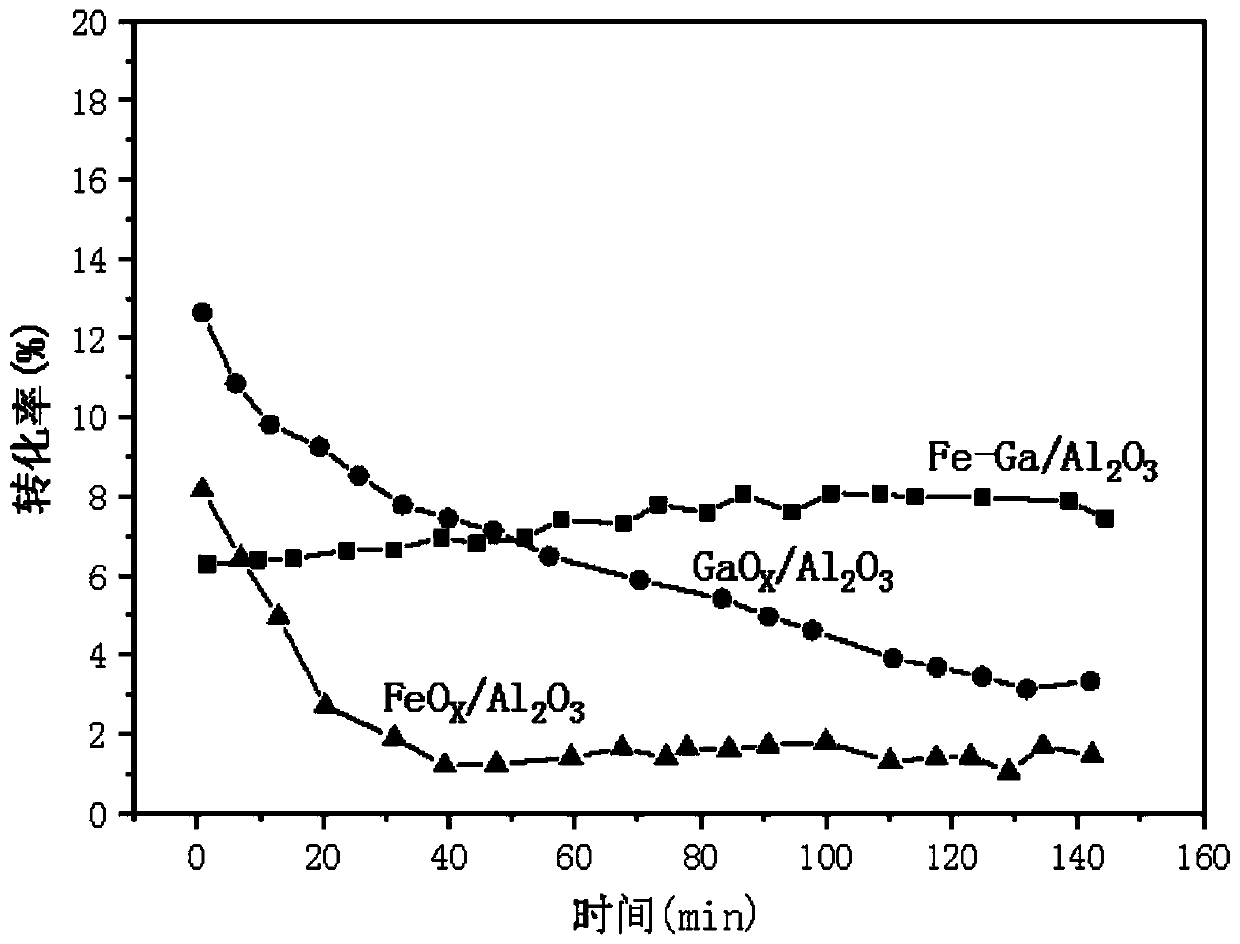

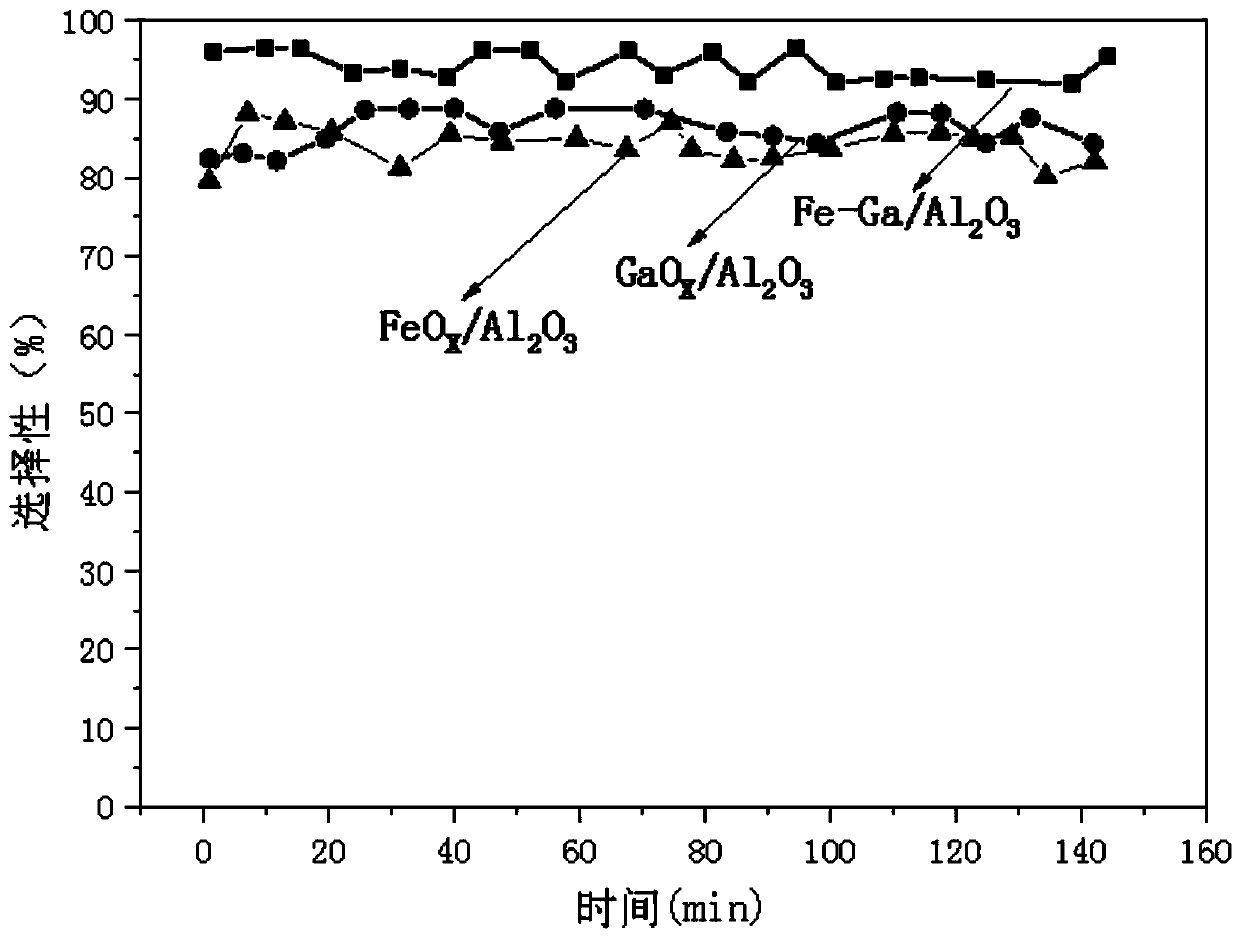

Iron-gallium-based propane dehydrogenation catalyst and preparation method thereof

A dehydrogenation catalyst, iron gallium propane technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as catalyst reduction, deactivation, etc. The effect of improved conversion and selectivity, good stability and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for an iron-gallium-based propane dehydrogenation catalyst, comprising the following steps:

[0025] (1) Calcining pseudo-boehmite at 700°C for 6h into γ-Al 2 o 3 ;

[0026] (2) Weigh gallium nitrate, add deionized water, 70 ℃ water bath, magnetically stir for 0.5h, until the gallium nitrate is completely dissolved, and prepare gallium nitrate solution; weigh ferric nitrate, add deionized water, 70 ℃ water bath, magnetically stir 0.5h until ferric nitrate is completely dissolved to obtain ferric nitrate solution; add alumina carrier to 0.60mol / L gallium nitrate solution, stir evenly, add dropwise 1.0mol / L sodium hydroxide aqueous solution to adjust the pH value to 4, static Set aging for 2h;

[0027] (3) Add 3.00 mol / L ferric nitrate solution dropwise to the aged solution in step (1), after stirring evenly, add 1.0 mol / L sodium hydroxide aqueous solution dropwise to adjust the pH value to 7 to form ferric hydroxide and hydrogen Precipitation of ...

Embodiment 2

[0031] A preparation method for an iron-gallium-based propane dehydrogenation catalyst, comprising the following steps:

[0032] (1) Calcining pseudo-boehmite at 850°C for 5h into δ-Al 2 o 3 ;

