Patents

Literature

148 results about "Gallium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gallium nitrate (brand name Ganite) is the gallium salt of nitric acid with the chemical formula Ga(NO₃)₃. It is a drug used to treat symptomatic hypercalcemia secondary to cancer. It works by preventing the breakdown of bone through the inhibition of osteoclast activity, thus lowering the amount of free calcium in the blood. Gallium nitrate is also used to synthesize other gallium compounds.

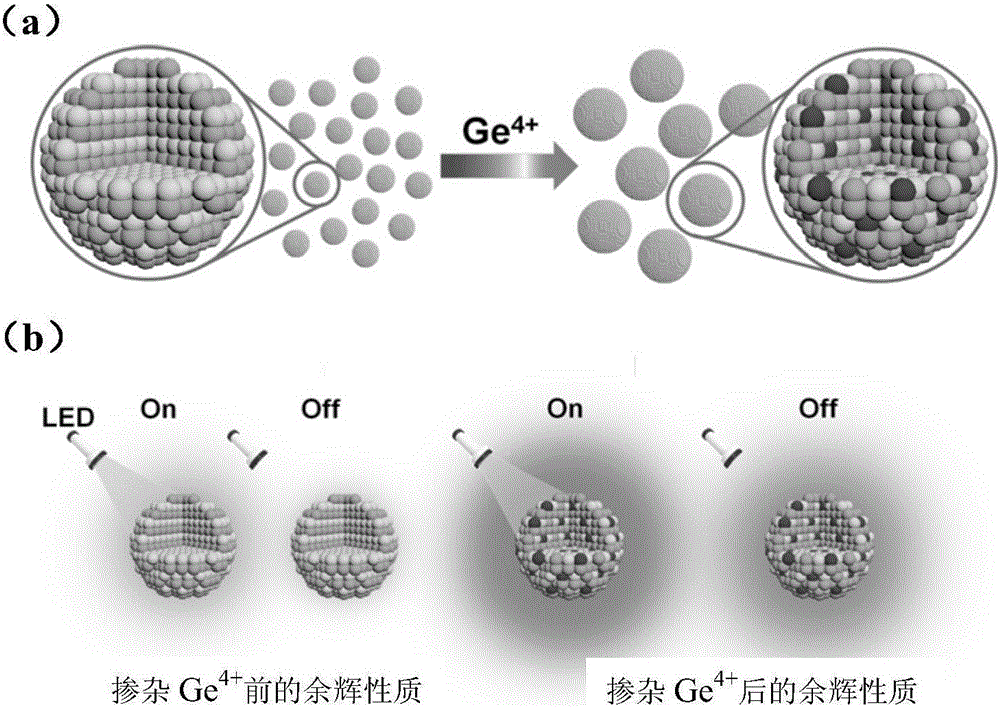

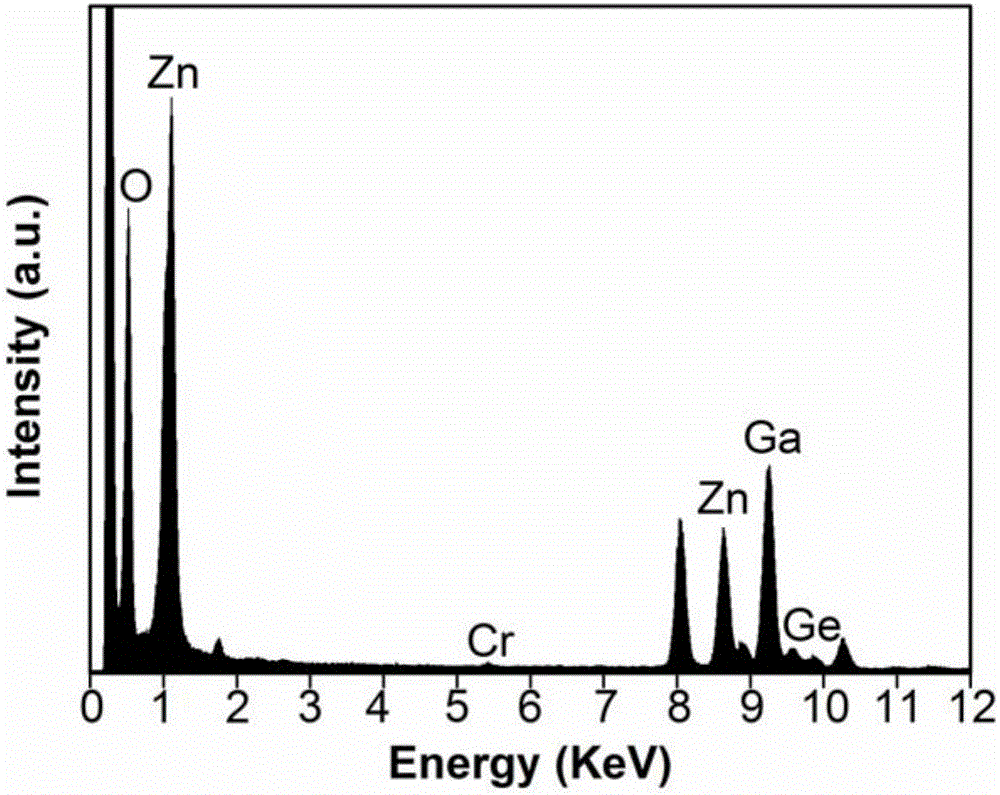

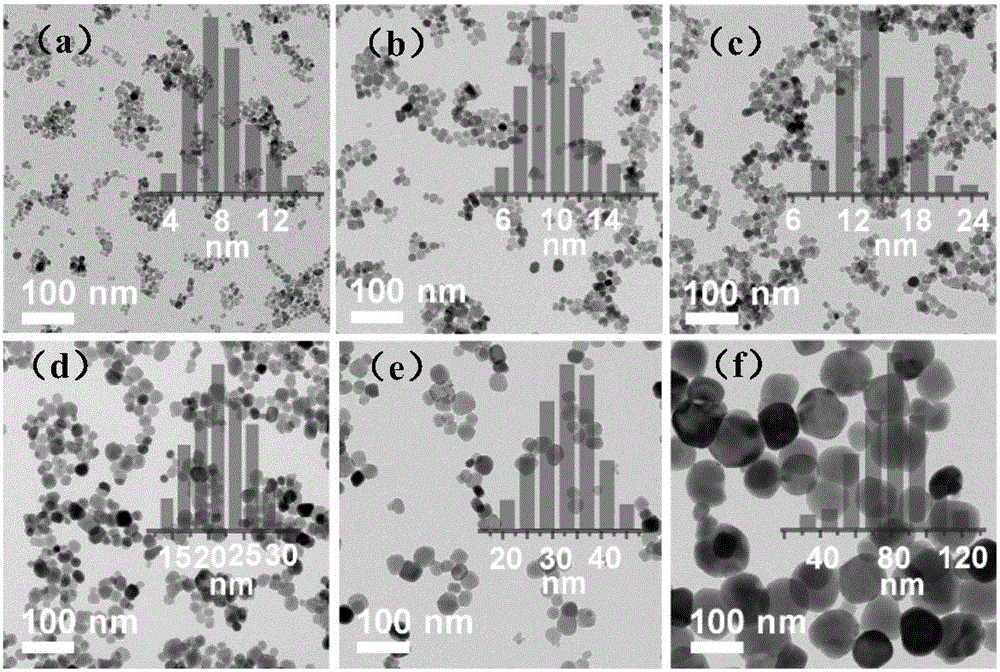

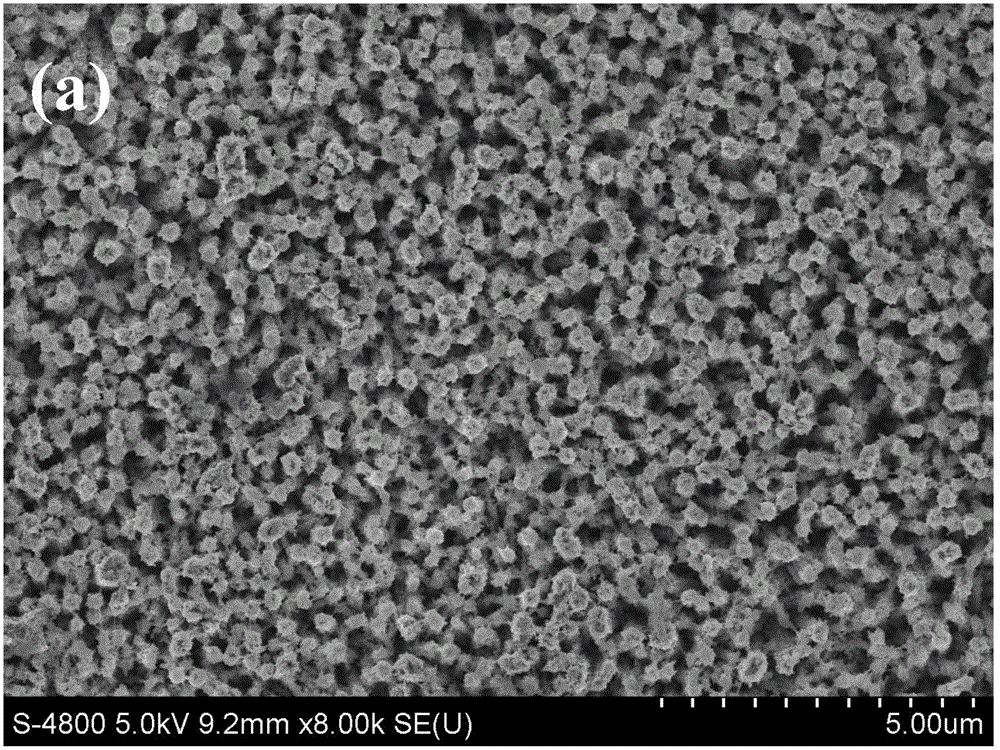

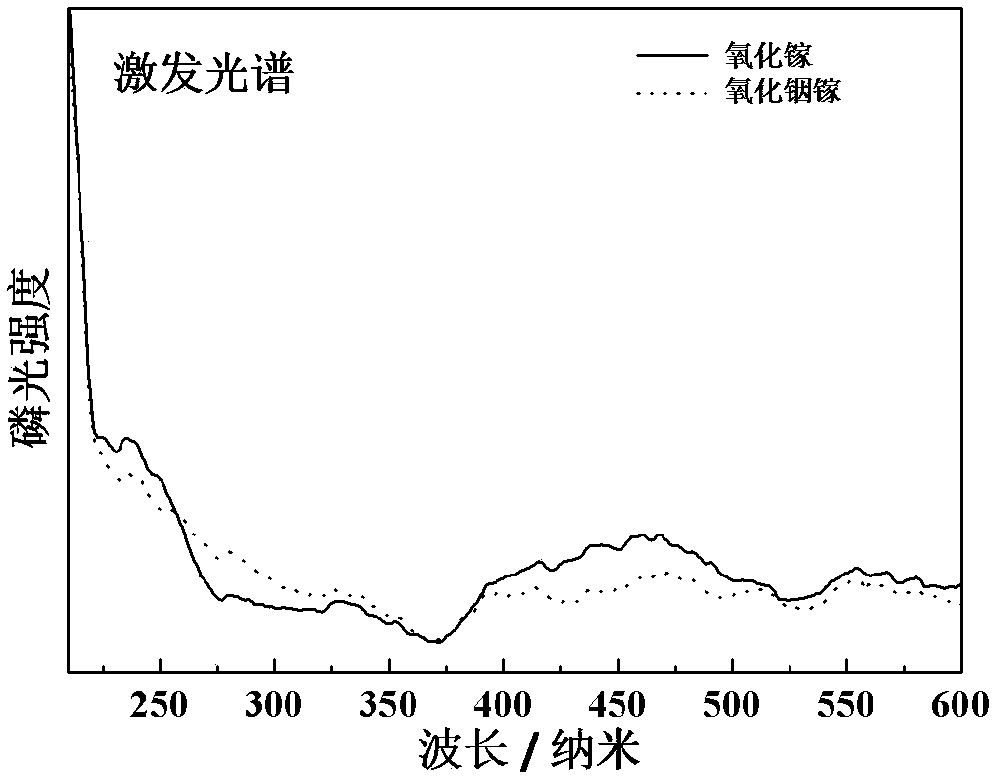

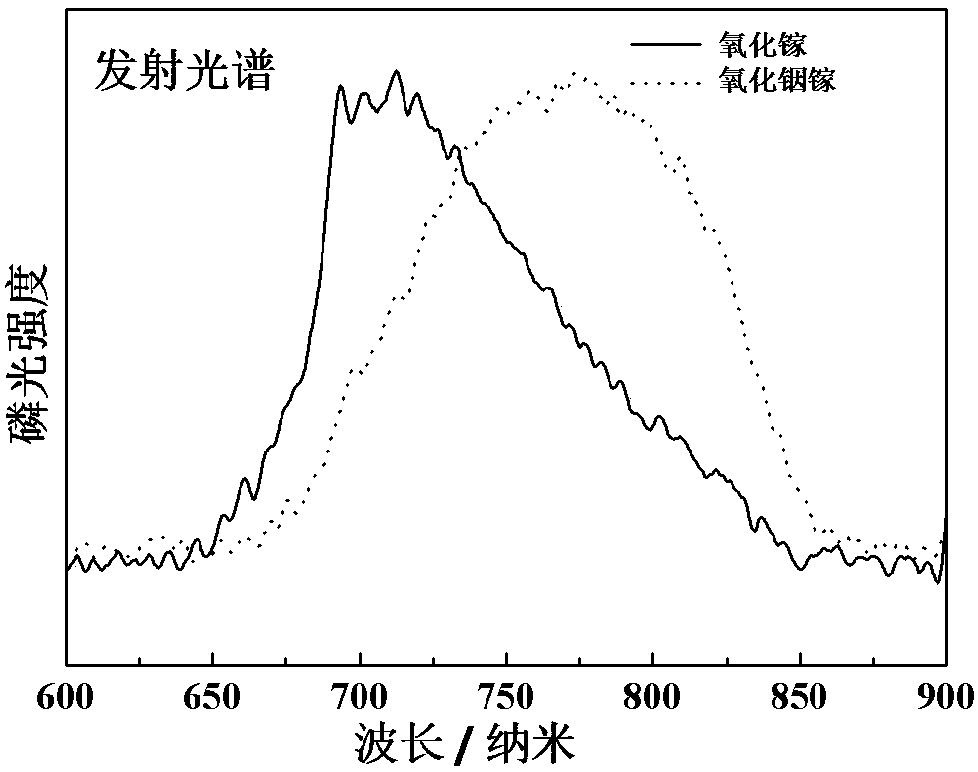

Long-afterglow nanomaterial based on ion doping as well as preparation method and application of long-afterglow nanomaterial

InactiveCN105754595AAbundant and easy to get raw materialsThe synthesis method is simpleIn-vivo testing preparationsLuminescent compositionsZinc nitrateChromium nitrate

The invention discloses an afterglow nanomaterial and a preparation method of a long-afterglow nanomaterial with sizes and spectrum adjusted on basis of ion doping. An expression formula of the nanomaterial is Zn(1+x)Ga(2-2x)GexO4:0.75%Cr, wherein x is larger than or equal to 0 and smaller than or equal to 0.5, and the particle size is 7 nm-80 nm. According to the preparation method, a zinc nitrate solution, a gallium nitrate solution, a sodium germinate solution and a chromium nitrate solution in specific proportions are mixed together, ammonia water is added rapidly while the mixture is stirred, and the pH of the mixed solution is adjusted to 10; then, the mixed solution is transferred to a high-temperature hydrothermal kettle and reacts at the temperature of 120 DEG C, and the afterglow nanomaterial is obtained. The method is simple and easy to implement, severe experiment conditions and complicated large instruments are not required, synthesized nanoparticles are uniform in sizes and have a good water-phase dispersion property and high afterglow strength, the afterglow time can reach 10 h, and accordingly, the synthesized nanoparticles are suitable for improving the physical and chemical properties of the long-afterglow nanomaterial.

Owner:WUHAN UNIV

Ultraviolet detector and preparation method thereof

InactiveCN106549079AGood light responseImprove stabilityFinal product manufactureSemiconductor devicesHexamethylenetetramineUltraviolet lights

The invention discloses an ultraviolet detector. A gallium oxide / zinc oxide based core shell nano-rod structure layer is arranged between a quartz substrate and a transparent contact electrode of the detector, wherein the contact electrode is an ITO conductive thin film which is deposited on a glass substrate and is provided with a 0.2cm channel; the gallium oxide / zinc oxide based core shell nano-rod structure layer is composed of a ZnO nano-array seed layer and a beta-Ga2O3 layer which grows on the surface of the ZnO nano-array seed layer, the beta-Ga2O3 layer is composed of a nano beta-Ga2O3 crystal with a spherical shape, and the average size of the nano beta-Ga2O3 crystal is 30nm. The core shell nano-rod structure layer can be used for preparing a beta-Ga2O3 / ZnO core shell nano-rod structure through the steps of taking the ZnO nano-array as a carrier, adopting gallium nitrate and hexamethylenetetramine as materials, firstly growing a GaOOH precursor on the surface of ZnO by using a low-temperature water solution, and then implementing high-temperature heating. The preparation method disclosed by the invention is simple in process and low in reaction temperature; and in addition, prepared products have very good photoresponse to the ultraviolet light.

