Self-purification type developing solution composition, preparation method thereof and developing method using self-purification type developing solution composition

A developing solution and composition technology, applied in the field of developing solution, can solve problems such as substrate contamination, hindering the development process, and inaccurate photoresist images, so as to reduce the probability of agglomeration, have no photoresist residue, and have good developing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1, preparation of developing solution S1: at normal temperature, 95% inorganic alkali (Na 2 CO 3 ), 2.2% sulfonate type anionic surfactant (ABS), 2% defoamer (GPE), 0.8% inhibitor (C 2 H 2 O 4 ), add it into deionized water and stir well to get it.

[0027] S2-S9 and D1-D4 were prepared by mixing the components in exactly the same way as in Example 1.

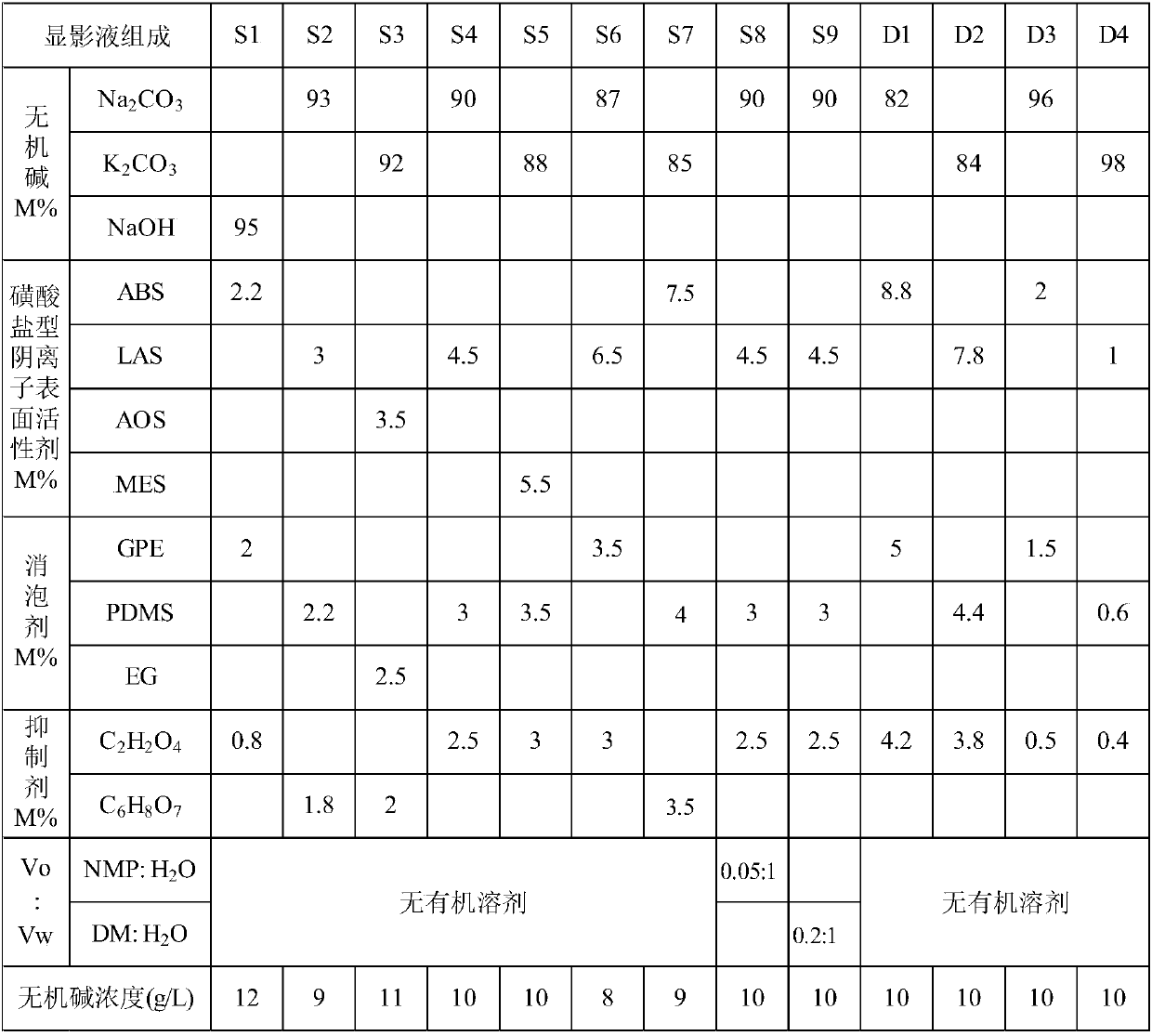

[0028] Table 1 List of component names and dosages of developers S1-S9 and D1-D4

[0029]

[0030] ABS: branched alkyl benzene sulfonate

[0031] LAS: Sodium Linear Alkylbenzene Sulfonate

[0032] AOS: alpha-olefin sulfonate

[0033] MES: α-sulfomonocarboxylic acid and its derivatives

[0034] GPE: Polyoxypropylene polyoxyethylene glycerol ether

[0035] PDMS: Polydimethylsiloxane

[0036] EG: Emulsified Glycerin

[0037] C 2 H 2 O 4 :oxalic acid

[0038] C 6 H 8 O 7 : Citric acid

[0039] NMP: N-Methylpyrrolidone

[0040] DM: Diethylene glycol monomethyl ether

[0041] Vo: volume of organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com