A kind of cyclic impregnation preparation cu 2 znsn(s 1‑x ,se x ) 4 nanocrystalline thin film method

A cyclic impregnation, nanocrystal technology, applied in nanotechnology, nanotechnology, sustainable manufacturing/processing, etc., can solve the problems of long material preparation time, low utilization rate of raw materials, restricting large-scale production, etc., and achieve good market application Prospects, abundant raw material reserves, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

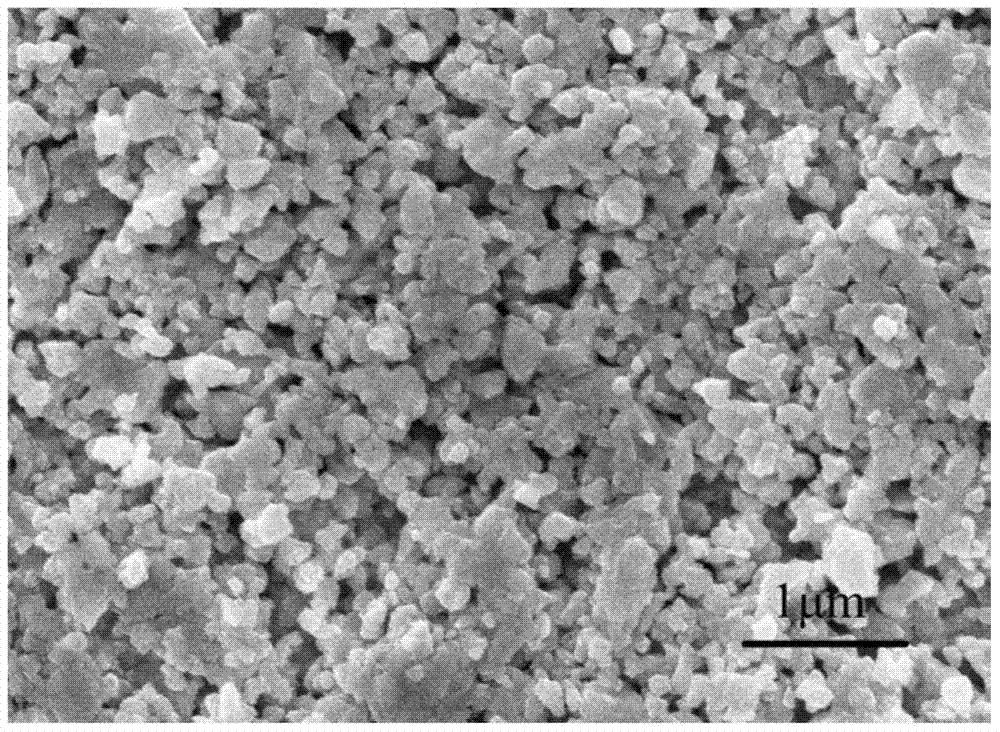

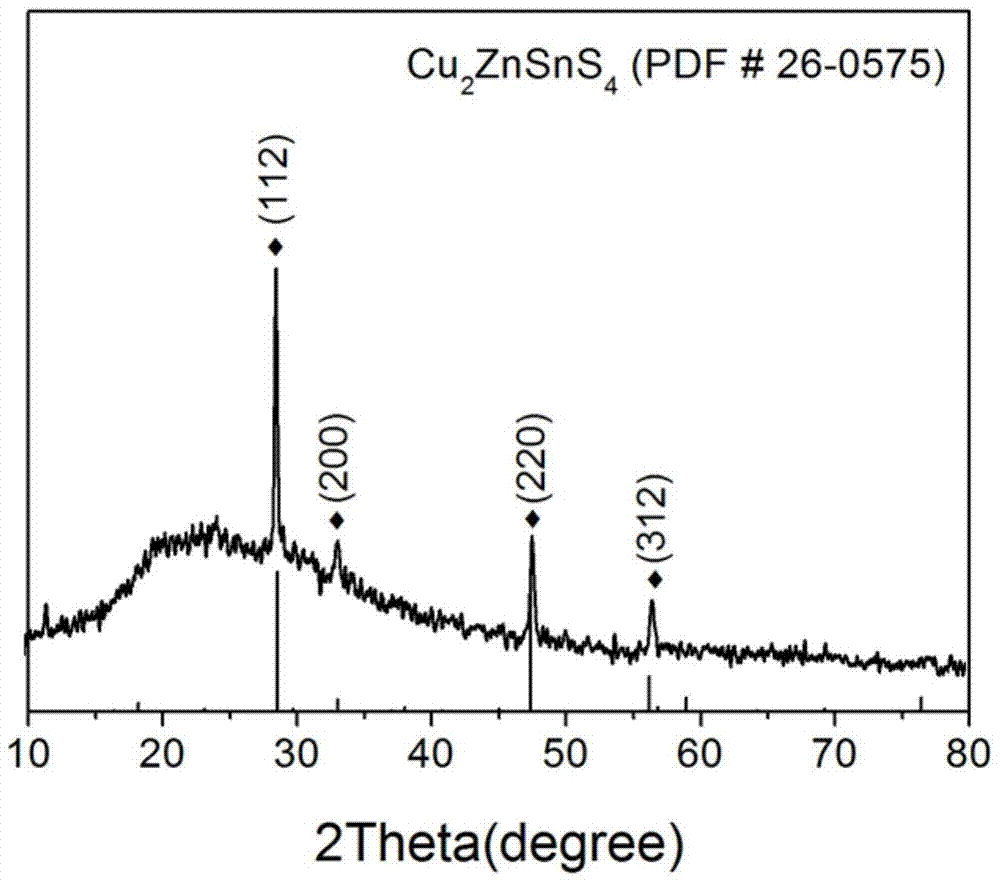

Embodiment 1

[0025] This embodiment prepares Cu 2 ZnSnS 4 The specific process of nanocrystalline thin film is:

[0026] (1), respectively prepare CuSO with a concentration of 0.02mol / L 4 ·5H 2O solution, 0.01mol / L ZnSO 4 ·7H 2 O solution, 0.02mol / L SnCl 2 2H 2 O solution and 0.16mol / L Na 2 S·9H 2 O;

[0027] (2) Preparation of cationic precursor solution: Measure 10ml of CuSO with a graduated cylinder 4 ·5H 2 O solution, 10ml of ZnSO 4 ·7H 2 O solution and 10ml of SnCl 2 2H 2 After O, mix them together and place them in a 50ml beaker, add 5.845g of urea, stir evenly at room temperature, transfer to a water bath at 50°C, adjust the pH to 3.0 with dilute ammonia water, and obtain a cationic precursor;

[0028] (3), the preparation of anion precursor solution: measure the Na of 30ml respectively with measuring cylinder 2 S·9H 2 The O solution was placed in a 50ml beaker, transferred to a water bath at 50°C, and adjusted to a pH of 6.0 with dilute hydrochloric acid to obtain ...

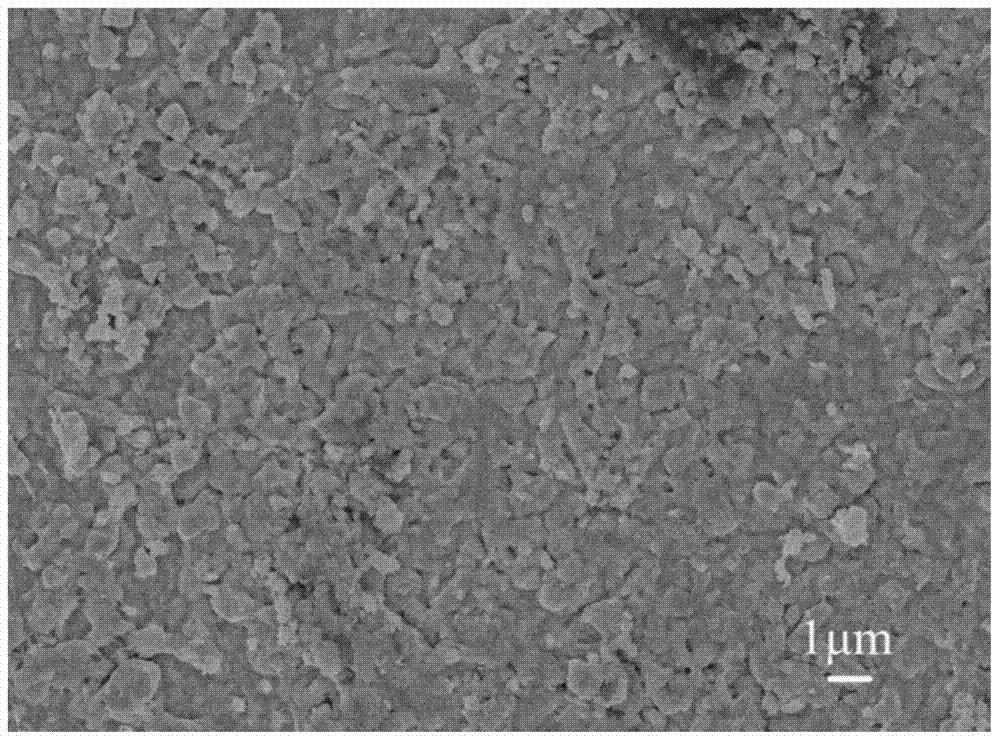

Embodiment 2

[0033] The specific preparation process of the present embodiment is:

[0034] (1), respectively prepare a CuCl solution with a concentration of 0.03mol / L and a ZnCl solution with a concentration of 0.015mol / L 2 solution, 0.03mol / L SnCl 4 ·5H 2 O solution and 0.24mol / L CH 3 CSNH 2 ;

[0035] (2) To prepare cationic precursor solution, measure 15ml of CuCl solution and 15ml of ZnCl with graduated cylinder 2 solution and 15ml of SnCl 4 ·5H 2 O, then mix together and place in a 100ml beaker, add 9.009g of urea, stir evenly at room temperature, transfer to a water bath at 60°C, adjust its pH to 3.0 with dilute ammonia water, and obtain a cationic precursor;

[0036] (3) To prepare anion precursor solution, measure 45ml of CH with a graduated cylinder 3 CSNH 2 The solution is placed in a 100ml beaker, transferred to a 60°C water bath, and adjusted to a pH of 6.0 with dilute hydrochloric acid to obtain an anion precursor;

[0037] (4), measure 45ml of deionized water with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com