Owner:DALIAN NATIONALITIES UNIVERSITY

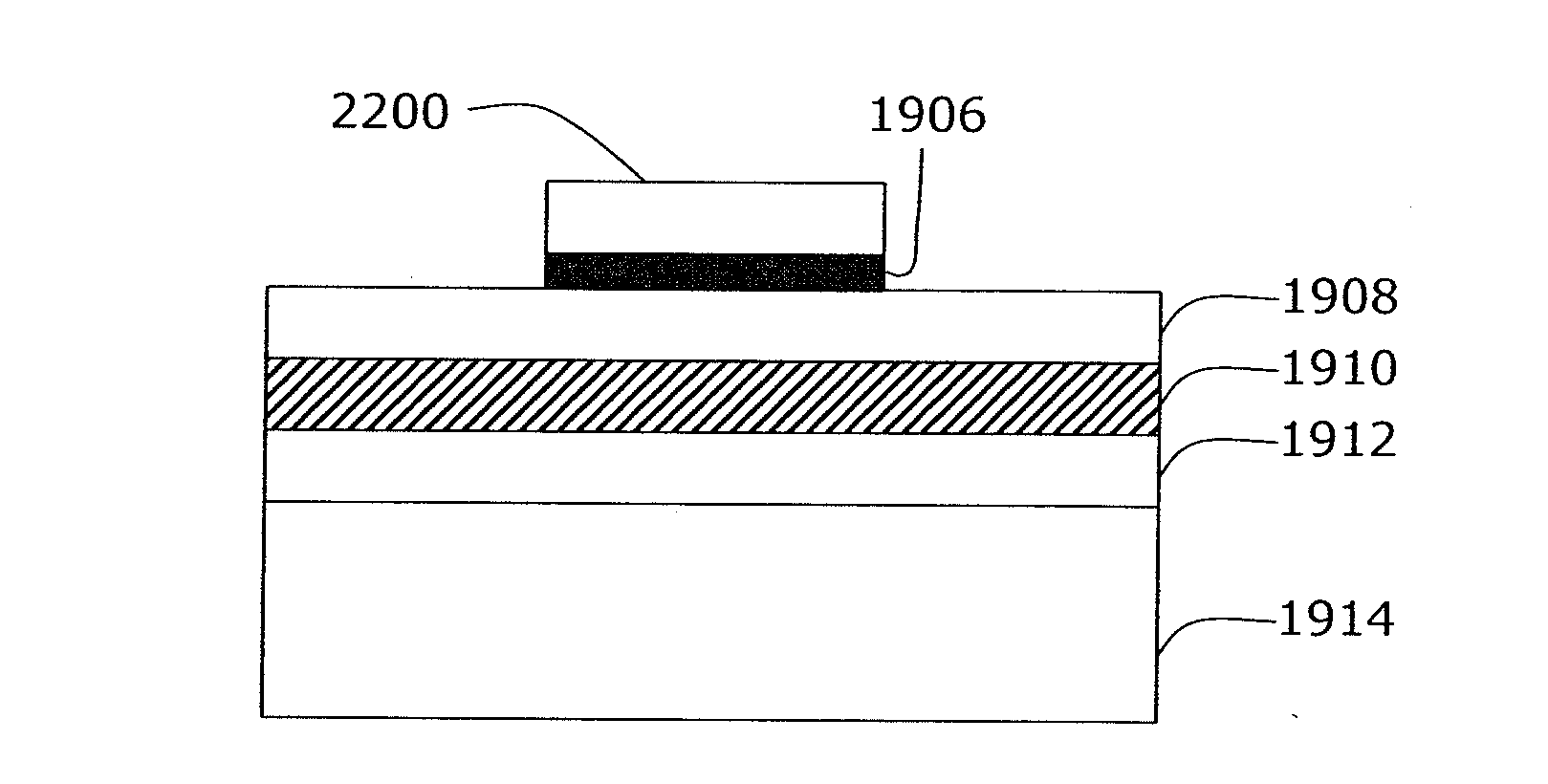

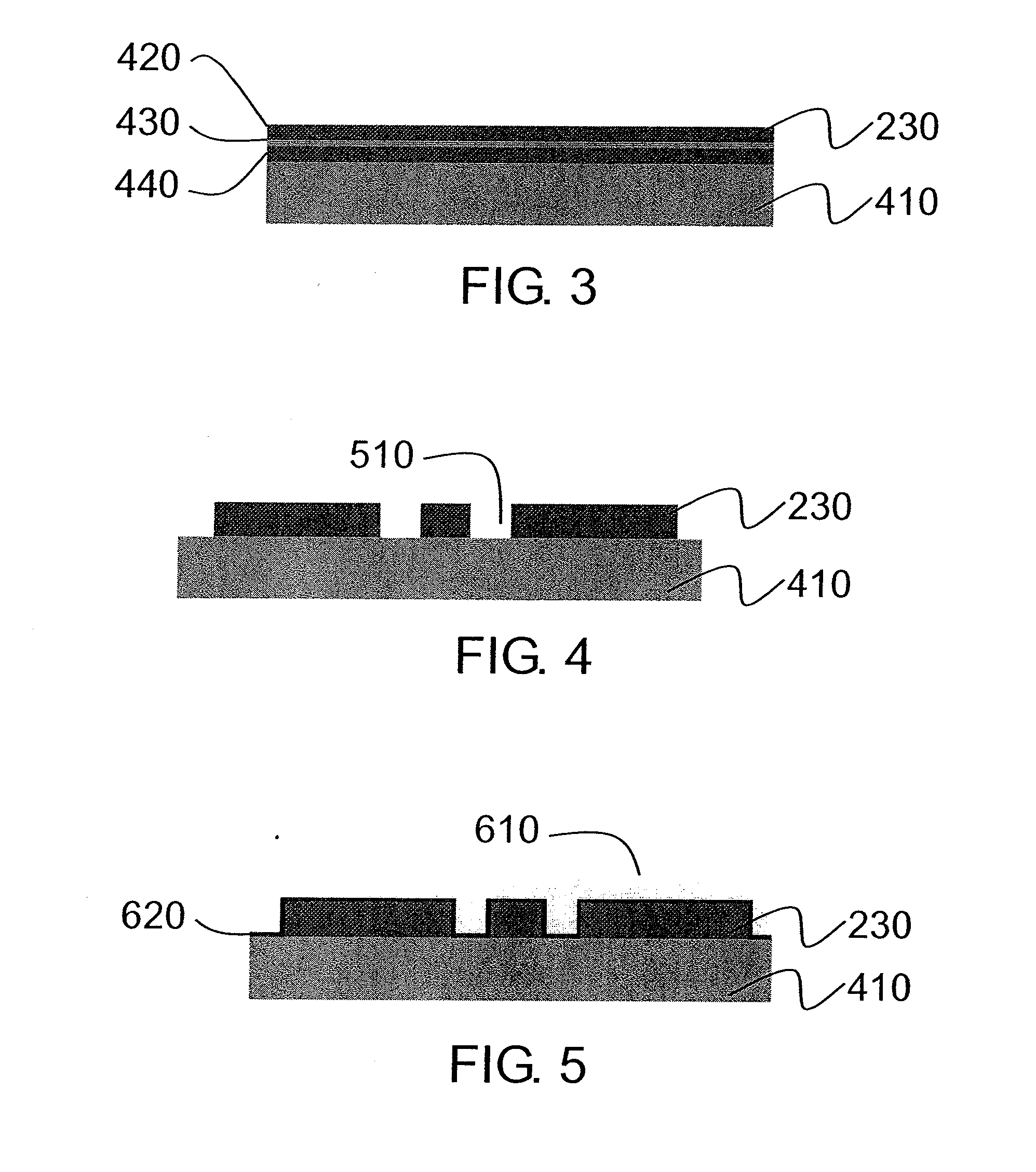

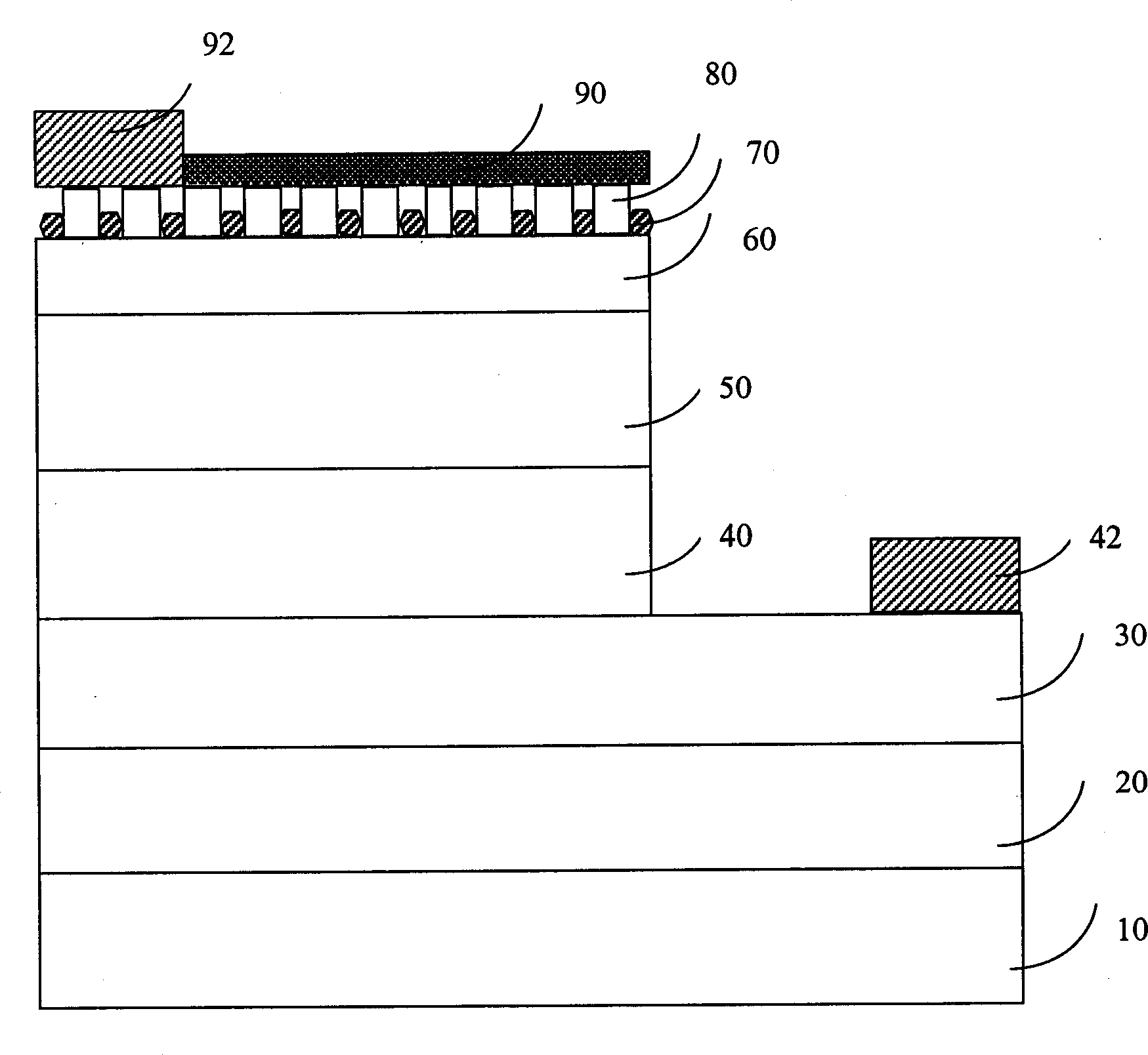

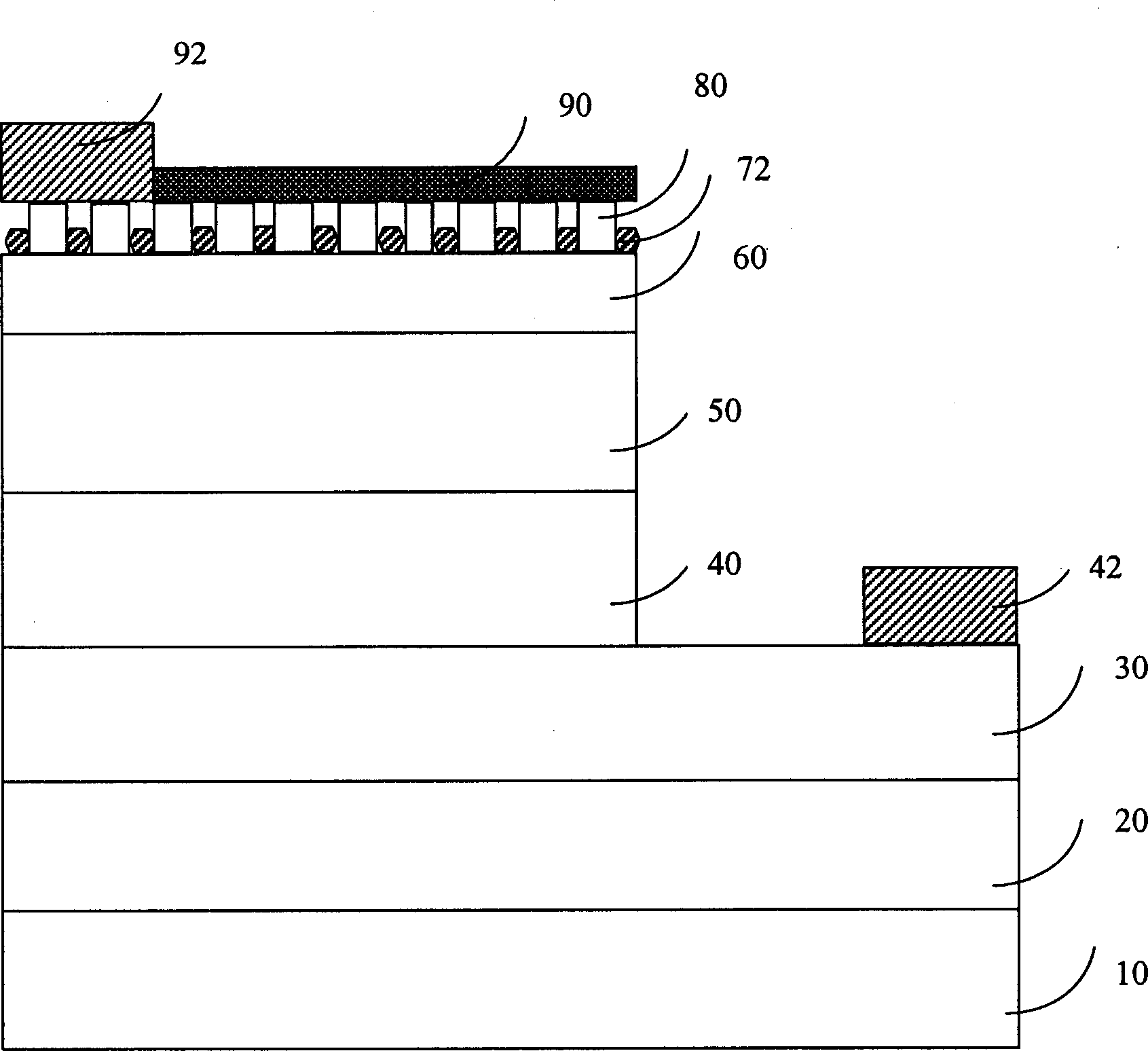

Vertical light emiting diode and method of making a vertical light emiting diode

ActiveUS20090039383A1Readily apparentSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringThinning

A vertical gallium-nitrate-based LED and method of making a vertical gallium-nitrate-based LED using a stop layer is provided. Embodiments of the present invention use mechanical thinning and a plurality of superhard stop points to remove epitaxial layers with a high level of certainty. According one embodiment, the method of making a vertical LED includes forming a plurality of layers on a sapphire substrate, forming a plurality of stop points in the plurality of layers, removing the sapphire substrate and part of a u-GaN layer using mechanical thinning, wherein the mechanical thinning stops at an end of the plurality of stop points, selectively etching the u-GaN layer and exposing at least a part of the highly doped stop layer, and forming an n-electrode on the highly doped stop layer.

Owner:HONG KONG APPLIED SCI & TECH RES INST

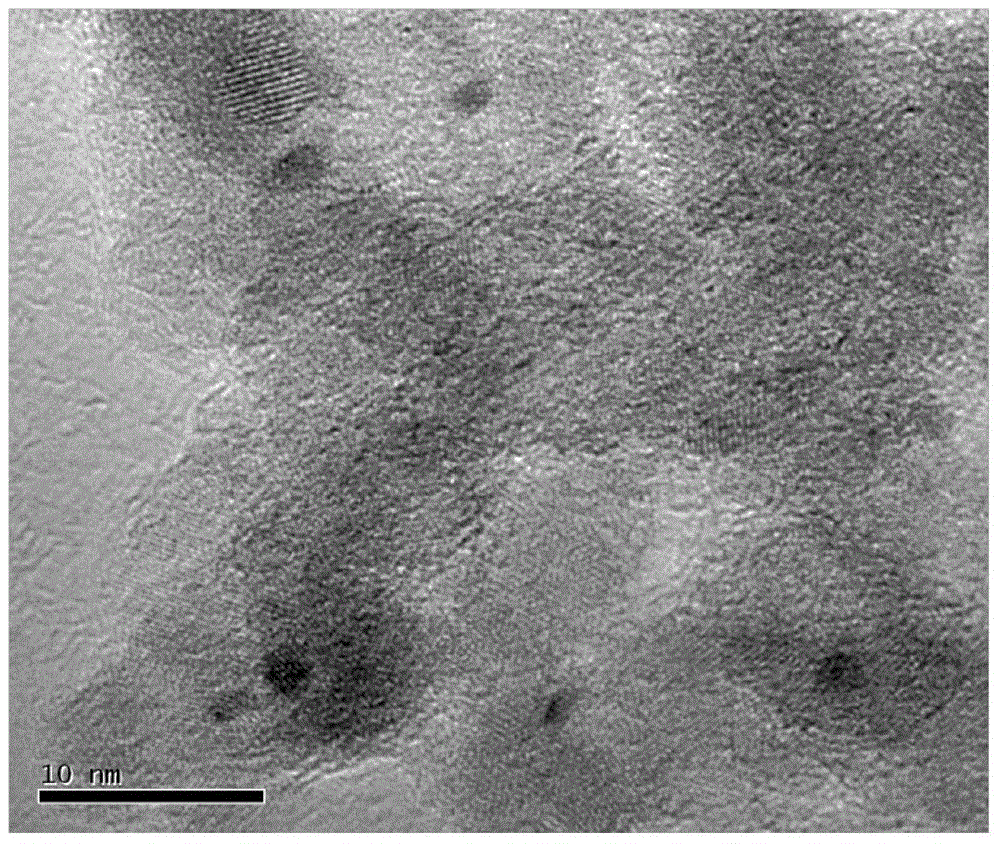

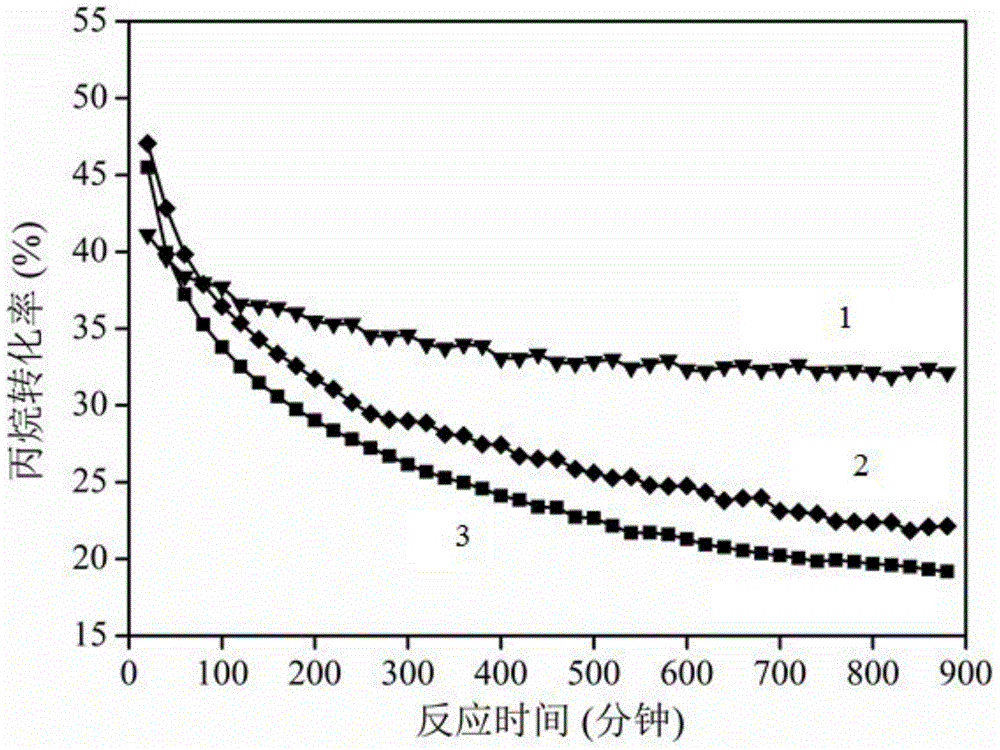

Platinum-gallium catalyst loaded on double-oxide composite carrier as well as preparation method and application of platinum-gallium catalyst

ActiveCN104525196AHigh selectivityImprove stabilityCatalyst carriersHydrocarbonsAlkaneCarbon storage

The invention discloses a platinum-gallium catalyst loaded on double-oxide composite carrier as well as a preparation method and an application of the platinum-gallium catalyst. A CeO2-Al2O3 double-oxide carrier is prepared by using CeO2-Al2O3 double-oxide as a carrier, Pt as an active component and Ga as an assistant in a leaching method; the obtained carrier is steeped into chloroplatinic acid and gallium nitrate solutions, is dried and baked to obtain the catalyst. The catalyst is suitable for low alkane dehydrogenized olefin under a hydrogen atmosphere. Taking propane dehydrogenized propylene as an example, because of the addition of CeO2, lattice oxygen is provided to help inhibiting carbon storage; alloys are formed by Ga and Pt to change acting force of products and reactants and Pt in activity center, and Ga is embedded into the lattice of CeO2, so that the oxygen storage and oxygen moving capability of CeO2 are improved. Because of the addition of CeO2 and Ga, the selectivity of propylene and the carbon storage resisting capability are improved, and the relatively-high reaction stability of the catalyst under a high-temperature condition is guaranteed.

Owner:TIANJIN UNIV

Nanometer gallium oxide and application thereof

InactiveCN103086420AEfficient removalEfficient degradationMaterial nanotechnologyGallium/indium/thallium compoundsWater bathsUltraviolet

The invention aims to provide a nanometer gallium oxide with high catalytic activity to perfluorocarboxylic acids and application of the nanometer gallium oxide. The nanometer gallium oxide is prepared by the following steps of: (1) solving gallium nitrate hydrate in water, and adding a surface regulating agent; (2) heating the prepared solution in the step (1) in water bath; (3) placing products prepared in the step (2) in a hydrothermal kettle, and heating under constant temperature; and (4) sintering the product of the hydrothermal kettle in the step (3) to finally obtain the nanometer gallium oxide product. According to the nanometer gallium oxide and the application thereof, disclosed by the invention, the prepared product is combined with ultraviolet rays of 185nm / 25nm so that the efficiency of degrading the perfluorocarboxylic acids in different water can be improved, and the perfluorocarboxylic acids in the water can be effectively removed.

Owner:TSINGHUA UNIV

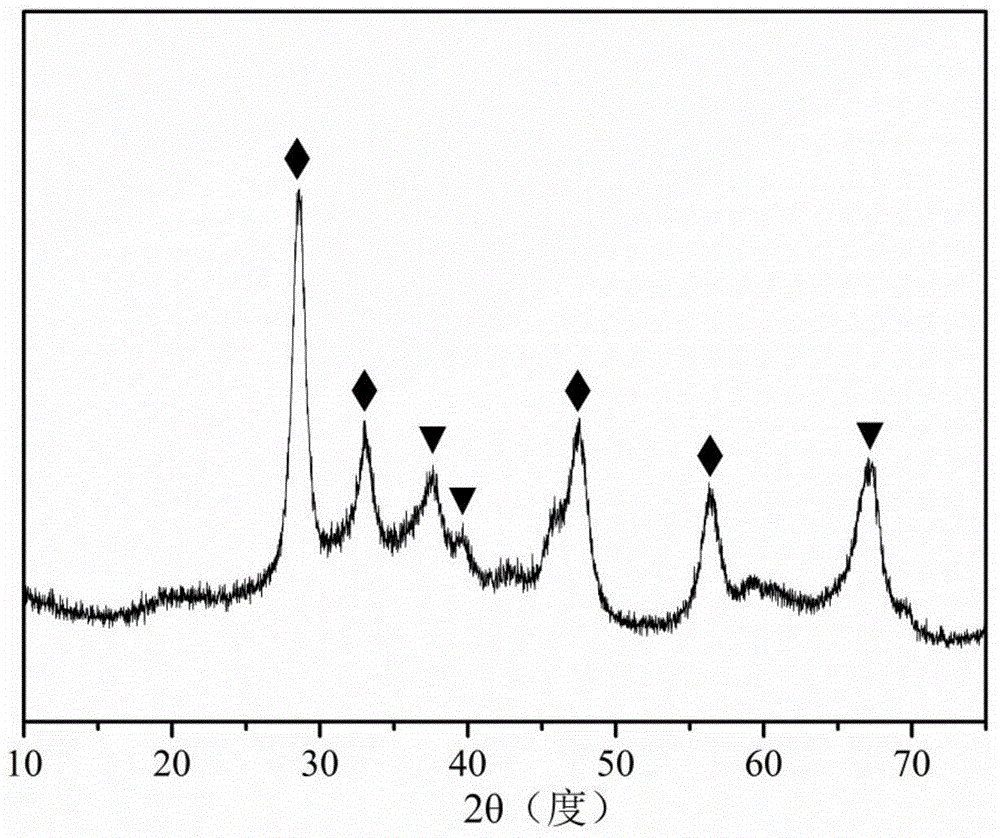

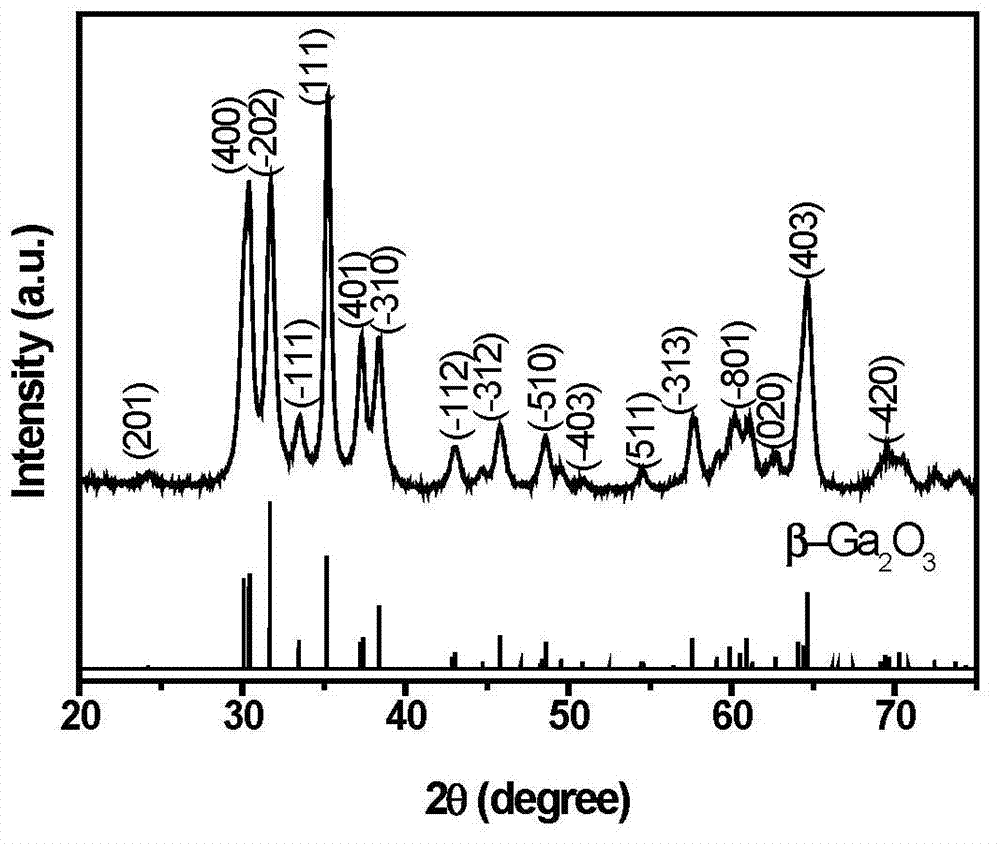

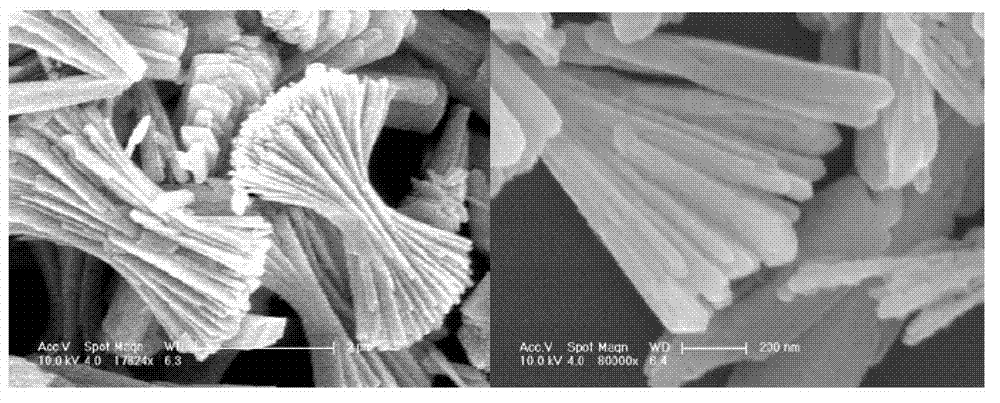

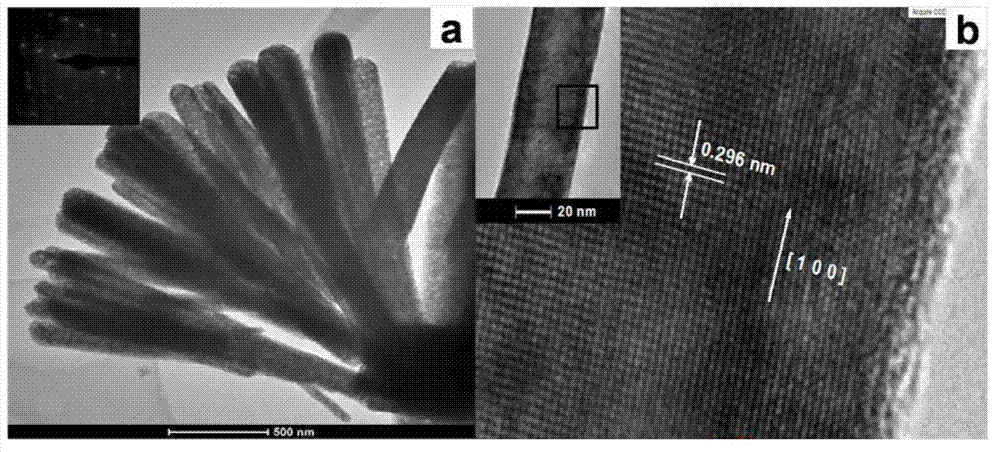

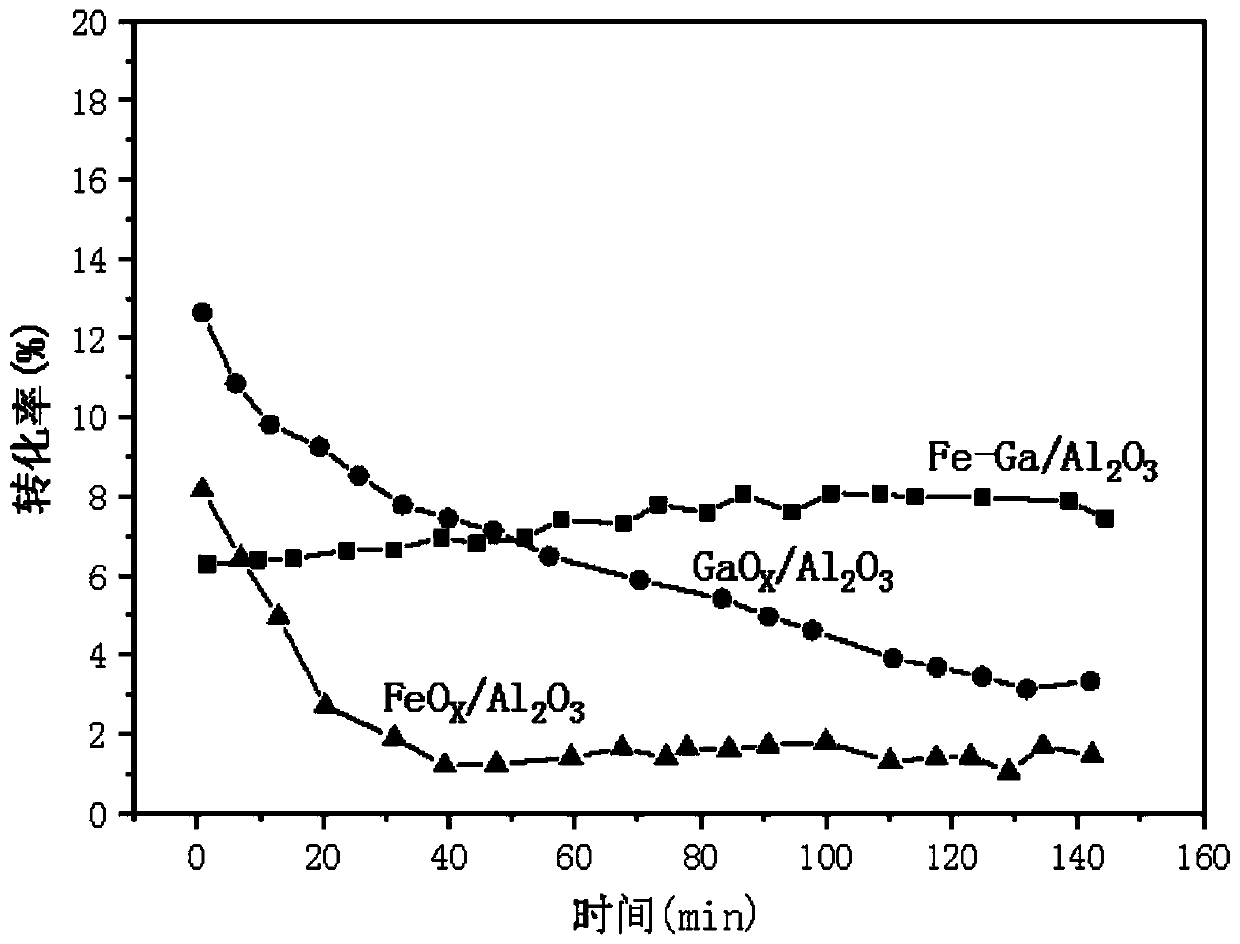

Iron-gallium-based propane dehydrogenation catalyst and preparation method thereof

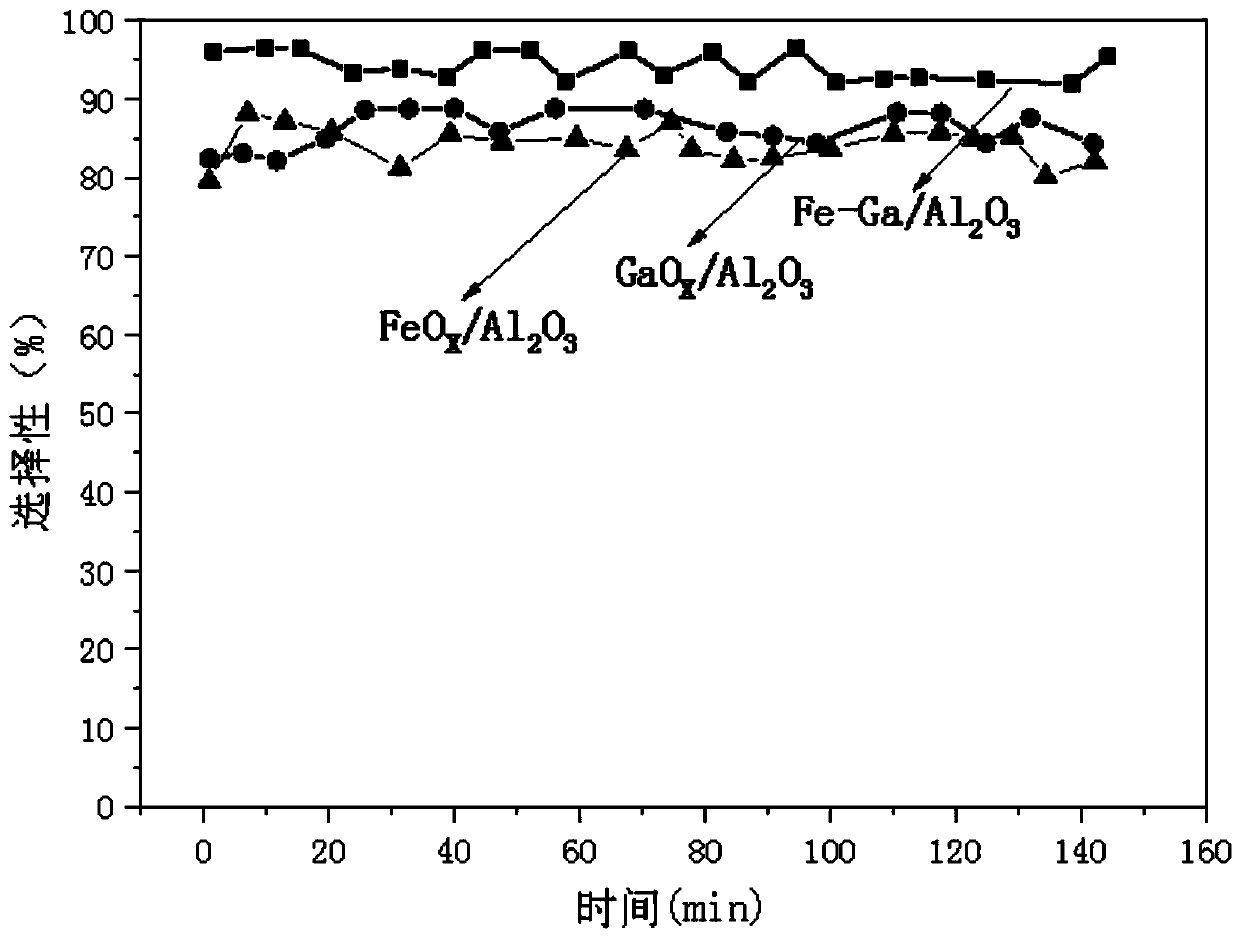

ActiveCN109939688AReduce typesImprove stabilityCatalyst activation/preparationHydrocarbonsDehydrogenationPore diameter

The invention provides an iron-gallium-based propane dehydrogenation catalyst, which uses alumina as a carrier, wherein the content of an iron element is 1-10wt% of the alumina carrier; the content ofa gallium element is 1-10wt% of the alumina carrier; the molar ratio of the iron element to the gallium element is 1: 4-6: 1; the content of an oxygen element is 47-52.5wt% of the alumina carrier; and the surface area of the alumina carrier is 50-200m <2> / g, the pore diameter is 10-20nm, and the pore volume is 0.4-0.5cm <3> / g. The preparation method of the catalyst comprises the following steps of: adding an alumina carrier into a gallium nitrate solution, uniformly stirring, adjusting the pH value to be 3-4, and standing and aging; adding a ferric nitrate solution, uniformly stirring, adjusting the pH value to be 5-7, and standing and aging; and filtering, washing, drying, reducing and annealing the precipitates to form the propane dehydrogenation catalyst. The iron-gallium-based propanedehydrogenation catalyst is high in conversion rate and selectivity and good in stability; and the preparation method is simple and easy to operate.

