Defect-based compound anchored monatomic composite material as well as preparation method and application thereof

A composite material and compound technology, applied in the field of electrochemical energy materials, can solve problems such as high cost and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned defect-based compound-anchored single-atom composite material, which includes:

[0034] Mix graphene oxide, carbon nanotubes, surfactants, polysulfides, metal salt precursors and solvents evenly, then add metal single-atom precursors, and undergo a hydrothermal reaction at 120-200°C for 12 hours;

[0035] and, in NH 3 And / or in an inert atmosphere, the obtained hydrothermal reaction product is heat-treated at 100-500° C. for 10-120 minutes to obtain a single-atom composite material anchored by defect-based compounds.

[0036] In some more specific embodiments, the preparation method includes: ultrasonically dispersing graphene oxide, carbon nanotubes and surfactants in a solvent, then adding a metal salt precursor and mixing thoroughly to form a first dispersion, and then adding The polysulfide solution is added to the obtained first dispersion liquid for ...

Embodiment 1

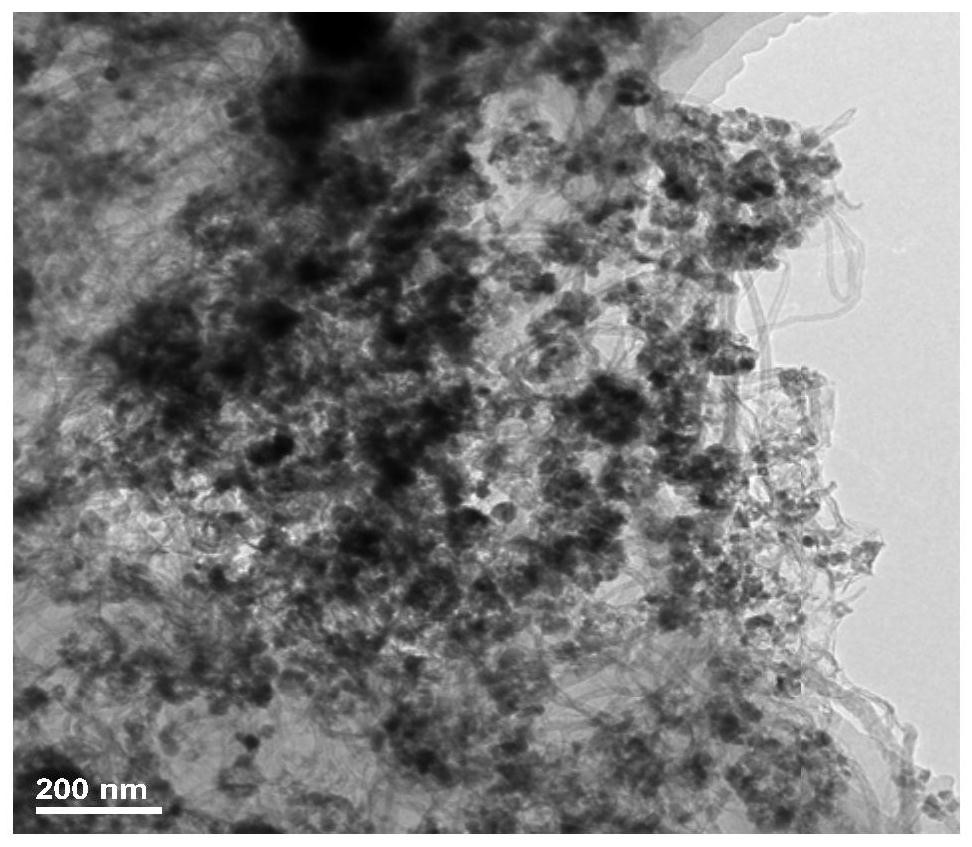

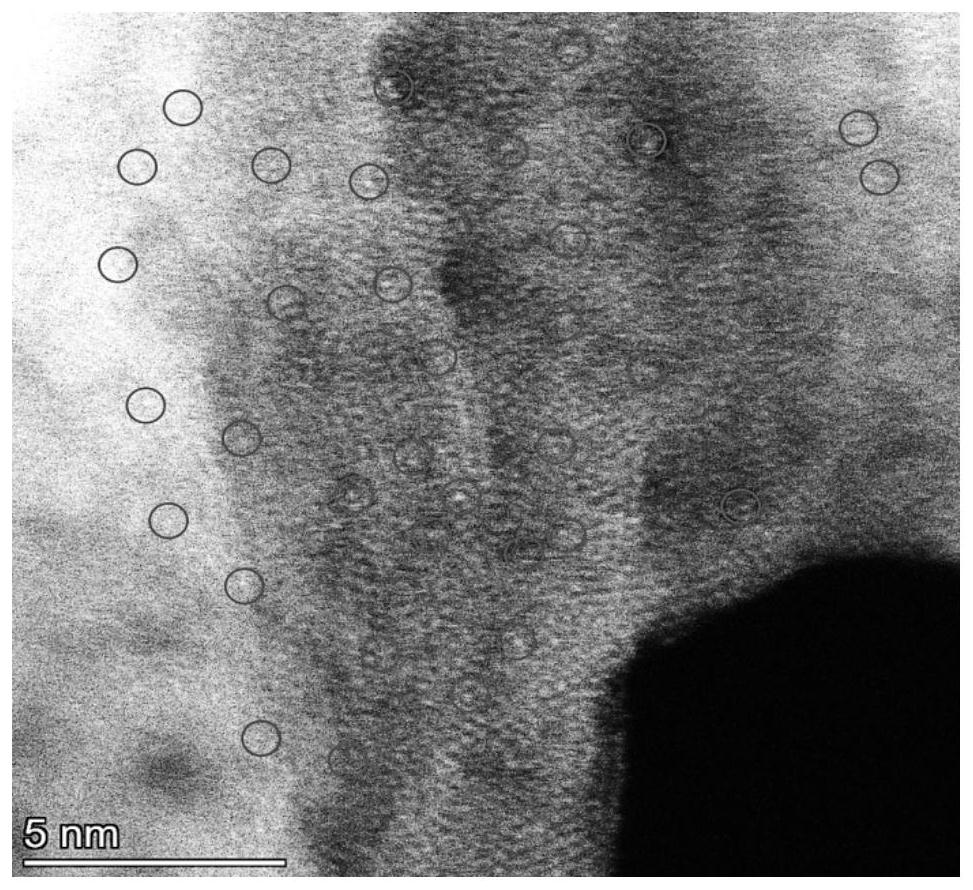

[0074] Take by weighing 720mg of sulfur powder and 580mg of sodium sulfide and stir in 25mL of ultrapure water to form a yellow sodium polysulfide solution; measure 50mL of graphene oxide solution (4mg / mL) and 200mg of carbon nanotube powder on the surface Under the action of the active agent, it is effectively ultrasonically dispersed in 250mL of ultrapure water; weigh a certain amount of ferrous