Patents

Literature

199results about How to "Less production equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

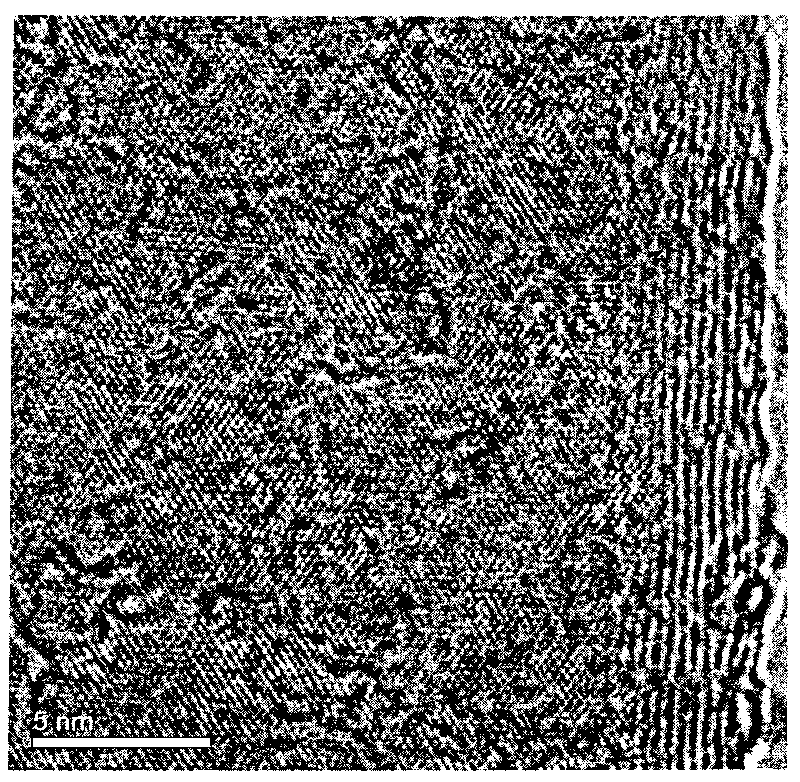

Method for preparing multi-layer graphene

ActiveCN101746755AImprove conductivityImprove thermal conductivityUltrasonic dispersionMaterials science

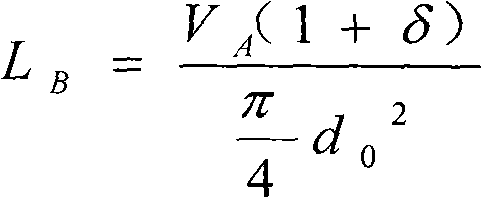

The invention relates to a method for preparing multi-layer graphene, and belongs to the technical field of carbon materials. The multi-layer graphene is prepared from expanded graphite serving as a raw material through ultrasonic dispersion, solid-liquid separation and drying. The thickness of the multi-layer graphene prepared by the method is between 1 and 10nm; the number of layers is between 2 and 20 layers; and the aperture is mainly between 6 and 50nm. The multi-layer graphene has the characteristics of high electrical conductivity, high heat conductivity, high electromagnetic wave absorptivity, wear resistance and the like. The method has the advantages of simpleness, convenient operation and low production cost, capability of reducing production energy consumption, no three wastes emission, environmental friendliness and convenient popularization and application. The multi-layer graphene prepared by the method can be used as the electrode materials of batteries and super capacitors, can also be used as the conductive agents of high molecular materials, ceramic materials, silicate materials and the like, and can also be used as the conductive agents of lithium batteries, alkaline batteries and nickel-metal hydride batteries.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