Owner:EAST CHINA UNIV OF SCI & TECH

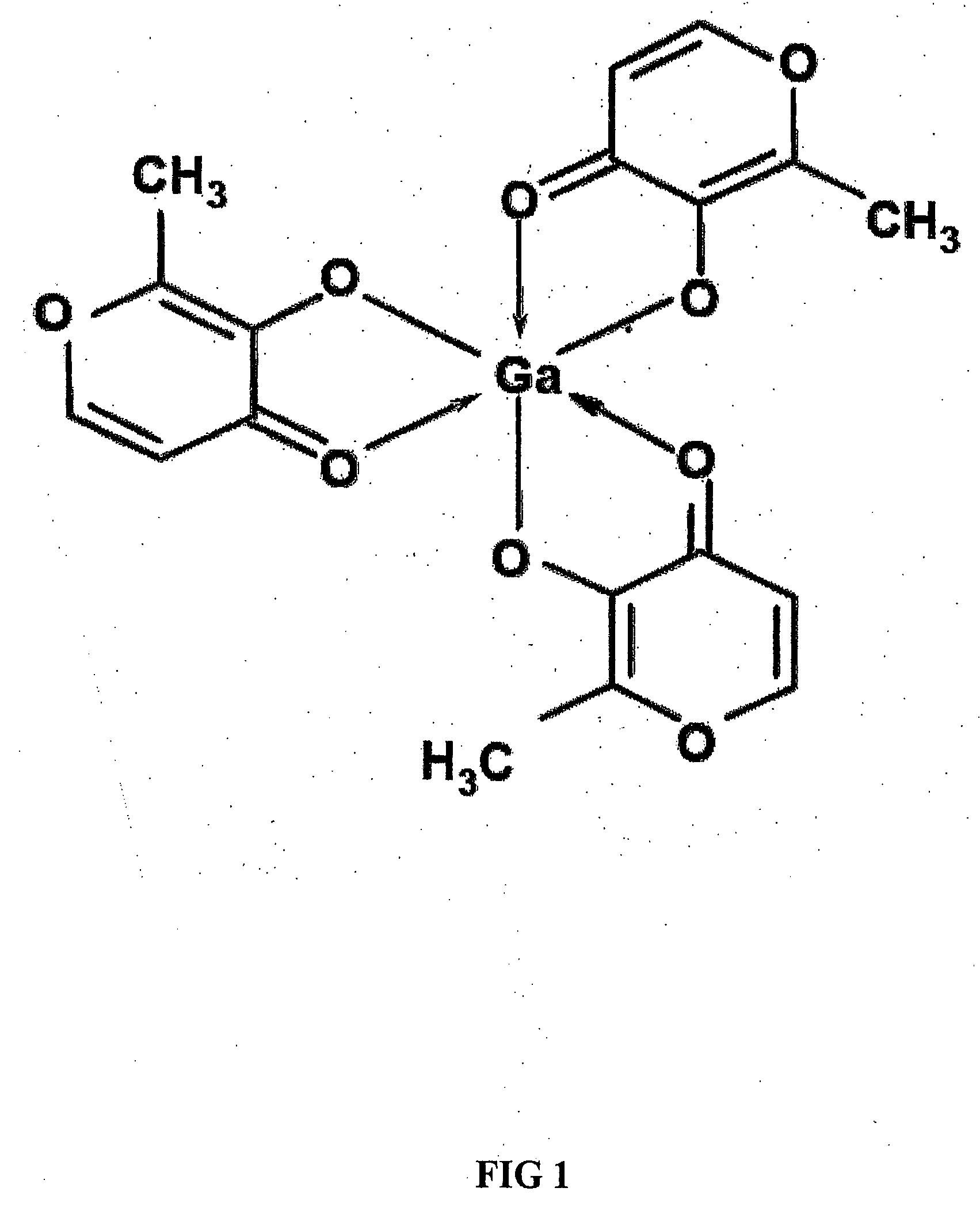

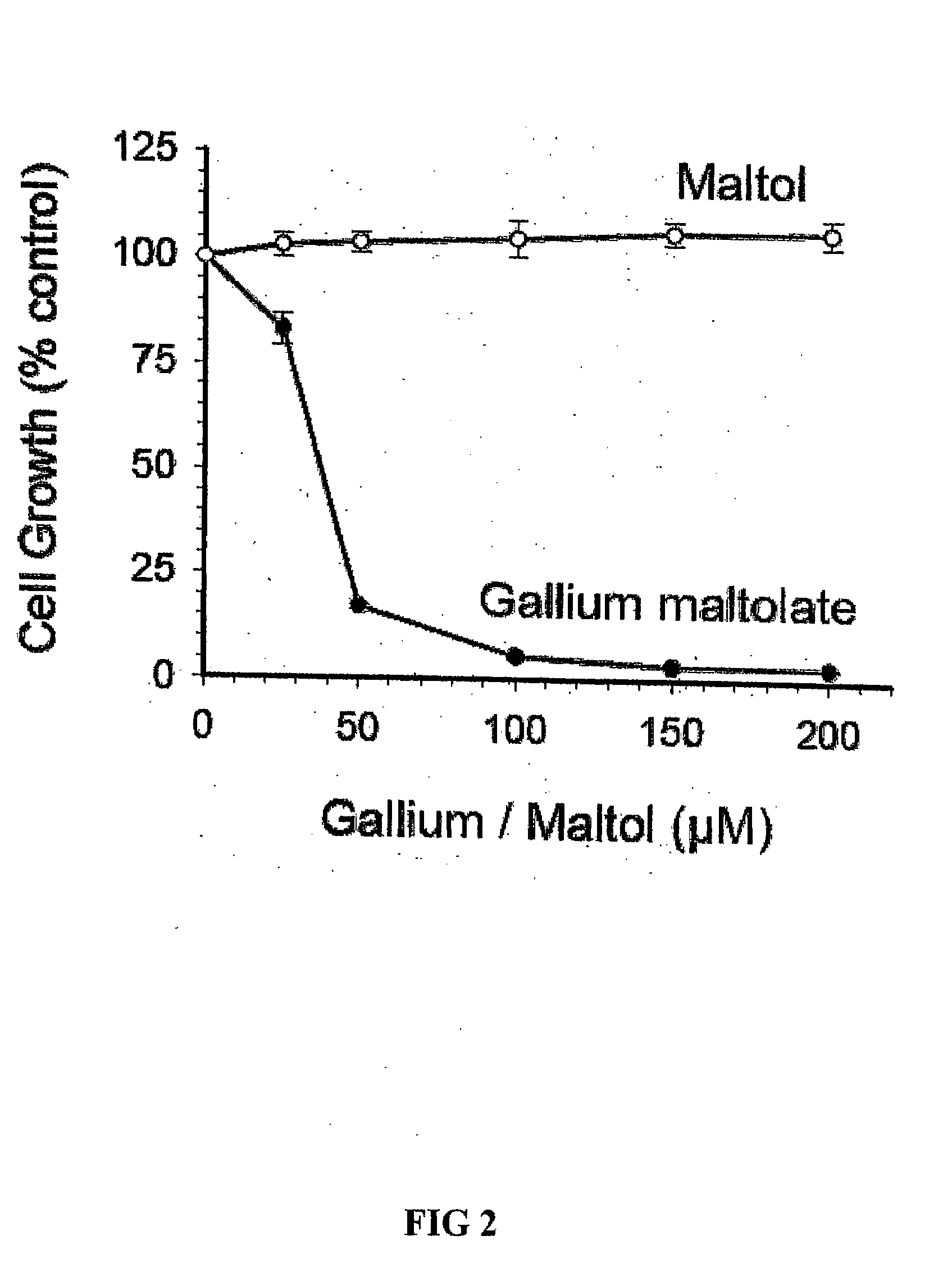

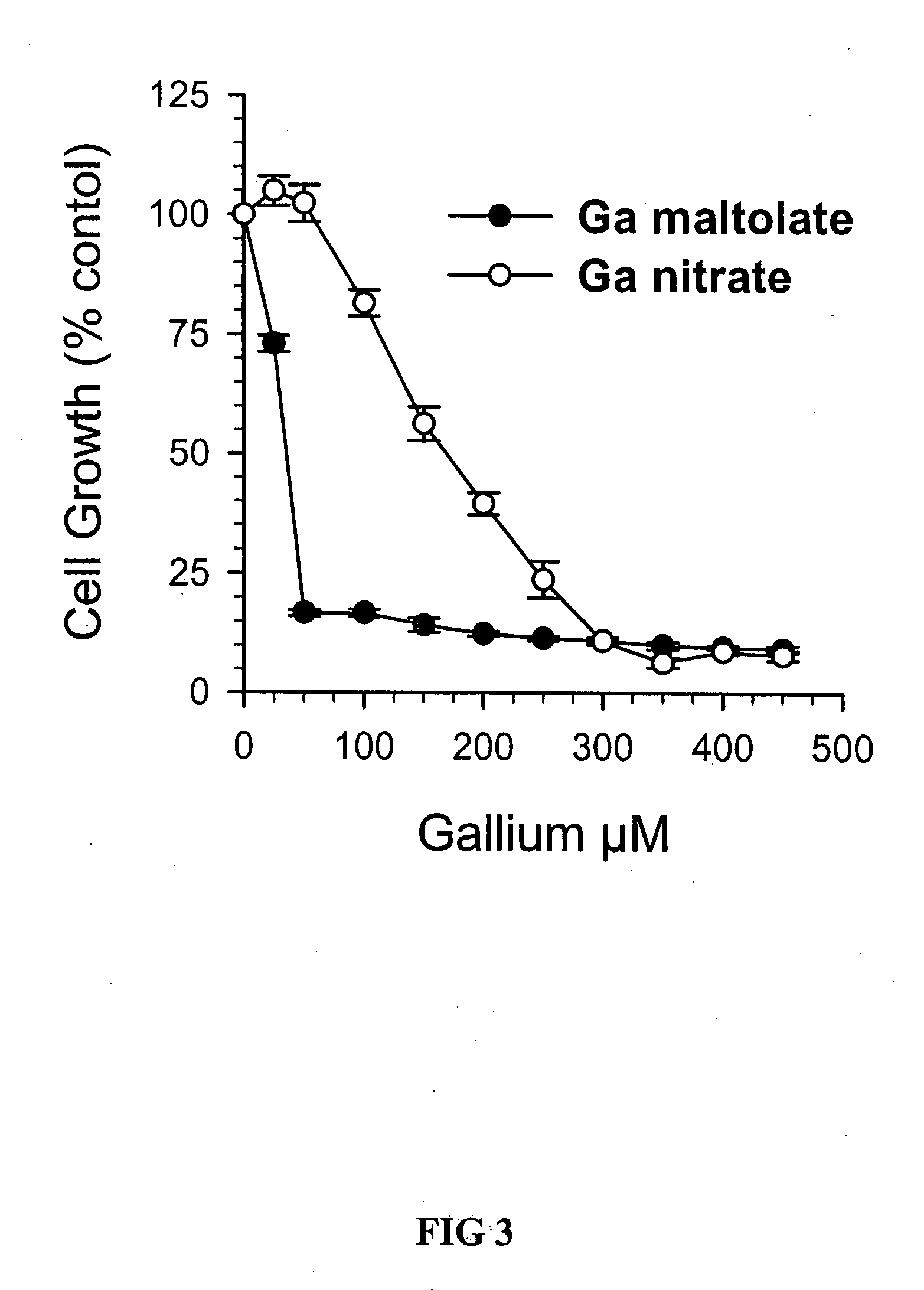

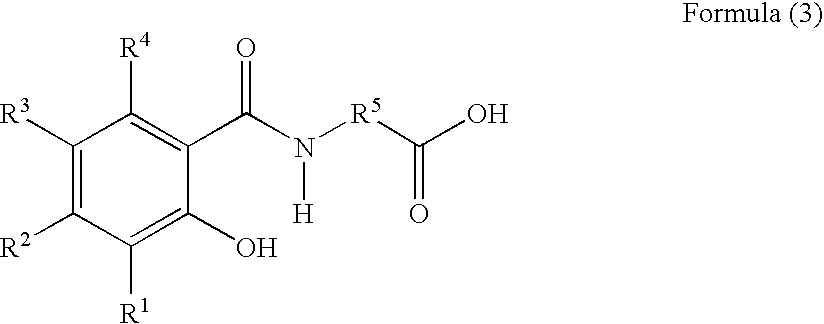

Method of treating gallium-nitrate resistant tumors using gallium-containing compounds

Owner:CHITAMBAR CHRISTOPHER R

Pharmaceutical Formulations of Gallium Salts

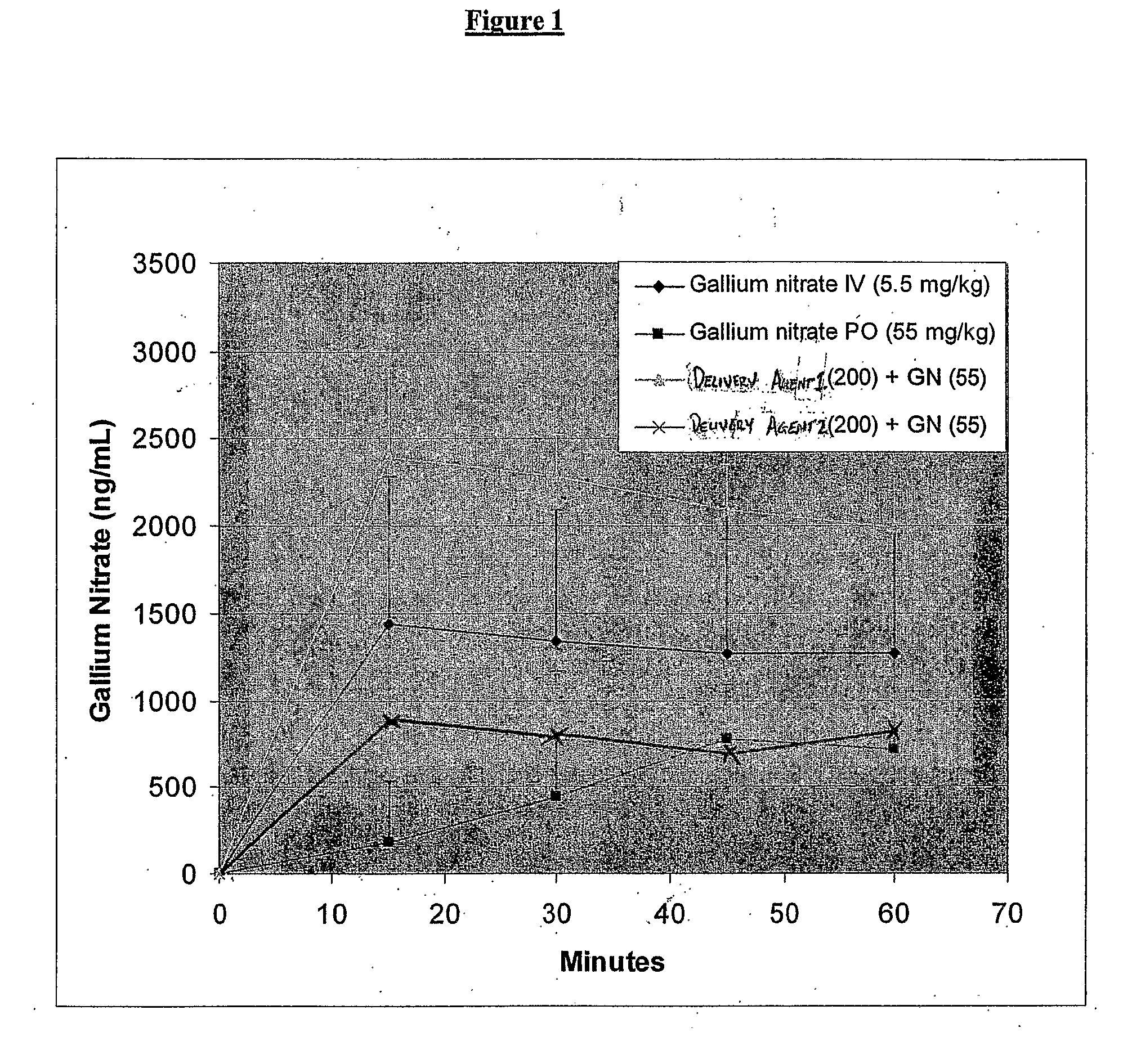

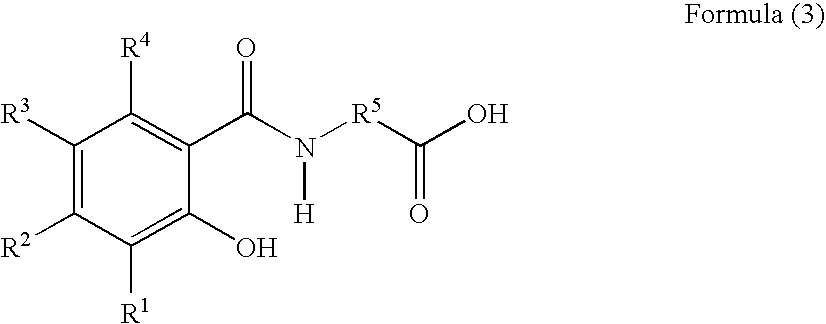

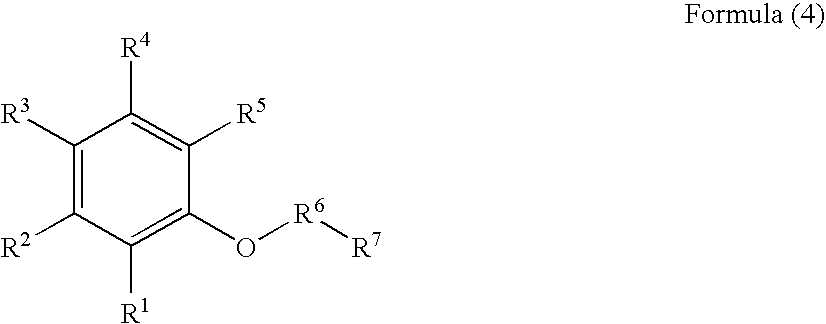

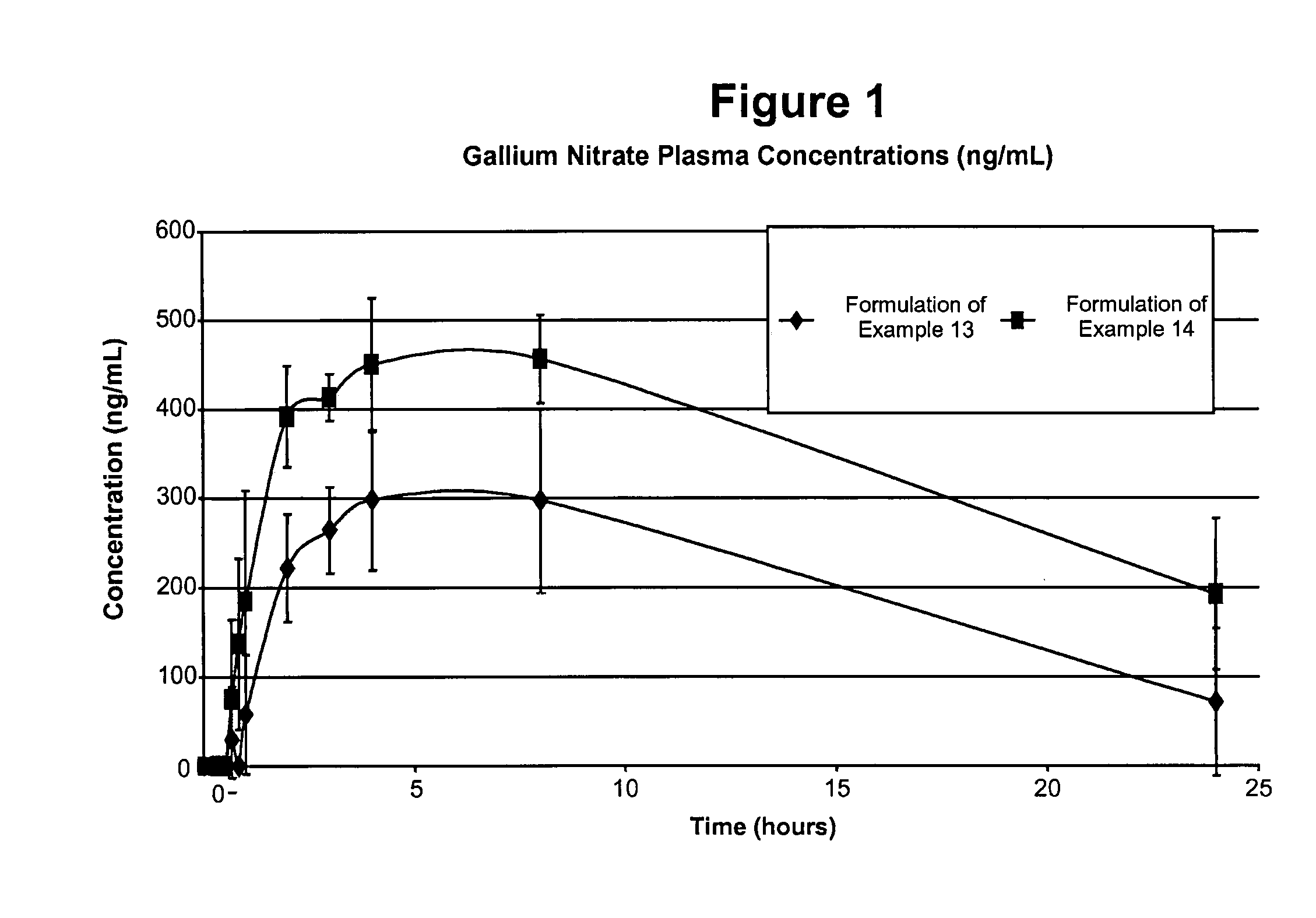

ActiveUS20090123562A1Reduce deliveryImprove bioavailabilityAntibacterial agentsHeavy metal active ingredientsPharmaceutical formulationGallium alloy

Owner:NOVO NORDISK AS

Gallium nitrate formulations

ActiveUS20100239658A1Prevent discolorationHeavy metal active ingredientsBiocideCombinatorial chemistryPharmaceutical medicine

Owner:D DUE DIV LASER +1

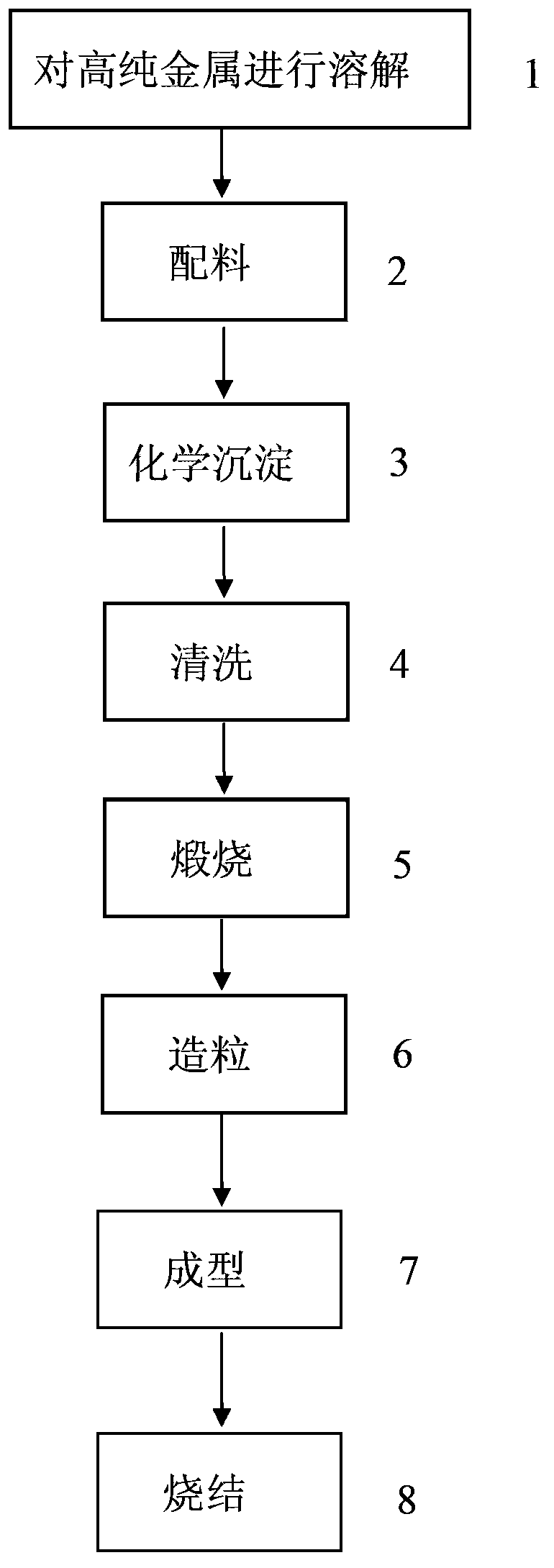

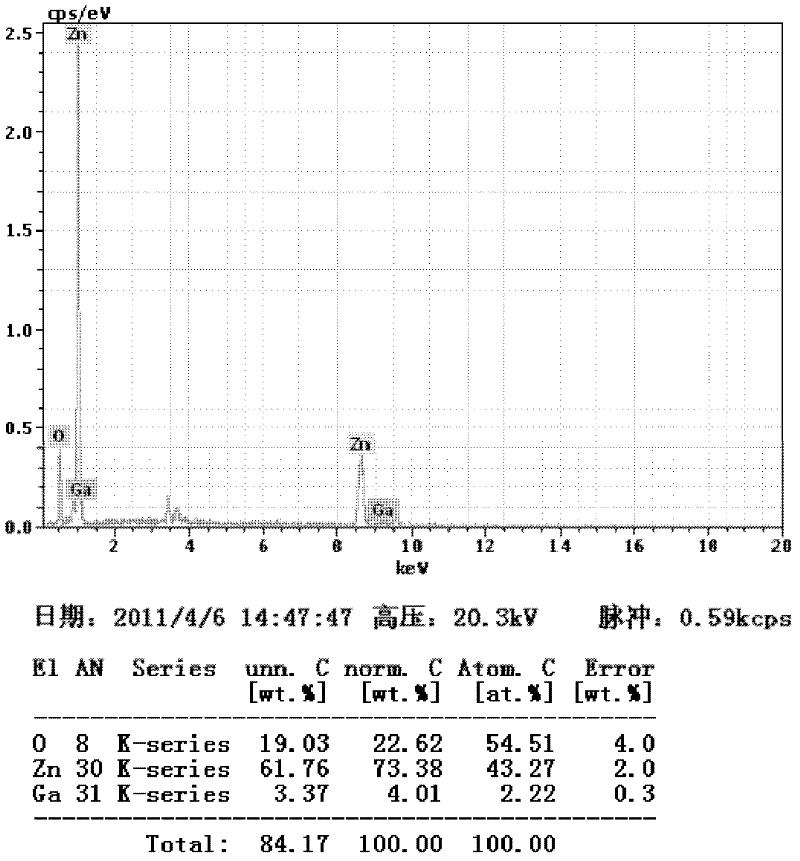

Aluminum-gallium co-doping zinc oxide nano-powder and preparation method for high intensity high conductivity sputtering coating target material thereof

InactiveCN103408062AImprove compactnessImprove conductivityZinc oxides/hydroxidesAdhesiveZno nanoparticles

The invention discloses aluminum-gallium co-doping zinc oxide nano-powder and a preparation method for a high intensity high conductivity sputtering coating target material thereof. The preparation method comprises the following steps: 1, dissolving high pure metal so as to form transparent aluminum nitrate, zinc nitrate and gallium nitrate solutions; 2, dosing: putting the three kinds of solutions in containers respectively according to the proportion; 3, performing chemical precipitation: mixing the transparent solutions as per proportion and specified procedures through adopting the homogeneous precipitation method so as to prepare aluminum-gallium co-doping zinc oxide nano-powder; 4, cleaning: washing the mixed precipitate via deionized water, and fully stirring till no other irons exist in the mixture; 5, calcining: putting the nano-powder into a high temperature furnace for calcination to obtain the aluminum-gallium co-doping zinc oxide nano-powder; 6, prilling: adding adhesive into the aluminum-gallium co-doping zinc oxide nano-powder and drying to obtain aluminum-gallium co-doping zinc oxide nano-powder to be formed; 7, forming: pressing the aluminum-gallium co-doping zinc oxide nano-powder to be formed into the initial blank; 8, sintering: putting the initial blank into the high temperature furnace for free pressure sintering or gas pressure sintering.