acetate powder and add it to the above dispersion liquid, stir well, and then slowly add 3mL of sodium polysulfide solution to the dispersion liquid , then add 20mg of Ni(Ac) 2 4H 2 O, hydrothermal reaction at 150°C for 12 hours, then filtered and washed, and freeze-dried to obtain the initial sample; under the atmosphere of Ar, rise to 500°C for 30 minutes, keep it warm for 30 minutes, and cool to room temperature to obtain a defect-based compound-anchored nickel atom composite. Depend on figure 1 It can be seen that the nanoparticle size of the prepared composite material is rela...

Embodiment 2

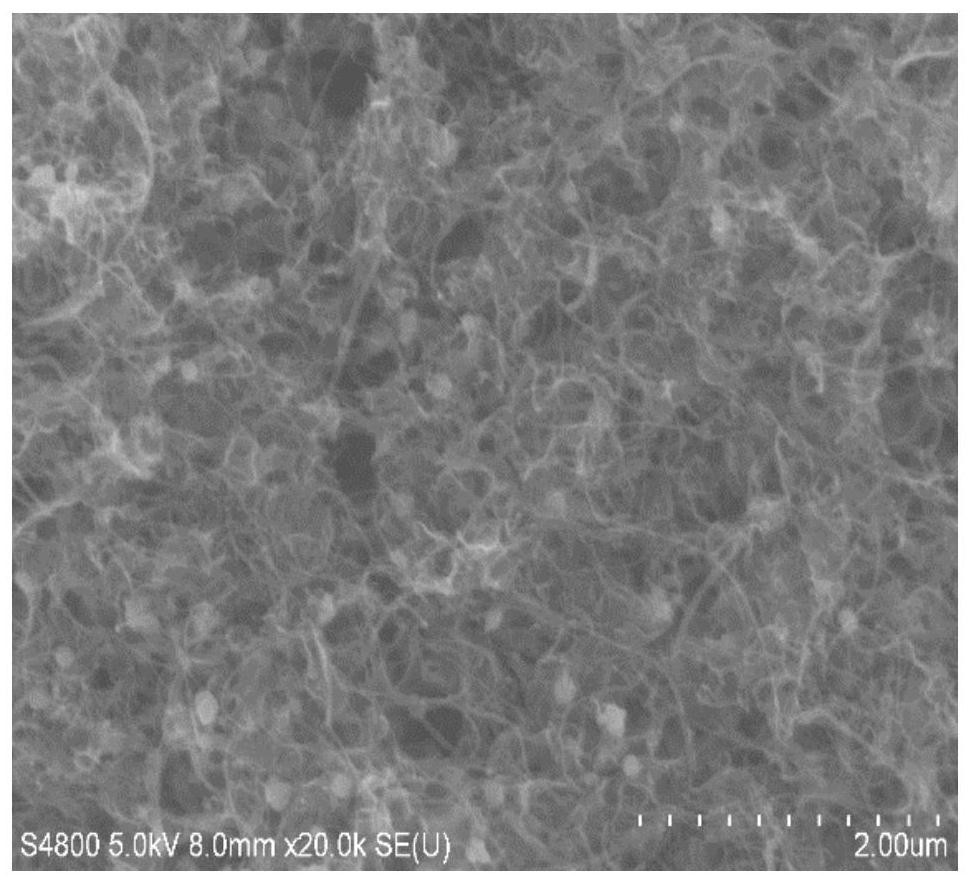

[0076] Take by weighing 720mg of sulfur powder and 580mg of sodium sulfide and stir in 25mL of ultrapure water to form a yellow sodium polysulfide solution; measure 50mL of graphene oxide solution (4mg / mL) and 200mg of carbon nanotube powder on the surface Under the action of the active agent, ultrasonically disperse effectively in 250mL of ultrapure water; weigh a certain amount of ferrous acetate powder and add it to the above dispersion liquid, and stir thoroughly; then slowly add 3mL of sodium polysulfide solution to the dispersion liquid , then add 50mg of Co(Ac) 2 , hydrothermal reaction at 120°C for 12h, then filtered, washed, and freeze-dried to obtain the initial sample; in Ar / NH 3 Under an atmosphere of 100°C for 30 minutes, keep it warm for 120 minutes, and cool to room temperature to obtain a defect-based compound-anchored cobalt atom composite material. figure 2 It can be seen that the nanoparticle size of the prepared composite material is relatively small, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com