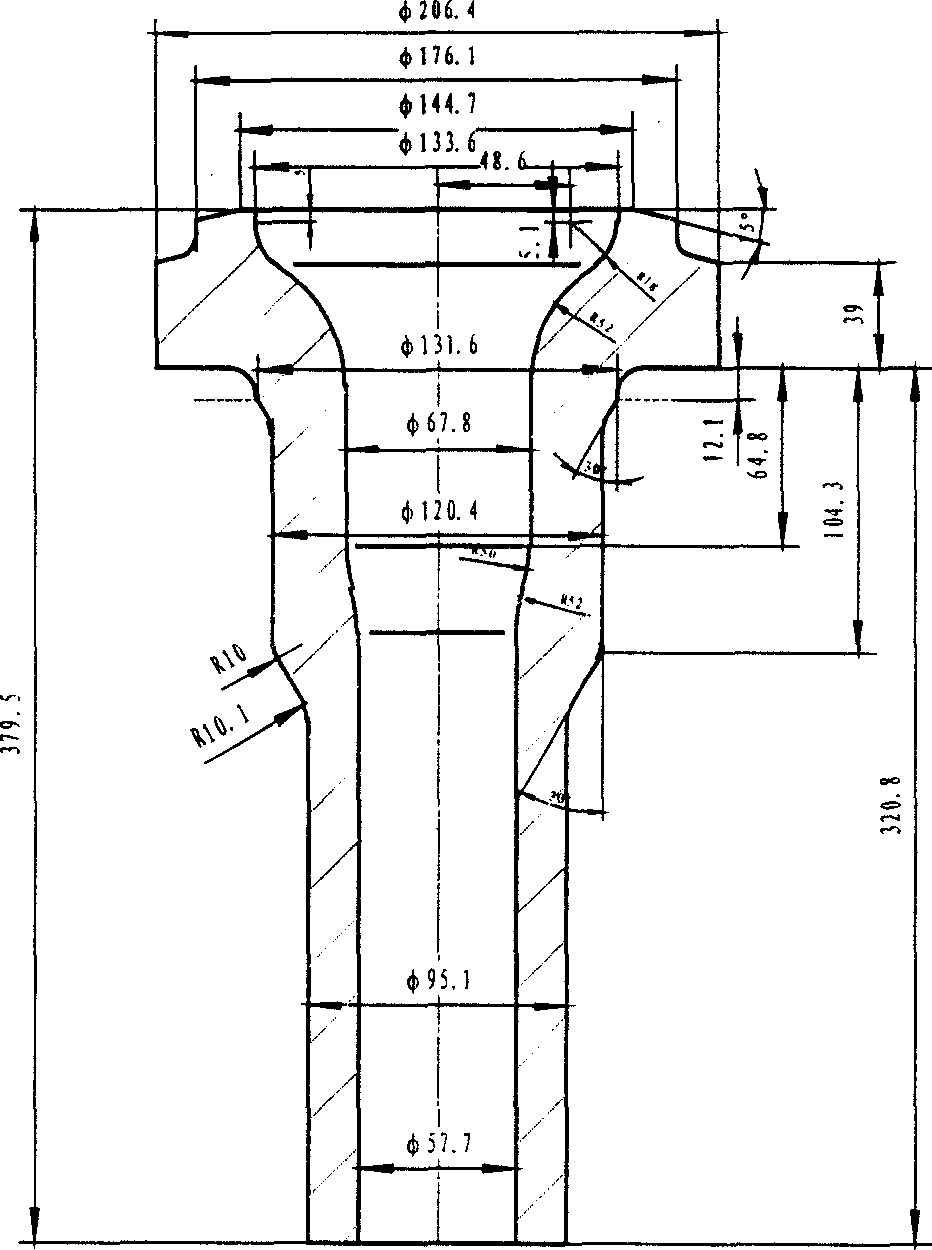

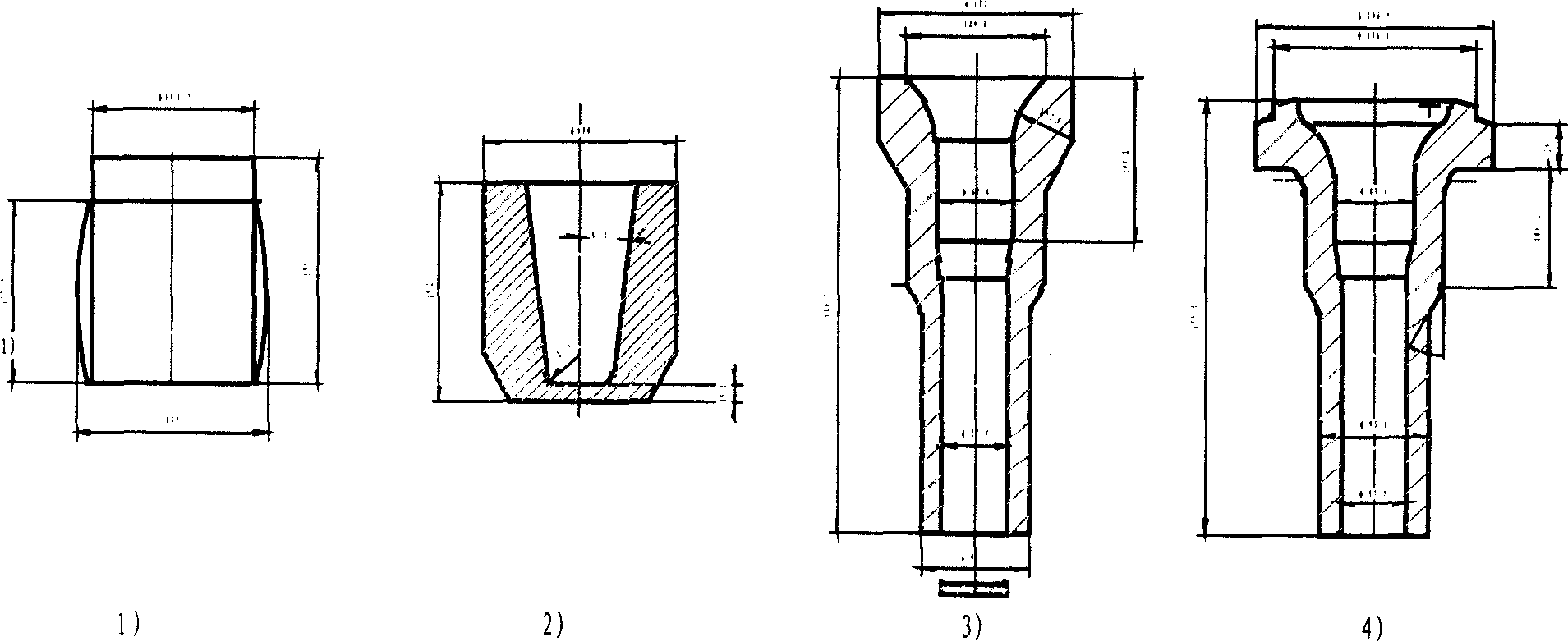

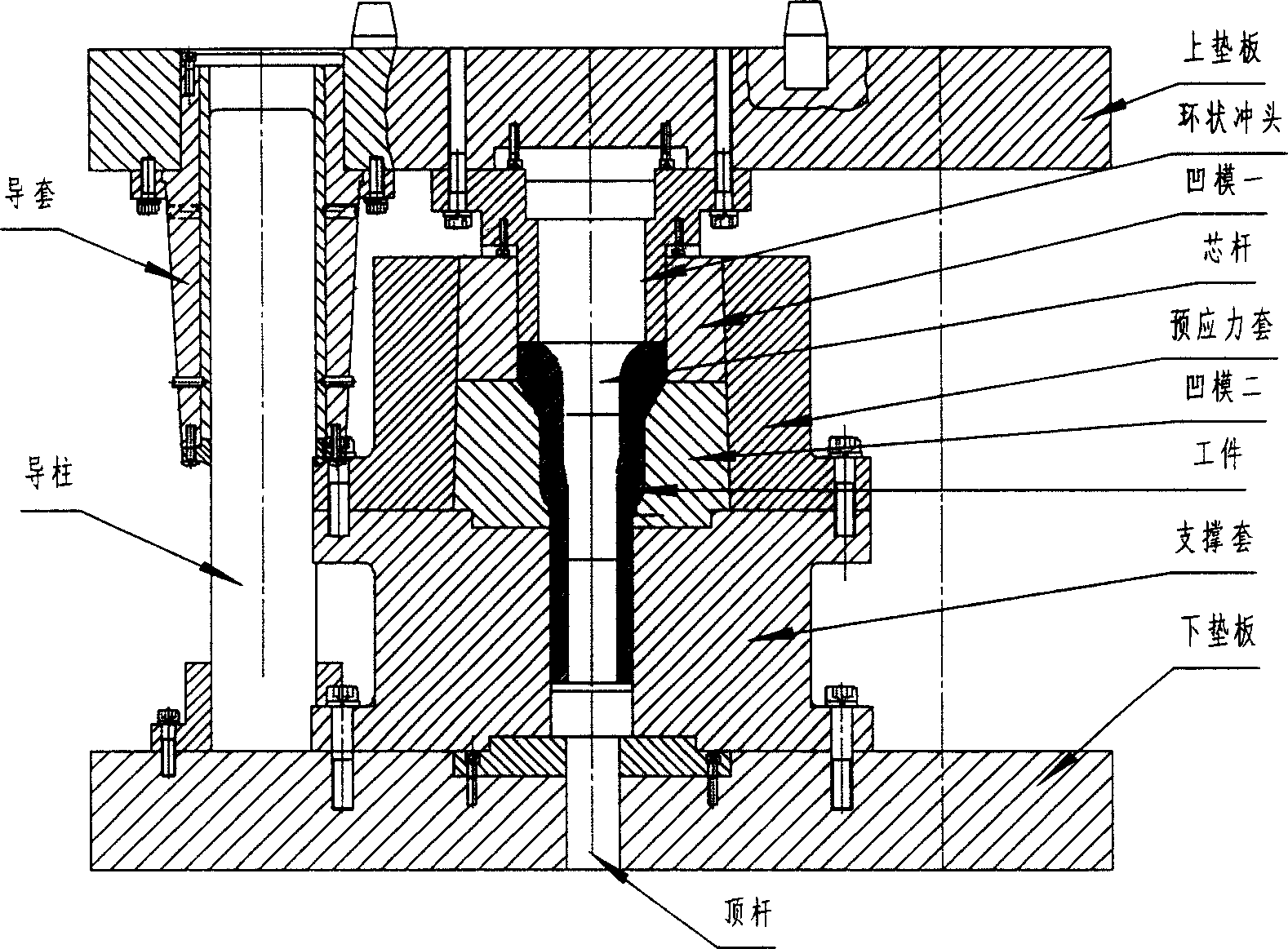

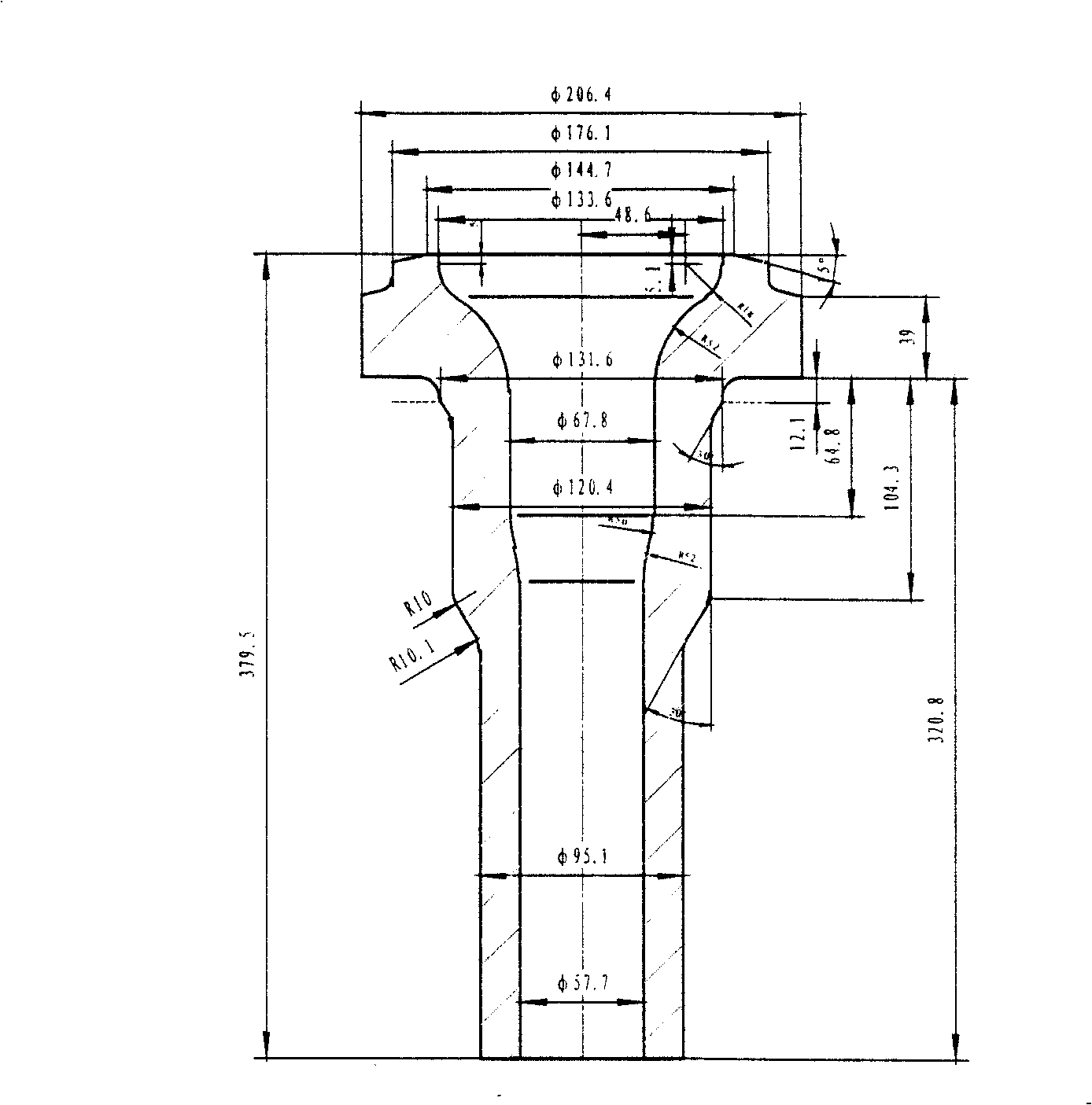

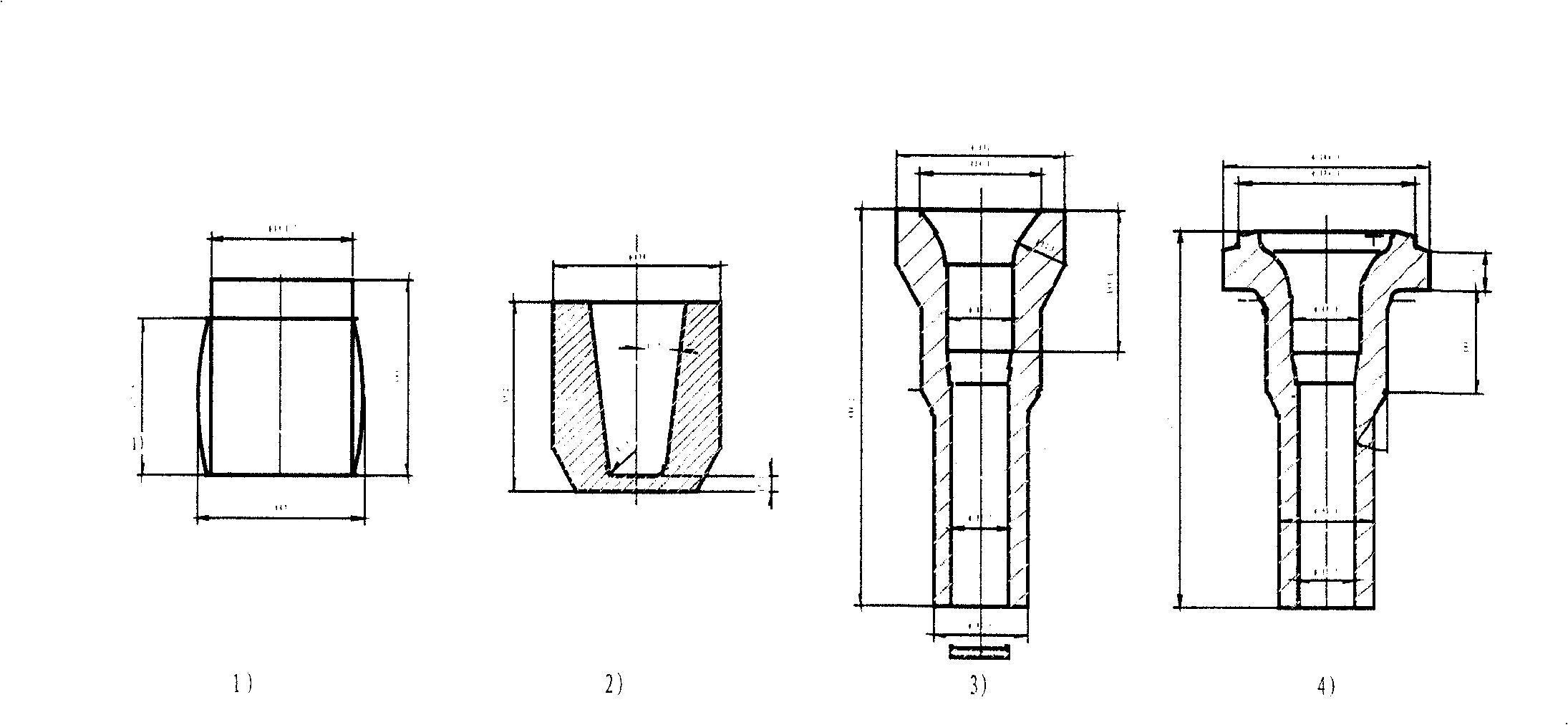

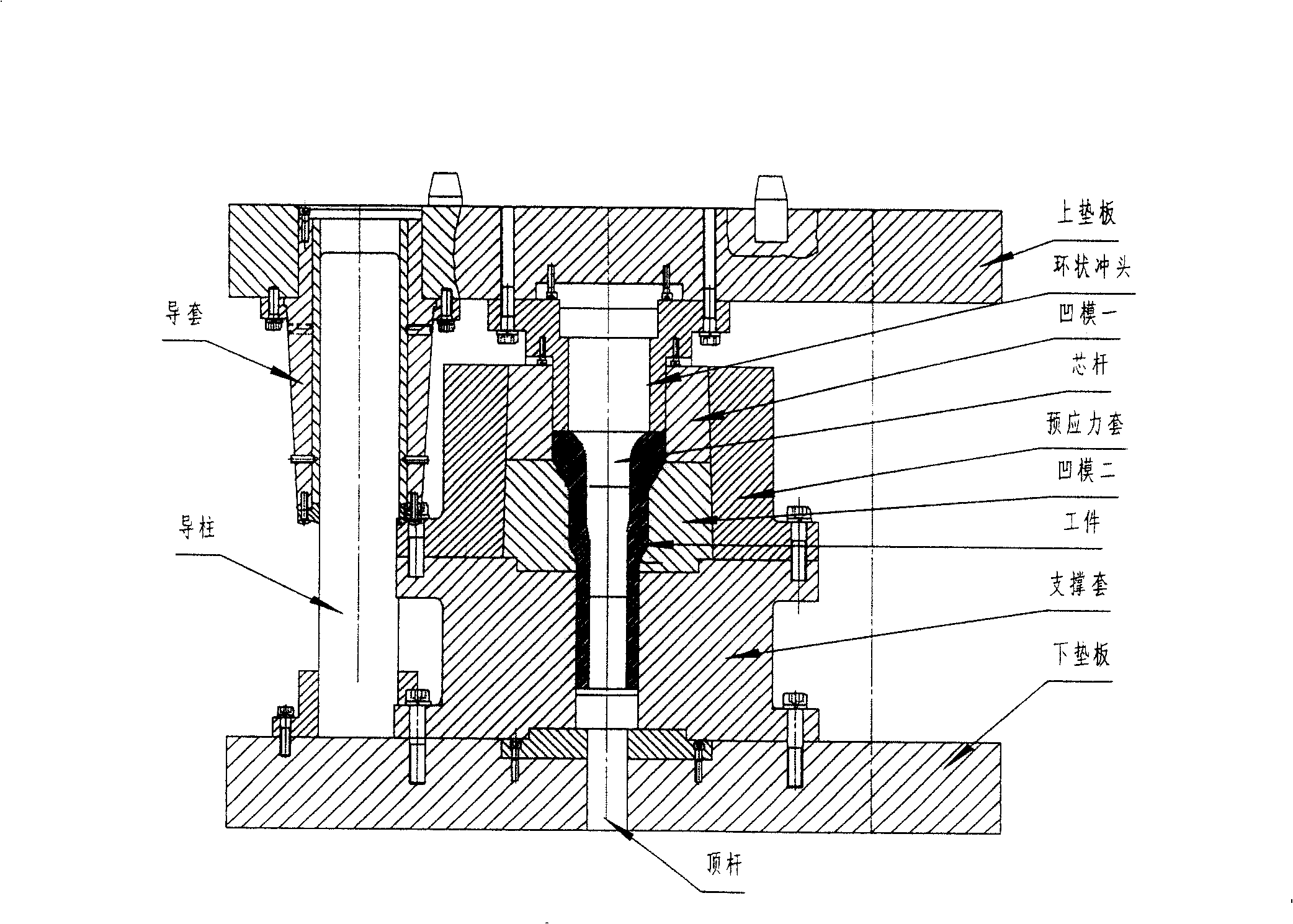

Fast precise semi-axle casing extruding formation process

InactiveCN1672863AImprove the state of stressGuaranteed dimensional accuracyMetal-working apparatusOther manufacturing equipments/toolsEngineeringMachining

The technological process of fast forming precise semi-axle casing with circular rod material heated to forging temperature includes four steps of upsetting, punching hole, perforating and positive extruding. The present invention realizes the fast formation of precise semi-axle casing in only four steps. Combined male die structure is adopted to simplify the technological process of extruding hollow rod, and the present invention has high production efficiency and raised material utilization.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