Owner:BEIHANG UNIV +1

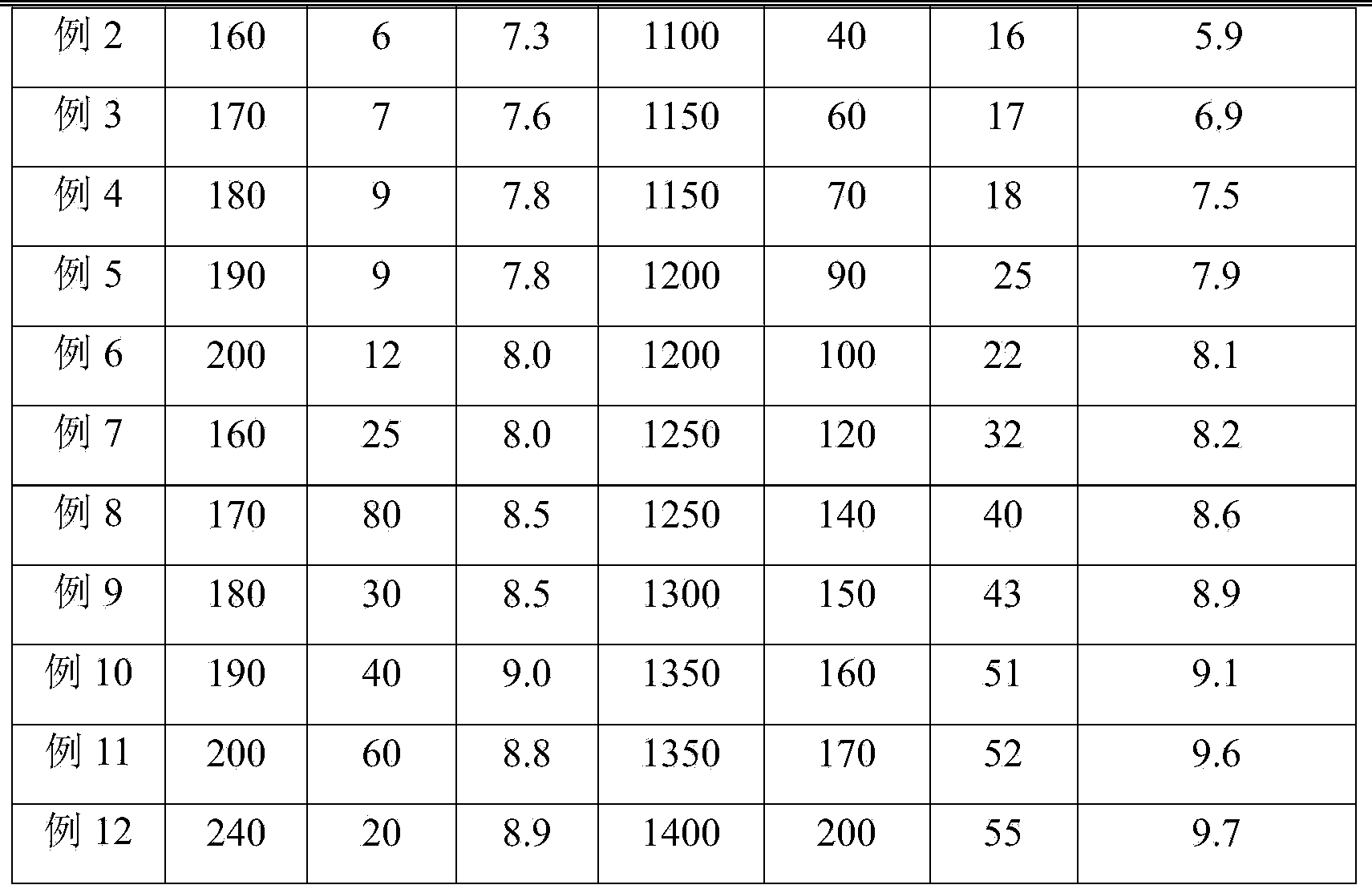

Large-discharge-current-capacity low-residual-voltage high-gradient zinc oxide piezoresistor ceramic

The invention relates to a large-discharge-current-capacity low-residual-voltage high-gradient zinc oxide piezoresistor ceramic. The invention is characterized in that the ceramic comprises the following formula components: zinc oxide ZnO, bismuth oxide Bi2O3, antimony trioxide Sb2O3, manganese peroxide MnO2, chromic oxide Cr2O3, cobaltic oxide Co2O3, silicon dioxide SiO2, silver oxide Ag2O, gallium nitrate Ga(NO3)3 and yttrium nitrate Y(NO3)3. By using the ceramic, the leakage current is inhibited; and by adding the Y and Ga elements, the ZnO piezoresistor prepared according to the formula has more stable aging resistance, thereby overcoming the defect that the leakage current can not be inhibited when the single Ag ions are added.

Owner:TSINGHUA UNIV

High brightness gallium nitrate kind LED structure

InactiveCN1787241AAvoid Total Internal ReflectionImprove external quantum efficiencySemiconductor devicesQuantum efficiencyRefractive index

The invention advances a structure of high brightness GaN LED, which uses silicon nitride, magnesium nitride or silicon- and magnesium- highly doped aluminum gallium indium nitride to form a mask buffer layer comprising plural random distributed crowded masks, then growing a p-type rough contact layer composed of p-type aluminum gallium indium nitride which is not directly grown on the mask buffer layer but grown from the top surface of the part of the p-type contact layer unmasked by the mask buffer layer, and not stop growing the p-type rough contact layer until it extends to exceed the masks of the buffer layer by a certain height. The structure can roughen the surface of the GaN LED, avoiding the inner all reflection and then raise the outer quantum efficiency and light emitting efficiency.

Owner:FORMOSA EPITAXY INCORPORATION +1

Preparation method of long afterglow nanocrystal with controllable emission wavelength

ActiveCN107674673ALong afterglowEmission wavelength controllableGallium/indium/thallium compoundsNanoopticsIndium TrichlorideMuffle furnace

The invention discloses a preparation method of a long afterglow nanocrystal with controllable emission wavelength. The long afterglow nanocrysta is prepared by adopting an ethylene glycol assisted hydrothermal route. The method comprises the following steps: taking ethylene glycol as an assistant, and taking a gallium nitrate solution and an indium trichloride solution as a substrate; doping a chromium ion mixed solution and uniformly stirring; carrying out special water treatment at the temperature of 170 DEG C, and carrying out centrifugal separation and vacuum drying; finally, calcining aproduct in a muffle furnace at the temperature of 700DEG C and 1000DEG C in sequence, thus obtaining the long afterglow nanocrystal with the average particle size of about 20 nanometers and the adjustable emission wavelength. The preparation method disclosed by the invention has the advantages that the long afterglow nanocrystal prepared by the method has excellent properties of smaller size, controllable emission wavelength within a near infrared light zone (about 770 nanometers), long afterglow and the like; the preparation method has the characteristics of simple operation, low cost, no reductive atmosphere in the preparation process and no pollution to the environment.

Owner:喀什大学

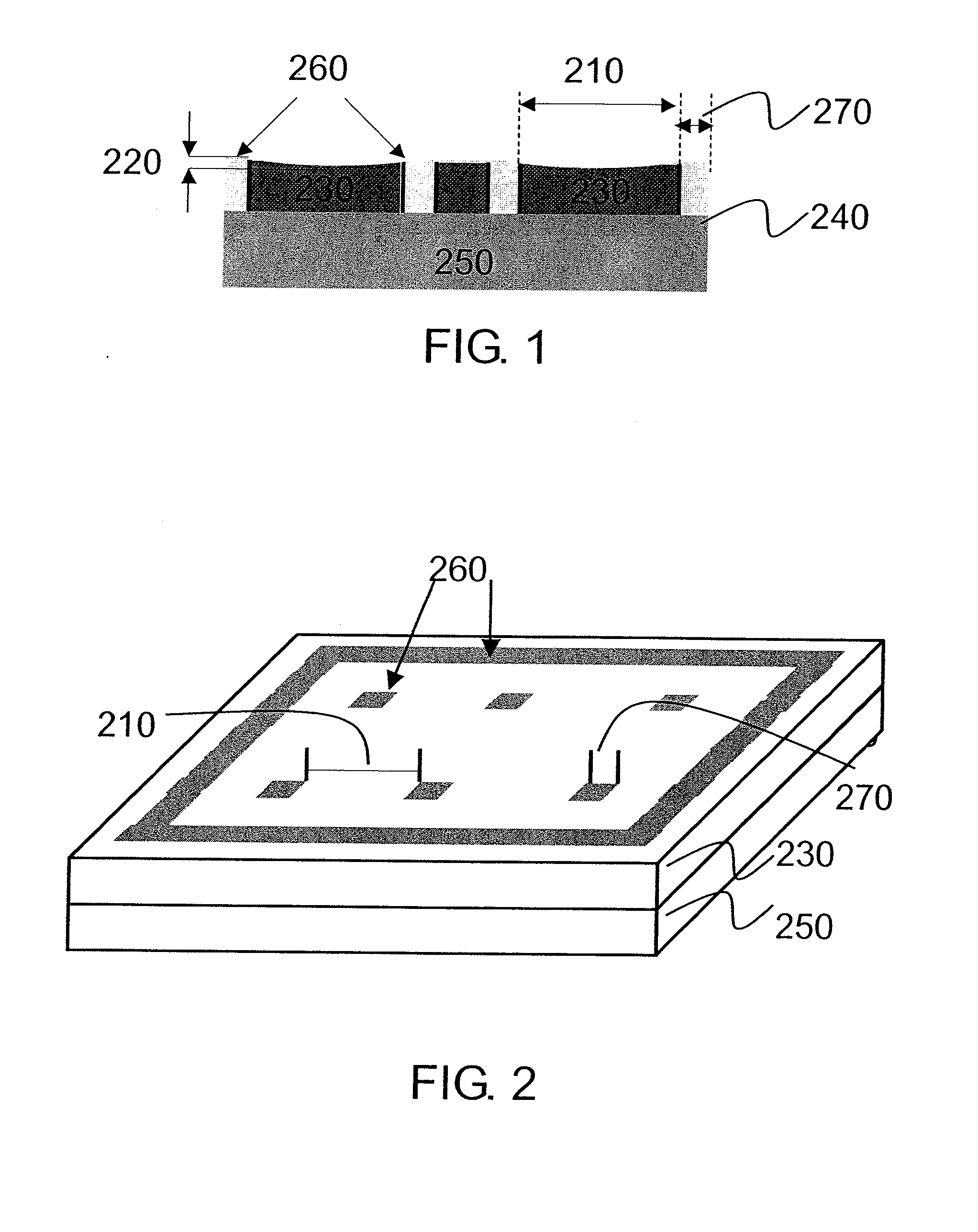

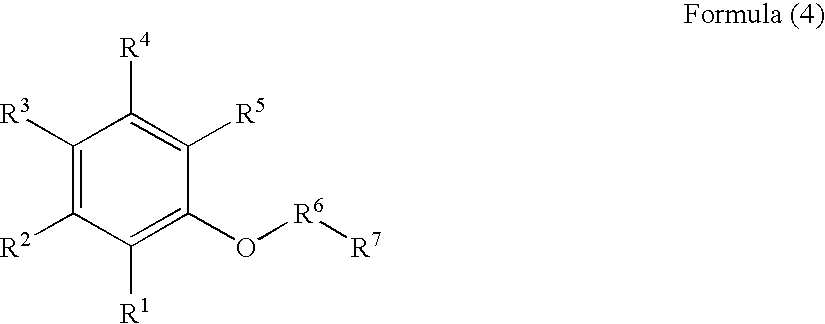

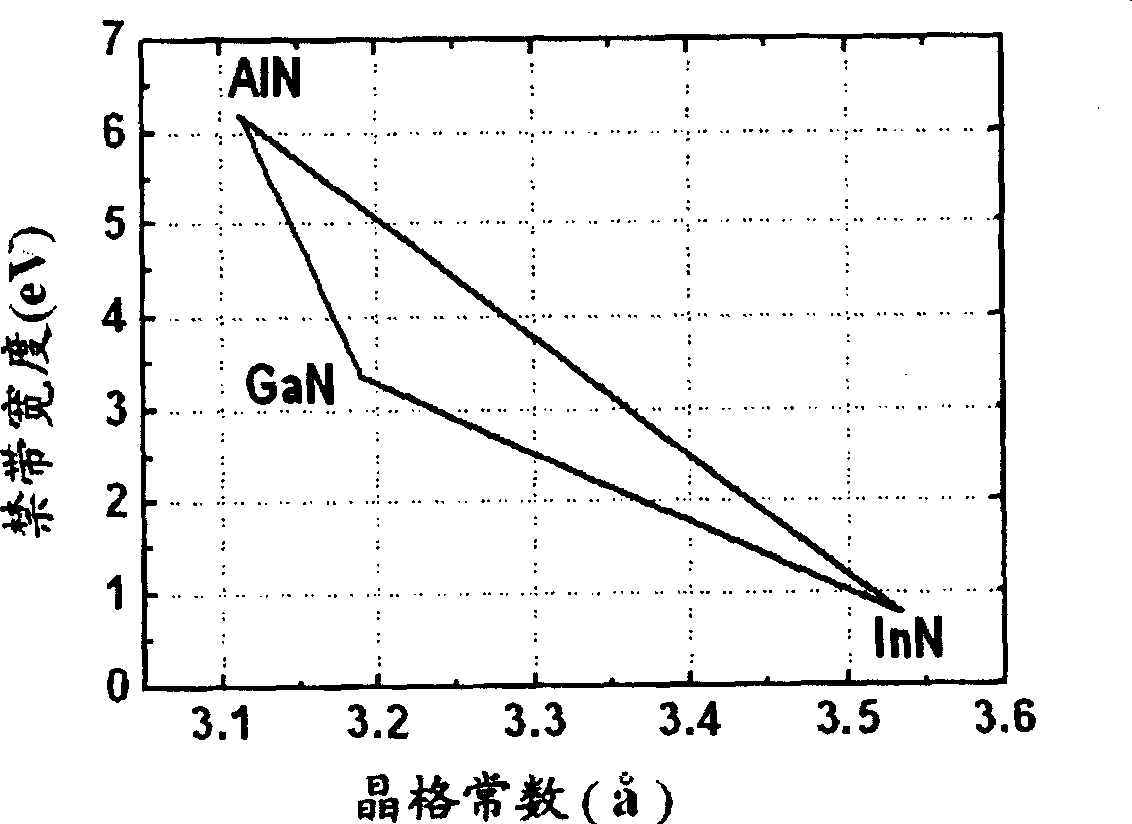

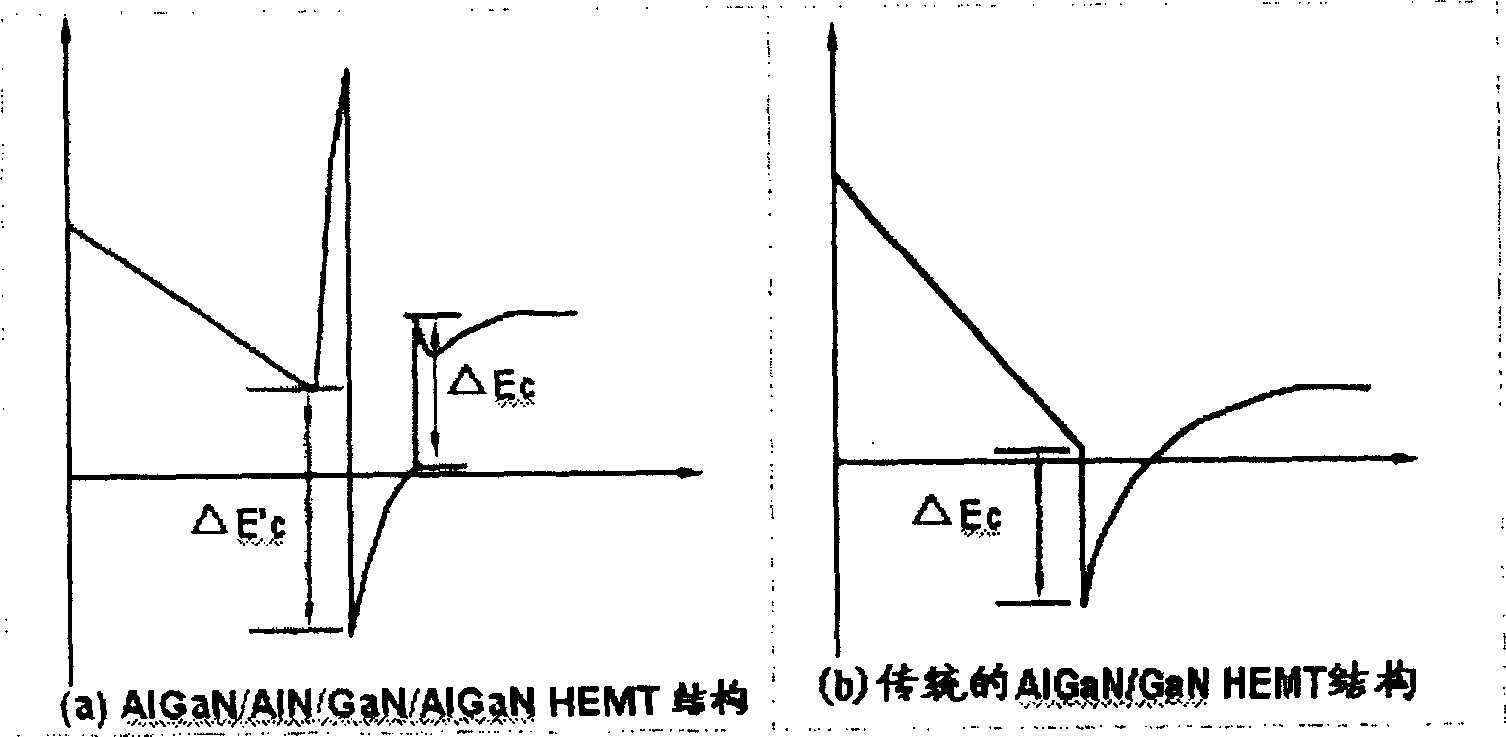

Crystal tube structure with high electronic shifting ratio of gallium nitrate base of double heterogenous structure and mfg. method thereof

InactiveCN1787229AControl leakageIncrease concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceGallium nitride

The invention is a double-heterostructured GaN-base high-electron migration rate transistor structure, characterized in comprising: a sapphire, silicon carbide or silicon substrate; a high resistance GaN buffer layer made on the substrate; a thin unpurposed doped GaN insert layer made on the buffer layer; a high-migration rate GaN channel layer made on the thin unpurposed doped GaN insert layer; a thin AlN insert layer made on the channel layer; a n-type doped or unpurposed doped Al-Ga-N barrier layer made on the thin AlN insert layer.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for preparing textured ZnO membrane with pyramid-like structure

InactiveCN101562216ANo pollutionFinal product manufactureLiquid/solution decomposition chemical coatingChemical productsSolvent

The invention relates to a method for preparing a textured ZnO membrane with a pyramid-like structure. The method comprises the following steps: taking zinc acetate as a Zn source, indium nitrate or indium acetate as a doped indium source, aluminum nitrate or aluminum acetate as a doped aluminum source, gallium nitrate or gallium acetate as a doped gallium source and anhydrous ethanol and / or water as a solvent; preparing a zinc source solution and a doped source solution with certain concentration respectively, and mixing the zinc source solution and the doped source solution; adding glacial acetic acid into the mixture; using high-purity N2 or air as carrier gas; and conveying the reaction liquid into a membrane precipitation chamber for growth, wherein a substrate can be glass or stainless steel and the like, and the growth temperature is between 300 and 550 DEG C. The method adopts cheap and nontoxic chemical products and utilizes a low-cost ultrasonic atomizer to directly obtain the ZnO membrane with a textured structure and light scattering characteristic under the condition of not requiring the doping of B2H6, so that the method cannot pollute the environment, belongs to 'environment-friendly' technology, and can be suitable for the preparation of the large-area (for example, S is equal to 1.2X0.6 meter) ZnO transparent conductive film.

Owner:NANKAI UNIV

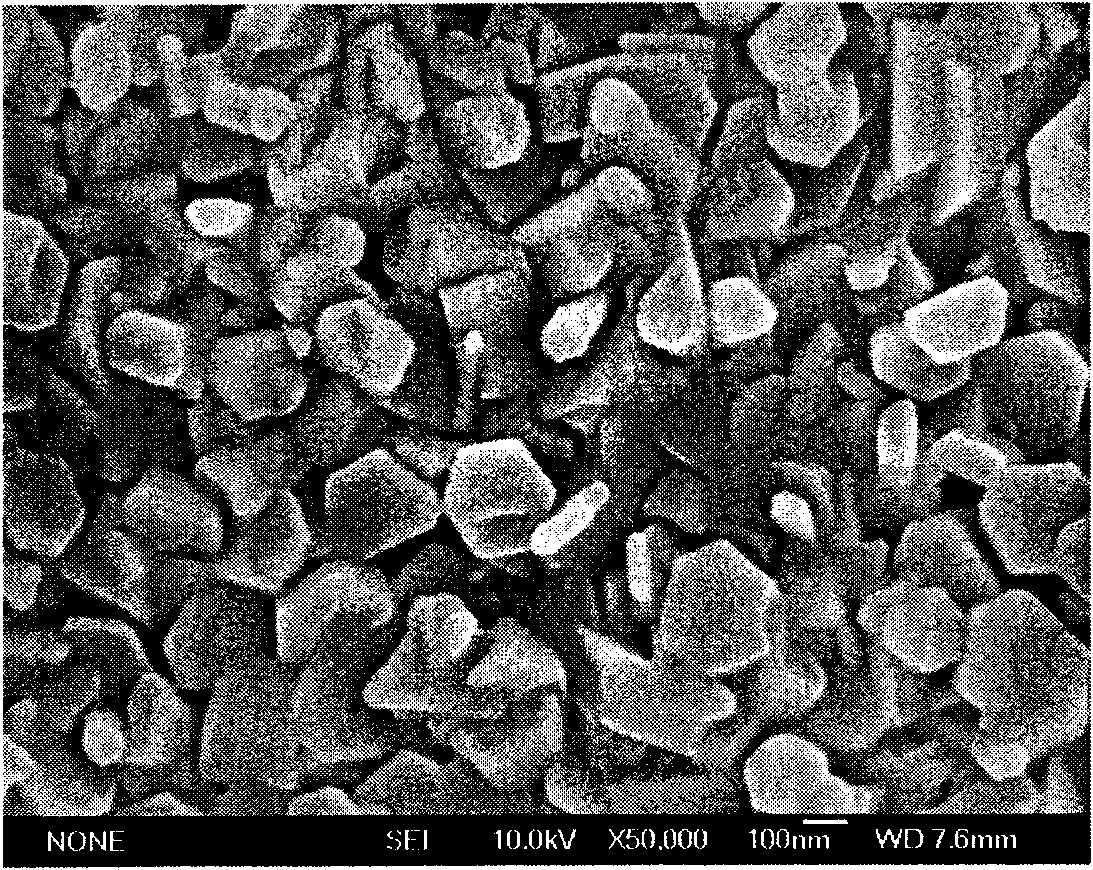

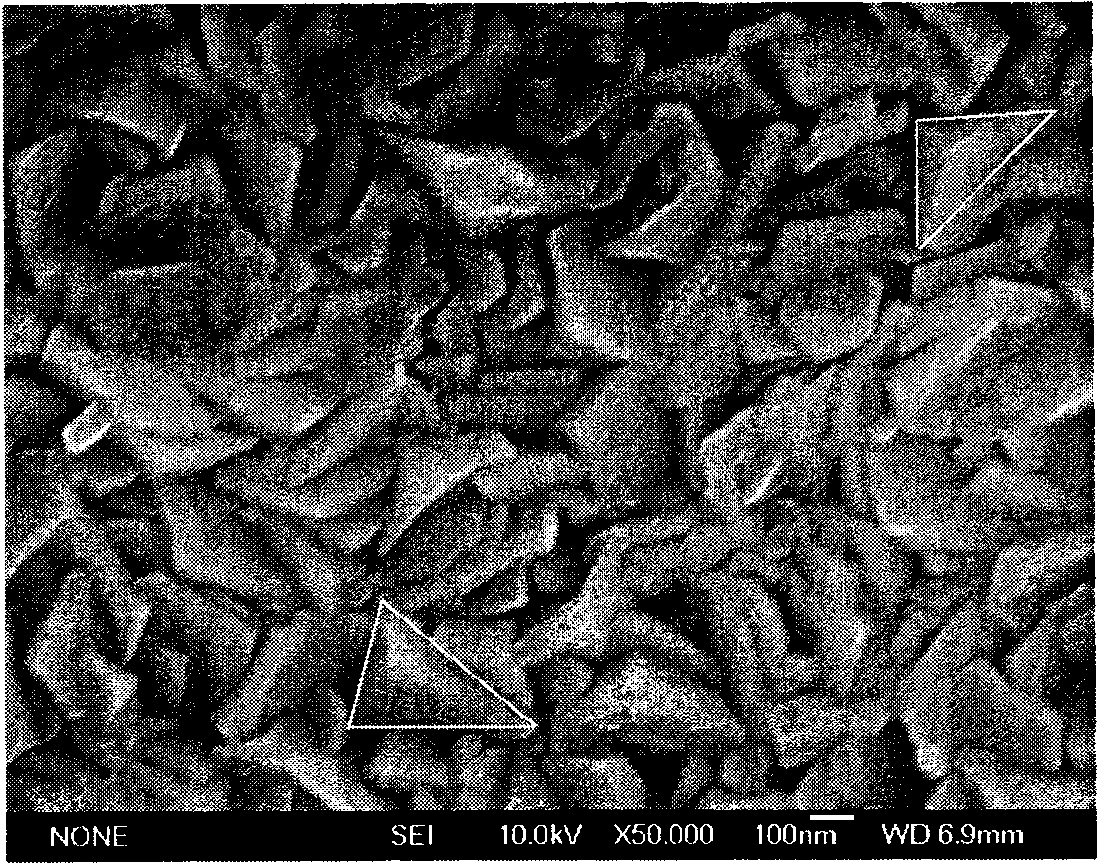

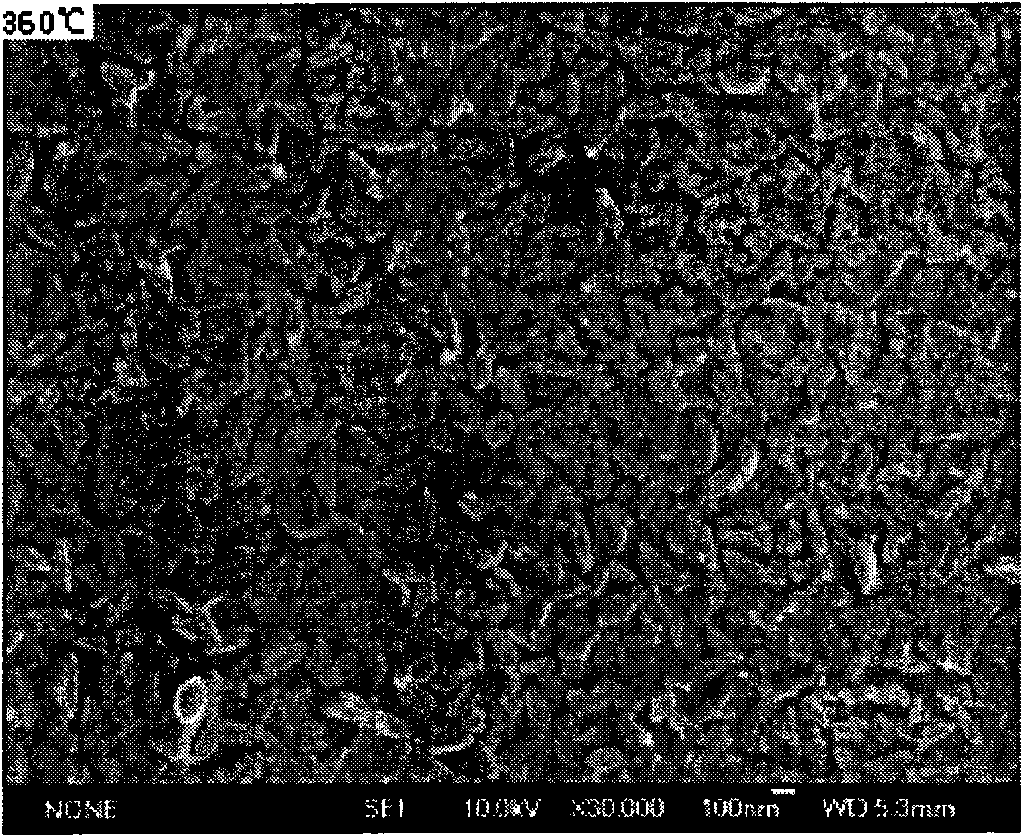

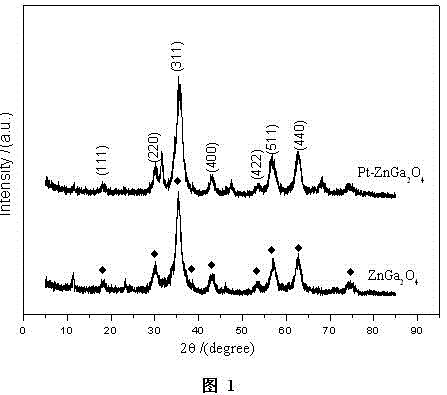

Preparation method of photocatalyst Pt-ZnGa2O4 efficient in CO2 reduction under sunlight drive

