Preparation method of high-purity gallium oxide

A gallium oxide, high-purity technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of low purity of gallium oxide, unsatisfactory use, high equipment investment, etc., to achieve high purity and production The effect of high efficiency and less production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

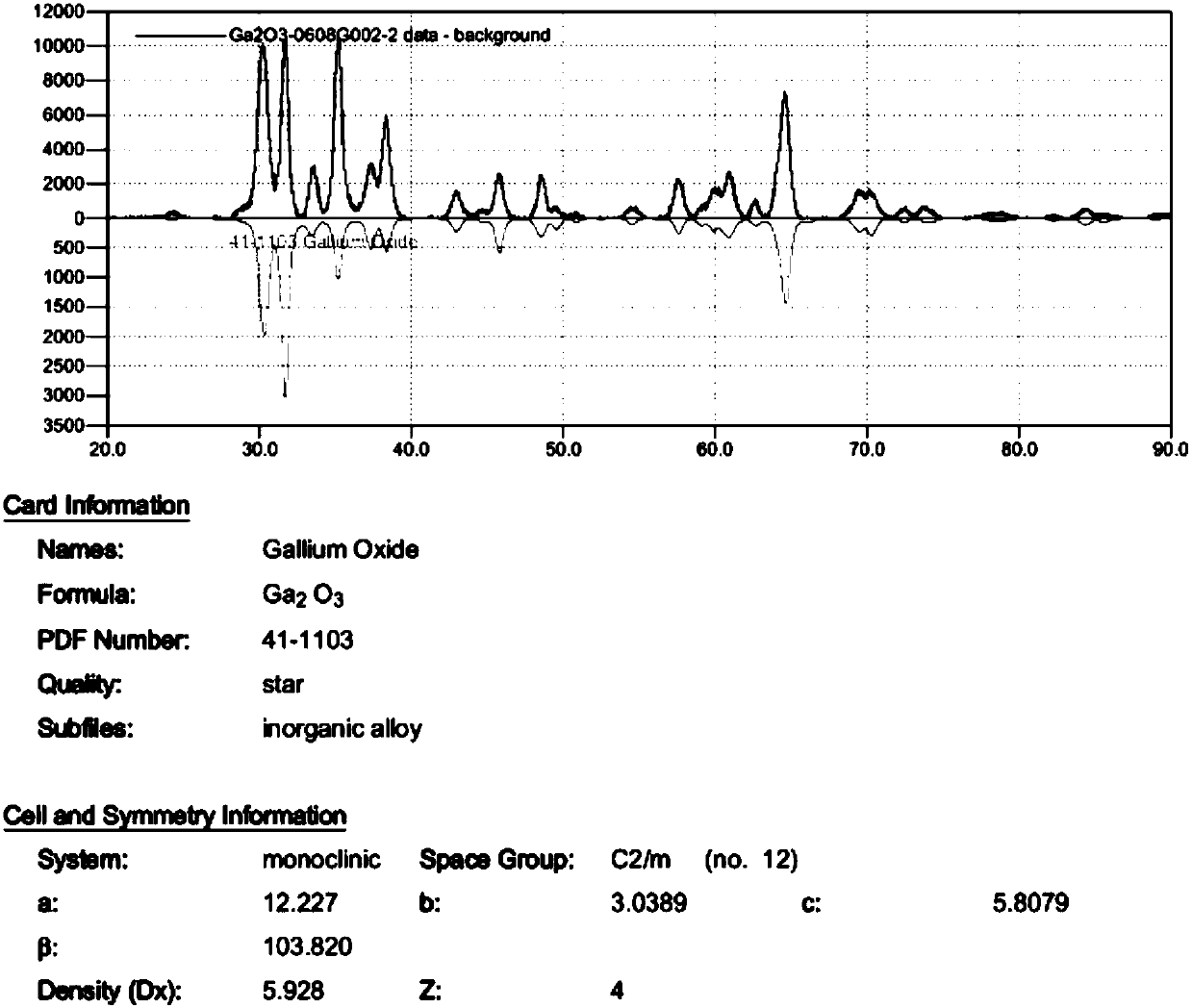

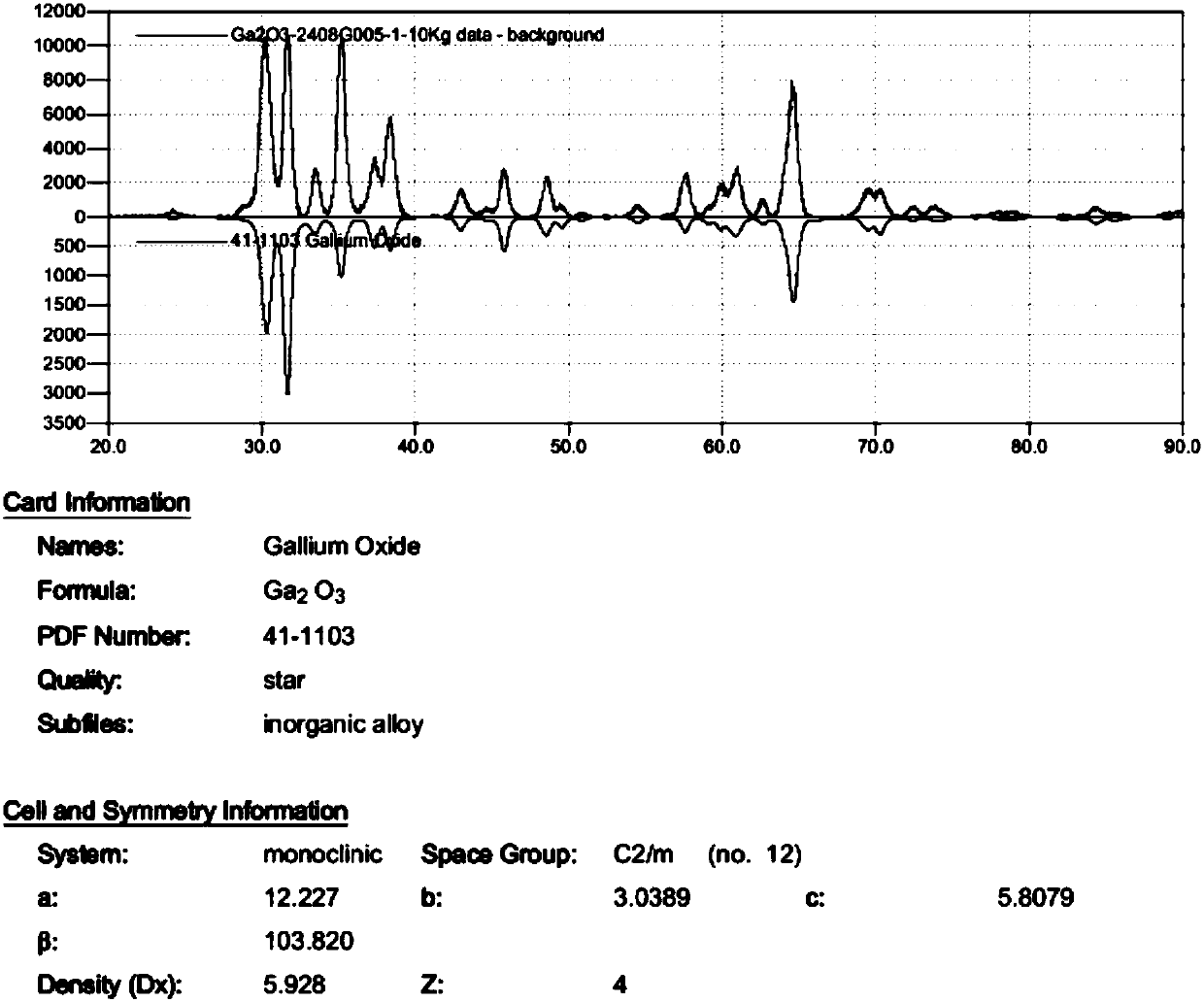

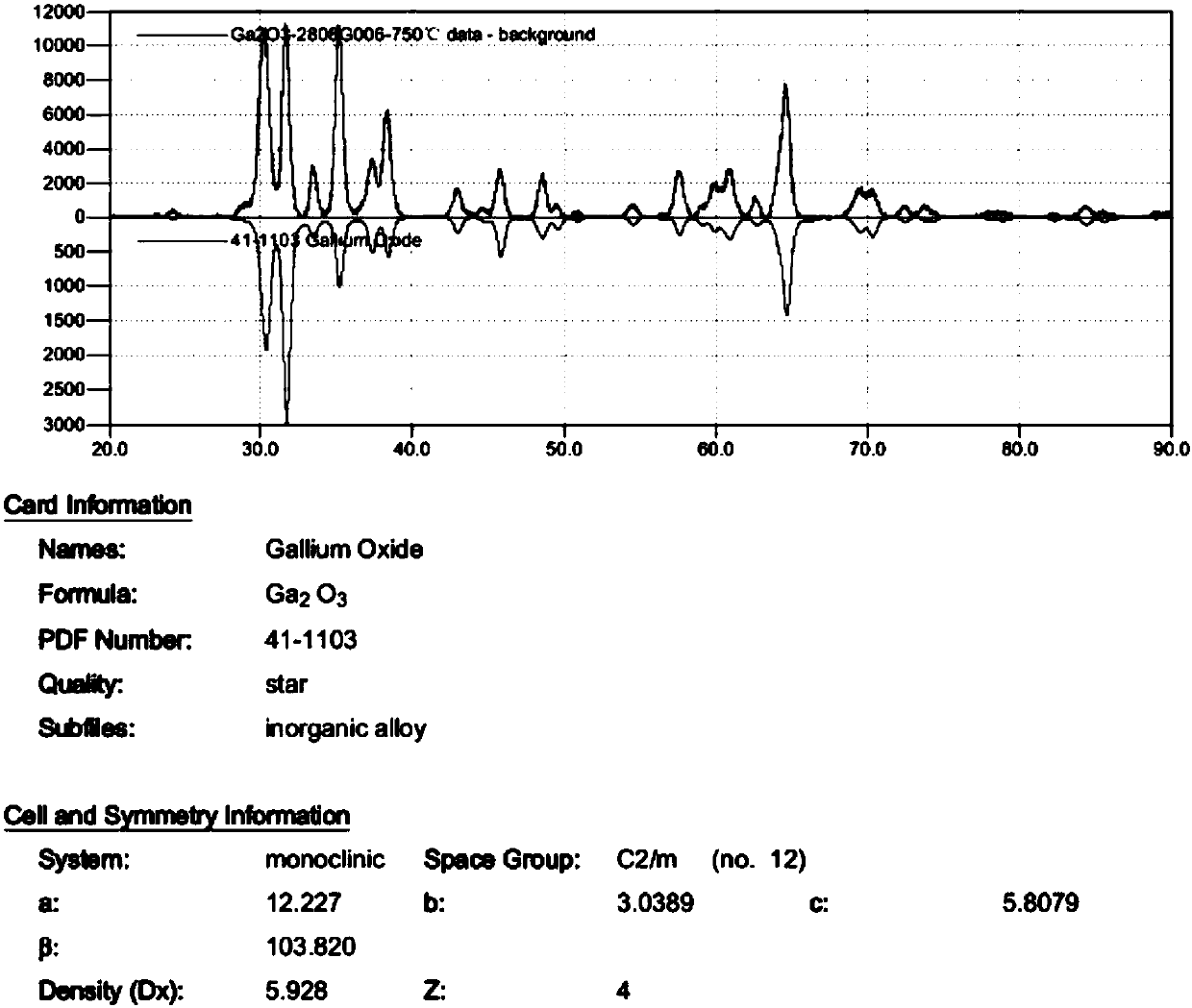

Image

Examples

preparation example Construction

[0015] The preparation method of high-purity gallium oxide according to the present application includes steps: S1, adding solvent water into the reaction kettle, raising the temperature to above 30°C, then adding metal gallium, turning on the stirring device to disperse the metal gallium evenly, and then adding React with nitric acid, filter to remove unreacted solid impurities after the reaction, and obtain gallium nitrate solution; S2, place the filtered gallium nitrate solution in the reaction kettle, start the stirring device, and then add ammonia water to react until the pH value of the reaction system Stable and unchanged, end the reaction, stop