A large-area two-dimensional gallium nitride thin film and its preparation method

A gallium nitride, large-area technology, applied in the field of gallium nitride materials, can solve problems such as the difficulty of single-layer thickness of GaN, and achieve the effects of strong thickness controllability, reduced time consumption, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

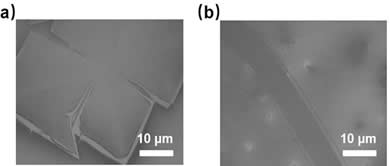

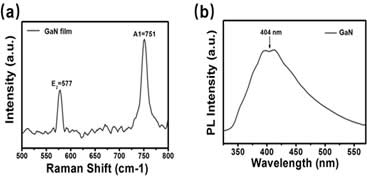

[0043] The invention discloses a method for preparing a large-area two-dimensional gallium nitride film. A tube furnace with dual temperature zones is used as a reaction device. A porcelain boat with built-in urea and a ceramic boat coated with urea are respectively placed in the two temperature zones in the tube furnace. For the sapphire substrate of gallium nitrate solution, under the condition of protective atmosphere, the temperature of the porcelain boat and the sapphire substrate were respectively raised, and the heating rate was controlled to reach 138°C at the porcelain boat while the temperature at the sapphire substrate was 900°C. The decomposition product of gallium nitrate solution was vapor-phase deposited to form a large-area two-dimensional gallium nitride film.

[0044] In this embodiment, the gallium nitrate solution is coated on the sapphire substrate by spin coating, and the spin coating rate is 10000 RPM. The concentration of gallium nitrate solution is 15w...

Embodiment 2

[0048] The invention discloses a method for preparing a large-area two-dimensional gallium nitride film. A tube furnace with dual temperature zones is used as a reaction device. A porcelain boat with built-in urea and a ceramic boat coated with urea are respectively placed in the two temperature zones in the tube furnace. For the sapphire substrate of gallium nitrate solution, under the condition of protective atmosphere, the temperature of the porcelain boat and the sapphire substrate were respectively raised. Large-area two-dimensional gallium nitride thin films were formed by vapor deposition of gallium nitrate solution decomposition products.

[0049] In this embodiment, the gallium nitrate solution is coated on the sapphire substrate by spin coating, and the spin coating rate is 8000 RPM. The concentration of gallium nitrate solution is 10wt%. The gallium nitrate solution is a solution formed by dissolving gallium nitrate in water, and dilute nitric acid is added dropwis...

Embodiment 3

[0053] The invention discloses a method for preparing a large-area two-dimensional gallium nitride film. A tube furnace with dual temperature zones is used as a reaction device. A porcelain boat with built-in urea and a ceramic boat coated with urea are respectively placed in the two temperature zones in the tube furnace. For the sapphire substrate of gallium nitrate solution, under the condition of protective atmosphere, the temperature of the porcelain boat and the sapphire substrate were respectively raised, and the heating rate was controlled to reach 130°C at the porcelain boat while the temperature at the sapphire substrate was 950°C. The decomposition product of gallium nitrate solution was vapor-phase deposited to form a large-area two-dimensional gallium nitride film.

[0054] In this embodiment, the gallium nitrate solution is coated on the sapphire substrate by spin coating, and the spin coating rate is 6000 RPM. The concentration of gallium nitrate solution is 20wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com