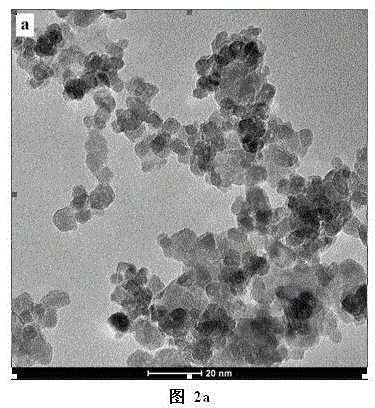

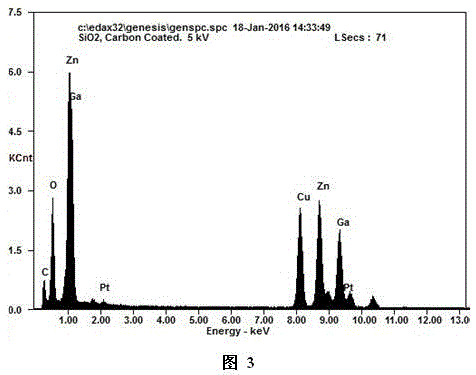

InactiveCN105618039AReduce the chance of reunionLarge specific surface areaOrganic compound preparationHeterogenous catalyst chemical elementsPolyethylene glycolMicroparticle

The invention discloses a preparation method of a photocatalyst Pt-ZnGa2O4 efficient in CO2 reduction under sunlight drive. The method includes: (1) dissolving zinc nitrate and gallium nitrate into deionized water to form a mixed solution, wherein a ratio of the zinc nitrate to the gallium nitrate is 1:2; (2) adding polyethylene glycol into the mixed solution, and adding 20% ammonia water dropwise to regulate a pH value of the solution to be weakly alkaline; (3) transferring a reaction system to a reaction kettle to realize hydrothermal and aging reactions; (4) subjecting reaction products to leaching, washing, drying and calcining to obtain ZnGa2O4 high in specific surface area; (5) dispersing the ZnGa2O4 into deionized water, and adding chloroplatinic acid to realize reduction deposition of Pt4+ onto the surface of the ZnGa2O4; (6) centrifugally separating the products, washing with deionized water, and drying to obtain the Pt-ZnGa2O4. By the preparation method, uniform particles, simplicity, energy saving, environment friendliness and stability are realized, and the photocatalyst Pt-ZnGa2O4 is efficient in CO2 reduction under sunlight irradiation.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

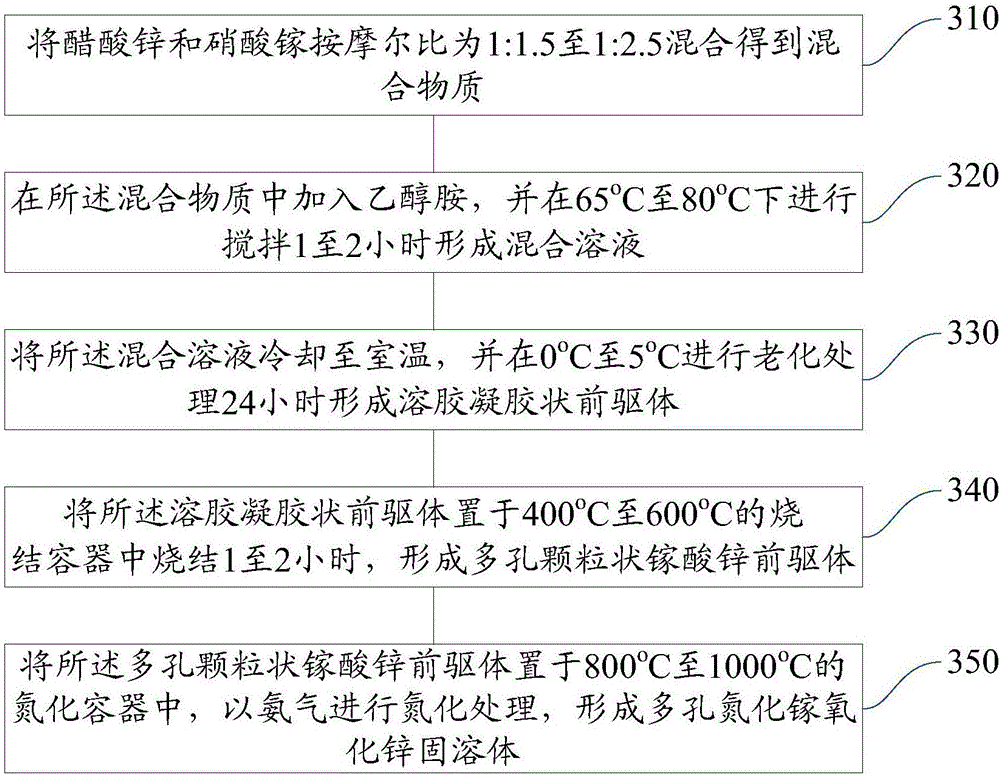

Preparation method of air purifying material and air purifying material

InactiveCN106824242AImprove utilization efficiencyGood photodegradation effectGas treatmentDispersed particle separationZinc gallateGallium nitride

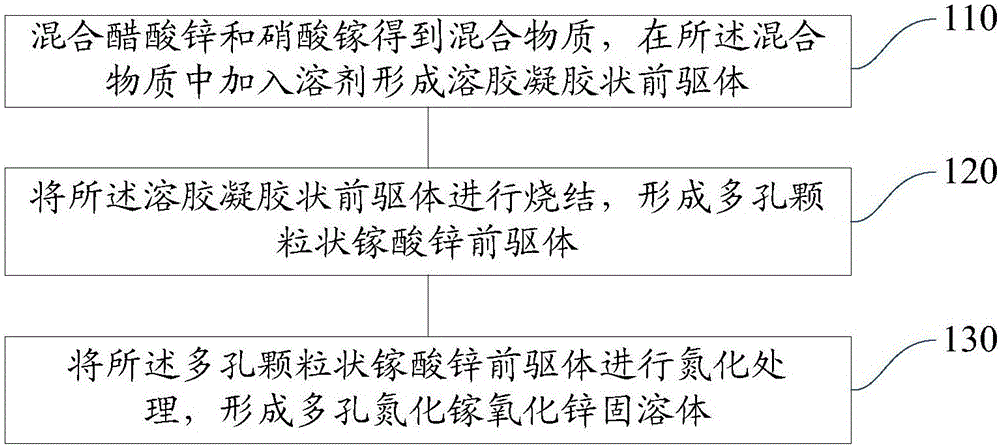

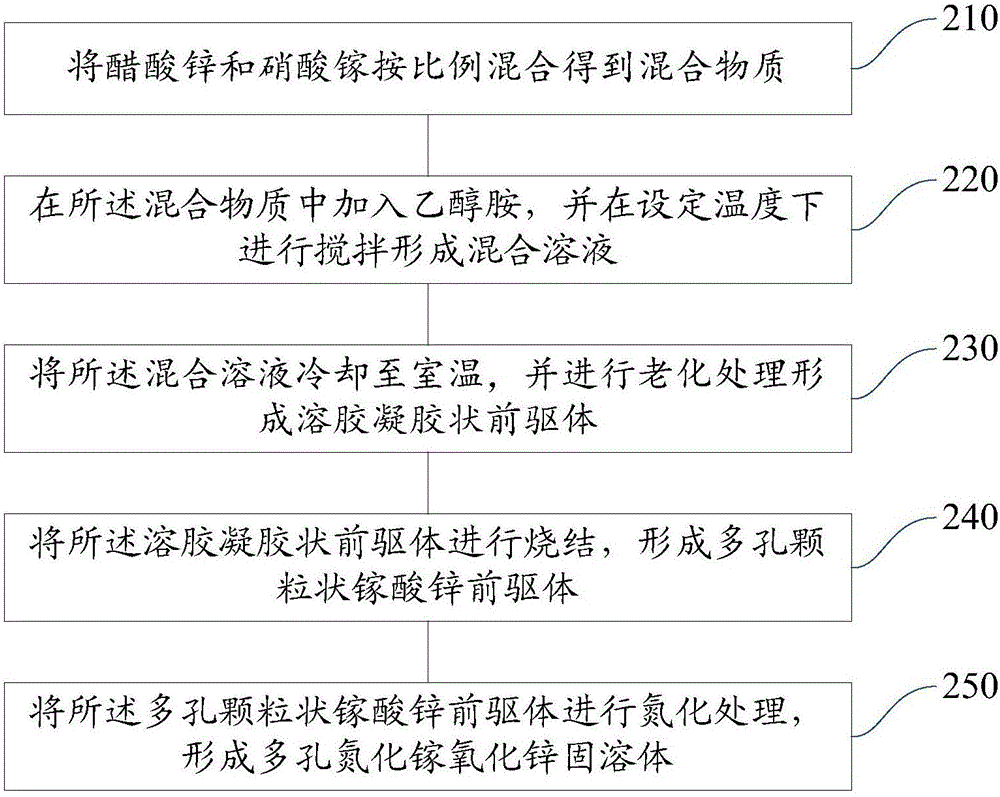

The embodiment of the invention provides a preparation method of an air purifying material and the air purifying material and relates to the technical field of photocatalytic semiconductors. The preparation method comprises the following steps of: mixing zinc acetate and gallium nitrate to obtain a mixed substance; adding a solvent into the mixed substance to form a sol-gel shaped precursor; sintering the sol-gel shaped precursor to form a porous granular zinc gallate precursor; and nitriding the porous granular zinc gallate precursor to form a porous gallium nitride zinc oxide solid solution. Therefore, the problems that the utilization ratio of solar energy by a conventional photocatalyst is not high, the contact area with organic pollutants is relatively small, and the photo-degradation effect of the organic pollutants is poor are solved. The porous gallium nitride zinc oxide solid solution is synthesized through the sol-gel method and can respond to visible light, so that the utilization efficiency of solar energy is increased; meanwhile, the contact surface area with the organic pollutants is increased due to the porous structure, the utilization efficiency of a photocatalyst is increased, and the photo-degradation effect of the organic pollutants is enhanced.

Owner:BOE TECH GRP CO LTD

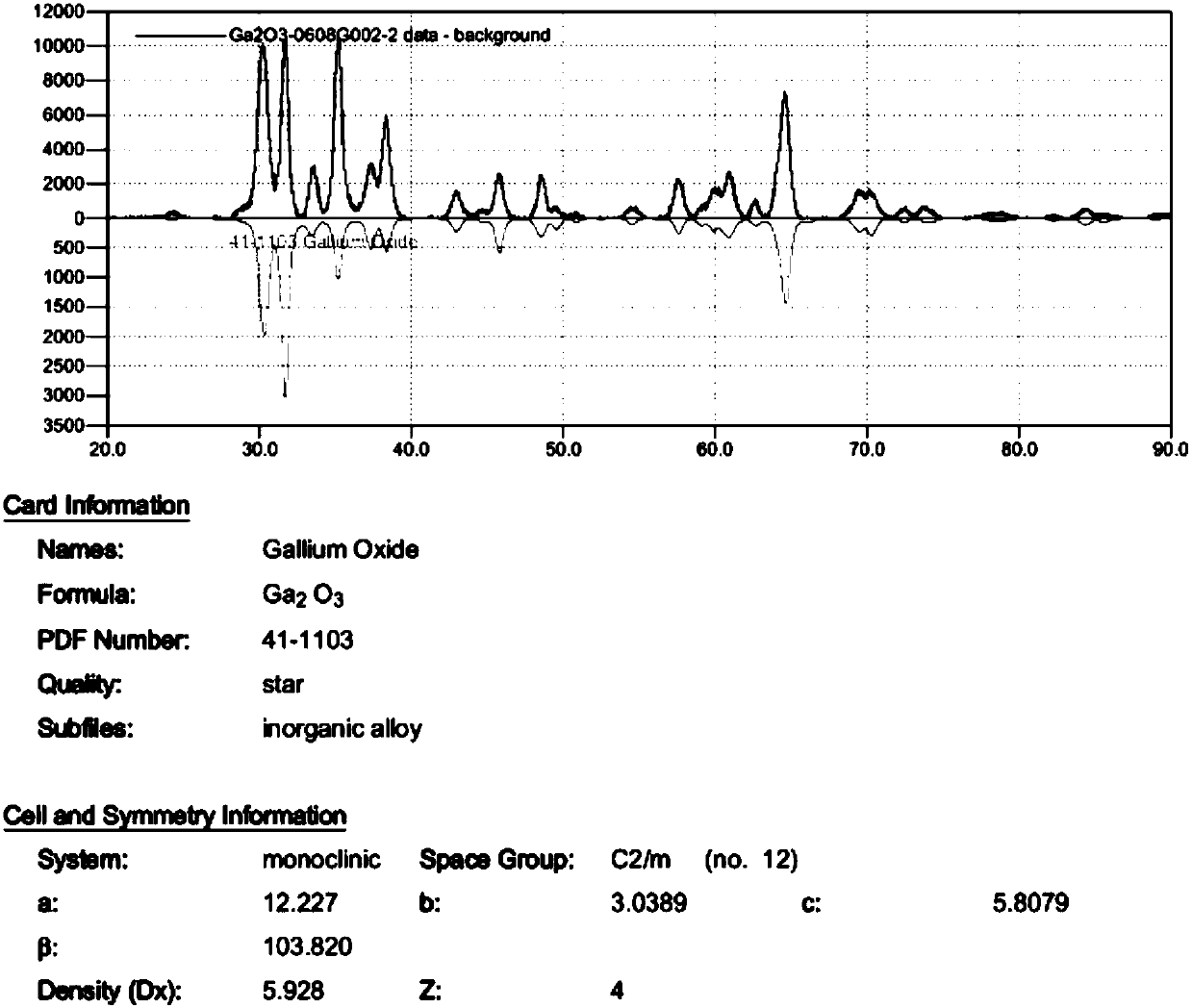

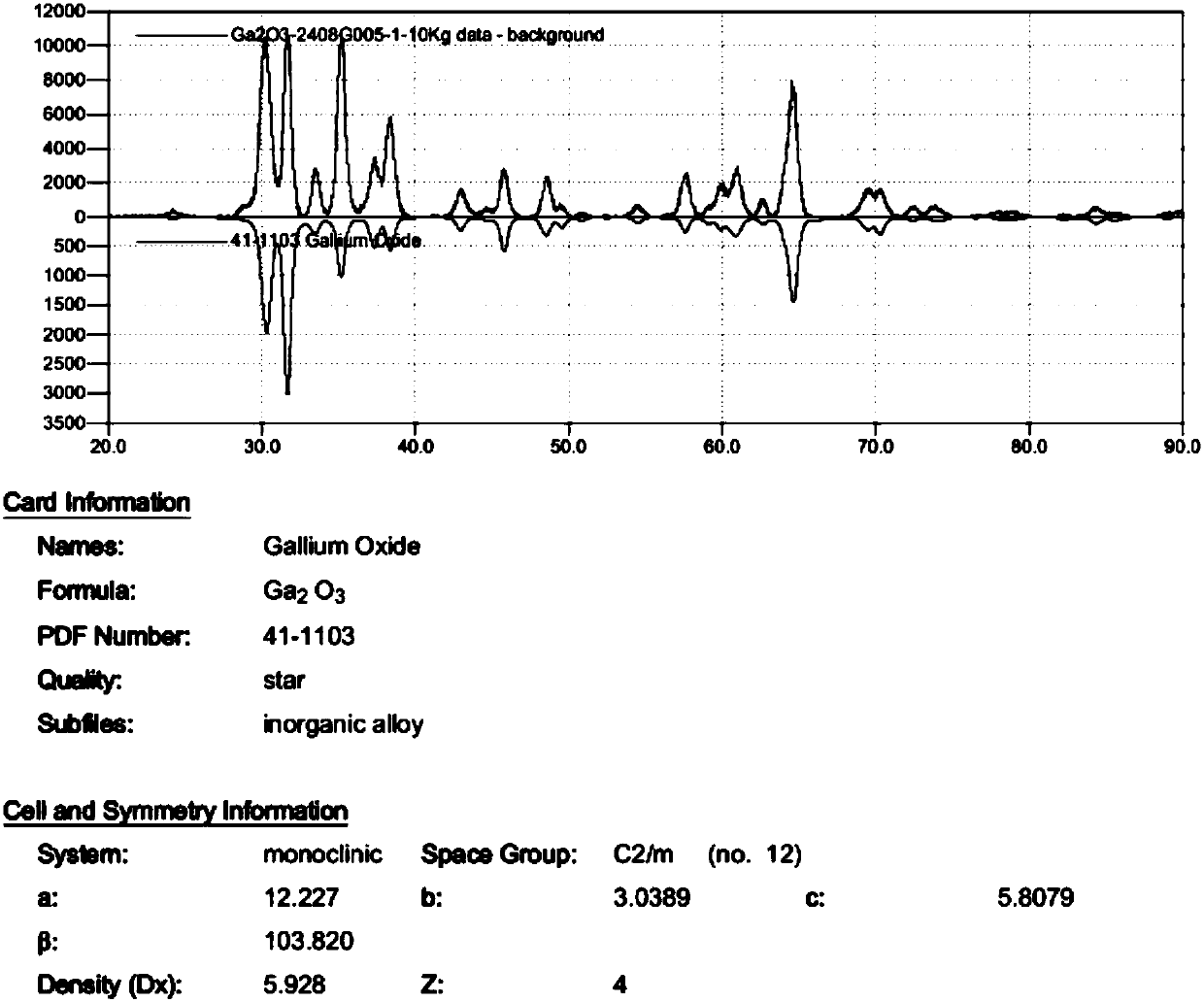

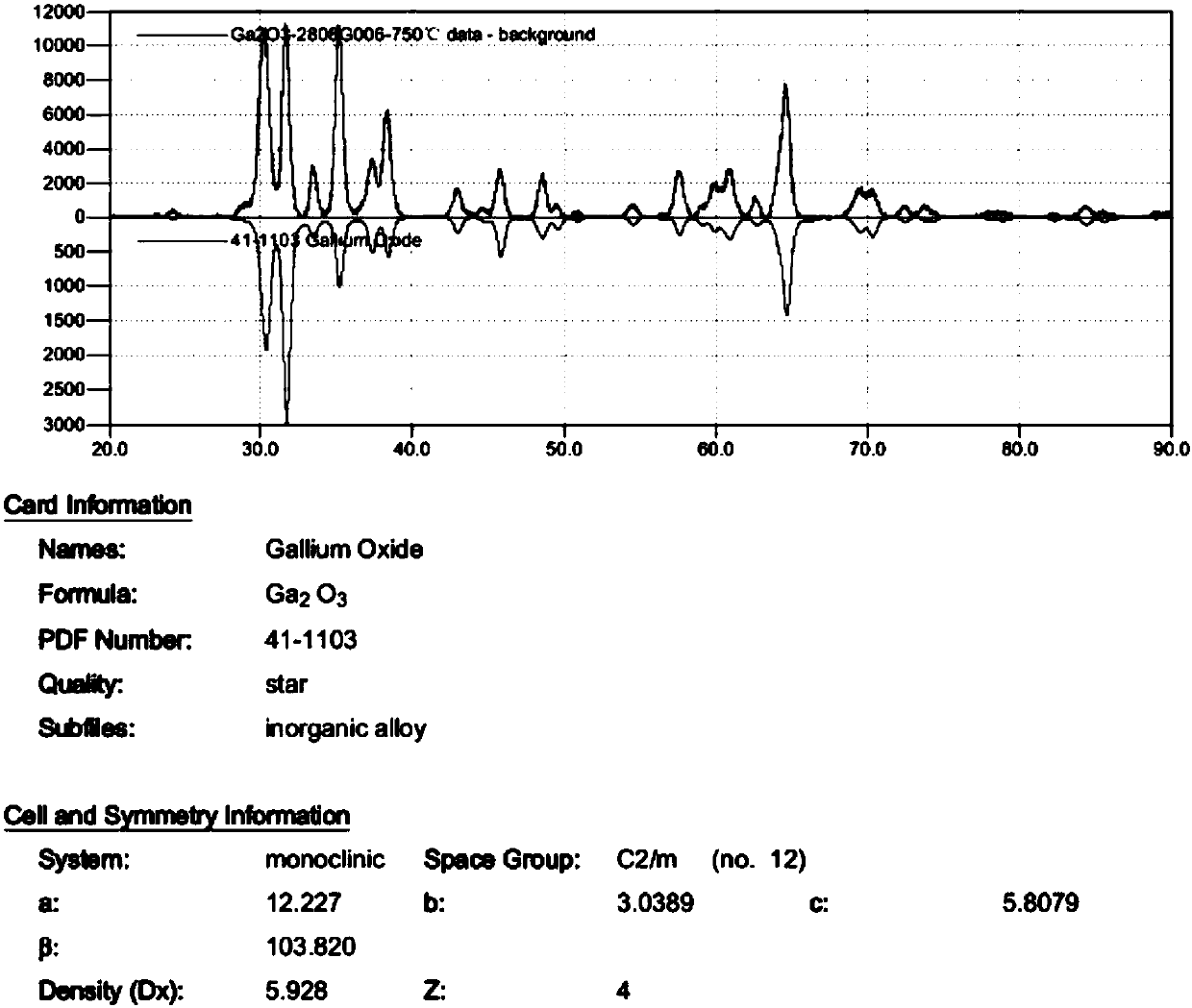

Preparation method of high-purity gallium oxide

The application provides a preparation method of high-purity gallium oxide, comprising the steps of adding solvent water into a reactor, heating to 30 DEG C and above, adding metallic gallium, starting a stirring device to evenly disperse the metallic gallium, adding nitric acid into the reactor to allow reaction, and filtering after reaction to remove non-reacted solid impurities to obtain gallium nitrate solution; adding the filtered gallium nitrate solution into the reactor, starting the stirring device, adding ammonia water to allow reaction until pH of the reaction system remains stable and unchanged, stopping stirring or starting phased stirring so that the reacted material ages at 40-110 DEG C, restarting the stirring device after ageing to continuously stir the material until evendispersion, centrifuging with a centrifuge, washing, spin-drying, discharging, and calcining in a non-reducing gas atmosphere to obtain high-purity gallium oxide. The preparation method herein uses few production equipment and has low production cost and high production efficiency, and the produced gallium oxide has high purity.

