Defect detection method, mask manufacturing method and semiconductor structure forming method

A defect detection and defect technology, which is applied in semiconductor/solid-state device testing/measurement, photolithographic process of patterned surface, optics, etc., can solve the problem that the yield rate of semiconductor structure needs to be improved, and achieve the effect of improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As mentioned in the background, the yield of the semiconductor structure formed by the optical proximity corrected mask in the prior art still needs to be improved. The following will describe in detail in conjunction with the accompanying drawings.

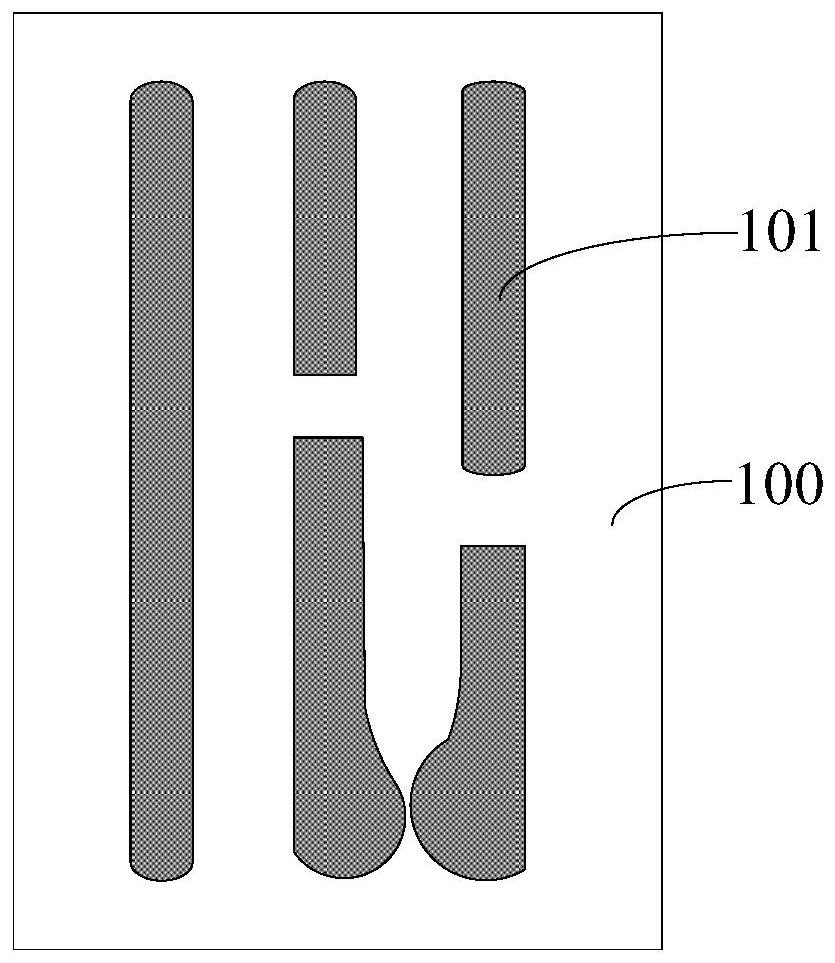

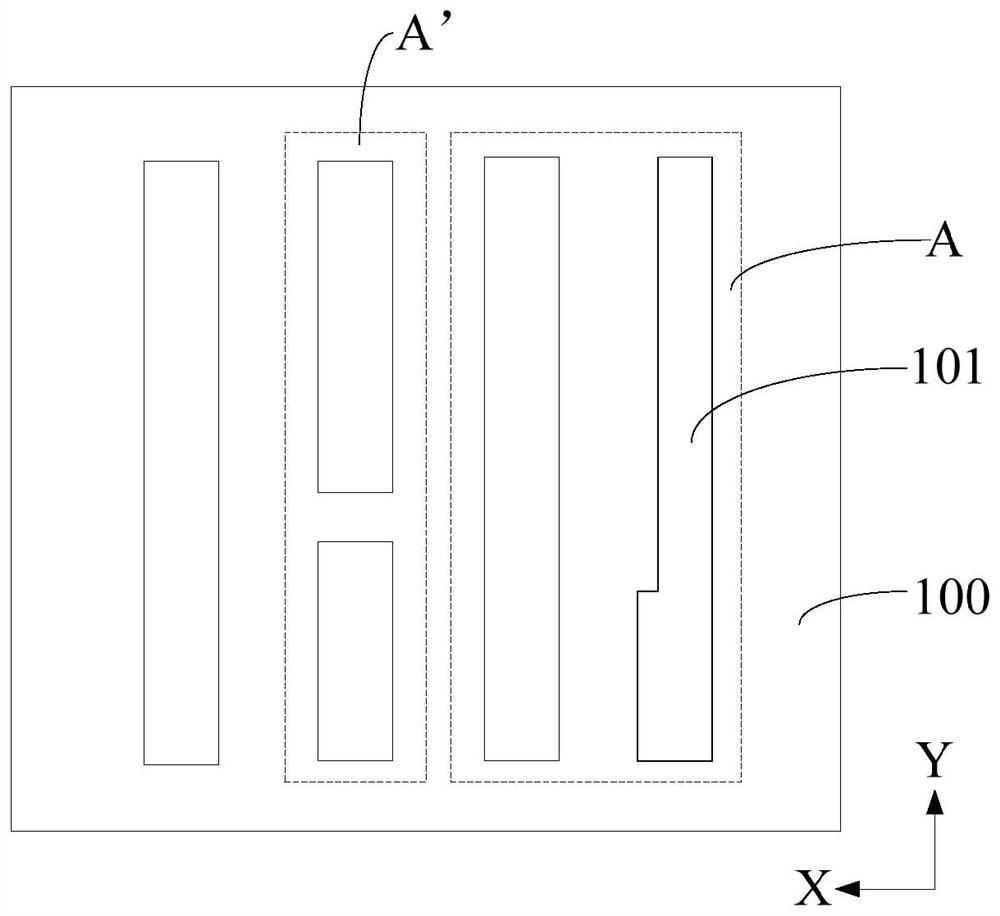

[0040] Please refer to figure 1 , providing a substrate 100, the surface of the substrate has a layer to be etched (not shown); providing a mask (not shown); using the mask as a mask, the layer to be etched is patterned process, forming several core layers 101 on the substrate.

[0041] In this embodiment, although the reticle has undergone several optical proximity corrections, as the current minimum feature size continues to decrease, the graphics in the reticle will be short-circuited during the exposure process ( bridge), if this short circuit phenomenon is solved only by its own mask, in some cases it will be very cumbersome and difficult, or even impossible to solve, so it will cause a short circuit between the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com