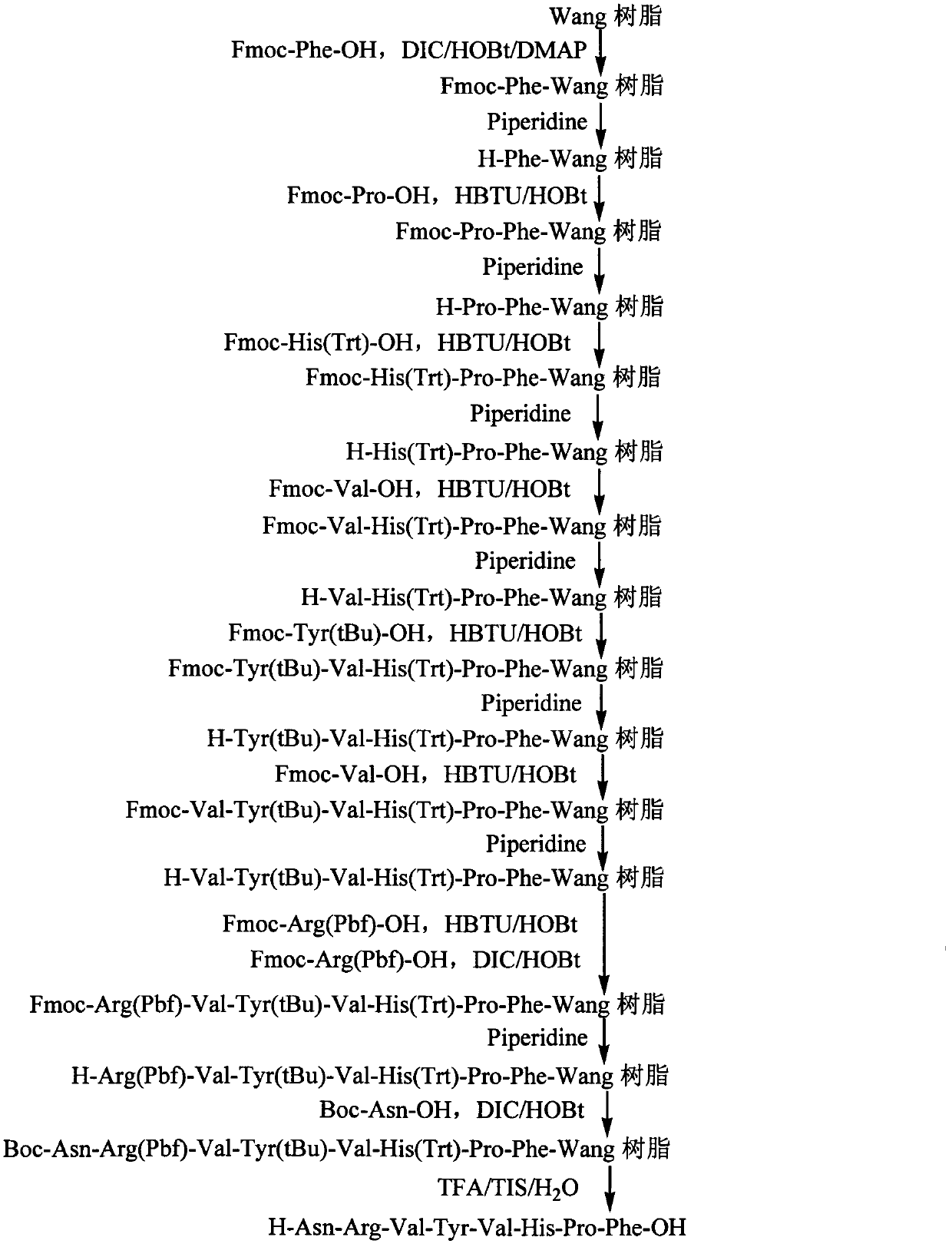

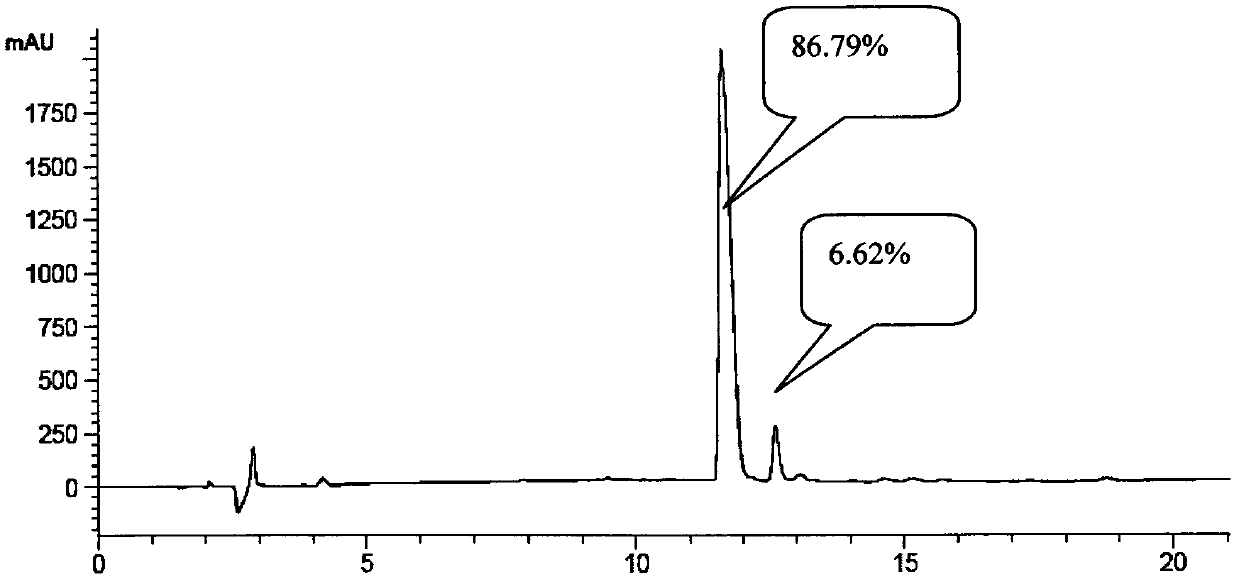

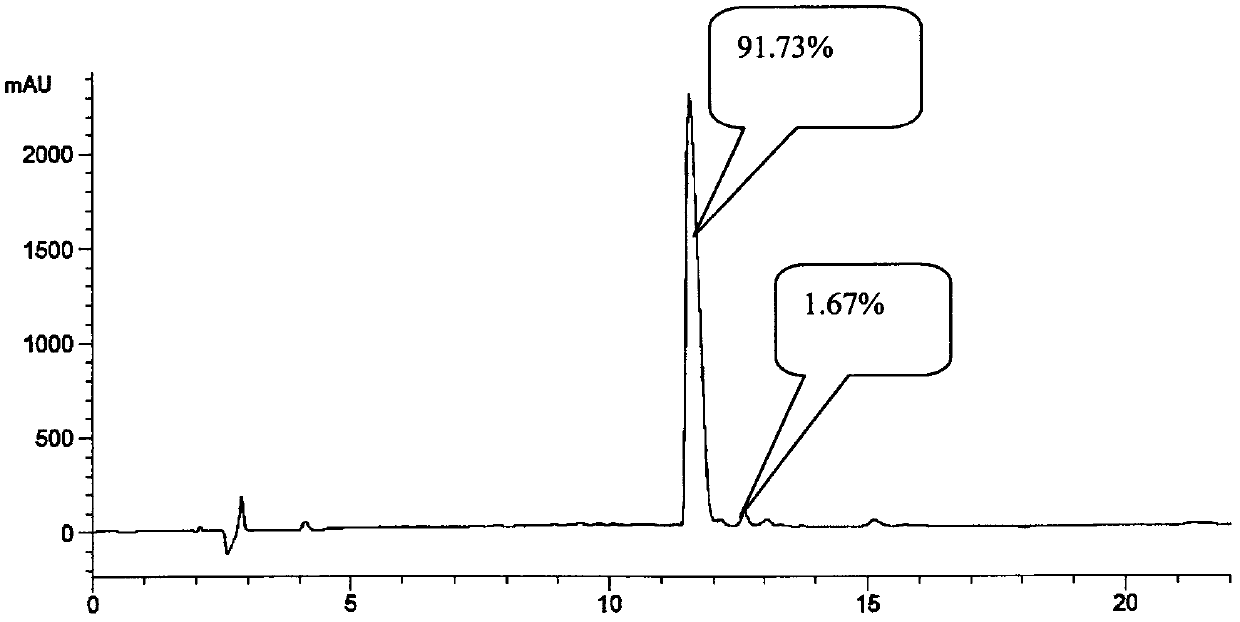

One-step method based solid-phase polypeptide synthesis method

ActiveCN103374054AHigh purityHigh yieldPeptide preparation methodsChemical reactionSynthesis methods

The invention discloses a one-step method based solid-phase polypeptide synthesis method. The technology of blowing in nitrogen or insert gases to volatilize a volatile solvent and reduce the temperature is adopted in each condensation reaction of connected protected amino acids, the nitrogen or the insert gases are filled into a reaction mixture so that the volatile solvent is volatilized and the temperature of a reaction system can be maintained at 15-20 DEG C, after an auxiliary condensing agent is added to start the condensation reaction, the temperature of the condensation reaction system is always stabilized at 22-28 DEG C by a heat insulation device, and during condensation of protected amino acids, the amino acids are unnecessary to be activated at low temperature in an activator and then be transferred to a condensation reactor, thus all the chemical reactions for synthesizing polypeptide are continuously completed in the same reactor in sequence. The method for synthesizing angiotensinamide is environment-friendly and efficient, has low requirements for equipment and can be applied to large-scale industrial production.

Owner:SPH NO 1 BIOCHEM & PHARMA CO LTD

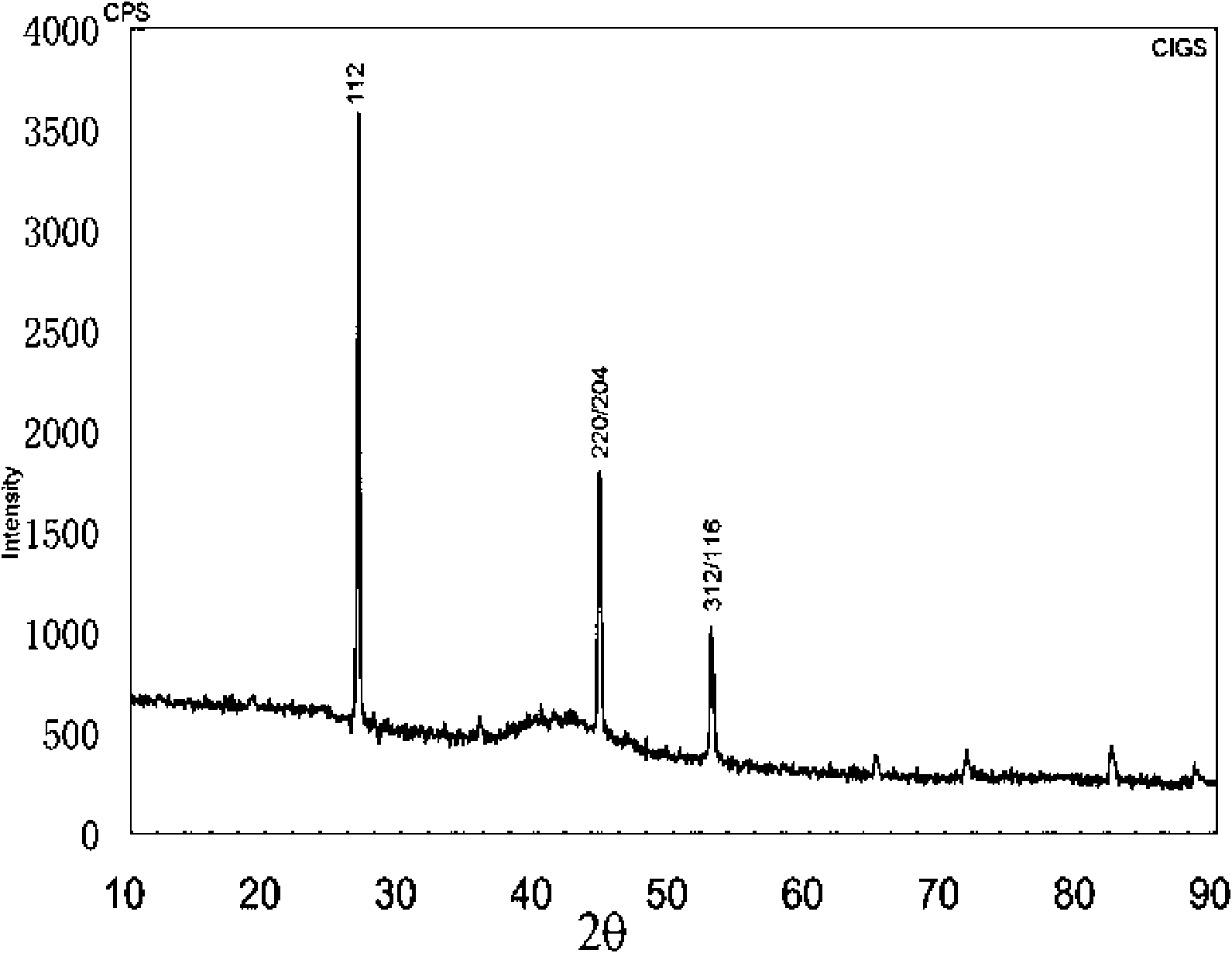

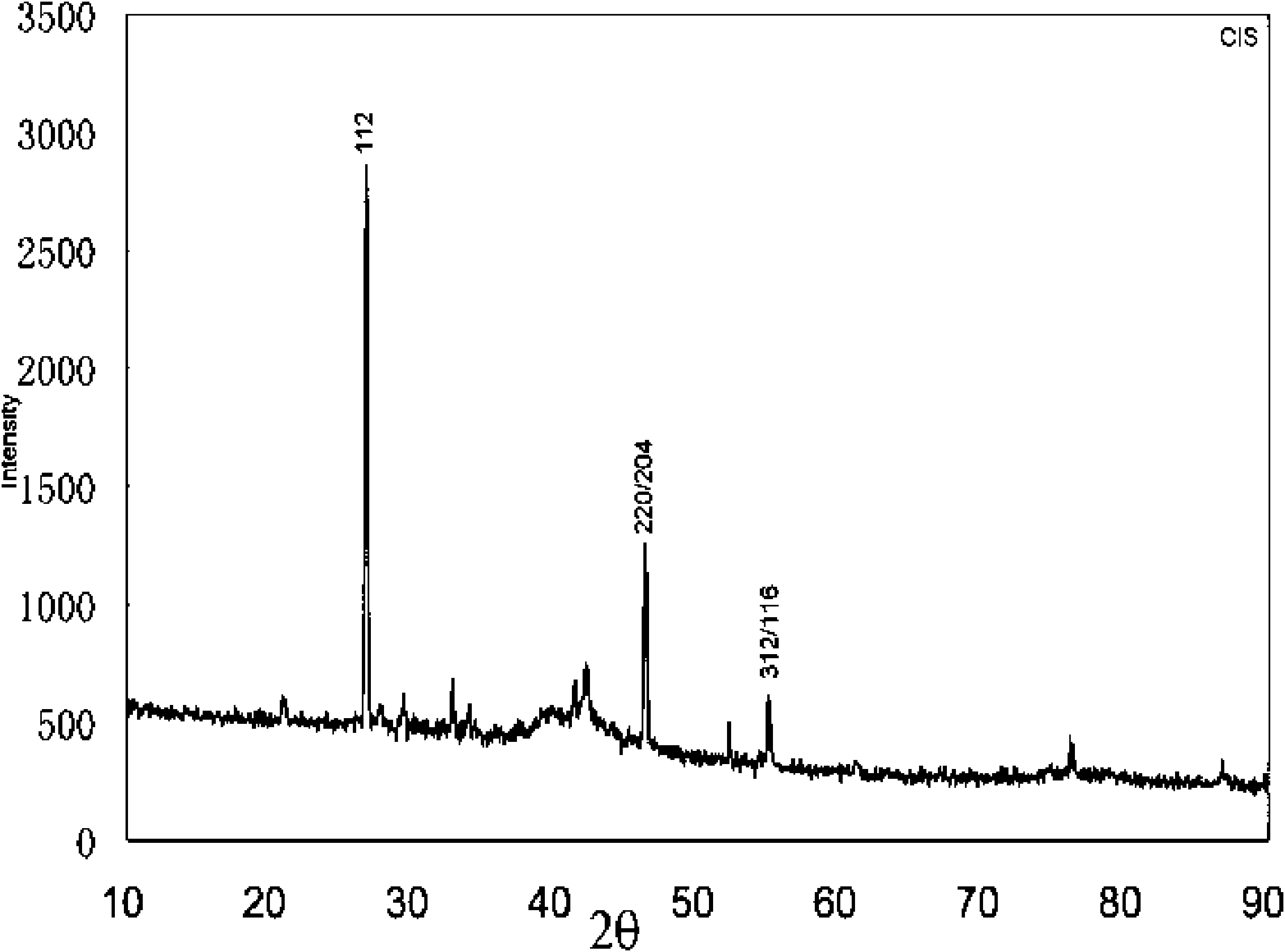

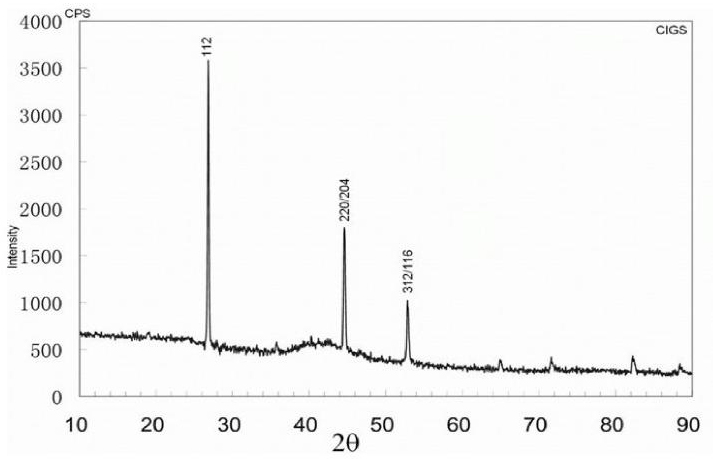

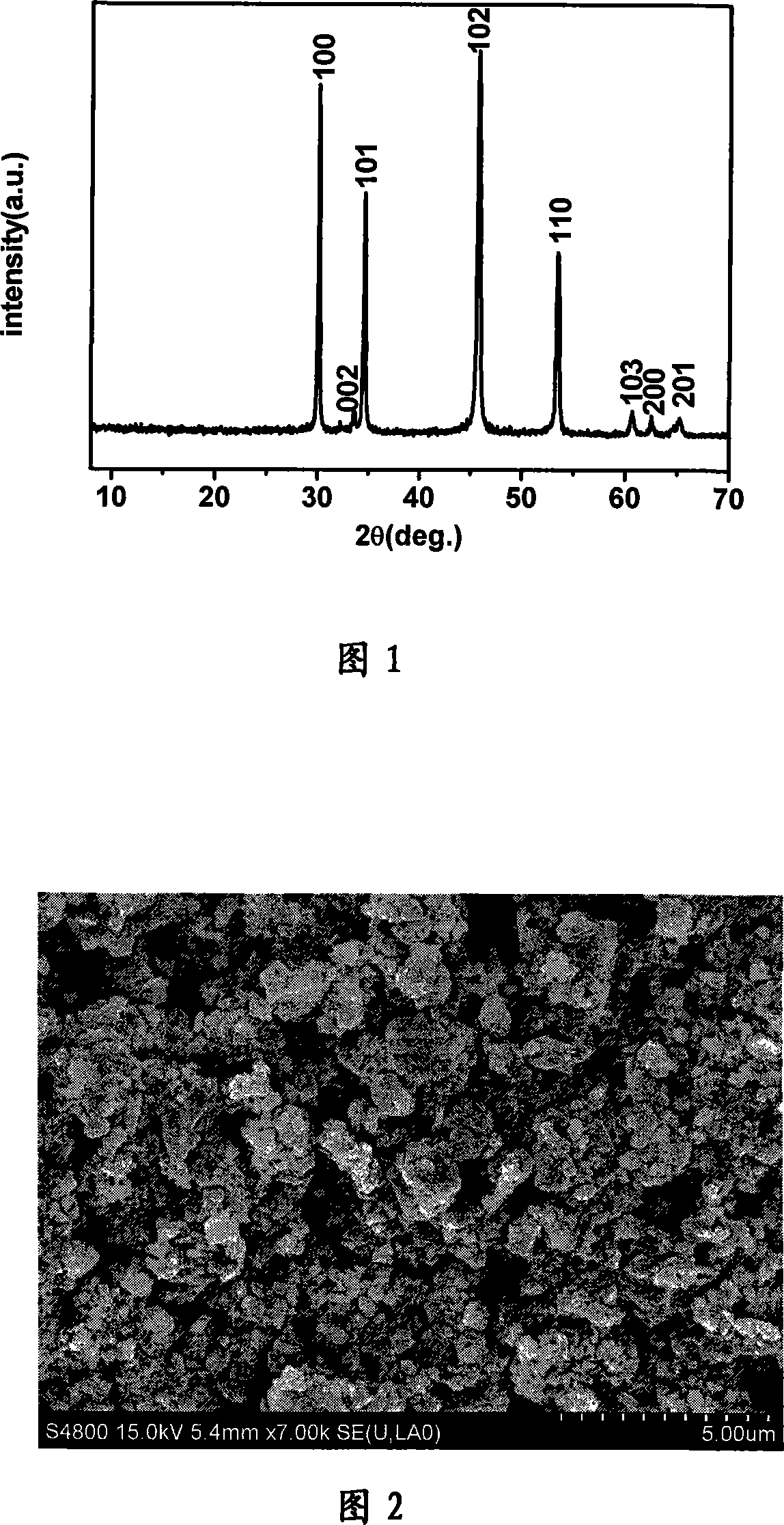

Method for preparing thin film solar cell from multi-element alloy single target material

ActiveCN102054897AAvoid pollutionAvoid dangerFinal product manufactureVacuum evaporation coatingEnvironmental resistanceAlloy

The invention discloses a method capable of preparing a I-III-VI2 multi-element thin film solar cell with a chalcopyrite structure. The method comprises the following steps of: preparing a solar cell absorption layer from the single target material of a multi-element alloy by a vacuum magnetron sputtering method on a soda glass Mo substrate or a stainless steel plate Mo substrate; annealing the solar cell absorption layer to grow grains of an alloy metal prefabricated layer; and preparing a buffer layer, an i-ZnO high-impedance layer and a ZnO low-impedance layer. Each layer of thin film is prepared by a dry technique completely, and the thin film solar cell with the chalcopyrite structure is obtained finally without selenizing the main absorption layer of the chalcopyrite structure, so the manufacturing cost is saved, the time is shortened, and the hazard of the hypertoxicity of H2Se or Se in a selenizing process is avoided. The buffer layer does not contain cadmium, so the thin film solar cell is environmentally-friendly. The preparation technical equipment is simple and the energy consumption is low, so the method is suitable for industrial production and has economic benefit.

