Preparation method of air purifying material and air purifying material

An air purification material, gallium nitride zinc oxide technology, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve problems such as waste of photocatalysts, waste of solar energy, and small contact surface area of organic pollutants. Achieve the effects of improving utilization efficiency, increasing contact surface area, and increasing photodegradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

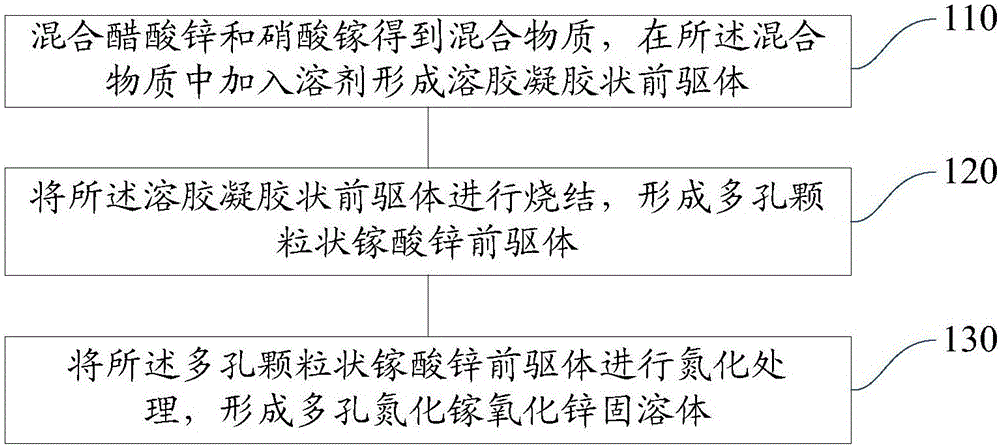

[0038] refer to figure 1 , shows a flow chart of the steps of a method for preparing an air purification material according to an embodiment of the present invention, which may specifically include the following steps:

[0039] In step 110, zinc acetate and gallium nitrate are mixed to obtain a mixed substance, and a solvent is added to the mixed substance to form a sol-gel precursor.

[0040] In a preferred embodiment, zinc acetate with a purity of more than 99% and gallium nitrate with a purity of more than 99% can be mixed to obtain a mixed substance, and a solvent is added to the mixed substance to form a sol-gel ZnGa 2 o 4 Precursor. Both the zinc acetate and gallium nitrate are powdery substances.

[0041] Step 120, sintering the sol-gel precursor to form a porous granular zinc gallate precursor.

[0042] In a preferred embodiment, the sol-gel ZnGa 2 o 4 The precursor is placed in a sintering container for sintering, the sintering container includes a muffle furnac...

Embodiment 2

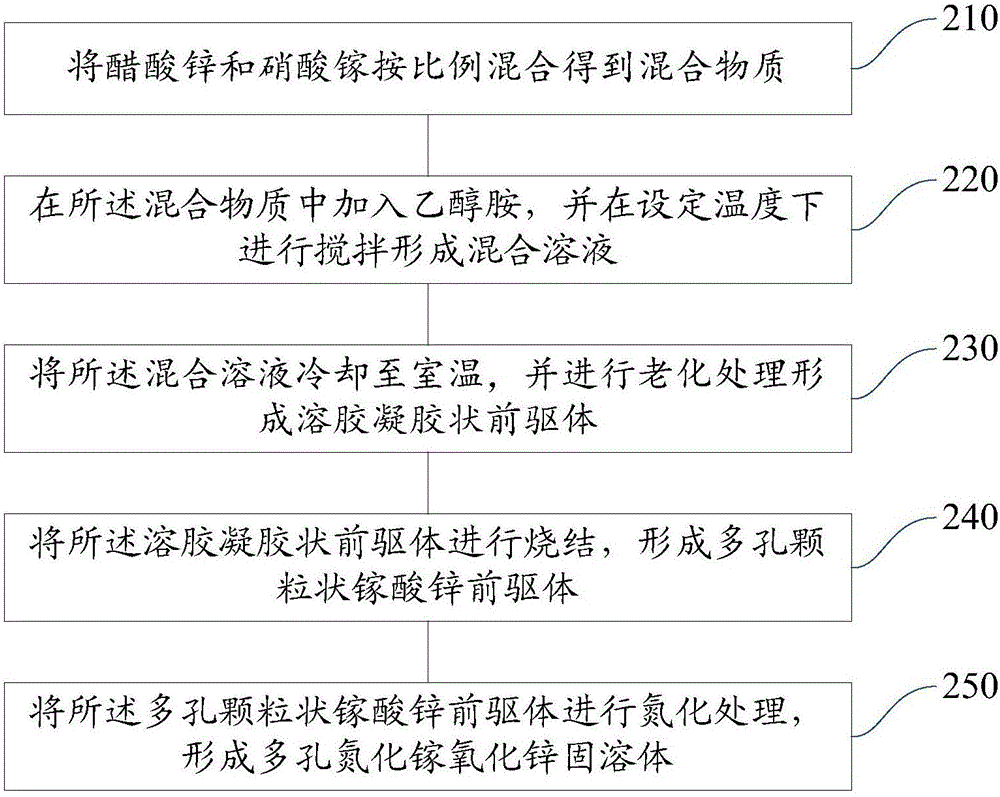

[0048] refer to figure 2 , shows a flow chart of the steps of a method for preparing an air purification material according to an embodiment of the present invention, which may specifically include the following steps:

[0049]Step 210, mixing zinc acetate and gallium nitrate in proportion to obtain a mixed substance.

