Defect-based compound-anchored single-atom composite material and its preparation method and application

A composite material and compound technology, applied in the field of electrochemical energy materials, can solve problems such as high cost and complex process, and achieve the effects of mild conditions, simple preparation process and overall electrochemical performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Another aspect of the embodiments of the present invention also provides the aforementioned preparation method of the defect-based compound-anchored single-atom composite material, comprising:

[0034] Mix graphene oxide, carbon nanotubes, surfactant, polysulfide, metal salt precursor and solvent evenly, then add metal single-atom precursor, and perform a hydrothermal reaction at 120-200 ° C for 12 hours;

[0035] and, in NH 3 and / or in an inert atmosphere, the obtained hydrothermal reaction product is heat-treated at 100-500° C. for 10-120 minutes to obtain a defect-based compound-anchored single-atom composite material.

[0036] In some specific embodiments, the preparation method includes: ultrasonically dispersing graphene oxide, carbon nanotubes and a surfactant in a solvent, then adding a metal salt precursor to fully mix to form a first dispersion, and then adding a The polysulfide solution is added to the obtained first dispersion liquid and mixed, and then the...

Embodiment 1

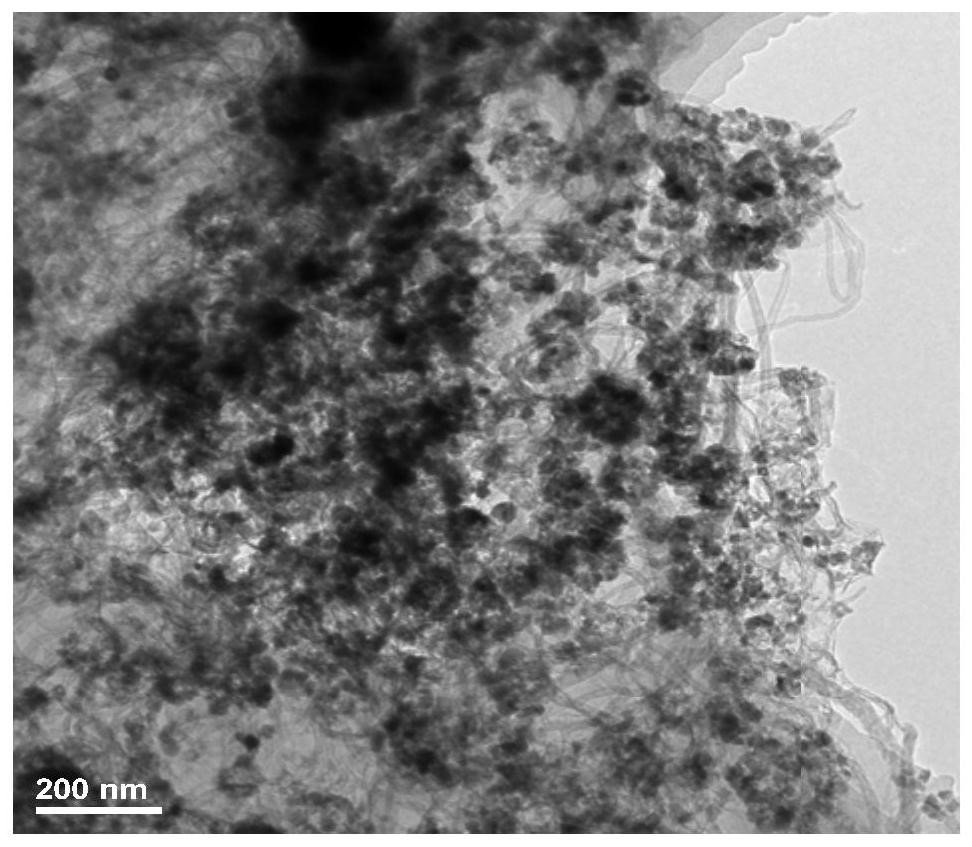

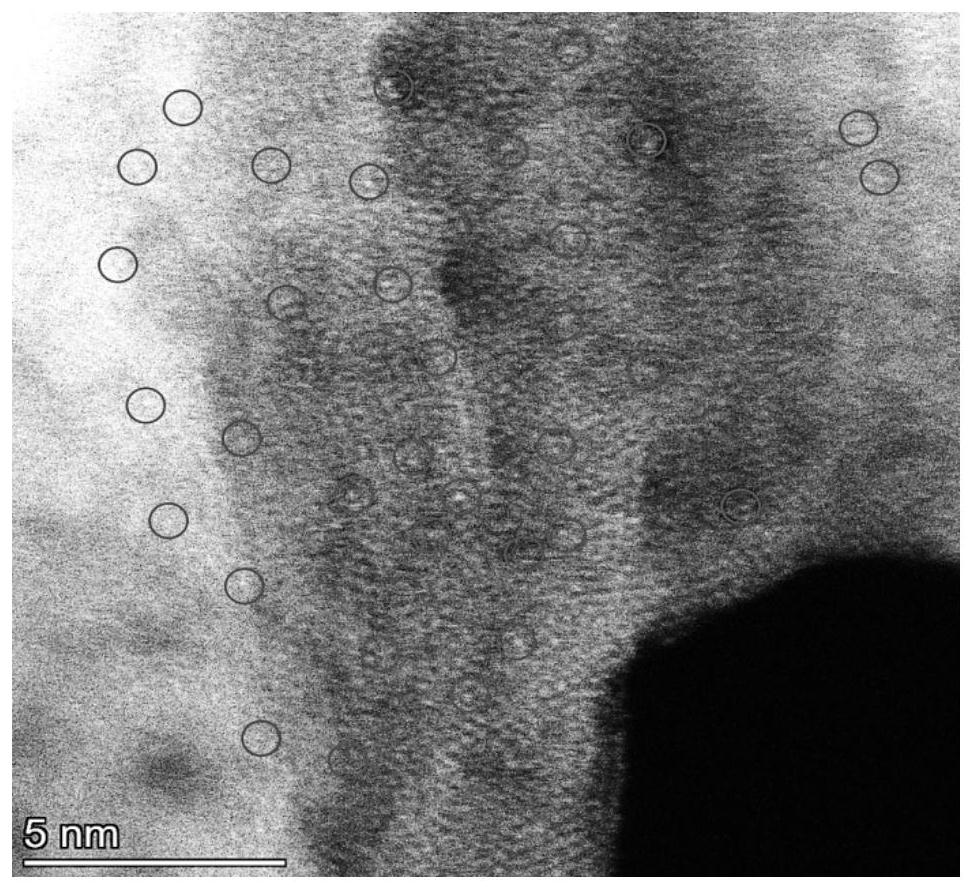

[0074] Weigh 720mg of sulfur powder and 580mg of sodium sulfide in 25mL of ultrapure water and stir to form a yellow sodium polysulfide solution; Measure 50mL of graphene oxide solution (4mg / mL) and 200mg of carbon nanotube powder, on the surface Under the action of the active agent, it was