Owner:PIONEER MATERIALS INC CHENGDU

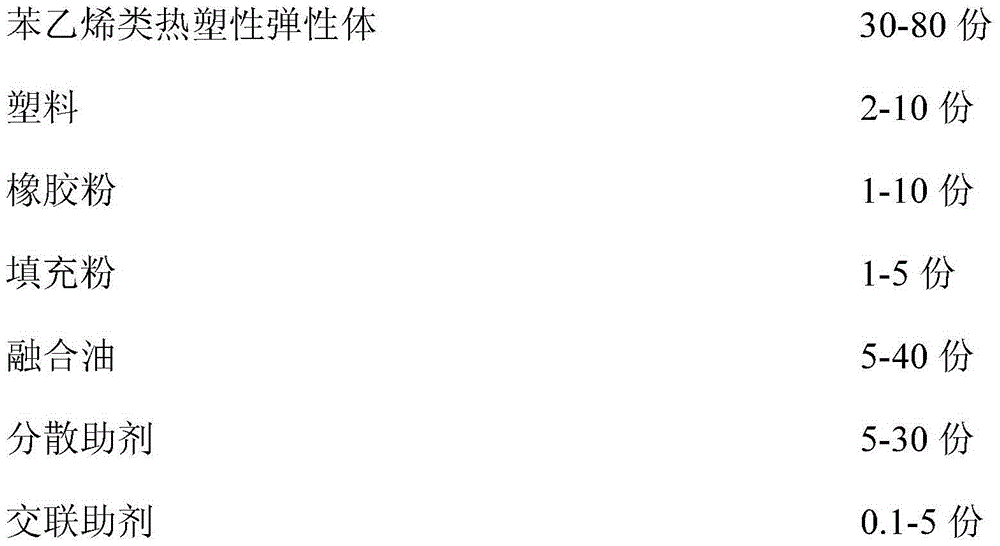

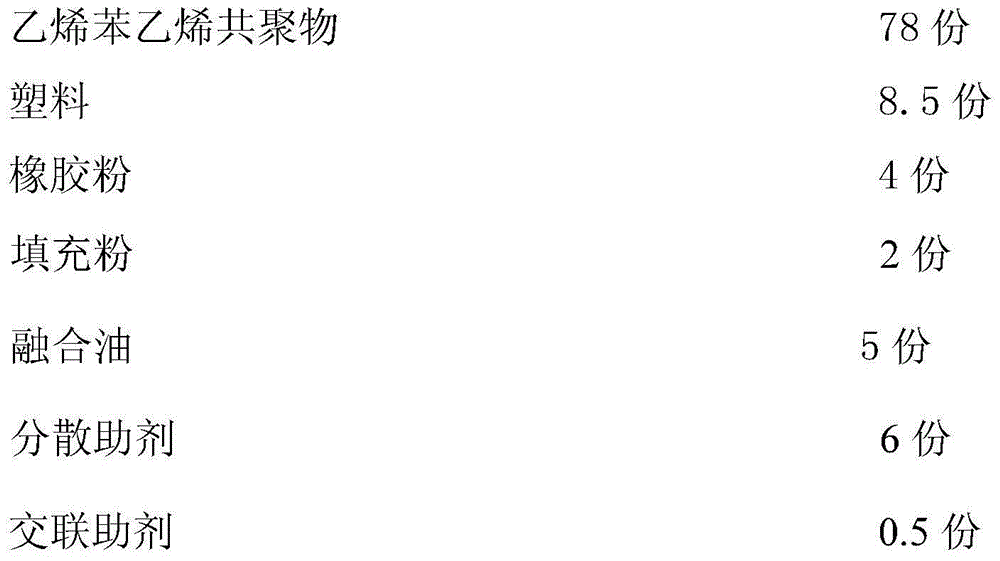

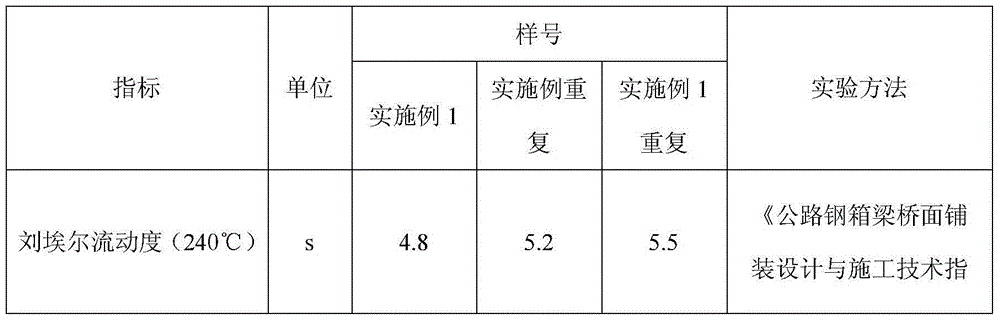

Direct vat set modifier of cast asphalt mixture and preparation method

InactiveCN103980650AImprove performanceLess production equipmentBuilding insulationsUltrasound attenuationThermoplastic elastomer

The invention discloses a direct vat set modifier of a cast asphalt mixture and is characterized in that the modifier is composed of the following components, by weight, 30-80 parts of a styrenic thermoplastic elastomer, 10-20 parts of plastic, 1-10 parts of rubber powder, 1-5 parts of a packing powder, 5-40 parts of fuser oil, 5-30 parts of a dispersing auxiliary agent and 0.1-5 parts of a crosslinking auxiliary agent. The invention also discloses a preparation method of the modifier and an asphalt mixture prepared from the modifier. The material can be directly put into a mixing plant cylinder to produce modified asphalt concrete. The produced asphalt concrete completely satisfies engineering needs. In comparison with a traditional SBS modification process, the method provided the invention has the following advantages: the step of producing modified asphalt in a traditional method is saved; production equipment of modified asphalt is save; there is no need in hot storage of modified asphalt; performance attenuation and separation of modified asphalt under hot storage condition are avoided; and positive contributions are made to low temperature and fatigue performance of the asphalt mixture.

Owner:CHONGQING SINO CANADA ASPHALT TECHN SERVICE

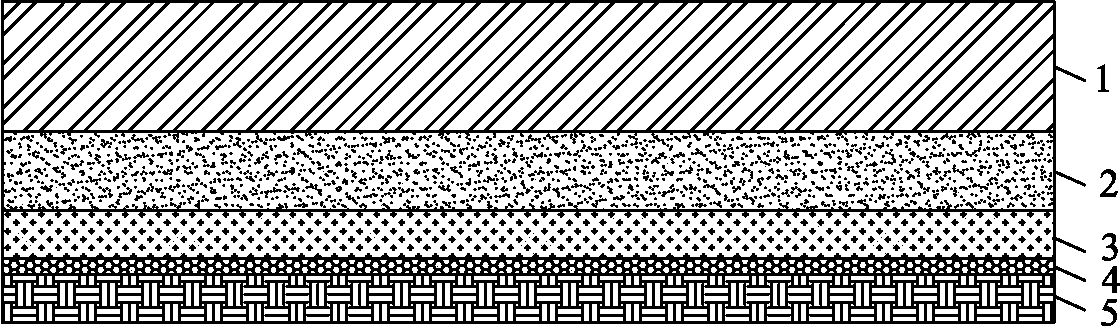

Super-specular anti-scraping transfer film and preparation method thereof

InactiveCN103434233AImprove adhesionStrong specular glossDuplicating/marking methodsSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

The invention relates to the technical field of transfer films, in particular to a super-specular anti-scraping transfer film and a preparation method thereof. The preparation method of the super-specular anti-scraping transfer film comprises the following steps that a PET (Polyethylene Terephthalate) thin film is taken; waterborne polyurethane, an alcohol organic solvent and water in parts by weight are mixed and stirred uniformly, and blended into waterborne release dope; the surface of the PET thin film is coated with the blended waterborne release dope to form a waterborne release coating layer; the waterborne release coating layer is dried to be a waterborne release layer; a semifinished PET thin film loaded with the waterborne release layer is prepared; the outer surface of the waterborne release layer is coated with information coating layer dope to form an information coating layer; a vacuum aluminum coated layer and a gum application layer are arranged on the surface of the information coating layer sequentially; and the finished super-specular anti-scraping transfer film is prepared. The super-specular anti-scraping transfer film is high in scraping resistance, and high in specular glossiness, and the preparation method of the super-specular anti-scraping transfer film is simple in technology and high in production efficiency.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

Flange producing technique

The invention discloses a flange producing technique. The flange producing technique comprises a flange stock forging and a blank cutting and shaping; the flange stock forging comprises an electric stove heating, forging and shaping after cooling, extruding and shaping, and solution heat treatment; the blank cutting and shaping includes punching hole, acid washing, rough and fine turning, outer hole drilling, and processing and shaping. A crystal grain of the forging stock is uniform in organization ,low in hardness, good in toughness, high in yield degree, strong in tensile strength, and standard elongation rate; the flange stock forging efficiency is improved by 300%, and materials can reach zero loss; the produced flange disk is accurate in dimension and good in surface finishing degree.

Owner:ANHUI HONGJIE PIPELINE MFG

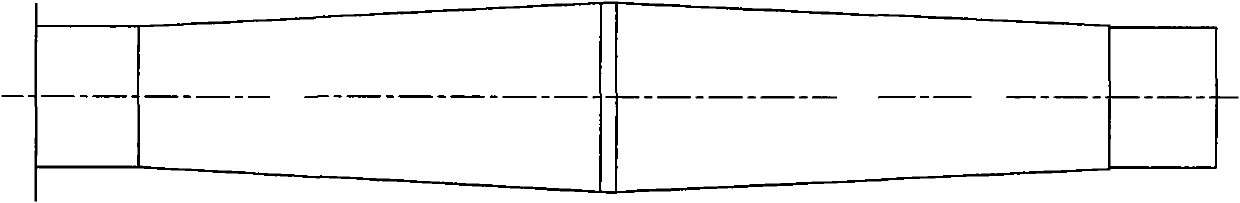

Process for forging rear axle shaft flange of automobile

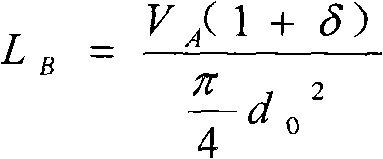

ActiveCN101947634AUniform deformationIncrease productivityRailway componentsVehicle componentsRound tableDiameter ratio

The invention discloses a process for forging a rear axle shaft flange of an automobile. The process comprises the following steps of: heating a round bar to the temperature of between 1,150 and 1,250 DEG C; upsetting and blanking the round bar on a horizontal forging machine by using a mold cone cavity so as to form a rear axle shaft middle blank of the automobile, wherein the rear axle shaft middle blank of the automobile is provided with a round table-shaped part which has a thicker front part and a thinner rear part, the length-to-diameter ratio of the round table-shaped part is 0.9 to 1.5, and the diameter is an average diameter of the round table-shaped part; controlling time for an upsetting and blanking process; keeping the temperature of the rear axle shaft middle blank of the automobile to be between 1,000 and 1,100 DEG C; and performing pendulum grinding and molding on the rear axle shaft middle blank of the automobile directly on a pendulum grinding machine so as to obtain the rear axle shaft flange of the automobile. The process has the advantages of improving the production efficiency of forging the rear axle shaft flange of the automobile, along with small required blanking and forging equipment, a small amount of scale produced by heating a forging piece, better surface quality of the forging piece, and the uniform deformation and high dimensional accuracy of the forged rear axle shaft of the automobile.

Owner:DONGFENG COMML VEHICLE CO LTD

Method for extracting tea polyoses from tea seed cake

The invention relates to a method for extracting tea polysaccharides from sesame meal of oiltea camellia. The sesame meal of the oiltea camellia is dipped in water according to a proportion of the sesame meal of the oiltea camellia of 10Kg to water of 100-200L and then heated and mixed. Filtration is done when the mixture is still hot and the filtrated solution is continuously heated to be concentrated to one fourth of the original volume; yeast is then added to the concentrated solution which is then kept at the temperature of 25-32 DEG C for vibrating fermentation for 0.5-3 days. After the vibration is stopped, the solution is precipitated and the upper clear solution is obtained and mixed with ethanol with a volume of three times as that of the clear liquid; next the mixture of the clear liquid and the ethanol is placed in a refrigerator for freezing; water is added to the frozen liquid obtained from the freezing step so as to dissolve and precipitate the frozen liquid and then take the upper layer liquid; the tea polysaccharides are finally obtained from the upper layer liquid after sprayed and dried. The invention solves the problem of complex technique, more production equipment and high production cost of the existing method for extracting tea polysaccharides from the sesame meal of the oiltea camellia.

Owner:黄宝生

Process for preparing biomedical graphene oxide paper

ActiveCN102926272AImprove adsorption capacityPromote healingSpecial paperPaper/cardboardEnvironmental resistanceIrritation

The invention discloses a process for preparing biomedical graphene oxide paper and belongs to the field of biomedical materials. According to the process, a graphene oxide bought from market serves as a raw material, and a product is obtained through ultrasonic oscillating dispersion, solid-liquid separation and drug loading. The biomedical graphene oxide paper prepared by the process has the advantages of being controllable in thickness, large in specific surface area, abundant in pore structure, good in adsorptivity, strength and flexibility, free from toxicity and bacteria, free from irritation on human bodies and cohesiveness on skin wounds, environment-friendly and the like. The process is simple in technology, convenient to operate, low in production cost, beneficial to popularization and application and the like. The product prepared by the process can be widely applied to medical external application materials which are used for treating skin wounds (such as burns), promoting wound healing and the like, and the product can also be used for electrode materials of super-capacitors and environmental protection materials for adsorption, purification and the like.

