Preparation method of photocatalyst Pt-ZnGa2O4 efficient in CO2 reduction under sunlight drive

A photocatalyst and nanophotocatalyst technology, applied in catalyst activation/preparation, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of limiting photocatalytic activity, low photocatalytic efficiency, reducing specific surface area, etc. Quantum efficiency, simple preparation process, uniform particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

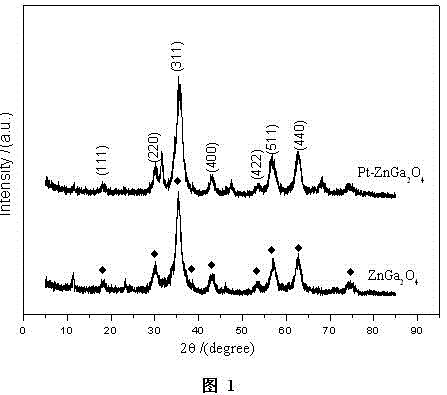

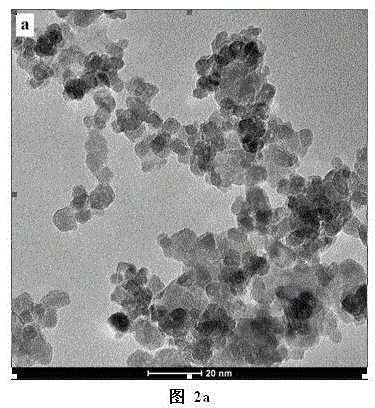

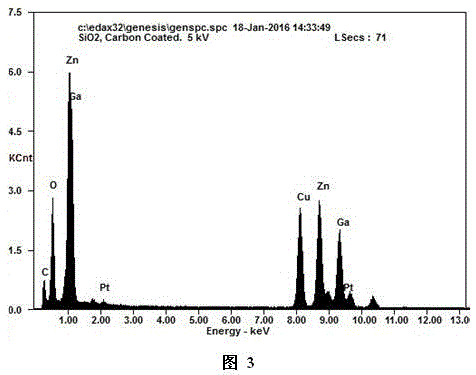

[0026] Weigh zinc nitrate and gallium nitrate with a molar ratio of Zn to Ga of 1:2 and dissolve them in deionized water under magnetic stirring to form a mixed solution. The ZnGa obtained by PEG-400 according to the reaction theory 2 o 4 Add 3% of the mass of the mixed nitrate solution into the mixed nitrate solution. After it is completely dissolved, add 20% ammonia water drop by drop under magnetic stirring to adjust the pH value of the solution to 8; transfer the mixed solution to a hydrothermal reaction kettle for hydrothermal 1. Aging reaction, the reaction temperature is 80°C, and the reaction time is 12 hours; the reaction product is poured into a vacuum filtration device for suction filtration, washed with deionized water, and vacuum-dried at 500°C for 3 hours to obtain nano-ZnGa with high specific surface area. 2 o 4 ; Take the obtained ZnGa 2 o 4 The product is dispersed in deionized water, fully stirred to form a suspension, and 2% H of its Pt load weight is add...

preparation Embodiment 2

[0028] Weigh zinc nitrate and gallium nitrate with a molar ratio of Zn to Ga of 1:2 and dissolve them in deionized water under magnetic stirring to form a mixed solution. The ZnGa obtained by PEG-4000 according to the reaction theory 2 o 4 Add 4% of the quality of the mixed nitrate solution into the mixed nitrate solution. After it is completely dissolved, add 20% ammonia water drop by drop under magnetic stirring to adjust the pH value of the solution to 9; transfer the mixed solution to a hydrothermal reaction kettle for hydrothermal 1. Aging reaction, the reaction temperature is 100°C, and the reaction time is 10 hours; the reaction product is poured into a vacuum filtration device for suction filtration, washed with deionized water, and vacuum-dried at 400°C for 4 hours to obtain nano-ZnGa with high specific surface area. 2 o 4 ; Take the obtained ZnGa 2 o 4 The product is dispersed in deionized water, ultrasonically dispersed and fully stirred to form a suspension, and...

preparation Embodiment 3

[0030] Weigh zinc nitrate and gallium nitrate with a molar ratio of Zn to Ga of 1:2 and dissolve them in deionized water under magnetic stirring to form a mixed solution. The ZnGa obtained by PEG-10000 according to the reaction theory 2 o 4 Add 6% of the mass of the mixed nitrate solution into the mixed nitrate solution. After it is completely dissolved, add 20% ammonia water drop by drop under magnetic stirring to adjust the pH value of the solution to 10; transfer the mixed solution to a hydrothermal reaction kettle for hydrothermal 1. Aging reaction, the reaction temperature is 120°C, and the reaction time is 8 hours; the reaction product is poured into a vacuum filtration device for suction filtration, washed with deionized water, and vacuum-dried at 300°C for 6 hours to obtain nano-ZnGa with a high specific surface 2 o 4 . Weigh a certain amount of ZnGa 2 o 4 Put it into a beaker, add 5mL absolute ethanol and sonicate for 10 minutes, then add H 2 PtCl 6 Aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com