Owner:清远先导材料有限公司

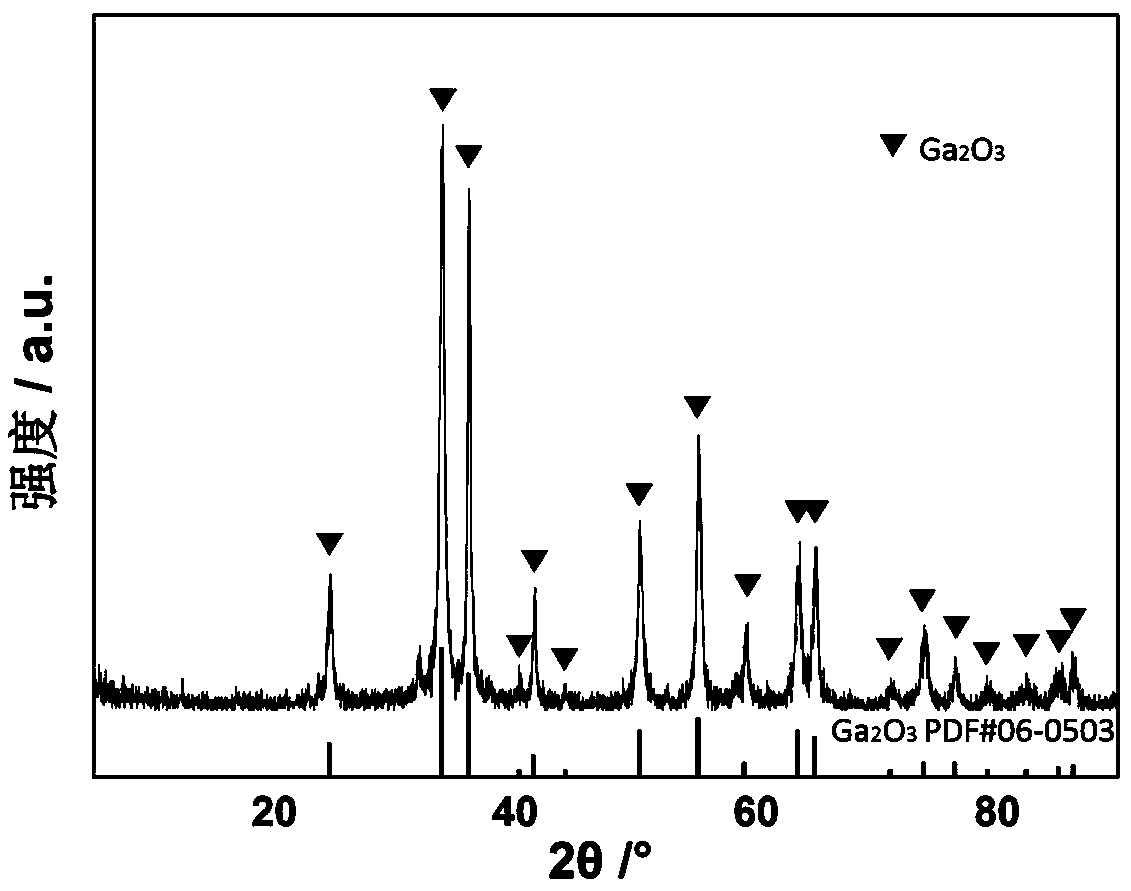

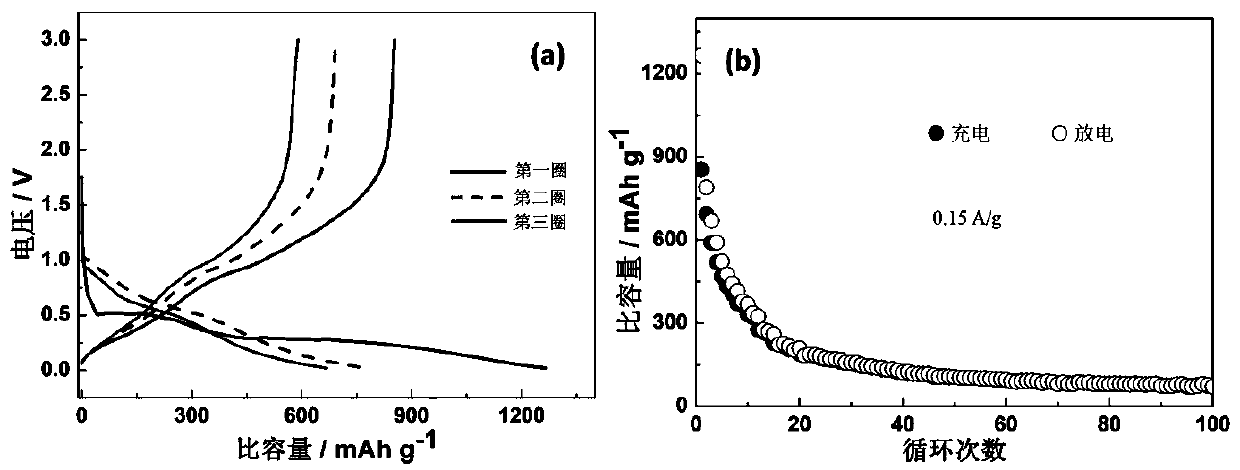

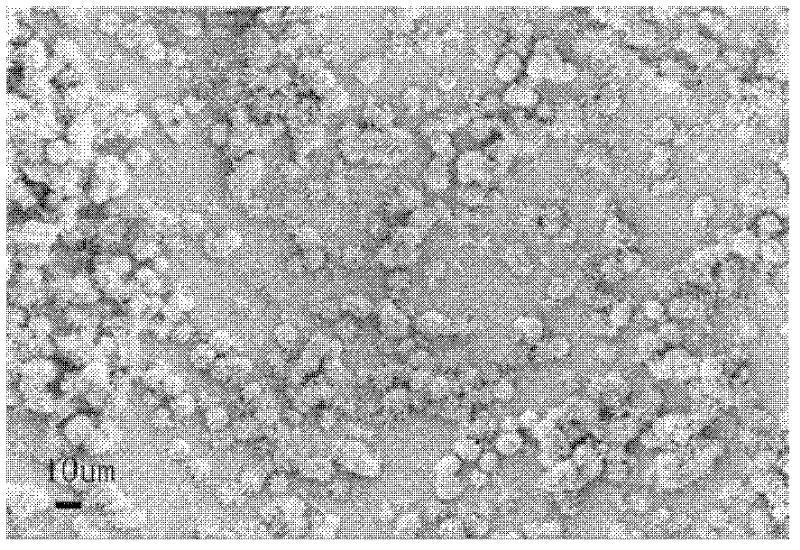

Stable compound lithium ion battery negative electrode material alpha-Ga2O3 and preparation method thereof

ActiveCN107732221ALow preparation temperatureSintering conditions are simpleCell electrodesHexamethylenetetramineActive component

The invention provides a stable compound lithium ion battery negative electrode material, and the active component of the material comprises alpha-Ga2O3. Alpha-Ga2O3 is composed of a great amount of micrometer cubes, the length of cubes is 1-1.5 [mu]m, and the width and height are in a range of 200-800 nm. The preparation method comprises the following steps: adding gallium nitrate, hexamethylenetetramine, sodium sulfate, and citric acid into a container, adding deionized water, stirring until all components are dissolved; transferring the solution to a hydrothermal inner container, adding deionized water; fixing the inner container, carrying out hydrothermal reactions in a blowing drying oven to obtain a precursor; drying the precursor, and sintering the precursor in a tubular furnace toobtain alpha-Ga2O3. The alpha-Ga2O3 can be used to prepare a lithium ion battery negative electrode and has very good electrochemical characteristics and a wide application prospect.

Owner:CHINA THREE GORGES UNIV

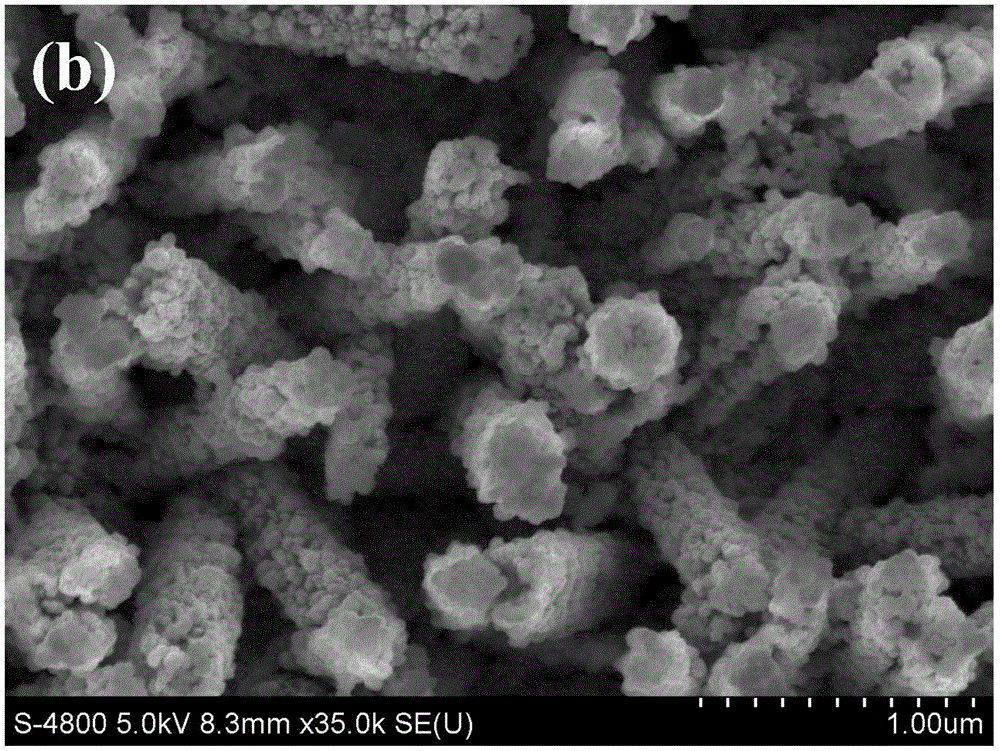

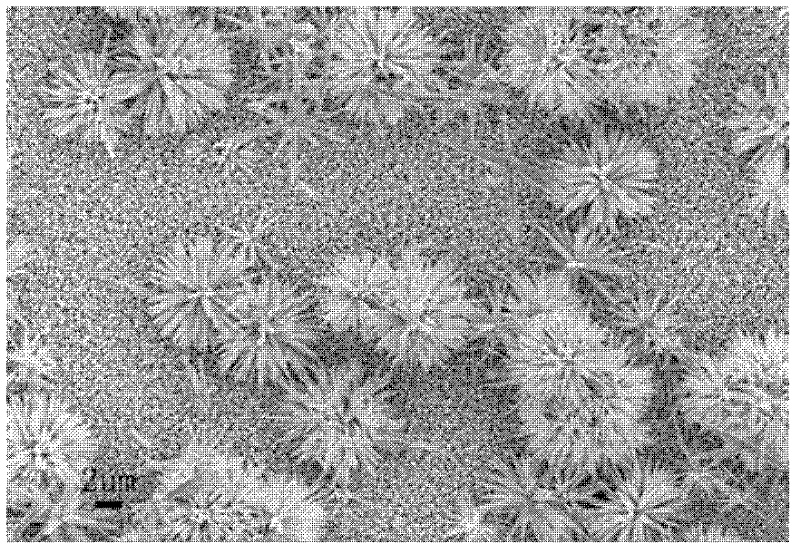

Preparation method for Ga-doped ZnO nanometer material

InactiveCN102509648ALow reaction temperatureImprove controllabilityLight-sensitive devicesFinal product manufacturePorosityReaction temperature

The invention discloses a preparation method for a Ga-doped ZnO nanometer material, and belongs to the technical field of preparation of nanometer materials. The preparation method is characterized by comprising the following steps of: dissolving zinc nitrate and gallium nitrate into de-ionized water, wherein the molar ratio of the zinc nitrate to the gallium nitrate is 1:0.01 to 1:0.1, and a PH value is controlled within the range of 9 to 11; performing ultrasonic treatment on the mixed solution for 30 minutes to obtain a reaction precursor solution; ultrasonically washing a fluorine-doped tin oxide (FTO) conductive glass substrate by using acetone, absolute ethanol, isopropyl alcohol and the de-ionized water, and drying the washed FTO conductive glass substrate; placing the treated glass substrate in the prepared reaction precursor solution, and sealing the reaction precursor solution and preserving the heat; and taking the glass substrate out, flushing the glass substrate by using the de-ionized water, and drying the glass substrate to obtain the glass substrate to which the Ga-doped ZnO nanometer material is attached. The preparation method is low in reaction temperature and low in cost, and simple equipment is used; and in addition, the prepared product has a fluffy and porous surface, high porosity and high electric conductivity, and is applicable to devices such as dye sensitized solar cells and the like.

Owner:UNIV OF SCI & TECH BEIJING

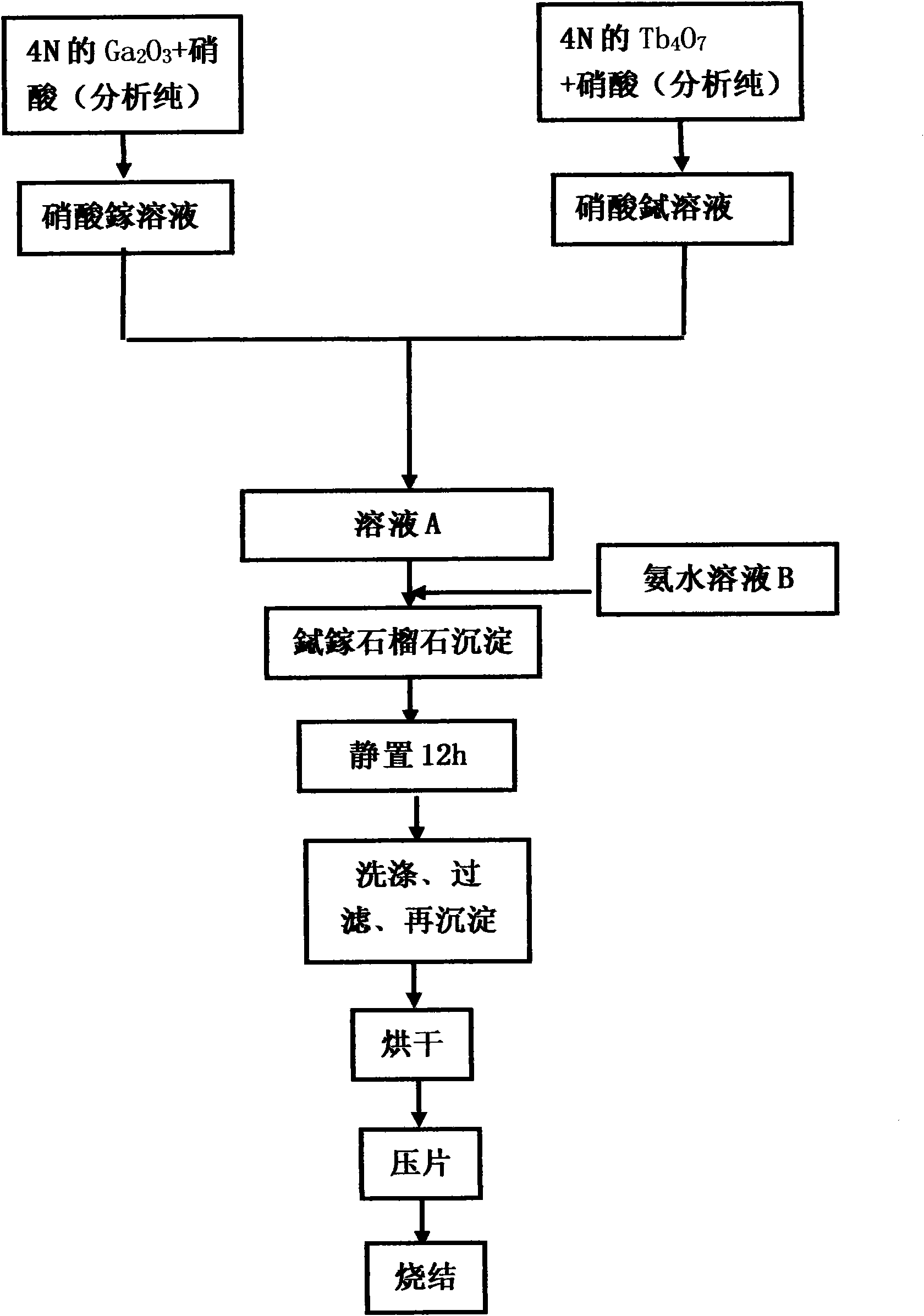

Synthesizing method for growing terbium gallium garnet crystal by pulling method

InactiveCN101649488APolycrystalline material growthSingle crystal growth detailsSingle crystalRaw material

The invention relates to a raw material synthesizing method for growing terbium gallium garnet crystal by a pulling method, which comprises the following steps: a. dissolving Ga2O3 into nitric acid solution to obtain gallium nitrate solution; b. dissolving Tb4O7 into the nitric acid solution to obtain terbium nitrate solution; c. fully mixing the two solutions according to the molar ratio of Ga:Tb=3:5 to obtain a mixing solution A; d. preparing ammonia solution with certain concentration of 2.5 mol / L; e. adding the mixing solution A and the ammonia solution dropwise into a bigger container, and keeping the pH value of the solution between 9 and 11 till the solution is completely deposited; d. keeping the sediments static for a certain period of time and then sequentially washing, filtering and depositing; e. drying and pressing the deposited terbium gallium garnet precursor; and f. sintering the pressed terbium gallium garnet at high temperature for a proper period of time. A terbium gallium garnet raw material can be used for growing a single crystal by a pulling method, the obtained crystal has high quality and no obvious cracking, scattering, stripes and black spots, and the processing finished product rate of the terbium gallium garnet crystal is high.

Owner:UNIONLIGHT TECH

Method for preparing gallium lanthanum niobate series nano powder

InactiveCN101190798AHigh puritySolve the problem of volatilityGallium/indium/thallium compoundsRare earth metal compoundsHydrofluoric acidCITRATE ESTER

A preparation method of nanometer powder of langanite series pertains to the technical field of the preparation of crystal growth material. The nanometer powder series comprises La3Ga5.5Nb0.5O14 (LGN), La3Ga5.5Ta0.5O14 (LGT) and La3Ga5SiO14 (LGS). The invention adopts citrate gel method to prepare the nanometer powder at a low temperature. Nb2O5, Ta2O5 or SiO2 is dissolved in concentrated hydrofluoric acid and then ammonium oxalate and ammonia are added to form sediment which is then dissolved in citrate solution. Gallium nitrate solution and lanthanum nitrate solution are then added and next the citrate is added and mixed evenly; then the gel is obtained after the solution is heated; the gel is kept at certain temperature to obtain foam-shaped fluffy solid which is calcined to obtain the nanometer powder. The synthesis of the method of the invention can be done at the low temperature to obtain the nanometer powder of langanite series with comparatively higher purity as the raw material for crystal growth, which dramatically improves the uniformity of the components of the crystal and reduces the cost of crystal growth.

Owner:SHANDONG UNIV

Making method of low-residual voltage piezoresistor of low-resistivity ZnO crystal grains

A making method of a low-residual voltage piezoresistor of low-resistivity ZnO crystal grains is characterized in that raw materials for making the low-residual voltage piezoresistor include zinc oxide (ZnO), bismuth oxide (Bi2O3), diantimony trioxide (Sb2O3), manganese dioxide (MnO2), chromium oxide (Cr2O3), cobalt sesquioxide (Co2O3), silica (SiO2), aluminum nitrate crystals (Al(NO3)3.9H2O) and gallium nitrate (Ga(NO3)3.9H2O); and the making method comprises the steps of crude seed crystal preparation, primary sintering, seed crystal refinement, raw material and secondary sintering. The method has the following advantages: the structure components and the structure change of the above material in the preparation method can be artificially controlled through strictly changing the sintering process flow and controlling process parameters, so the resistivity of the grains is reduced, the residual voltage of the ZnO piezoresistor is reduced, and increase of the leakage current and decrease of a nonlinear coefficient are inhibited, thereby the material has high performances and is suitable for industrial applications.

Owner:TSINGHUA UNIV

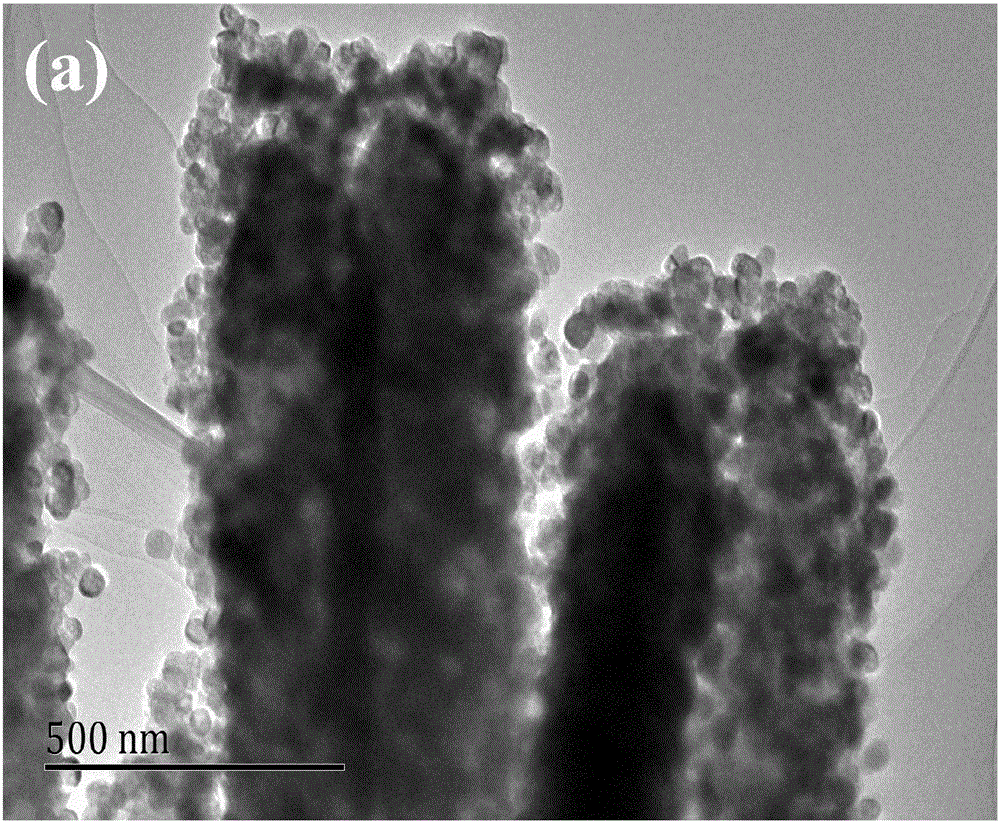

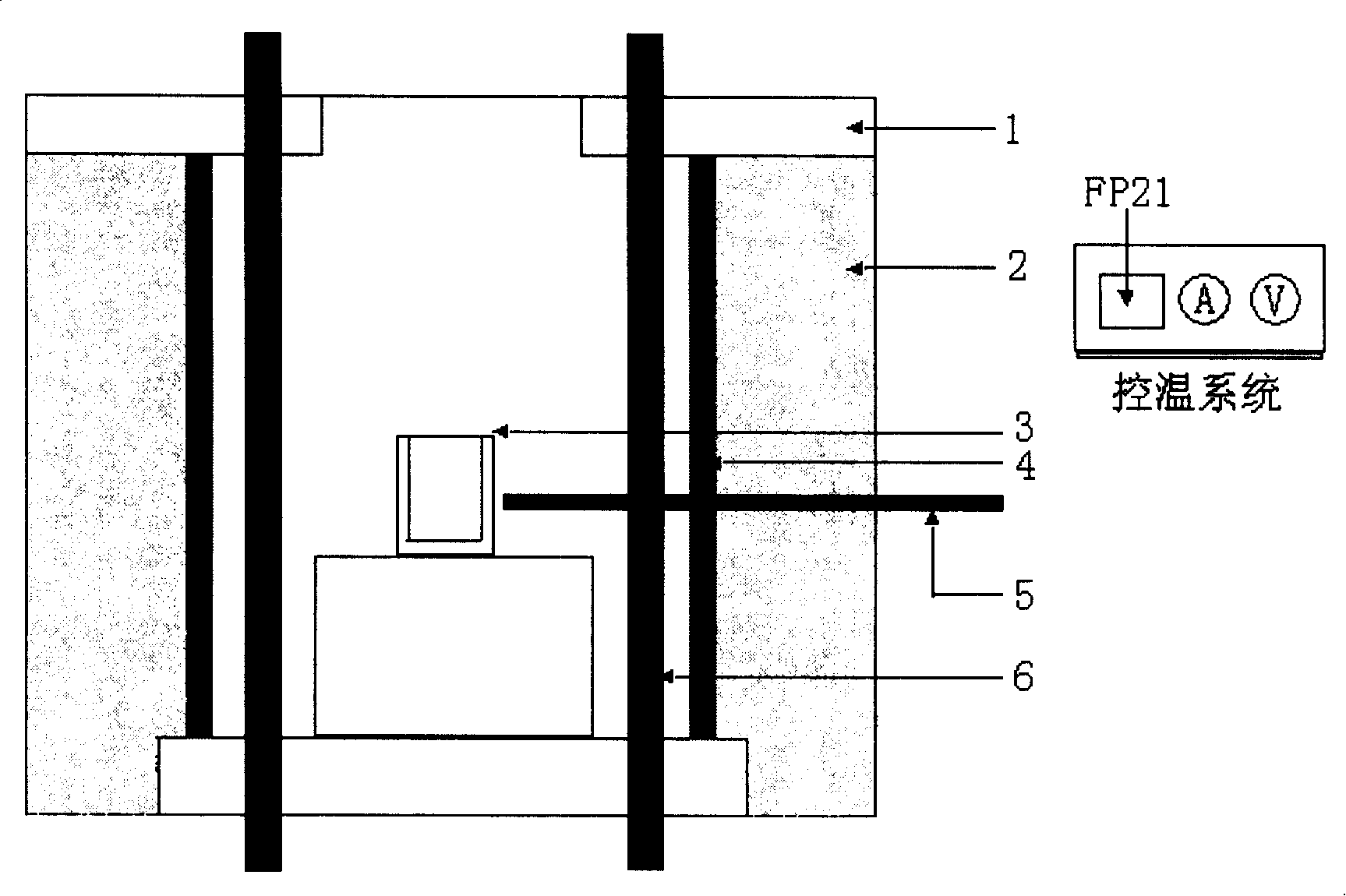

Preparation method for Ga-doped ZnO texture thermoelectric material

InactiveCN103708820AOrientation retention and enhancementImprove thermoelectric performanceCharge carrier mobilitySolvent

