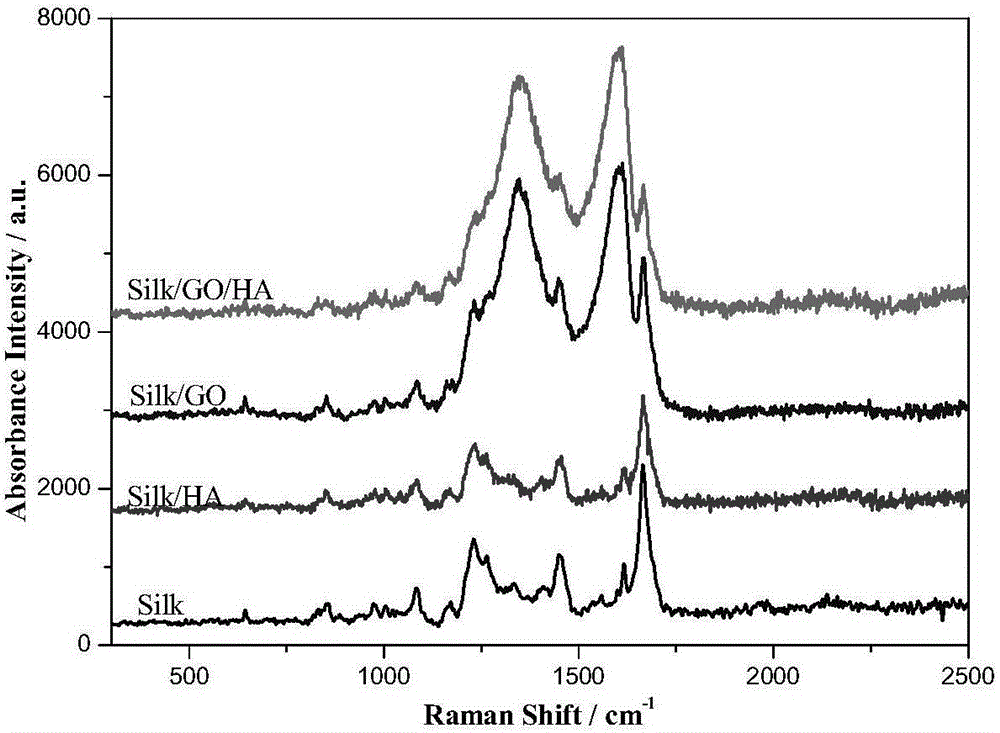

[0042] The materials obtained in Examples 1 to 3 are characterized by scanning electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mass volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com