[0050] In a preferred embodiment, zinc acetate with a purity of more than 99% and gallium nitrate with a purity of more than 99% can be mixed in proportion and poured into a beaker to obtain a mixed substance.

[0051] Step 220, adding ethanolamine into the mixed substance, and stirring at a set temperature to form a mixed solution.

[0052] In a preferred embodiment, ethanolamine with an analytical purity is added to the mixed substance in the beaker as a solvent, and stirred at a set temperature to form a mixed solution.

[0053] The ethanolamine whose purity is analytically pure refers to ethanolamine with high main component content, high purity, and low...

Embodiment 3

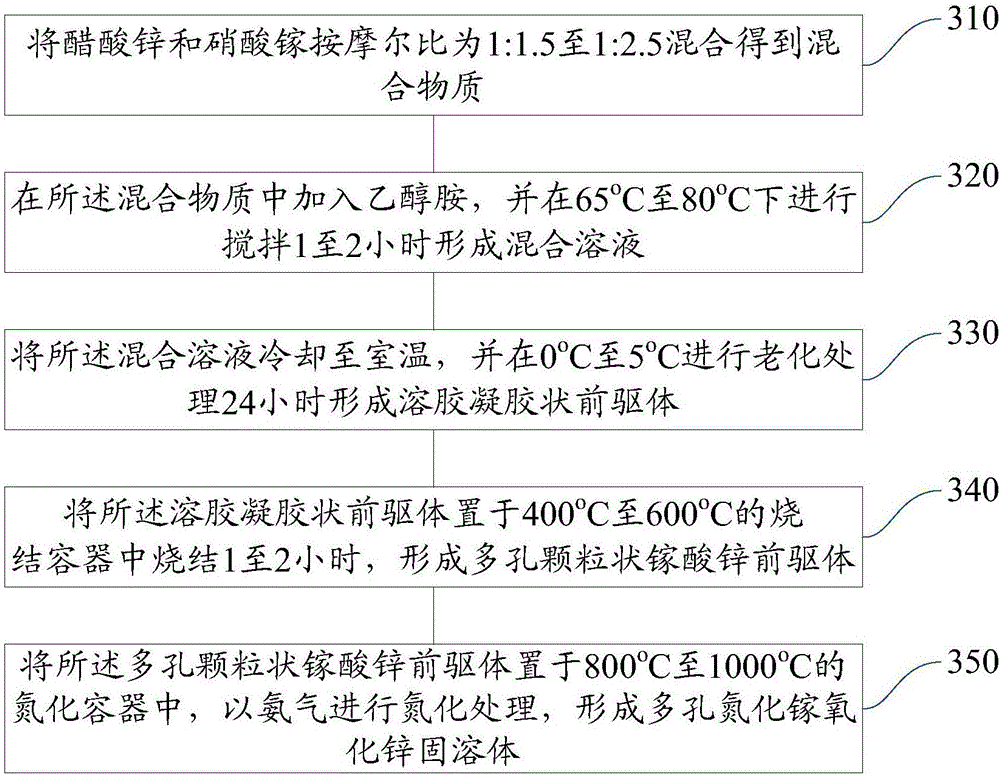

[0063] refer to image 3 , shows a flow chart of the steps of a method for preparing an air purification material according to an embodiment of the present invention, which may specifically include the following steps:

[0064] Step 310, mixing zinc acetate and gallium nitrate in a molar ratio of 1:1.5 to 1:2.5 to obtain a mixed substance.

[0065] In a preferred embodiment, zinc acetate with a purity of more than 99% and gallium nitrate with a purity of more than 99% can be mixed in a molar ratio of 1:1.5 to 1:2.5, for example, the molar ratio of zinc acetate to gallium nitrate 1:1.75, 1:2.15, 1:2.25, and poured into a beaker to obtain a mixed substance.

[0066] Step 320, adding ethanolamine to the mixed substance, and stirring at 65° C. to 80° C. for 1 to 2 hours to form a mixed solution.

[0067] In a preferred embodiment, analytically pure ethanolamine is added to the mixed substance in the beaker as a solvent, and stirred at a set temperature of 65° C. to 80° C. for 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com