Owner:重庆锦添翼新能源科技有限公司

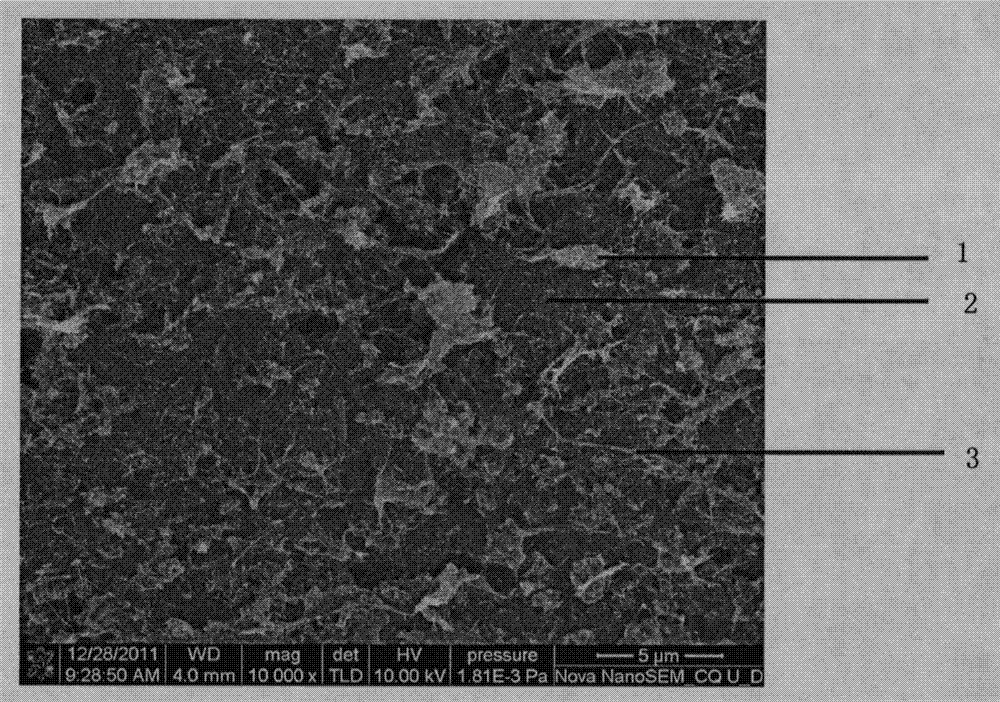

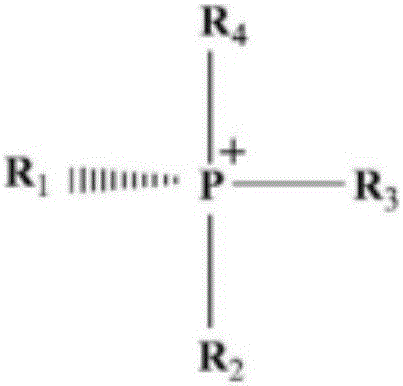

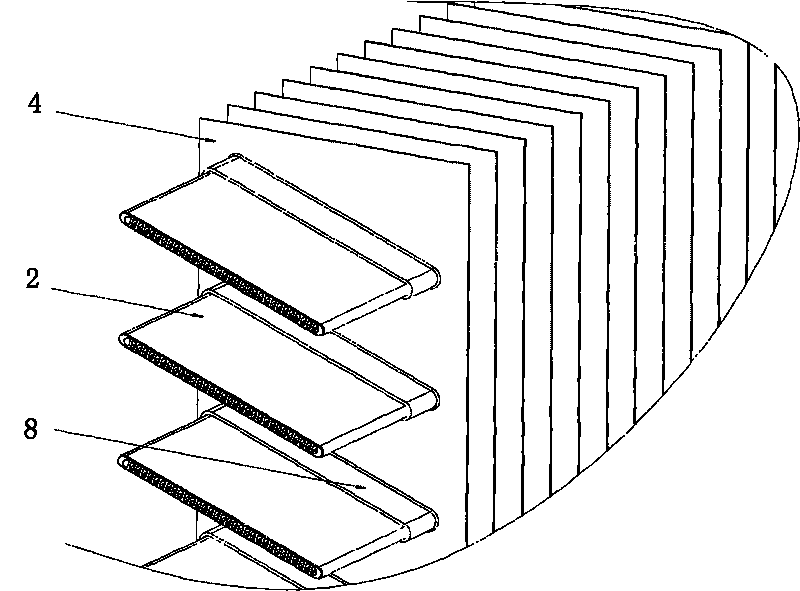

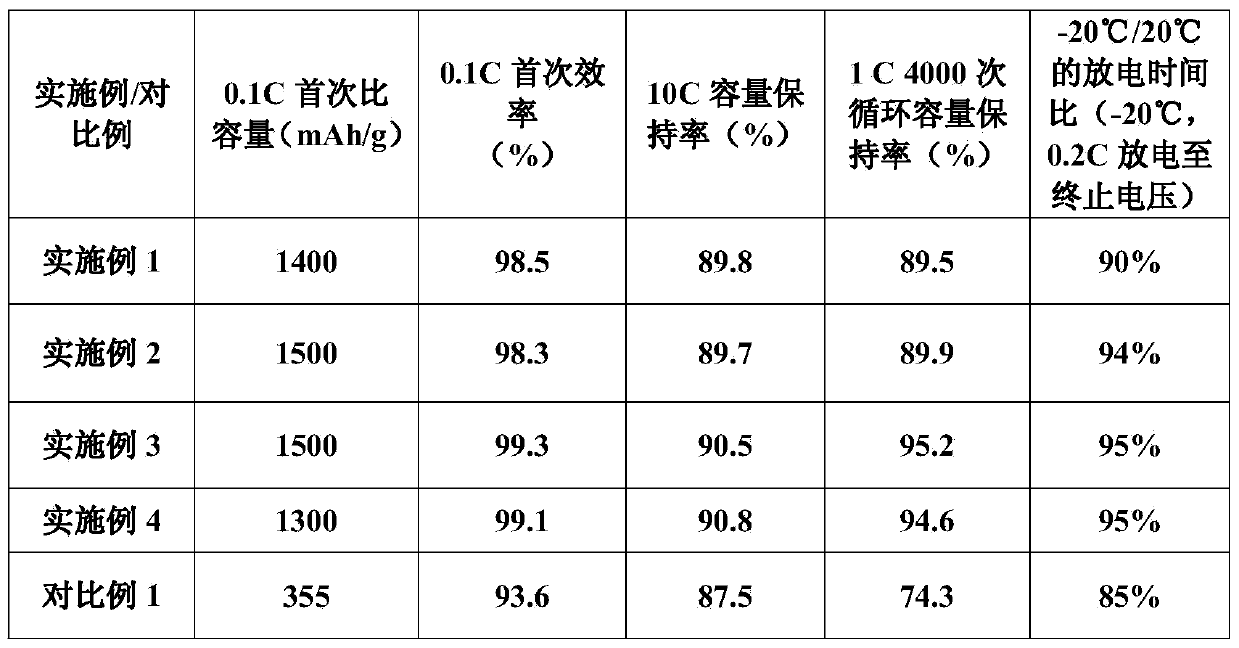

Preparation method of nitrogen and phosphorus co-doped carbon-coated graphite anode material

ActiveCN105720255AEasy to operateLess production equipmentCell electrodesSecondary cellsCarbonizationCarbon coated

The invention discloses a preparation method of a nitrogen and phosphorus co-doped carbon-coated graphite anode material, which comprises the following steps of: (1) coating, i.e. weighing graphite and ionic liquid, adding the graphite and the ionic liquid into a high-speed stirrer, carrying out dispersion for 1 to 4h at a rotating speed of 500 to 5,000r / min, and after completing processing, obtaining graphite coated with the phosphorus-containing ionic liquid; and (2) carbonization, i.e. placing the graphite coated with the phosphorus-containing ionic liquid in an atmosphere protection furnace to carry out sintering, heating to a temperature of 400 to 1,000 DEG C at a heating rate of 2 to 25 DEG C per min and carrying out heat preservation for 4 to 18 hours to obtain the nitrogen and phosphorus co-doped carbon-coated graphite anode material. By the structure, the electrical conductivity and the activity of a surface coating layer are greatly strengthened, not only the electronic conductivity of the nitrogen and phosphorus co-doped carbon-coated graphite anode material is effectively improved, but also diffusivity of lithium ions is greatly improved, and the obtained material has excellent rate capability and low-temperature discharge performance.

Owner:SHENZHEN XIANGFENGHUA TECH CO LTD +1

Printing ink cleaning fluid

InactiveCN101298523ARaw materials are easy to getNo stimulationChemical paints/ink removersNon toxicityKerosene

An ink washing liquid is made by mixing water with an emulsifier and a rubber anti-aging agent by taking the water as a main substrate. The proportion of each component is: 5-10 percent of emulsifier TX-10, 5-10 percent of emulsifier FM, 5-10 percent of sodium hydroxide, 5-10 percent of emulsifier PN, and 0.1-0.3 percent of the rubber anti-aging agent. The invention solves hazards that current printing industry uses organic solvents such gasoline, kerosene and ether, etc. as washing solvents, thus resulting in flammable, explosive and unsafe storage and use, and the deficiency of environmental contamination, health hazard and influence on printing quality, and has a plurality of advantages of easy access of raw materials, non-toxicity, non-stimulation, pollution-free, non-inflammability, the saving of the gasoline and the kerosene in shortage, simple technology and less production equipment.

Owner:祝永兴

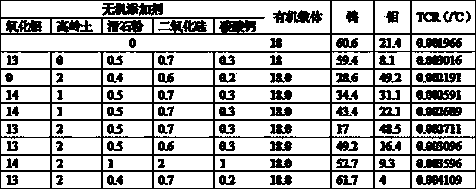

High-temperature co-firing ceramic slurry and preparation method thereof

ActiveCN103361531AMeet different requirements of temperature coefficient of resistanceSimple preparation processPlasticizerSlurry

The invention relates to a high-temperature co-firing ceramic slurry and a preparation method thereof. The slurry comprises the components of, by weight: 17-61.7% of tungsten powder, 4-48.5% of molybdenum powder, 0-20% of an inorganic additive, and 18% of an organic carrier. The inorganic additive can be one or more selected from alumina, kaolin, talcum powder, silica, and calcium carbonate. The organic carrier can be a plasticizer, a binder, and a dispersing agent. The raw materials with the ratio are mixed with the processed such as drying, sieving, rapid ball milling, and the like; and the mixture is rolled into slurry with a three-roller grinder, such that the high-temperature co-firing ceramic slurry is obtained. According to the invention, slurry resistance temperature coefficient can be adjusted through adjusting the ratios of tungsten and molybdenum in the slurry, such that wide resistance temperature coefficient can be obtained. Therefore, the formula can be regulated according to different requirements of different electronic components, such that an application purpose can be satisfied.

Owner:XIAMEN GREEN WAY ELECTRONICS TECH

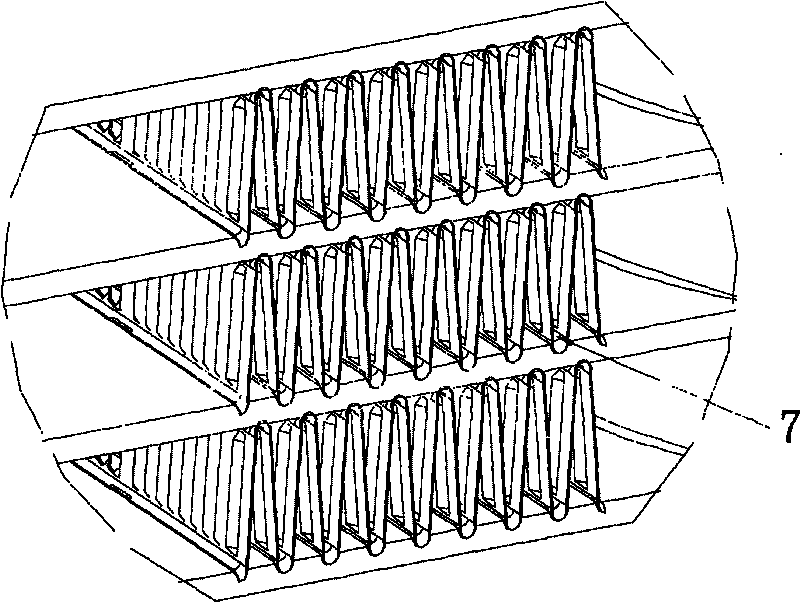

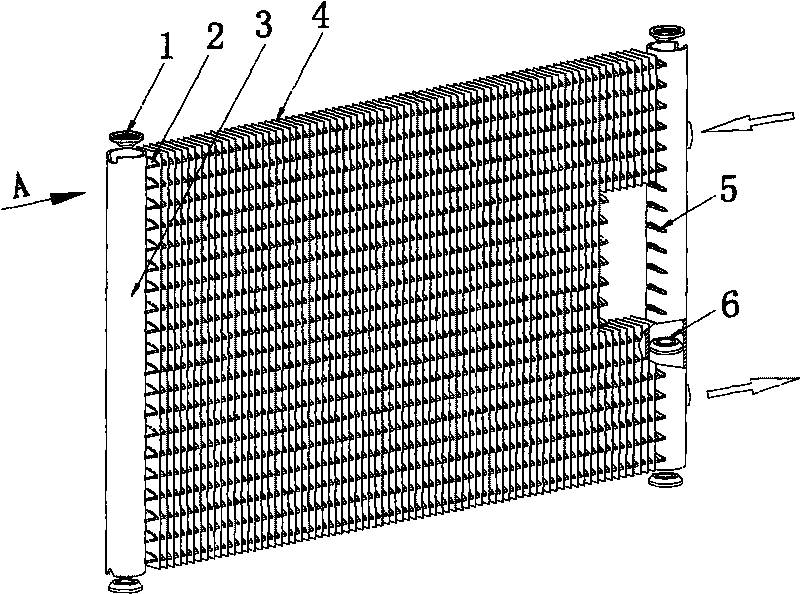

Heat exchanger beneficial to discharge of condensate water

InactiveCN101738008ASimple processing technologyLess production equipmentEvaporators/condensersTubular elementsFlangingEvaporator

The invention relates to a heat exchanger beneficial to discharge of condensate water, comprising a collecting pipe, a flat pipe and a fin. The heat exchanger is characterized in that one side of the collecting pipe and the fin are provided with regularly arrayed flat pipe holes, of which size and shape are matched with the size and shape of the flat pipe section; the flat tube is a flat and straight structure arranged in the transverse direction; the pin is a plain film or a corrugated sheet and is arranged in the longitudinal direction, the flat pipe is arranged in the flat pipe holes of a pin pack. The invention has the beneficial effect that instead of being horizontally arranged, the flat tube is now obliquely arranged, and instead of being staggeringly arranged with fold fin-flat pipe-fin, the fin is now arranged perpendicular to the flat pipe, so that condensate water on a core of the heat exchanger, which is produced by system operation can slide to an oblique fin flanging along the vertically arranged fin and then flow out of the core along the flanging without remaining condensate water. The heat exchanger of the invention can not only be applied to an outdoor unit of a single cold air conditioner but also to an outdoor condenser of an indoor evaporator and a heat pump air conditioner.