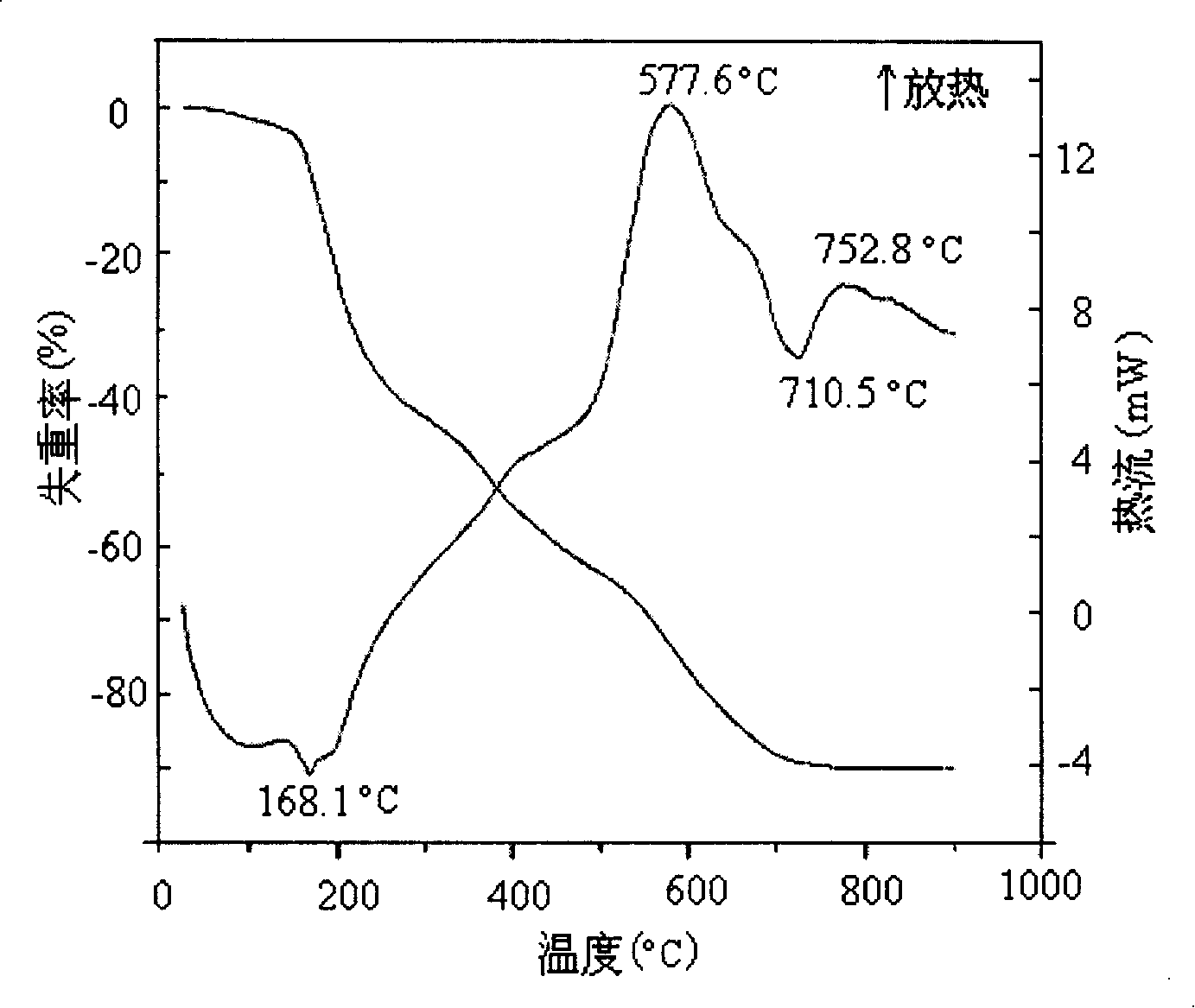

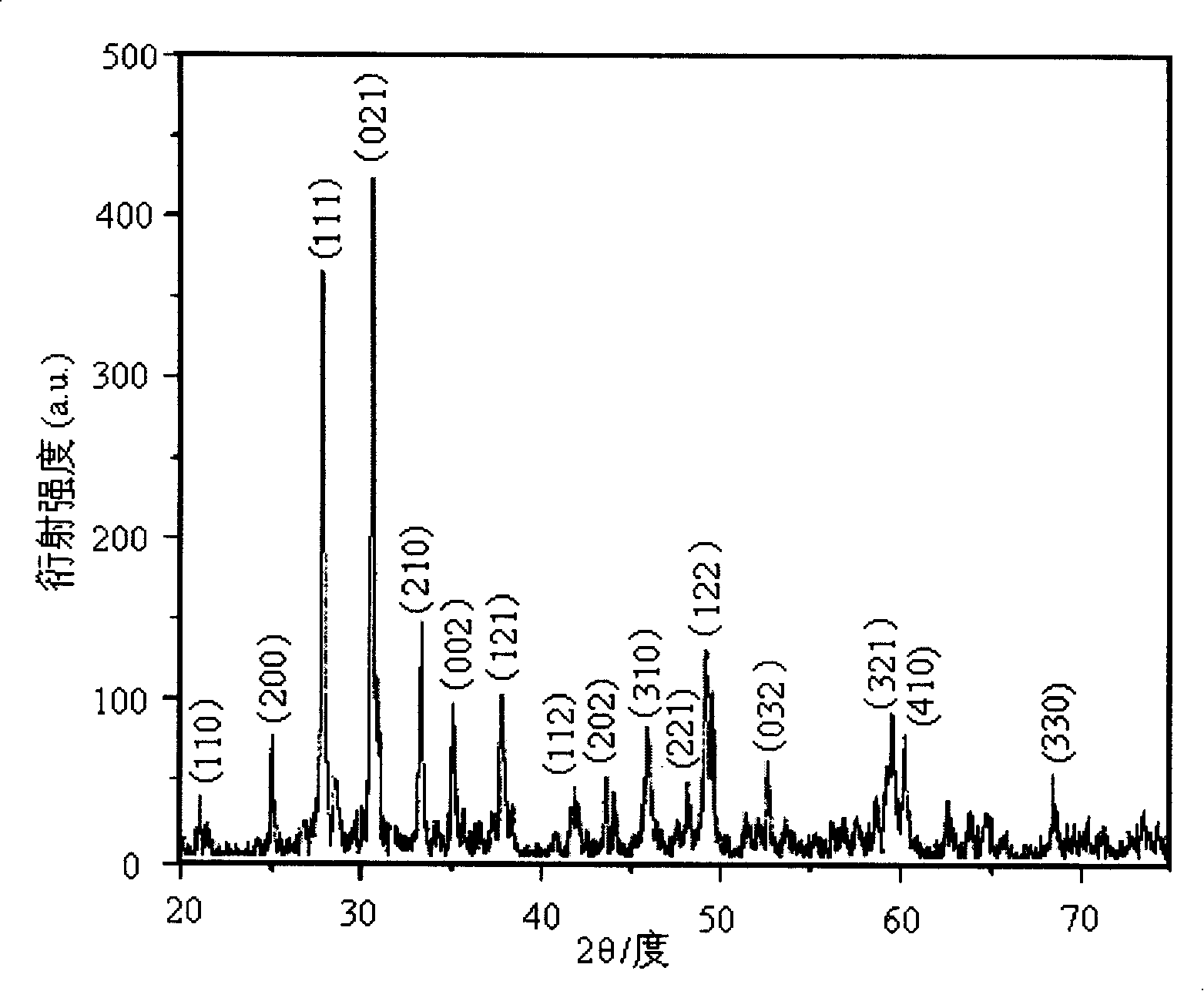

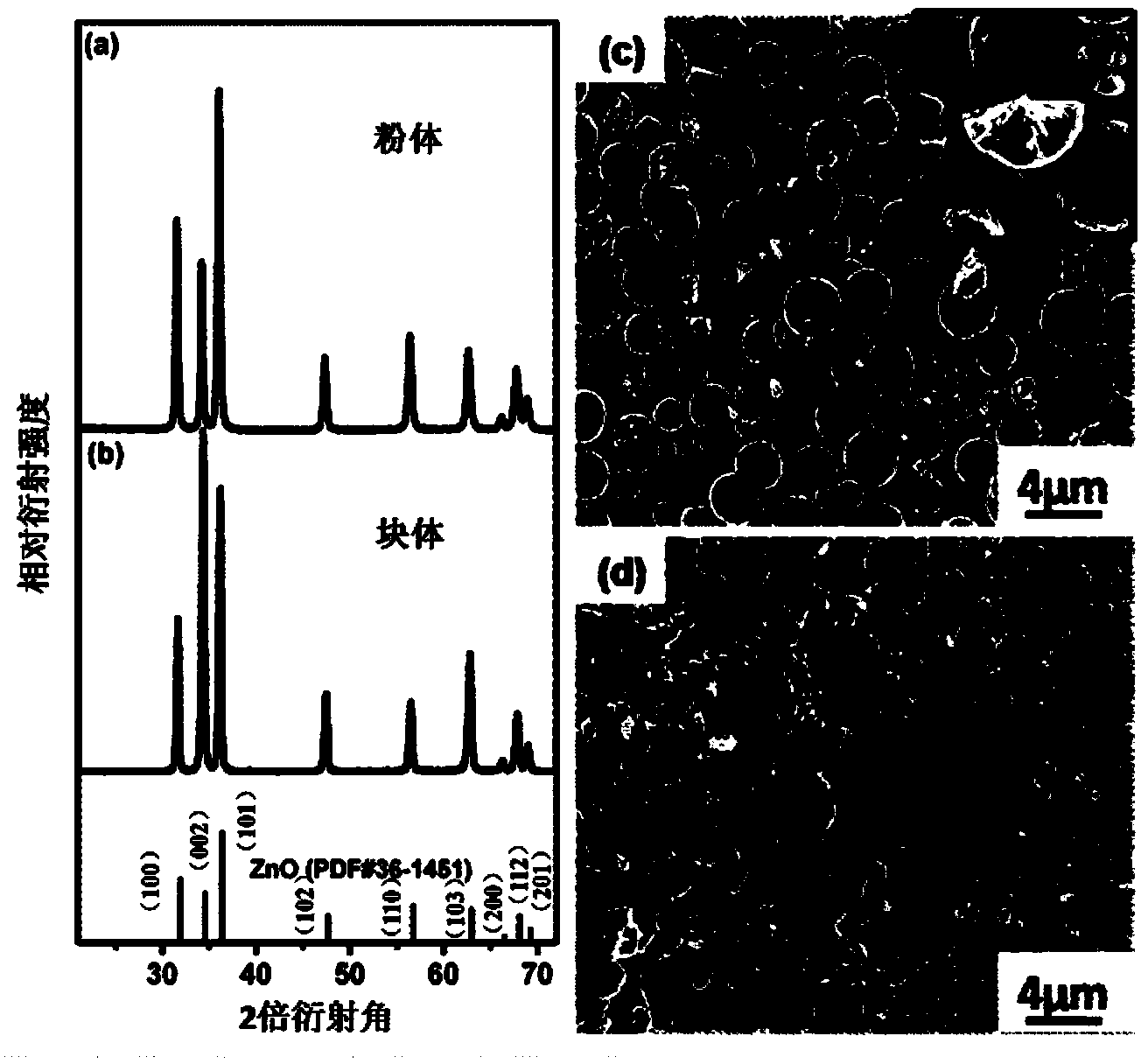

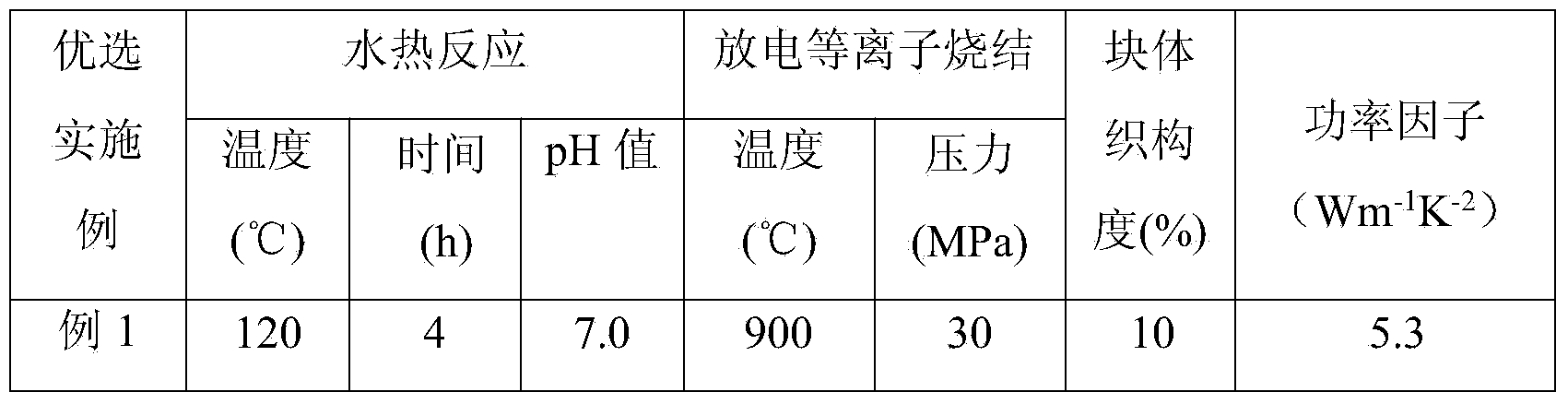

The invention provides a preparation method for a Ga-doped ZnO texture thermoelectric material and belongs to the technical field of energy source materials. The preparation method is characterized in that zinc acetate and gallium nitrate are used as raw materials and are prepared according to a chemical formula Zn1-xGaxO, wherein x is more than or equal to 0.001mol and less than or equal to 0.5mol; triethanolamine is used as a surfactant and de-ionized water is used as a solvent; the pH (Potential of Hydrogen) value is 7.0-9.0; a hydrothermal reaction is carried out at 120-240 DEG C for 4-80 hours; nano-micro composite spherical powder with the diameter of 1-10 microns, which is formed by self-assembly of nano particles with the size of 10nm-800nm, is prepared; a Ga-doped ZnO block material with the texture degree of 10%-55% is prepared by using a discharging plasma sintering technology under the pressure of 30MPa-200MPa and at temperature of 850-1400 DEG C, and keeping the heat and sintering for 1-30 minutes; the grain size is 100nm-900nm. According to the method, the Ga-doped ZnO block material with nano and texture structural characteristics can be simply and rapidly prepared; the carrier mobility is improved and the heat conductivity is reduced; the thermoelectric property can be improved.

Owner:UNIV OF SCI & TECH BEIJING

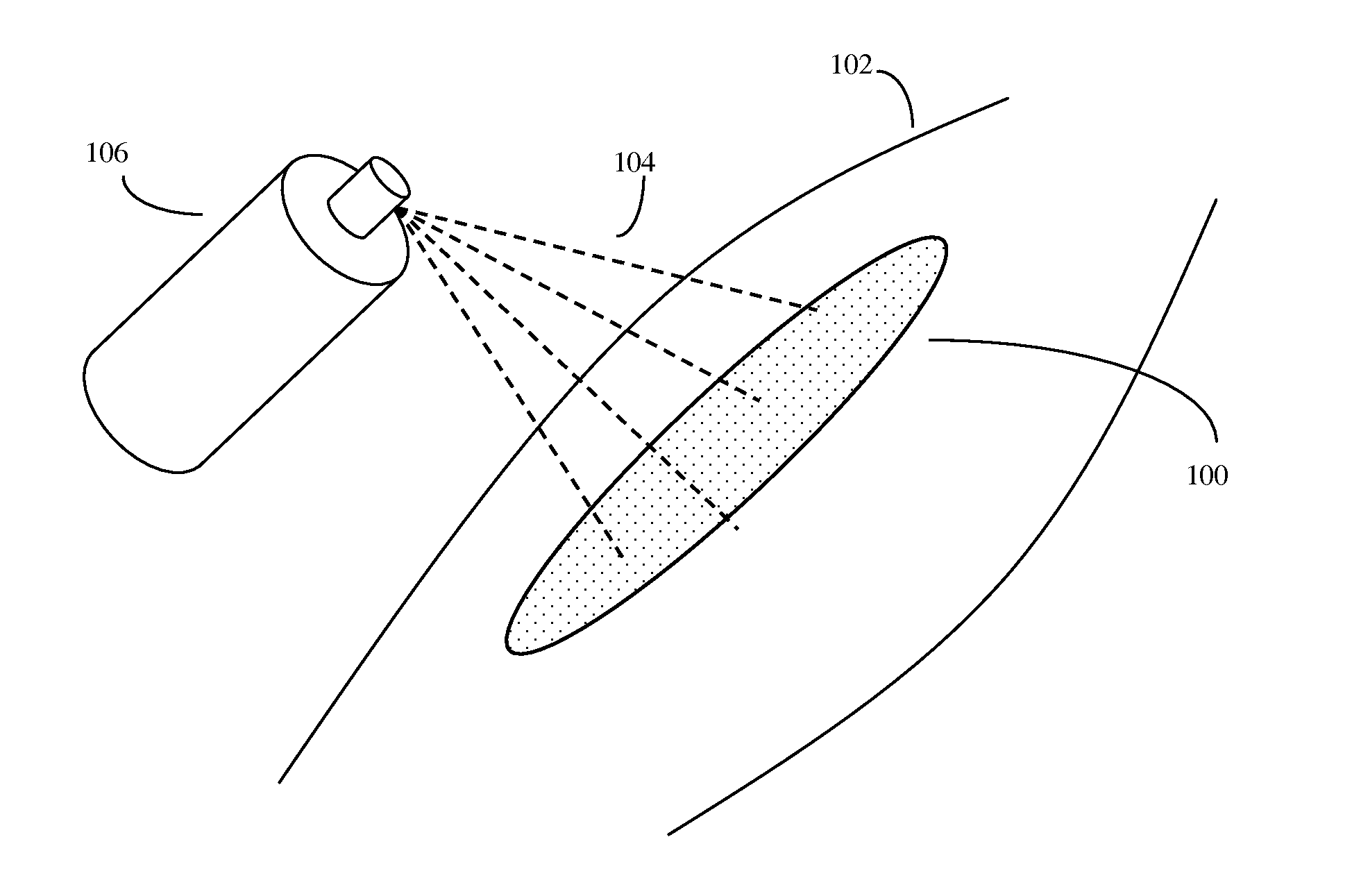

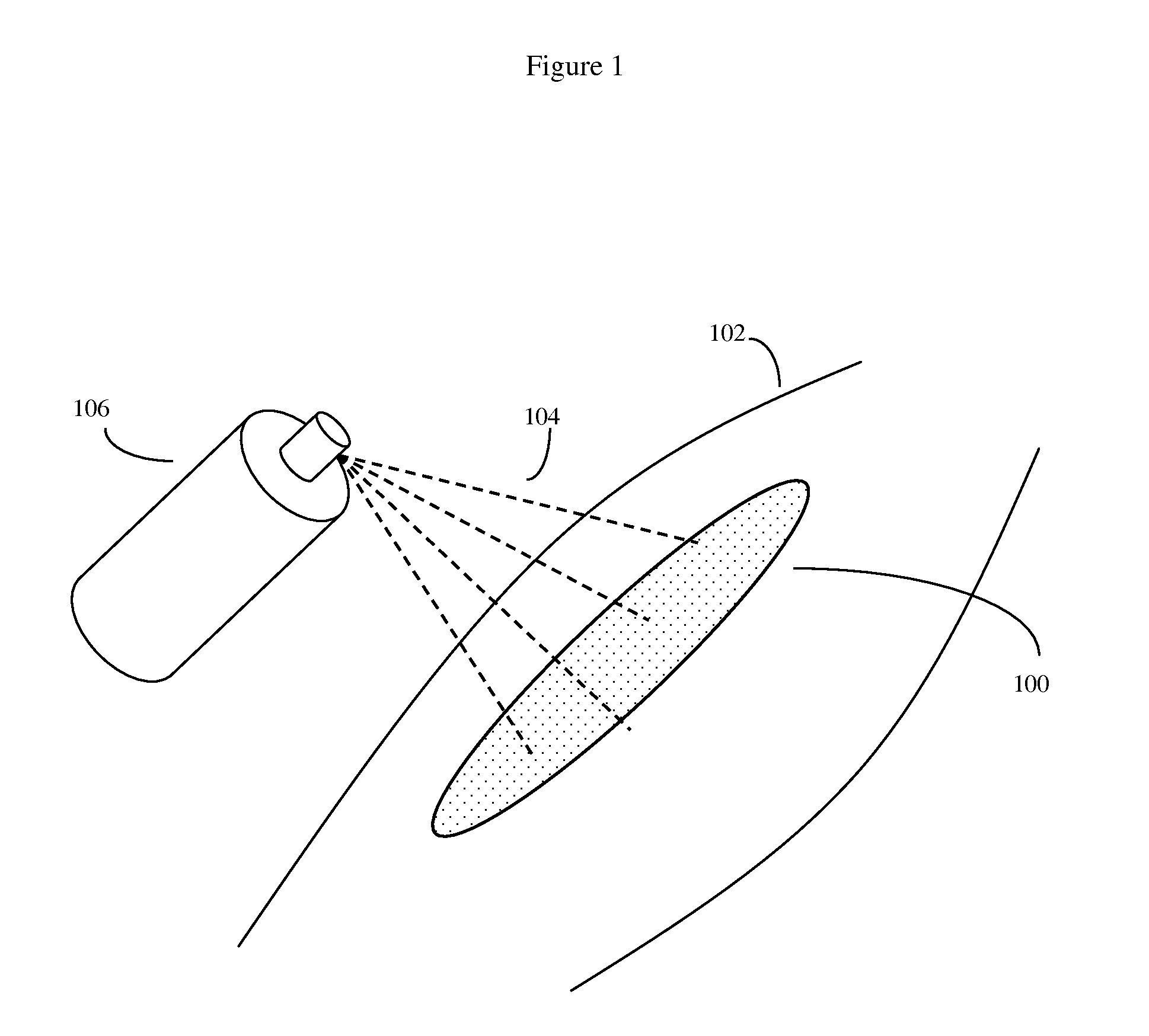

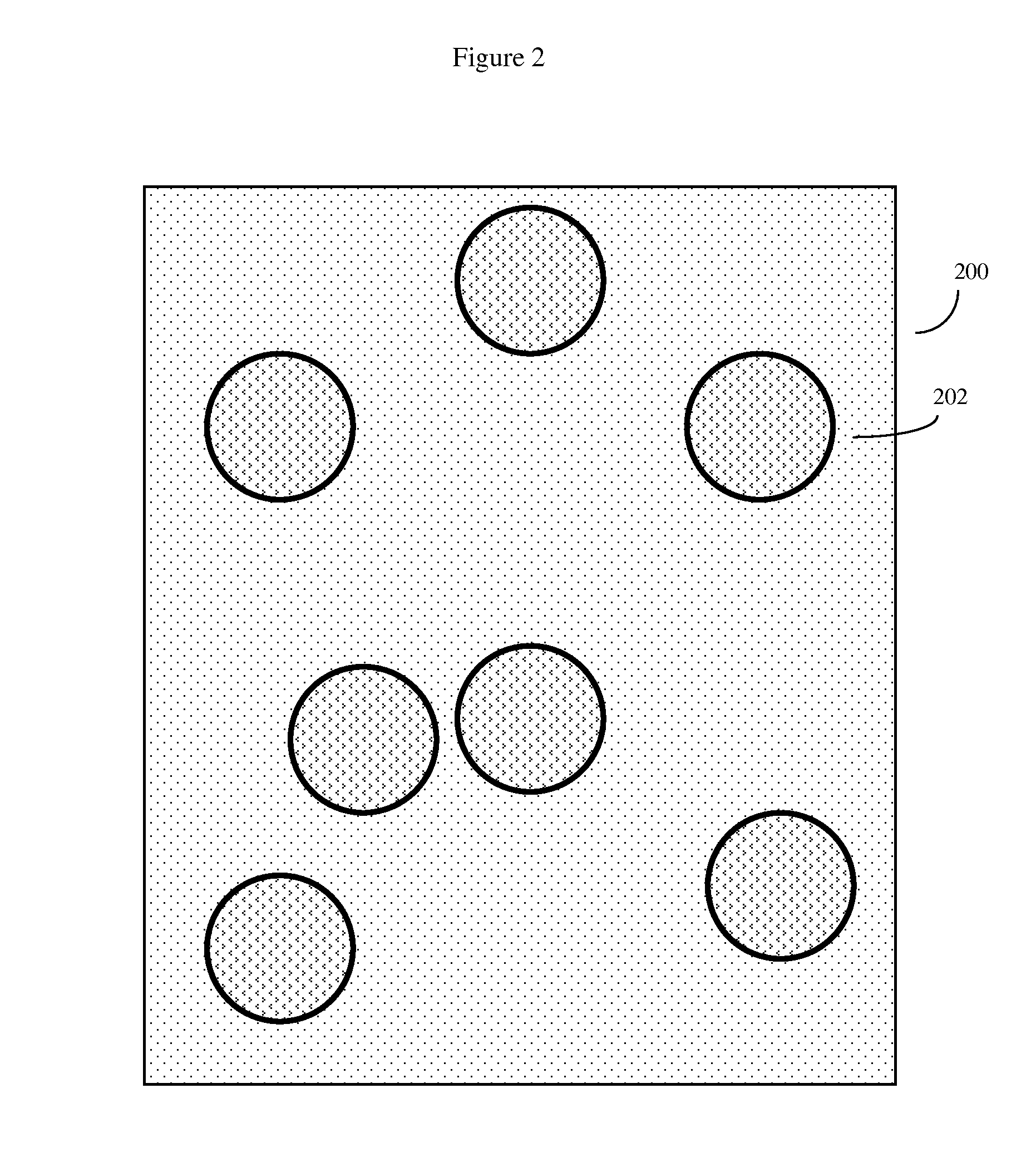

Method of wound treatment using liquid gallium nitrate

InactiveUS20110104246A1Promotion of the early stages of hemostasisBiocideHeavy metal active ingredientsAdditive ingredientTopical treatment

A pharmaceutical composition and method for topical wound treatment by topical treatment with gallium salts, preferably gallium nitrate. In a preferred embodiment, the gallium nitrate is in an aqueous form without coagulation inhibitors such as citrate. The aqueous gallium salt formulation may be administered by a variety of methods including spraying, topical lotions, topical foams, and / or bandages containing or packaged with breakable ampoules of aqueous gallium salt formulations, and liquid bandage formulations. The aqueous gallium salt formulation may additionally contain other active and inactive ingredients, such as viscosity modifying agents, foaming agents, antiseptics, antibiotics, enzymes, fibrinogen, fibrin, polymers and growth factors.

Owner:ROGOSNITZKY MOSHE

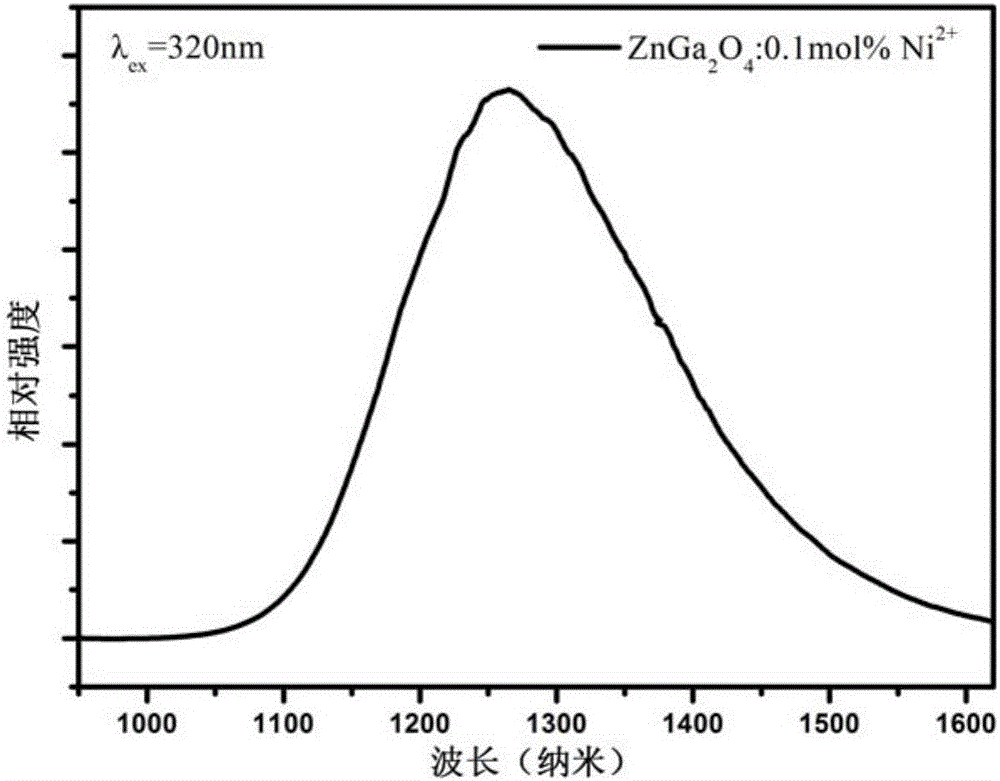

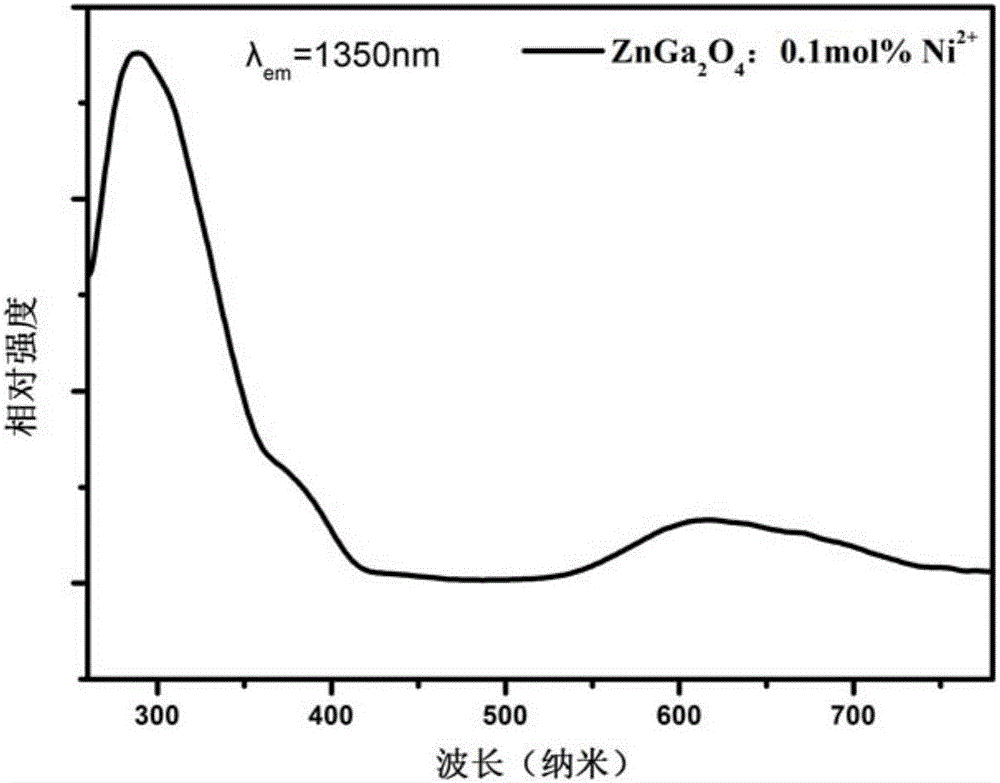

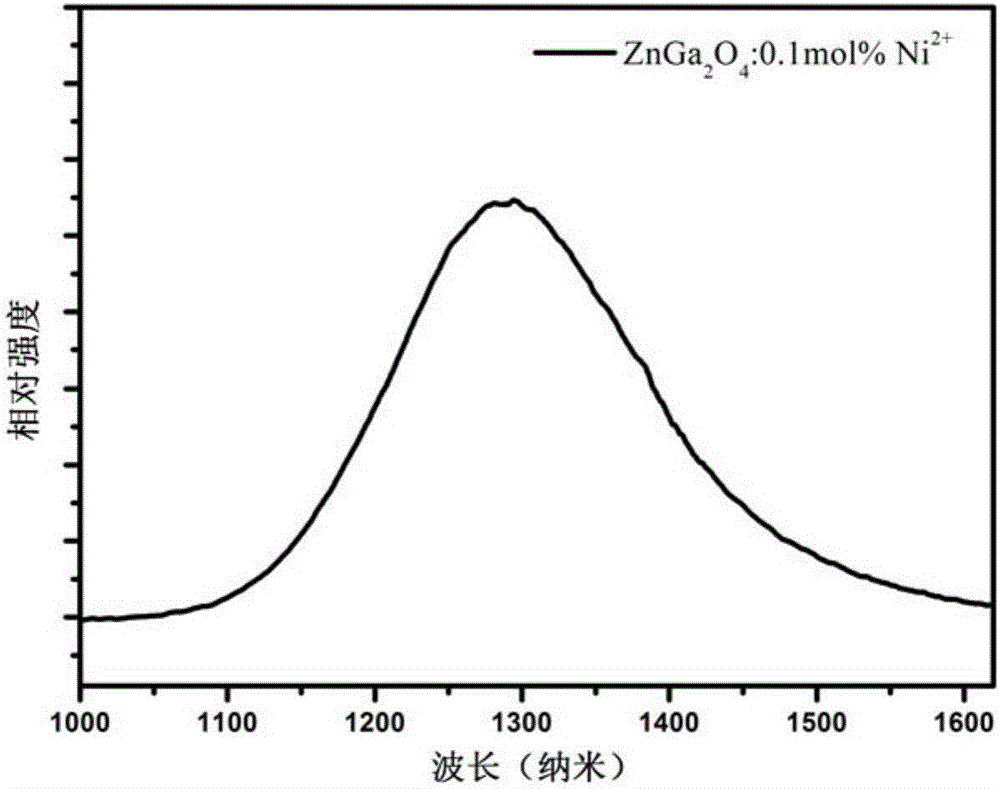

Bivalent nickel ion activated near-infrared long afterglow nano material and preparation method and application thereof