effectively ultrasonically dispersed in 250 mL of ultrapure water; a certain amount of ferrous acetate powder was weighed and added to the above dispersion, fully stirred, and then 3 mL of sodium polysulfide solution was slowly added to the dispersion. , followed by adding 20 mg of Ni(Ac) 2 ·4H 2 O, 150 °C hydrothermal reaction for 12 h, then filtered and washed, and freeze-dried to obtain the initial sample; in an Ar atmosphere, the temperature was raised to 500 °C for 30 min, maintained for 30 min, and cooled to room temperature to obtain the defect-based compound-anchored nickel atom composite material. Depend on figure 1 It can be seen that the nanoparticle size of the prepared compos...

Embodiment 2

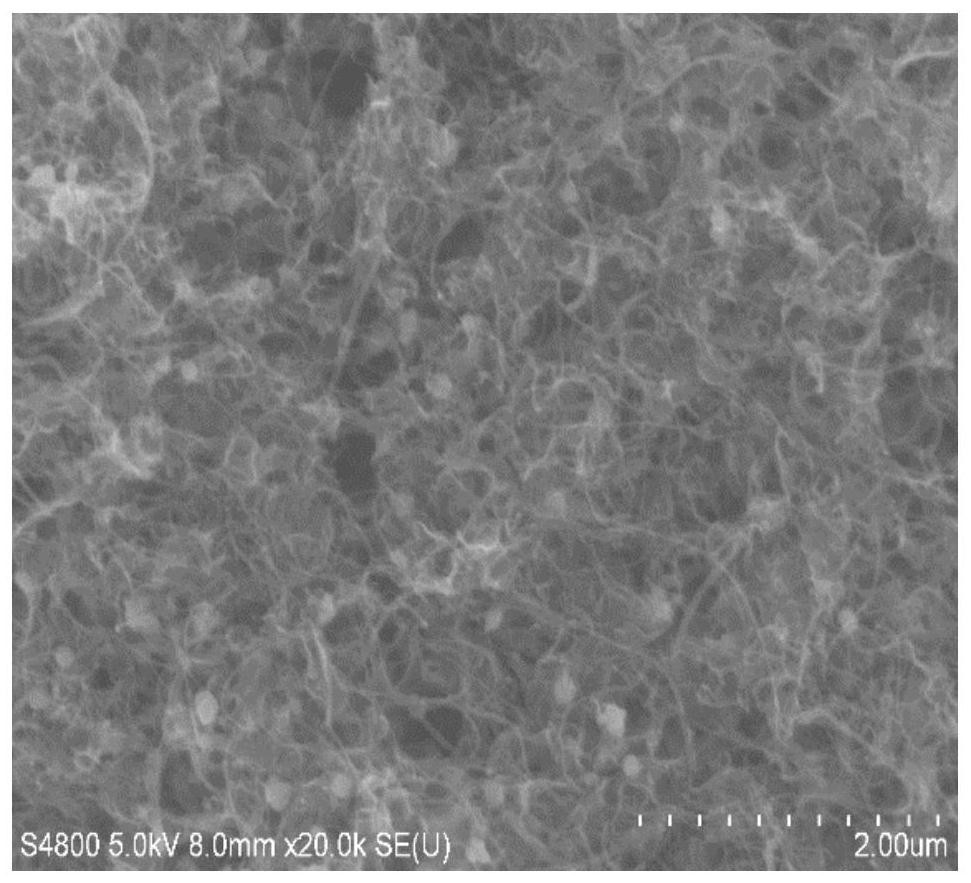

[0076] Weigh 720mg of sulfur powder and 580mg of sodium sulfide in 25mL of ultrapure water and stir to form a yellow sodium polysulfide solution; weigh 50mL of graphene oxide solution (4mg / mL) and 200mg of carbon nanotube powder, on the surface Under the action of the active agent, it was effectively ultrasonically dispersed in 250 mL of ultrapure water; a certain amount of ferrous acetate powder was weighed and added to the above dispersion, and stirred thoroughly; then 3 mL of sodium polysulfide solution was slowly added to the dispersion. , followed by the addition of 50 mg of Co(Ac) 2 , hydrothermally reacted at 120 °C for 12 h, then filtered and washed, and freeze-dried to obtain the initial sample; 3 In the atmosphere of 30min, it was raised to 100°C, kept for 120min, and cooled to room temperature to obtain the defect-based compound-anchored cobalt atom composite material. figure 2 It can be seen that the nanoparticle size of the prepared composite material is relativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com