Owner:JIANGSU KANGTAI HEAT EXCHANGE EQUIP ENG +2

Preparation method for porous graphene micro-sheet

InactiveCN105449210ALarge specific surface areaIncreased diffusion rateNegative electrodesSecondary cellsPorous grapheneNitrogen gas

The invention discloses a preparation method for a porous graphene micro-sheet. The preparation method is characterized by comprising the following steps: 1) pretreatment of graphite: putting graphite into a mixed solution consisting of an oxidizing agent and intercalator, performing ultrasonic stirring for 3-5h; washing, filtering and drying the obtained product, and putting the product into a muffle furnace, and processing the product in nitrogen atmosphere at a high temperature of 600-1,200 DEG C for 2-6h to obtain an expanded graphite product for use; and 2) preparation of the porous graphene micro-sheet: dissolving the expanded graphite obtained in the above step into a certain amount of deionized water, adding 0.1-2wt% of surfactant, performing ultrasonic stirring for 0.5-2h, and then adding a certain amount of pore forming agent, and putting into the muffle furnace under the N2 protective atmosphere for processing for 1-3h; washing the obtained product by dilute acid or dilute alkali and the deionized water solution for multiple times; drying the product in a vacuum drying oven for 2-6h to obtain the porous graphene micro-sheet. The porous graphene micro-sheet prepared by the preparation method provided by the invention is relatively high in specific surface area (850-1,000 m2 / g); and due to the porous structure, the diffusion rate of the lithium ions can be improved, and a relatively better electrochemical performance can be obtained.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Silicon dioxide-based CMP (Chemical Mechanical Polishing) solution and preparation method thereof

ActiveCN102796460AReduce surface activityLower free energyPolishing compositions with abrasivesElectrical conductorUltrasonic dispersion

The invention provides silicon dioxide-based CMP (Chemical Mechanical Polishing) solution which is applied to global planarization of a very large scale integrated circuit silicon substrate and an interlayer medium and a preparation method of the silicon dioxide-based CMP solution. The polishing solution contains the following components in percentage by weight: 10-50 percent of nano silicon dioxide grinding material, 0.1-10 percent of dispersant, 0.1-10 percent of wetting agent, 0.1-10 percent of chelating agent, 0.01-1 percent of pH (Potential of Hydrogen) regulator and the balance of de-ionized water. The polishing solution is prepared through the means of: modifying with a surfactant, strongly and mechanically stirring, performing high-shear grinding, performing ultrasonic dispersion and the like, and the problem of extreme easiness in flocculation and agglomeration of nano-scale grinding material particles is solved. Since the particle size distribution of the grinding material is narrow, the range is selectable, the polishing rate is easy to adjust and control and the polishing solution is alkaline, equipment is not corroded, less damage is caused, cleaning is easy and the environment is not polluted. The silicon dioxide-based CMP solution can be used for chemical mechanical polishing of the very large scale integrated circuit silicon substrate, the interlayer medium, a shallow trench isolation isolator, conductor and damascene metal.

Owner:ANTEDI TIANJIN TECH

Method for preparing doped graphene from supercritical fluid

InactiveCN105366667ALarge specific surface areaImprove conductivityBulk chemical productionDoped graphenePotassium

The invention discloses a method for preparing doped graphene from supercritical fluid. The method includes the following steps:1, preparation of graphene oxide, wherein graphite is added to a mixture of strong oxidizing acid and nitrate, after uniform mixing is conducted, strong oxidant containing potassium is added, water and a certain amount of hydrogen peroxide are added, after a full stirring reaction is conducted, cleaning is conducted repeatedly through a dilute acid solution and deionized water, various ions in a system are removed, then solid is collected through vacuum drying, and the graphene oxide is obtained; 2, preparation of the doped graphene, wherein after the obtained graphene oxide and an active doped element compound are premixed, a reaction is conducted in a supercritical state, and the element doped graphene is obtained. The reaction process is simple, the price is low, and emission of poisonous gas and solvent is avoided; a product has excellent electrochemical performance, and the doped graphene can be used for lithium ion batteries, lithium air batteries, super capacitor electrode materials and novel energy battery materials, such as fuel cell oxygen reduction catalysts.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Fast precise semi-axle casing extruding formation process

InactiveCN100431775CImprove the state of stressGuaranteed dimensional accuracyMetal-working apparatusOther manufacturing equipments/toolsEngineeringMachining

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

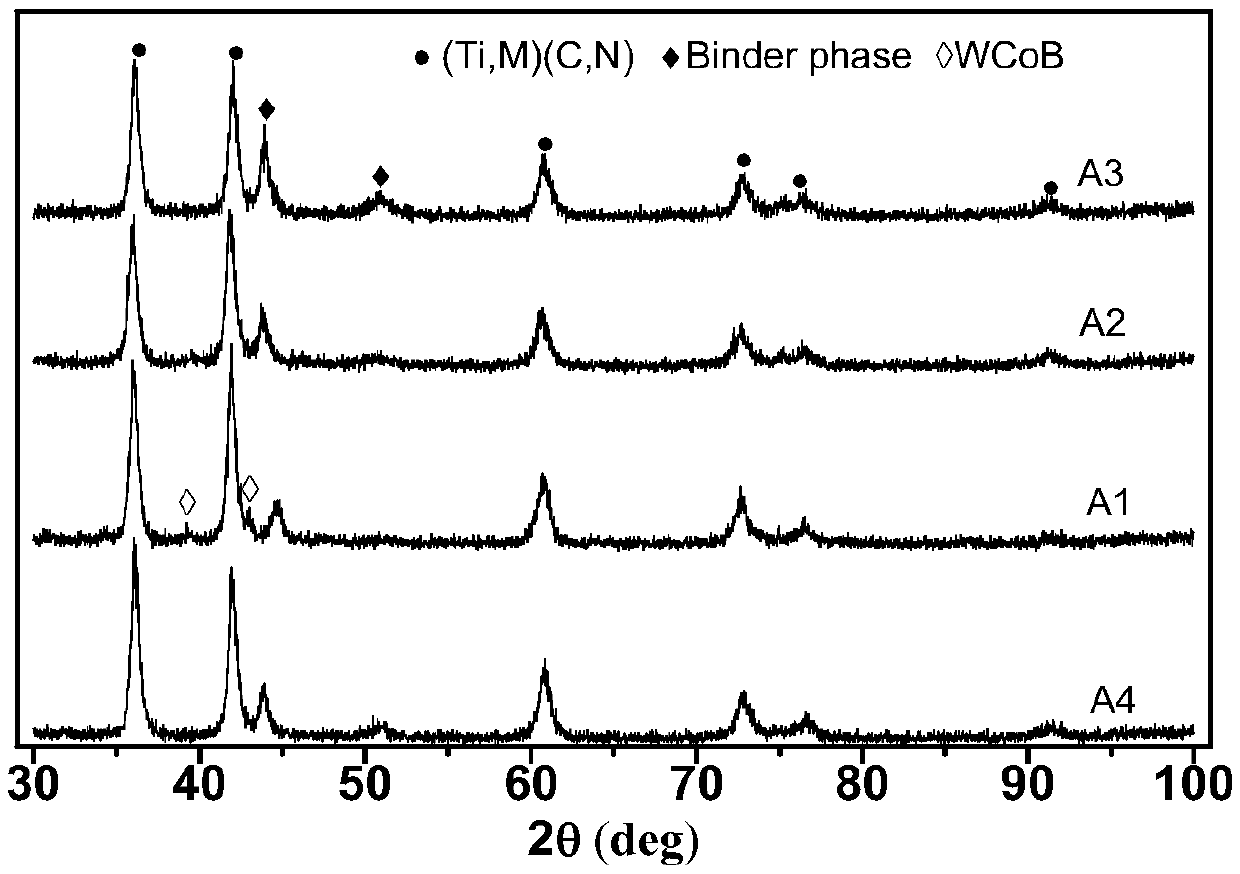

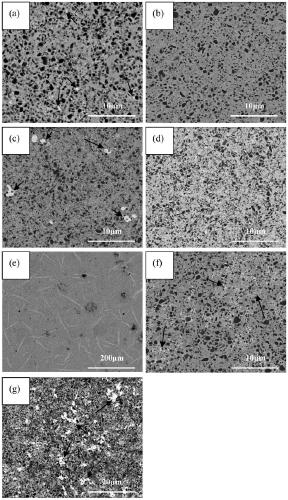

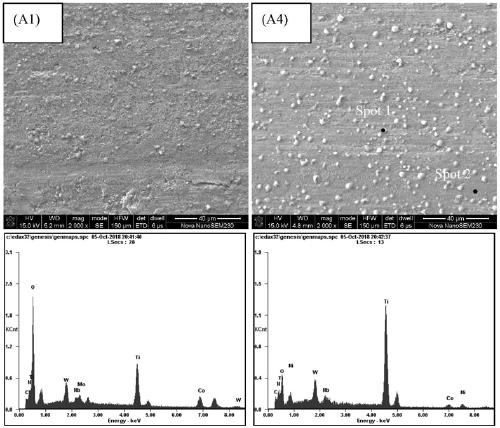

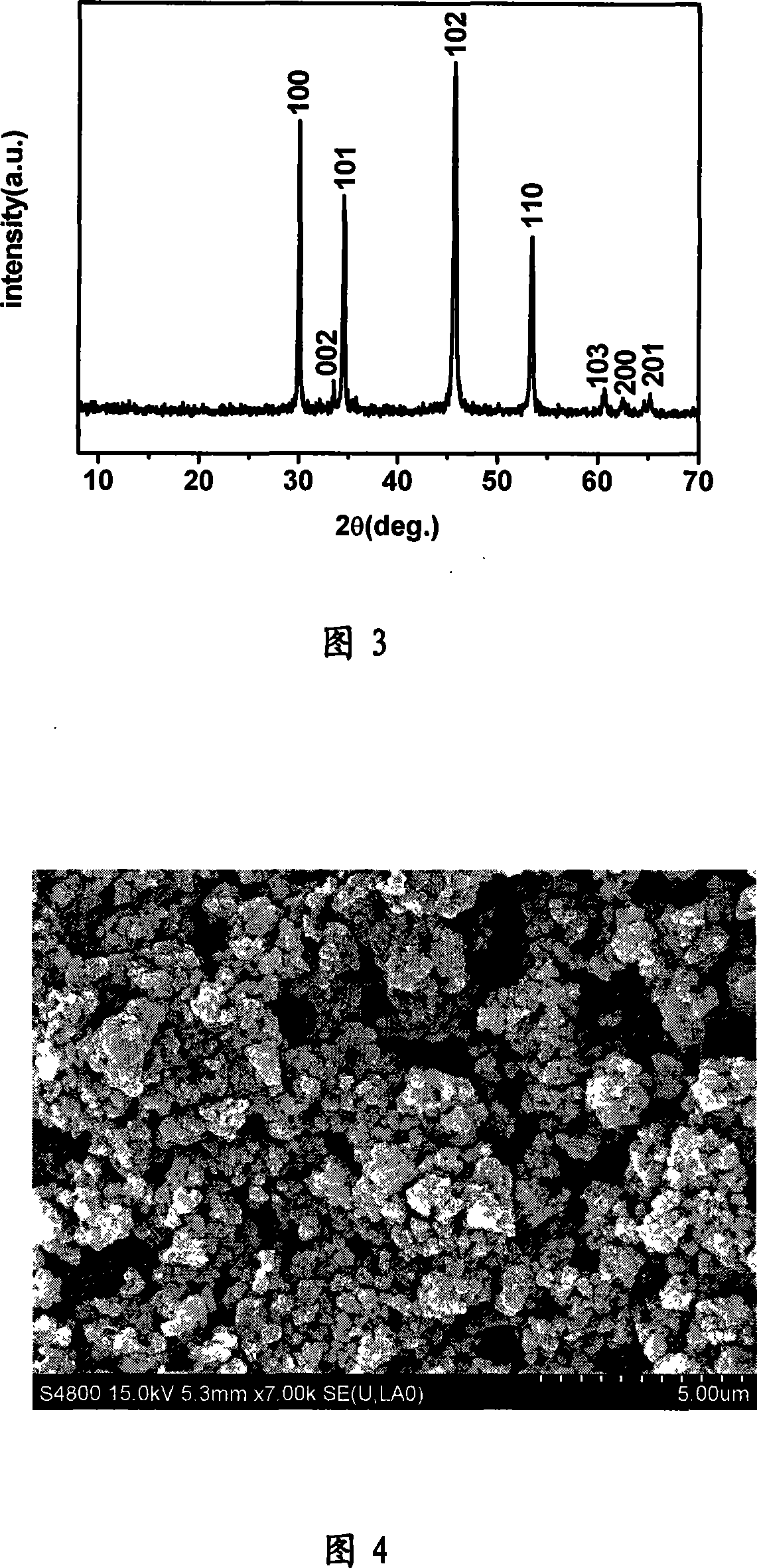

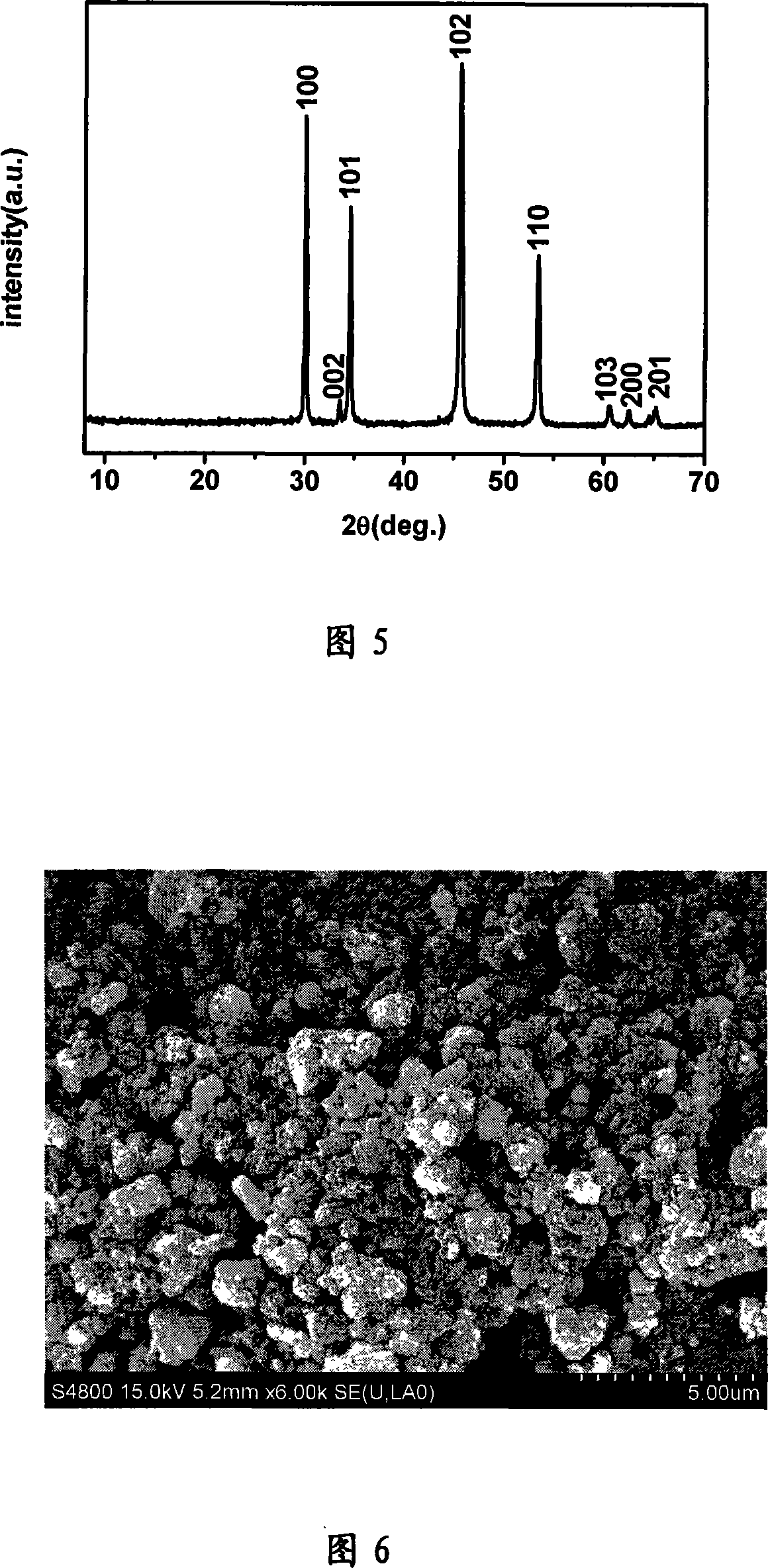

Ternary boride reinforced Ti-based (C,N) metal ceramic material and preparation method thereof

The invention discloses a ternary boride reinforced Ti-based (C,N) metal ceramic material and a preparation method thereof. The main preparation process comprises the following steps that Ti (C,N) metal ceramic raw material powder, carbide and nitride boride powder, binding phase raw material powder and binary boride powder are taken as raw materials, Ti-based (C,N) metal ceramic is prepared through the steps of ball milling mixing, drying, forming and sintering, wherein second phase ceramic particles generated by primary reaction are distributed in a binding phase of the metal ceramic material in a fine dispersion mode, the hardness and toughness of the metal ceramic material can be effectively improved through the phase. Compared with an existing technology for enhancing wear resistance,such as coating and surface treatment, the Ti-based (C,N) metal ceramic material prepared through the method has the advantages that the rockwell hardness reaches 91.5-94 HRA, the bending strength can reach 1800-2800 MPa, and the fracture toughness can reach 12-15 MPa.<-1 / 2>; and in addition, the depth of the grinding crack measured is reduced by about 70% compared with that of metal ceramic withthe same binding phase, and the friction coefficient is reduced by about 0.1.