ActiveCN106244140AImprove uniformityImprove stabilityNanoopticsLuminescent compositionsZinc Acetate DihydrateN-Butyl Alcohol

The invention discloses a bivalent nickel ion activated near-infrared long afterglow nano material which takes ZnGa2O4 as a base material and is doped with 0.1 mol%-5 mol% of Ni. The invention further discloses a preparation method of the near-infrared long afterglow nano material. The method comprises the steps that 1, zinc acetate, gallium nitrate and nickel nitrate serve as the raw materials, the raw materials are added into a mixed solution of water and ethyl alcohol and stirred at room temperature, acetylacetone is added, the mixture is stirred at room temperature, and a mixed solution is obtained; 2, the mixed solution is dried, and wet gel is obtained; 3, a mixed solution of n-butyl alcohol and ethyl alcohol is added into the wet gel, reacting and drying are conducted in sequence, and dried gel is obtained; 4, the dried gel is ground and then transferred into a crucible, burning is conducted in a smelting furnace at 900 DEG C to 1,200 DEG C for 2 h, and a power material is obtained. The afterglow bandwidth of the near-infrared long afterglow nano material ranges from 1,050 nanometers to 1,600 nanometers, the afterglow peak is located at 1,250 nanometers to 1,350 nanometers, and the bivalent nickel ion activated near-infrared long afterglow nano material can be well applied to the field of bioimaging.

Owner:SOUTH CHINA UNIV OF TECH

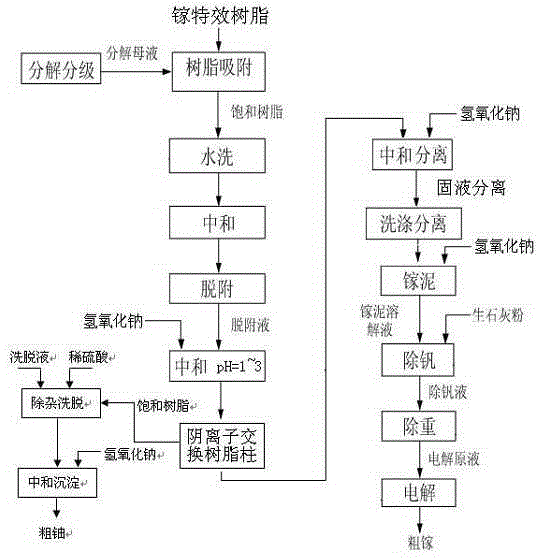

Uranium separation method during gallium treatment in aluminum oxide production through Bayer process

The invention discloses a uranium separation method during gallium treatment in aluminum oxide production through a Bayer process. The uranium separation method comprises the following steps that A, the pH of a special-effect resin acid desorption solution of gallium is controlled to be 1-3; B, a neutralization solution in the step A is made to flow through a pretreated anion exchange resin column, and a column passing solution is separated; C, the column passing solution is neutralized through sodium hydroxide till the pH value reaches 5-9, deposited gallium mud is obtained, the gallium mud is dissolved through alkali liquor, the gallium mud dissolved liquid is obtained, quick lime is added into the dissolved liquid, vanadium is removed through sedimentation, heavy metal in the solution is removed, electrolysis is conducted, and crude gallium products are obtained; D, the anion exchange resin column is subjected to cleaning and impurity removal through diluted acid, and uranium is eluted through acid nitrate or acid chloride; and E, sodium hydroxide is added into the uranium-contained water phase, the pH of the solution is adjusted to be 7-9, sodium diuranate sedimentation is generated, and crude uranium products are obtained after filtering and separation. The uranium separation method is designed according to different characteristics of uranium and gallium, uranium-gallium separation is achieved, and uranium can be recycled.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Preparation method for GaN nanoparticles

ActiveCN107089646AHigh purityRaw materials are easy to getMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsAir atmosphereNanoparticle

The invention discloses a preparation method for GaN nanoparticles. In the method, the mixture of gallium nitrate and melamine is sequentially roasted in high temperature under an inert atmosphere and an air atmosphere, and thereby the GaN nanoparticles are obtained. The purity of the GaN nanoparticles prepared by the method disclosed by the invention is high, the preparation process is simple and easy to operate, the cost is low, and the invention has the prospect of industrialized application.

Owner:SHAANXI NORMAL UNIV

Method for growing gallium nitride based on graphene and magnetron sputtered aluminium nitride

ActiveUS20190108999A1Quality improvementPolycrystalline material growthVacuum evaporation coatingSputteringGallium nitride

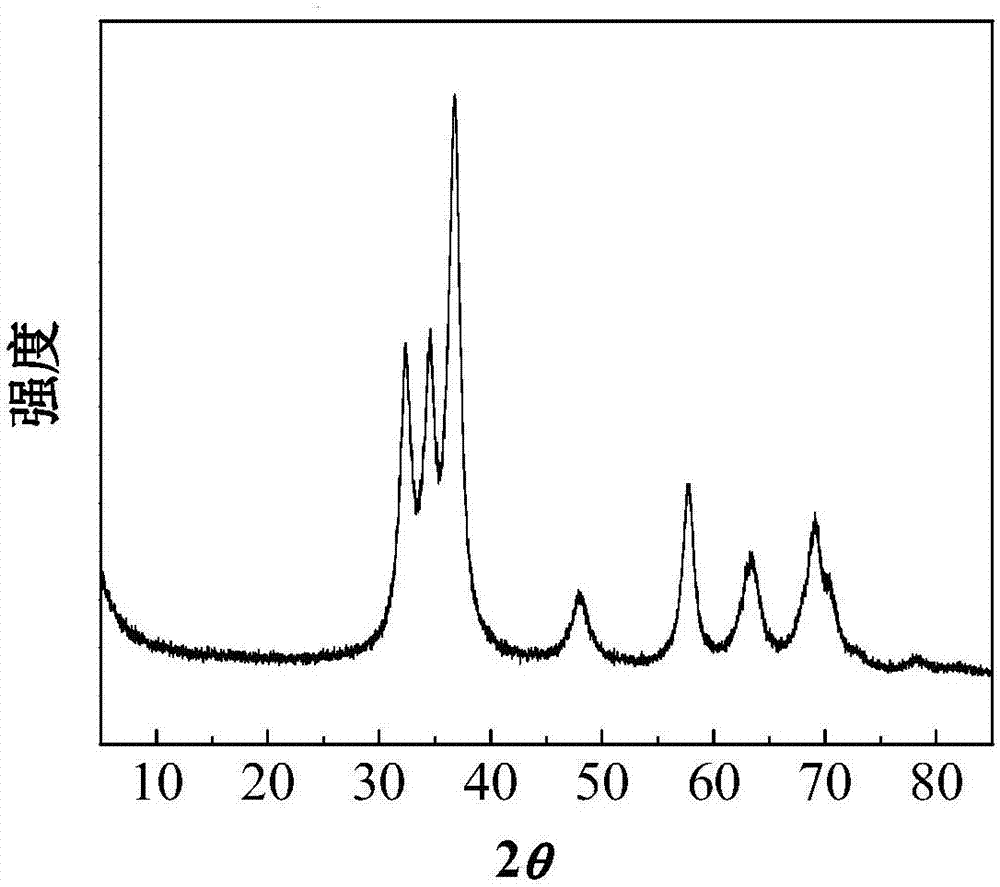

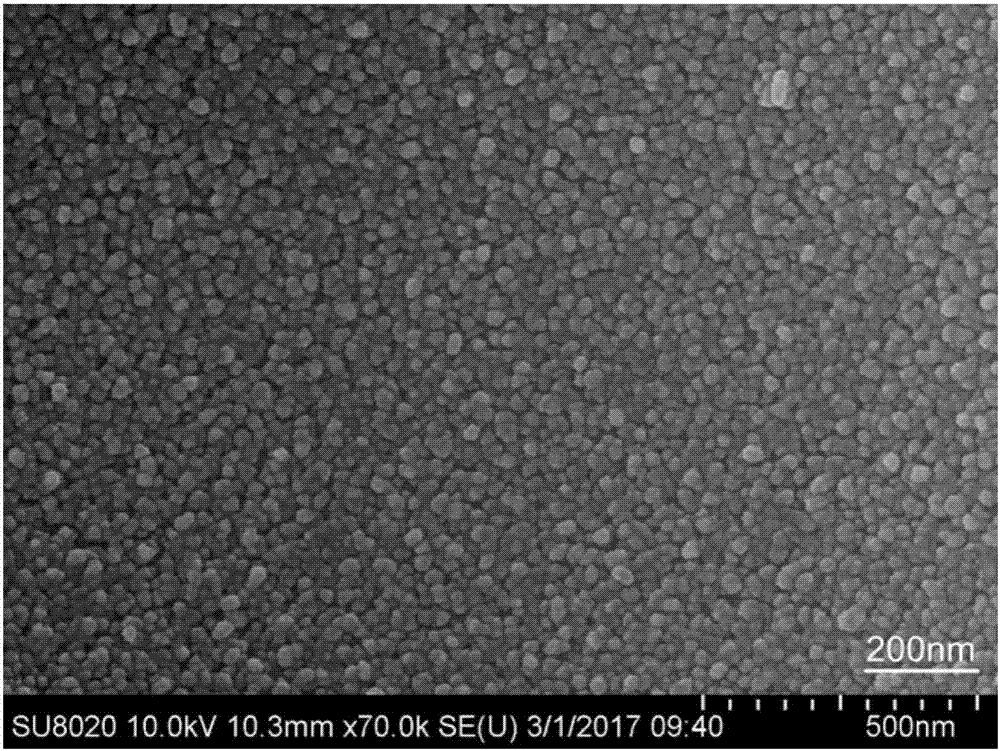

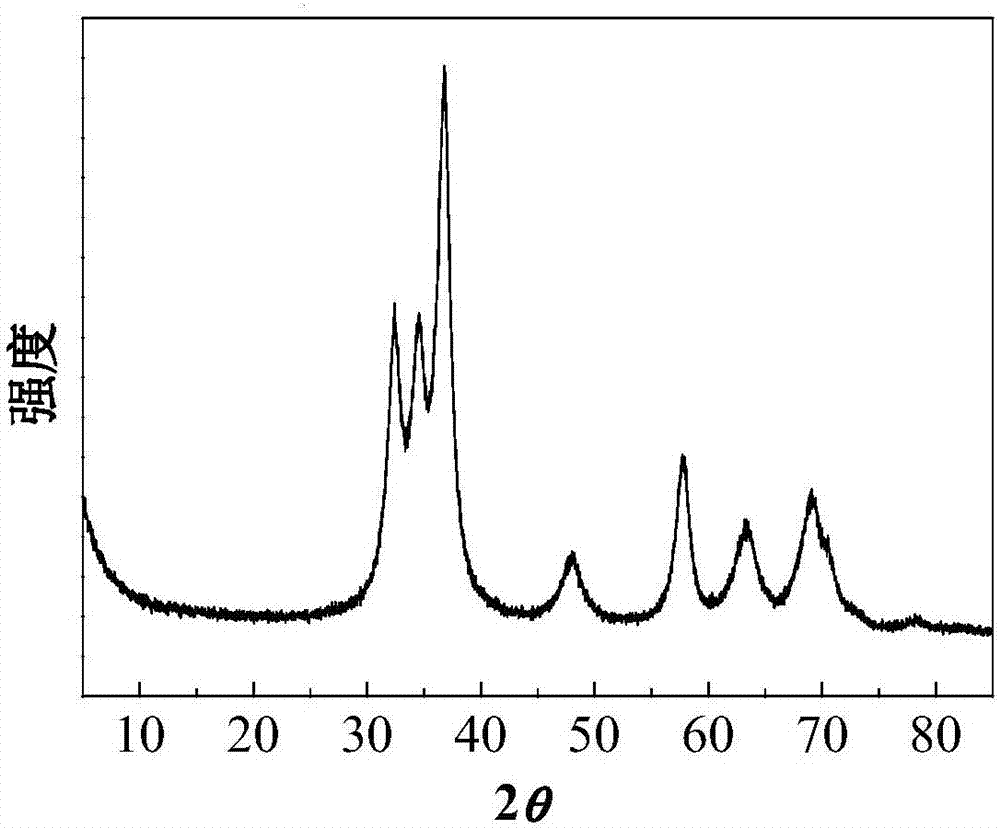

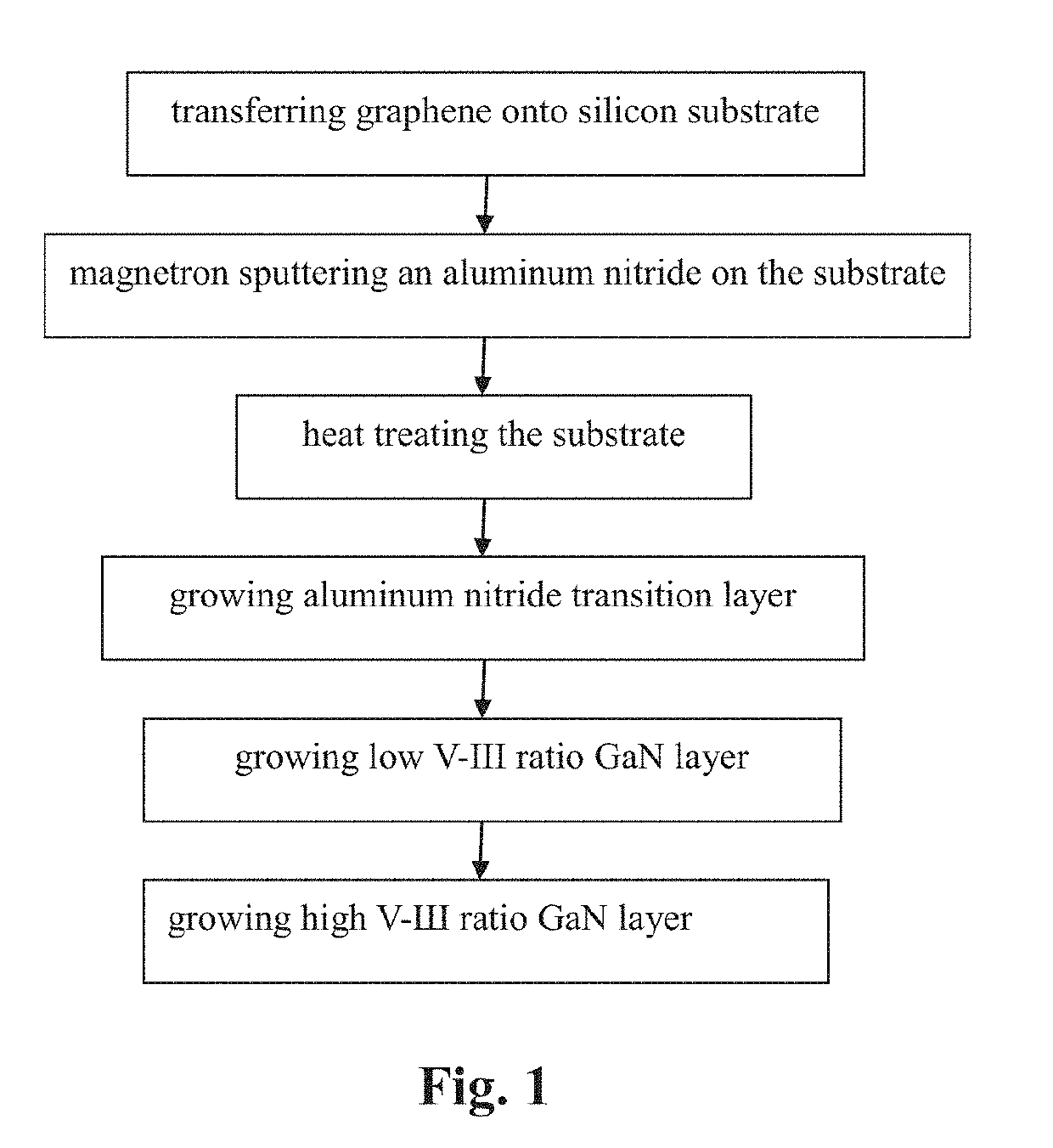

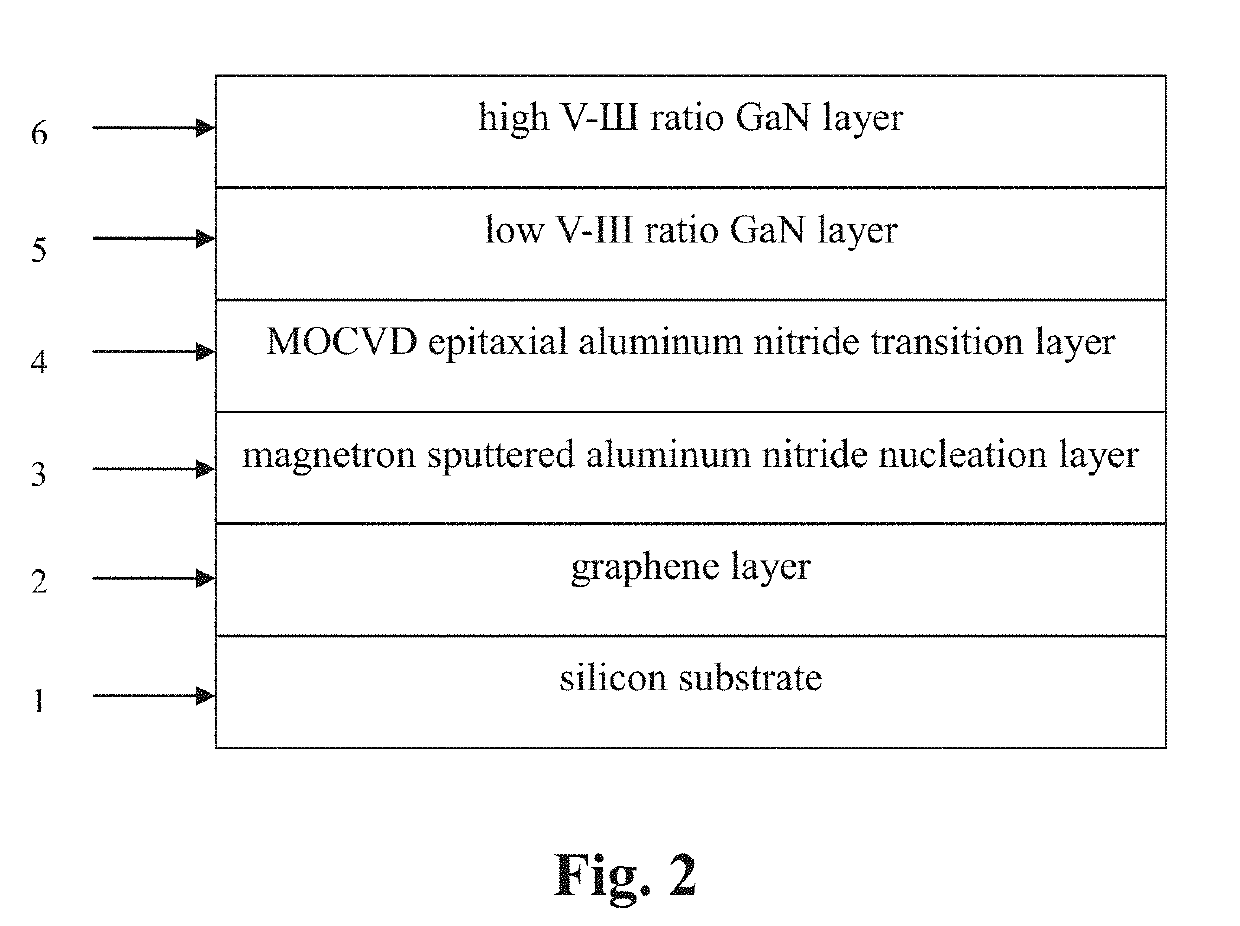

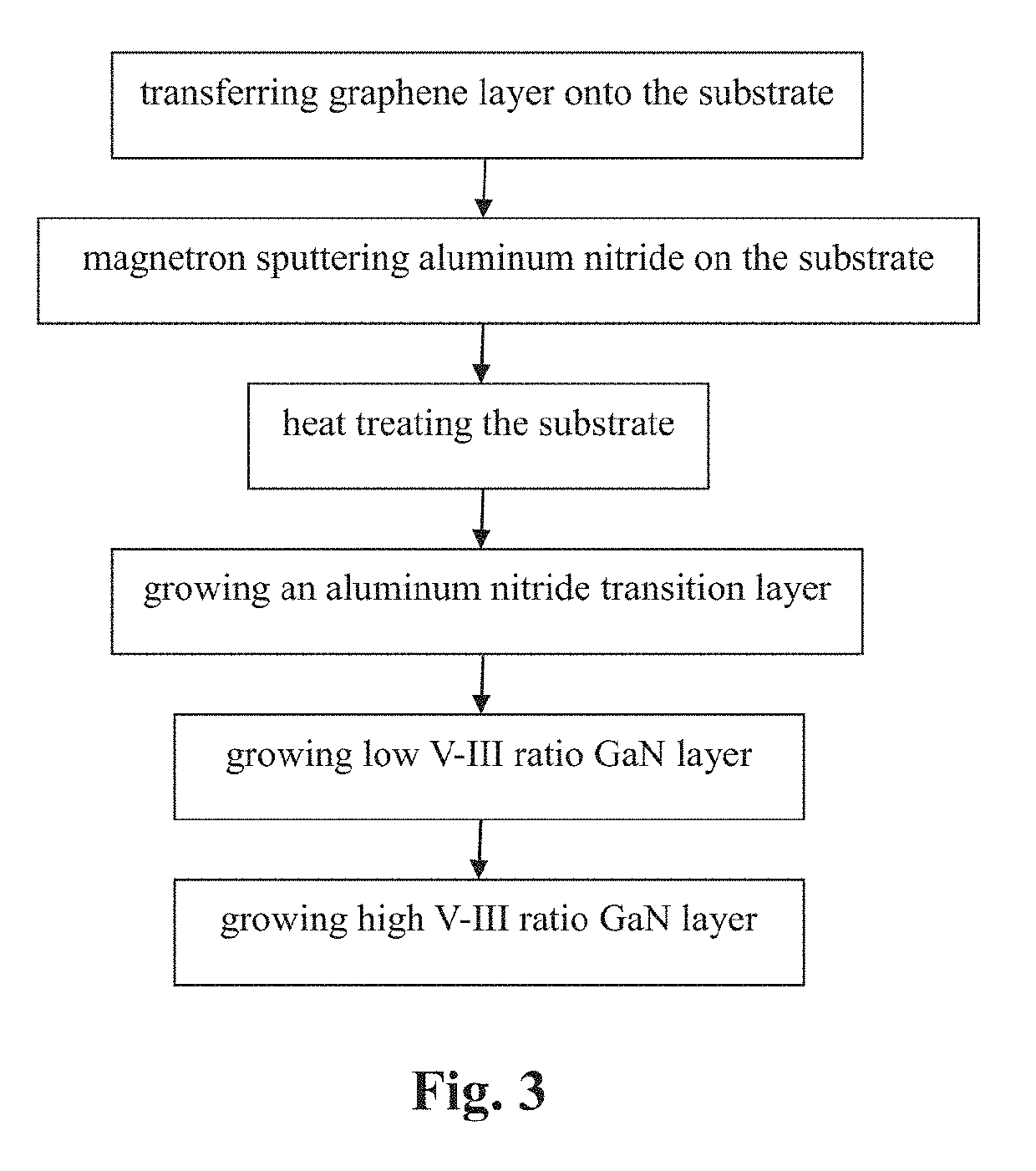

The present invention discloses a method for growing gallium nitride based on graphene and magnetron sputtered aluminum nitride, and a gallium nitride thin film. The method according to an embodiment comprises: spreading graphene over a substrate; magnetron sputtering an aluminum nitrite onto the graphene-coated substrate to obtain a substrate sputtered with aluminum nitrite; placing the substrate sputtered with aluminum nitride into a MOCVD reaction chamber and heat treating the substrate to obtain a heat treated substrate; growing an aluminum nitride transition layer on the heat treated substrate and a first and a second gallium nitride layer having different V-III ratios, respectively. The gallium nitrate thin film according to an embodiment comprises the following structures in order from bottom to top: a substrate (1), a graphene layer (2), an aluminum nitride nucleation layer (3) fabricated by using a magnetron sputtering method, an aluminum nitride transition layer (4) grown by MOCVD, and a first and a second gallium nitrate layer (5, 6) having different V-III ratios.

Owner:XIDIAN UNIV

Method for preparing Ga*O*-Al*O* catalyst for reduction of nitrogen oxide

InactiveCN1467025AAchieve the expected purposeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceNitrogen oxides

A process for preparing the Ga2O3-Al2O3 catalyst used in reduction of Nox includes such steps as preparing gallium nitrate from gallium oxide, preparing monohydrated bohmite by sol-gel method, mixing gallium nitrate with ethanediol, adding the mixture to monohydrated bohmite, vacuum distilling, drying and calcining. Its advantages are low cost, high specific surface area and activity, and high reducing rate as high as to 70-85%.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com