[0033] (2) Weigh gallium nitrate, add deionized water, 70 ℃ water bath, magnetically stir for 0.5h, until the gallium nitrate is completely dissolved, and prepare gallium nitrate solution; weigh ferric nitrate, add deionized water, 70 ℃ water bath, magnetically stir 0.5h, until ferric nitrate dissolves completely, makes ferric nitrate solution; Add alumina carrier in 0.40mol / L gallium nitrate solution, after stirring evenly, add dropwise 1.0mol / L sodium hydroxide aqueous solution to adjust pH value to 4, static Set aging for 2h;

[0034](3) Add 2.80mol / L ferric nitrate solution dropwise to the aged solution in step (1), after stirring evenly, add 1.0mol / L sodium hydroxide aqueous solution dropwise to adjust the pH value to 7 to form ferric hydroxide and hydroxide Gallium precipitat...

Embodiment 3

[0038] A preparation method for an iron-gallium-based propane dehydrogenation catalyst, comprising the following steps:

[0039] (1) Calcining pseudo-boehmite at 1000°C for 4h to form θ-Al 2 o 3 ;

[0040] (2) Weigh gallium nitrate, add deionized water, 70 ℃ water bath, magnetically stir for 0.5h, until the gallium nitrate is completely dissolved, and prepare gallium nitrate solution; weigh ferric nitrate, add deionized water, 70 ℃ water bath, magnetically stir 0.5h until ferric nitrate is completely dissolved to prepare ferric nitrate solution; add alumina carrier to 0.30mol / L gallium nitrate solution, stir evenly, adjust the pH value to 4, and let stand for aging for 2h;

[0041] (3) Add 1.80mol / L ferric nitrate solution dropwise to the solution after step (1) aging, after stirring evenly, adjust the pH value to 7 to form ferric hydroxide and gallium hydroxide precipitation, leave it to stand for aging for 12h; The iron element content in the ferric nitrate solution is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com