Owner:CENT SOUTH UNIV

Shape memory finishing processing method for slopwork

InactiveCN1804187AEmission reductionReduce consumptionFibre treatmentTextile shapingShape-memory alloyEngineering

The disclosed shape-memory sorting and processing method for ready-made clothes comprises: washing in water, dewatering; preparing sorting solution with weight as 60-80% of the clothes, spraying solution to the clothes for treatment; loose baking, forcing cold wind; high-temperature baking, cooling, and humidifying. This invention leaves out steps to decrease device and water consumption and release the pollution load, and improves work quality and efficiency.

Owner:胡金莲 +2

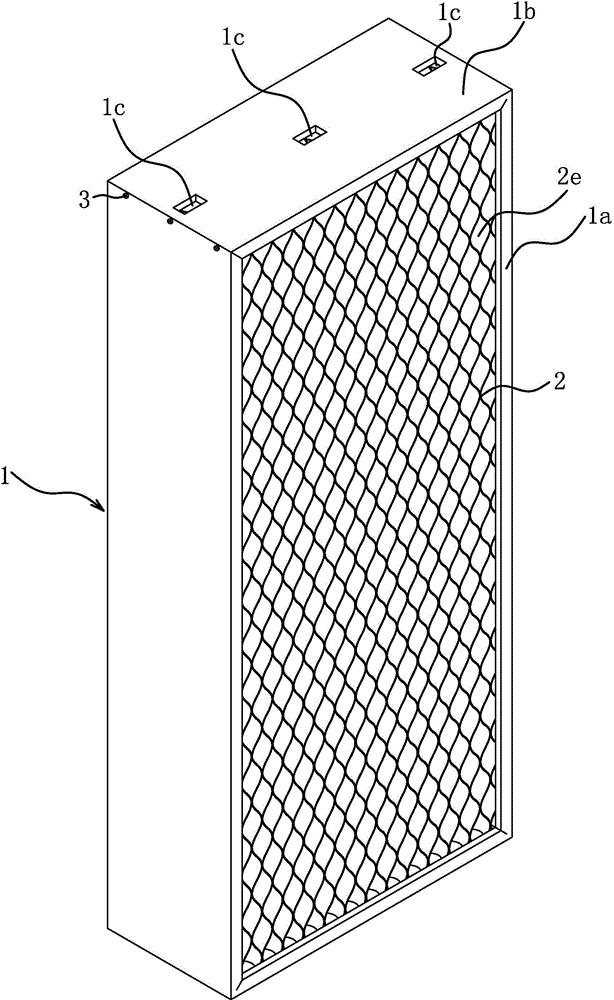

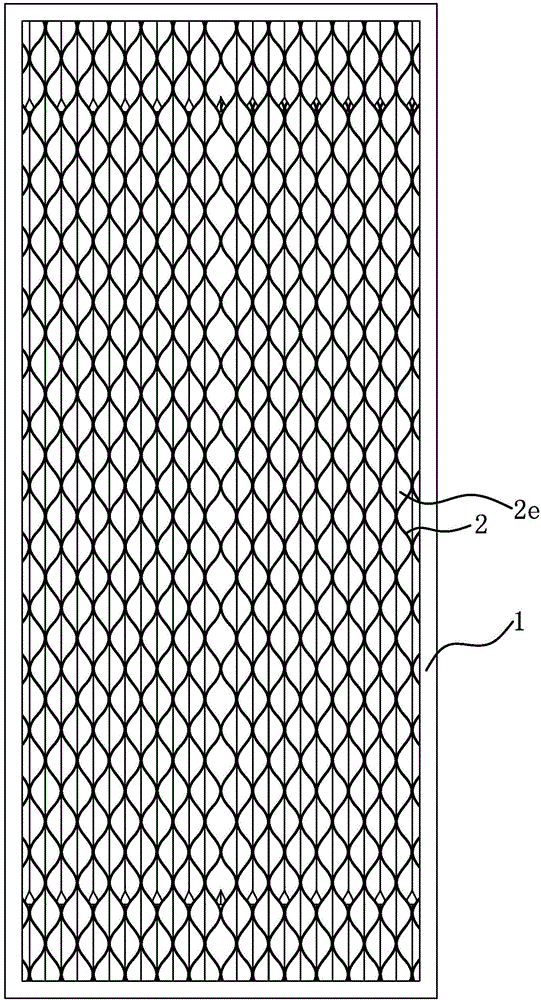

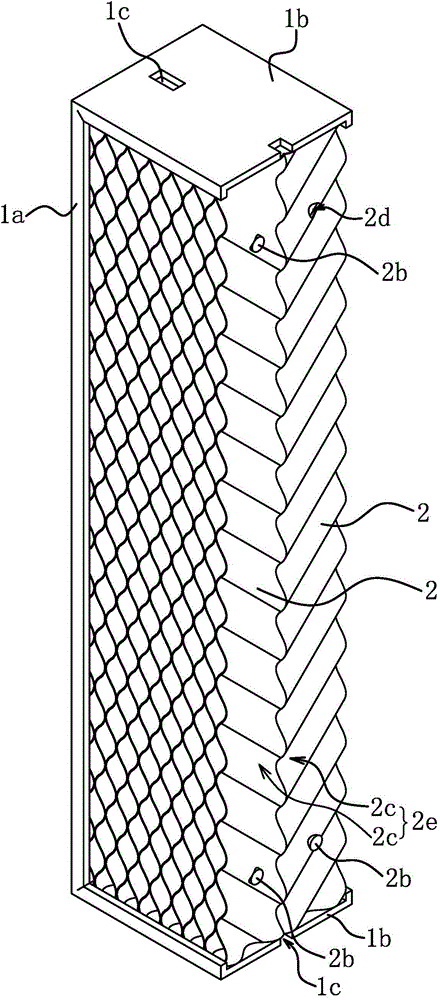

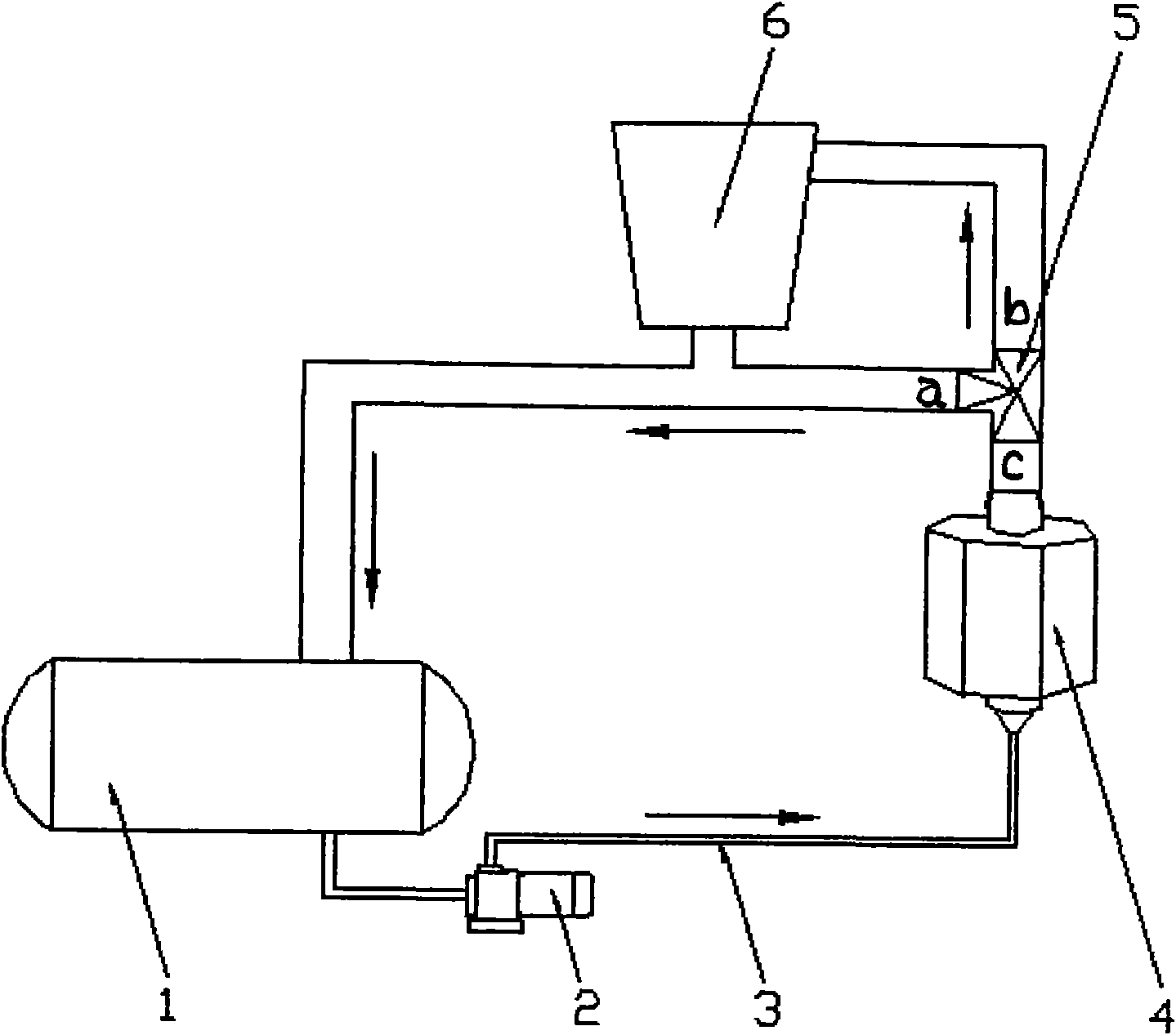

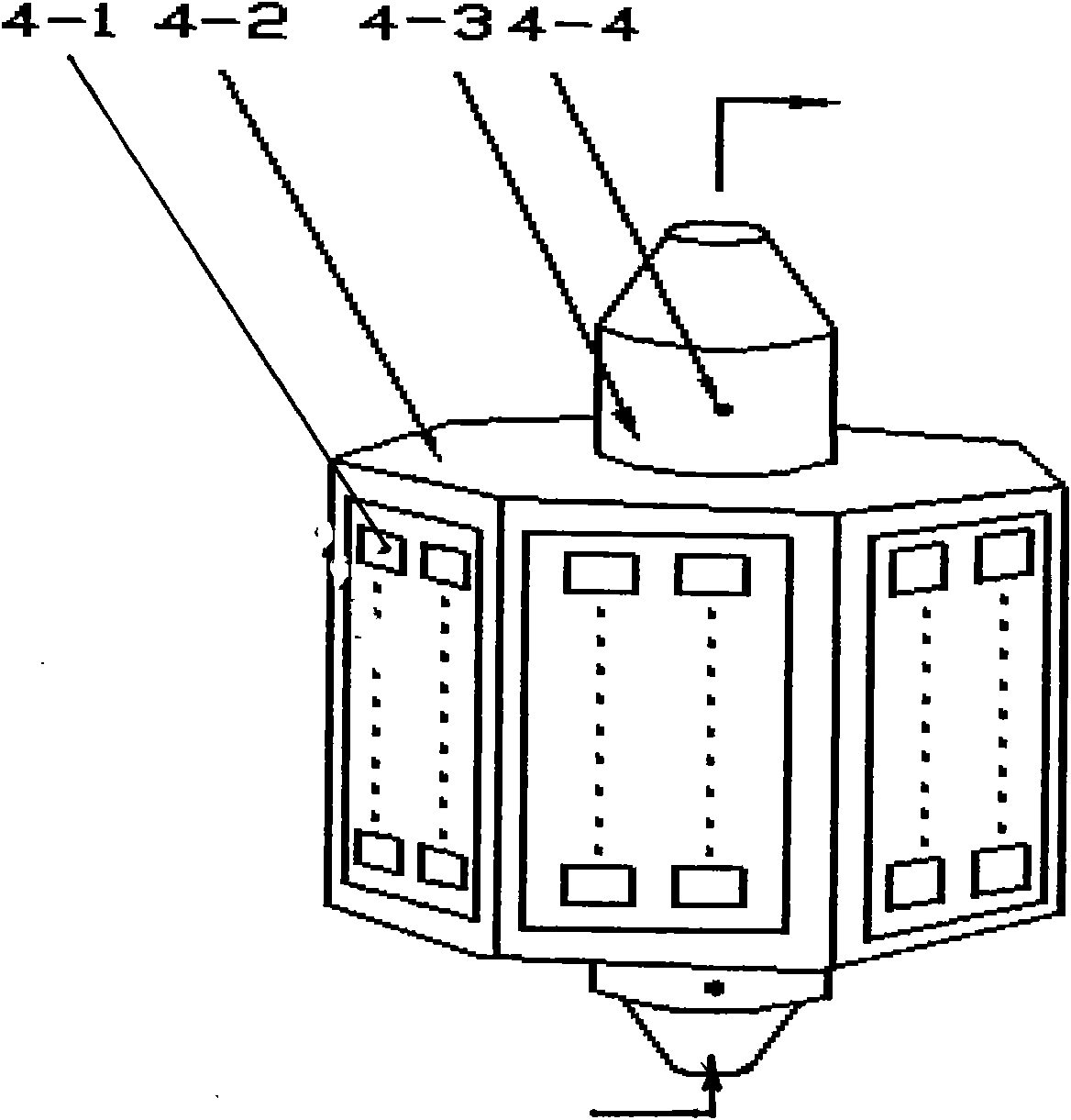

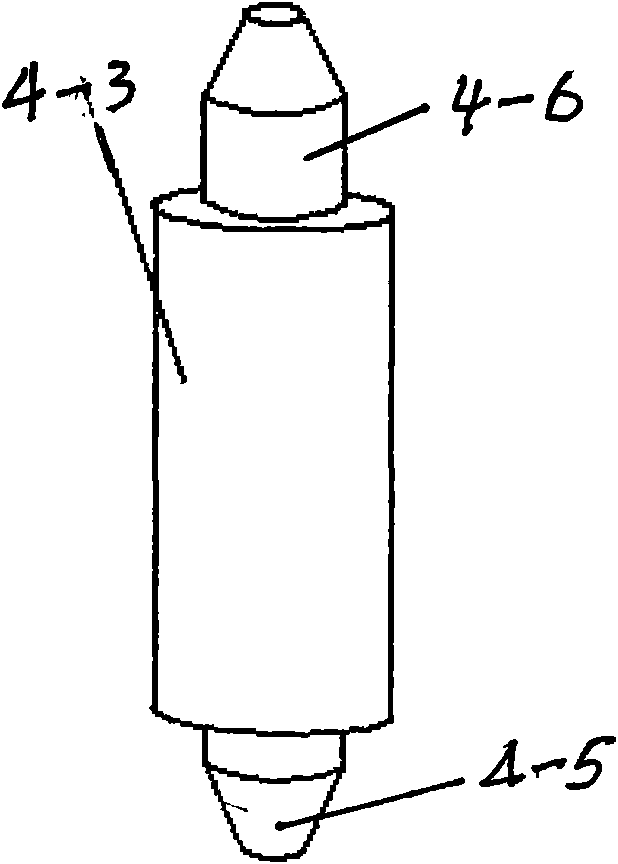

Airflow impurity separation device and manufacturing method of airflow impurity separation device

ActiveCN104606972AEasy to cleanImprove separation efficiencyCombination devicesDispersed particle filtrationWater vaporEngineering

The invention provides an airflow impurity separation device and a manufacturing method of the airflow impurity separation device, belonging to the technical field of operation, and solving the problem that the existing filter screen is easy to clog. The airflow impurity separation device comprises a frame and a plurality of folded plates arranged in the frame, wherein the folded plates are folded in a continuous wave mode to form a plurality of air channels; and a plurality of folded plates are folded to form a plurality of V-shaped separation filter holes. The airflow impurity separation device only needs to be cleaned on schedule and does not need to be replaced, and further, the use cost is reduced. The airflow impurity separation device is easy to clean, separated grease and water vapor can automatically flow out, and maintenance period is prolonged. The airflow impurity separation device is high in separation efficiency and stable in performance. The airflow impurity separation device manufactured by adopting the manufacturing method has the advantages that the number of production devices is few, the number of required processing parts is few, and production cost is low.