stirring or start periodic stirring to age the reacted material at 40°C to 110°C; S3, restart the stirring device after aging to continue stirring to make the material disperse evenly, and then use a centrifuge Centrifuge, wash, dry, discharge, and then calcined under non-reducing gas atmosphere to obtain high-purity gallium oxid...

Embodiment 1

[0038] Add 400L of purified water into the nitric acid corrosion-resistant Ti reaction kettle, raise the temperature to 40°C, then add 69.72kg (1000mol) of liquid metal gallium with a purity of 4N, then start stirring to make the metal gallium evenly distributed in the water, and then use a more uniform The speed of the reaction is to add an aqueous solution of nitric acid with a purity of chemical purity, wherein the molar ratio of metal gallium to nitric acid is 1:4, and the reaction is continued for 24 hours until the solution is clear and transparent. At this time, the pH of the solution is about 2.0, and then filtered through a precision filter. A solution of gallium nitrate was obtained.

[0039] Place the gallium nitrate solution in an interlayered Ti reaction kettle resistant to nitric acid corrosion, dilute it with purified water until the content of gallium in the solution is 20g / L, then add chemically pure ammonia water for reaction, when the pH of the solution is st...

Embodiment 2

[0044] Add 400L of purified water into the nitric acid corrosion-resistant Ti reaction kettle, raise the temperature to 40°C, then add 69.72kg (1000mol) of liquid metal gallium with a purity of 5N, then start stirring to make the metal gallium evenly distributed in the water, and then use a more uniform The rate of adding purity is chemically pure nitric acid aqueous solution to react, wherein the molar ratio of metal gallium and nitric acid is 1:4.5, continue to react for 16h until the solution is clear and transparent, the pH of the solution at this time is about 1.0, and then filtered through a precision filter, A solution of gallium nitrate was obtained.

[0045] Place the gallium nitrate solution in an interlayered Ti reaction kettle resistant to nitric acid corrosion, add purified water to dilute it until the content of gallium in the solution is 150g / L, then add chemically pure ammonia water for reaction, when the pH of the solution is stable End the reaction after 9.0,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com