Owner:陈美青

Aqueous phase cation polyacrylamide emulsion one-step synthesis method

The invention discloses a method used for synthesizing aqueous phase cation polyacrylamide emulsion by one step. The method is characterized in that polymerization adopts free radical evocating agent, firstly dispersant (such as poly methacrylatoethyl trimethyl ammonium chloride) is synthesized in aqueous solution, then inorganic salt, acrylamide monomer and a cationic monomer (such as methacrylatoethyl trimethyl ammonium chloride) are added for aqueous phase dispersion polymerization, thus obtaining aqueous phase emulsion cation polyacrylamide. The dispersion stabilizer of the invention is formed by in-situ polymerization in the aqueous solution, the obtained polymer aqueous solution is directly used as stabilizer component for aqueous phase dispersion polymerization of acrylamide and can be part objective product, and one-step preparation technique which contains the processes from feeding raw material to obtaining cation polyacrylamide aqueous base emulsion is realized. The method effectively reduces production device, improves raw material utilization factor, reduces energy consumption and cost and improves efficiency without using organic solvent, thus being safe and environmentally friendly.

Owner:BEIJING UNIV OF CHEM TECH

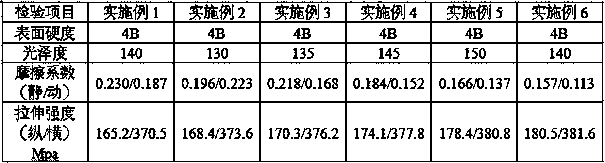

Polyurethane elastomer printing rubber roller and preparation method thereof

ActiveCN103483541AComponents with low viscosityImprove performanceRotary pressesPolyesterPolyurethane elastomer

The invention belongs to the technical field of organic polymer material products and in particular relates to a polyurethane elastomer printing rubber roller and a preparation method thereof. The polyurethane elastomer printing rubber roller is prepared from the following raw materials in parts by weight: 0.8-1.2 parts of polyalcohol, 0.25-0.4 part of polyisocyanate, 0.1-0.2 part of curing agent, and 0.00001 part of reaction control agent, wherein polyalcohol is polyester polyalcohol 218. The invention further provides the preparation method of the polyurethane elastomer printing rubber roller. The preparation method comprises the following steps of: preparing a prepolymer and a curing component at first; and pouring to obtain the polyurethane elastomer printing rubber roller. According to the invention, the processing technology is simplified, so that mixing, forming and vulcanizing of materials are integrated; the printing and dyeing rubber roller prepared by the invention is good in solvent resistance, easy for machining and good in elasticity; in the aspect of solvent resistance, the printing and dyeing rubber roller prepared by the invention is 2 times of other rubber rollers; the surface smoothness of the printing and dyeing rubber roller prepared by the invention can be up to the mirror state; the service life of the printing and dyeing rubber roller prepared by the invention is 2-3 times that of other rubber rollers; the service life of the general printing and dyeing rubber roller is 36 hours; and the service life of the printing and dyeing rubber roller prepared by the invention is about 80 hours.

Owner:淄博启明星新材料股份有限公司

Highlight scratch resistance agent and process for preparing highlight scratch resistance transparent PVC thin film by applying same

InactiveCN103073983AIncrease brightnessStrong scratch resistancePretreated surfacesPolyurea/polyurethane coatingsPolymer scienceOrganosolv

The invention relates to the technical field of a decorative film material, in particular to a highlight scratch resistance agent and a process for preparing a highlight scratch resistance transparent PVC (Poly Vinyl Chloride) thin film by applying the same. The highlight scratch resistance agent consists of the following components in part by weight: 95 to 105 parts of oil polyurethane, 15 to 25 parts of curing agent, 0.8 to 1.2 parts of drier, 0.1 to 1 part of smooth agent and 75 to 85 parts of organic solvent. The highlight scratch resistance agent disclosed by the invention has the characteristics of good toughness, high hardness, strong scratch resistance and high brightness; the process for preparing the highlight scratch resistance transparent PVC thin film by applying the highlight scratch resistance agent adopts a method of directly coating a highlight scratch resistance coating on a PVC thin film, adopts a simple preparation process, has high production efficiency, requires a small quantity of production equipment, can reduce cost and is beneficial to general popularization and application; and the prepared highlight scratch resistance transparent PVC thin film has the advantages of high hardness, good scratch resistance, flat surface, high brightness and stable quality.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

Microwave heating device for heating cold-rolling pickling process medium

InactiveCN101914778AZero emissionNo pollution in the processWork treatment devicesMetal rolling arrangementsMicrowaveProcess engineering

The invention provides a microwave heating device for heating a cold-rolling pickling process medium. The device comprises a circulating tank, a circulating pump, a pipeline, the microwave heating device, a three-way valve and a pickling tank, wherein the microwave heating device comprises a microwave heater, a cavity, a heating tube, a temperature sensor, a heat tube inlet and a heating tube outlet. The microwave heating device is arranged between the circulating tank and the pickling tank to ensure that the process medium is heated when passing through the microwave heating device, and the process medium is delivered to the pickling tank to wash a titanium belt when the repeatedly heated process medium is heated to the temperature meeting the production requirement. The device can directly heat the process medium without a heat exchange process, improves the efficiency, realizes zero emission of carbon, and avoids the problems of environmental pollution and energy waste caused by using a boiler.

Owner:KUNMING UNIV OF SCI & TECH +1

Low-temperature solid-phase synthesizing method for hexagonal-phase nickel sulfide submicron crystal

The invention relates to a low temperature solid phase synthesis method of hexagonal phase nickel purite submicron crystal. The molar ratios of nickel acetate and sulfur source of the invention are respectively 0.005molar and 0.005 to 0.0075molar, grinded nickel acetate and sulfur source powder are weighed and put into a crucible to stir until mixture is homogeneously mixed; the crucible which carries raw materials is put in a muffle furnace, reacts three hours at a temperature of 350 DEG C to 400 DEG C, and is naturally cooled to a room temperature; after being grinded, black powder hexagonal phase nickel purite submicron crystal is obtained. Defects of harsh conditions, high energy consumption, low yield, poor purity, expensive devices, high temperature, catalyst and virulent H2S gas, difficult processing of organic solvent, being difficult in industrialization and comparatively difficult in separating microemulsion, environment pollution, etc. of prior technique are overcome. The invention utilizes two reducing groups -NH2 at the sulfur source as protection, combing the advantage of liquid and solid fully contact and react in a heating up process, hexagonal phase NiS crystal product is directly synthesized by the muffle furnace at a low temperature condition in the air.

Owner:YANGZHOU UNIV

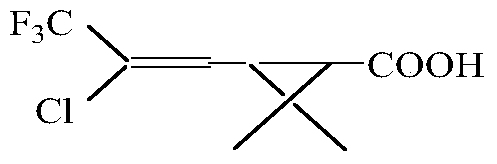

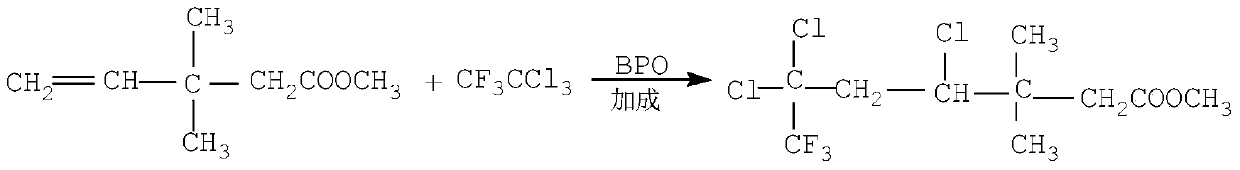

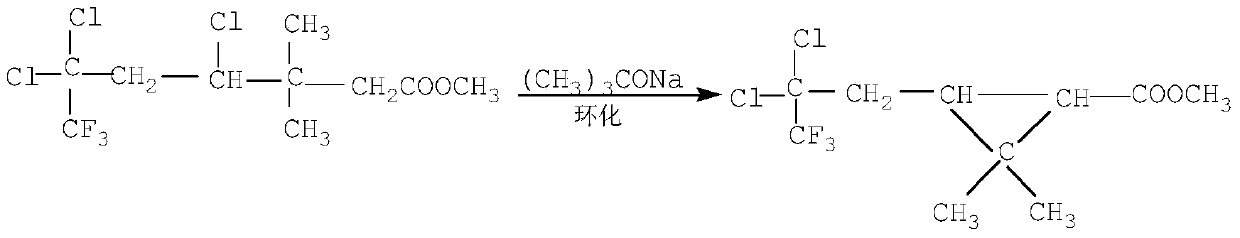

Continuous production method for trifluoro monochloro chrysanthemic acid

InactiveCN105503582ABest production methodQuality improvementOxygen-containing compound preparationOrganic compound preparation4-pentenoic acidChrysanthemic acid

The invention discloses a continuous production method for trifluoro monochloro chrysanthemic acid. The method includes the steps of (1) performing an addition reaction to prepare 3,3-dimethyl-4,6,6-trichloro-7,7,7-trifluoro heptylic acid ester with 3,3-dimethyl-4-pentenoic acid methyl ester and trifluorotrichloroethane as initial raw materials; (2) performing a cyclization reaction with sodium tert-butoxide to generate cis(trans)-3-(2,2-dichloro-3,3,3-trifluoropropyl)-2,2-dimethyl cyclocarboxylate; and (3) performing a saponification reaction to prepare 3-(2-chloro-3,3,3-trifluoro-propylene-1-yl)-2,2-dimethylcyclopropane carboxylic acid, namely, the trifluoro monochloro chrysanthemic acid. In the invention, continuous control is employed in the production method, so that the method is simple in process, is high in equipment utilization, is high in yield and stable in quality of products, is low in production cost and has a wide application prospect.

Owner:LIANYUNGANG CCA CHEM CO LTD

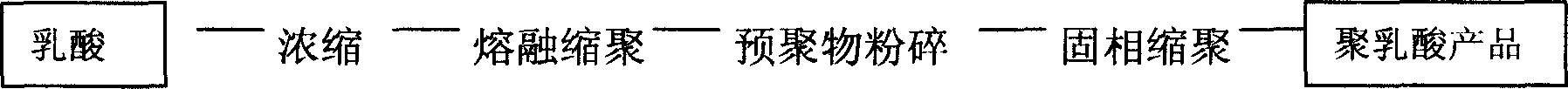

Technique of preparing poly lactic acid in use for spinning

InactiveCN1958640AAvoid bumpingHigh yieldMonocomponent polyesters artificial filamentBulk polymerizationAntioxidant

This invention relates to a method for preparing polylactic acid used in spinning. The method comprises: (1) dehydrating and concentrating lactic acid at certain temperature and vacuum degree to obtain dehydrated and concentrated lactic acid; (2) adding composite catalyst, and pre-polycondensing at certain temperature and vacuum degree for a certain time to obtain prepolymer powder; (3) adding stabilizer and antioxidant, and polymerizing at certain temperature and vacuum degree to obtain polylactic acid particles; (4) adding heat-modified and inorganic acid, and reacting at a certain temperature for a certain time to obtain polylactic acid. The method performs bulk polymerization on lactic acid monomer, and does not need solvent or inert atmosphere, thus the process is simple and easy to control. Besides, the method also has such advantages as high yield and little pollution. The obtained polylactic acid has high molecular weight and low heat shrinkage.

Owner:XI'AN POLYTECHNIC UNIVERSITY

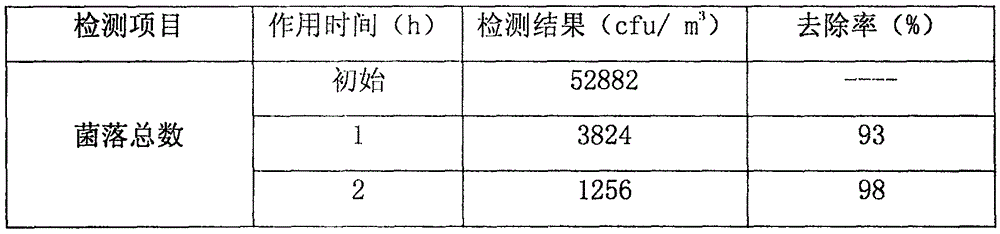

Air sterilizing disinfectant

InactiveCN106719796AImprove the bactericidal effectFast sterilizationBiocideGas treatmentDisinfectantPolyethylene glycol

The invention provides an air sterilizing disinfectant. The air sterilizing disinfectant is prepared from the following raw materials in parts by weight: 10 to 25 parts of sodium chlorite, 12 to 15 parts of sodium dichloro cyanurate, 1 to 5 parts of acid matter, 5 to 15 parts of disintegrant, 20 to 40 parts of alkaline matter, 10 to 20 parts of anhydrous sodium sulfate, and 3 to 8 parts of polyethylene glycol 6000. The air sterilizing disinfectant has the characteristics that the foreign odor is avoided, the mildewing is prevented, the carrying is convenient, the convenience in use is realized, the safety is realized, the efficiency is high, and the like.

Owner:湖南云康共享生物环保有限公司

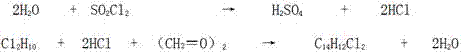

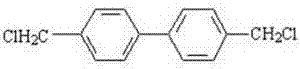

Preparation process for 4,4'-bis(chloromethyl)-1,1'-biphenyl

ActiveCN107473927AHigh yieldAvoid pollutionHalogenated hydrocarbon separation/purificationHalogen/halogen-acidsChemical synthesisCatalytic effect

The invention relates to a preparation process for 4,4'-bis(chloromethyl)-1,1'-biphenyl, and belongs to the technical field of chemical synthesis. The 4,4'-bis(chloromethyl)-1,1'-biphenyl is prepared by synthesizing raw materials paraformaldehyde and biphenyl under the catalytic action of zinc chloride, acetic acid and cyclohexane. According to the process, hydrogen chloride is continuously provided for synthesis reaction by virtue of reaction of sulfuryl chloride and concentrated hydrochloric acid to ensure smooth chloromethylation reaction, so that the yield and the product quality of the 4,4'-bis(chloromethyl)-1,1'-biphenyl are improved, the amount of sewage required to be treated is small, and the treatment cost is low. According to the preparation process for the 4,4'-bis(chloromethyl)-1,1'-biphenyl, the phenomenon that an excessive amount of water is introduced into a reaction system to further reduce the catalytic effect of the zinc chloride is avoided, and moreover, production of a highly carcinogenic intermediate product is avoided; the preparation process is environment-friendly and applied to industrial expanded production, and the production cost is reduced.

Owner:荆州三才堂化工科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com