Method for preparing thin film solar cell from multi-element alloy single target material

A solar cell and multi-element technology, applied in metal material coating technology, circuits, electrical components, etc., can solve problems such as increased risk factors, high energy consumption, and highly toxic steam, so as to avoid environmental pollution and simplify process steps , the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

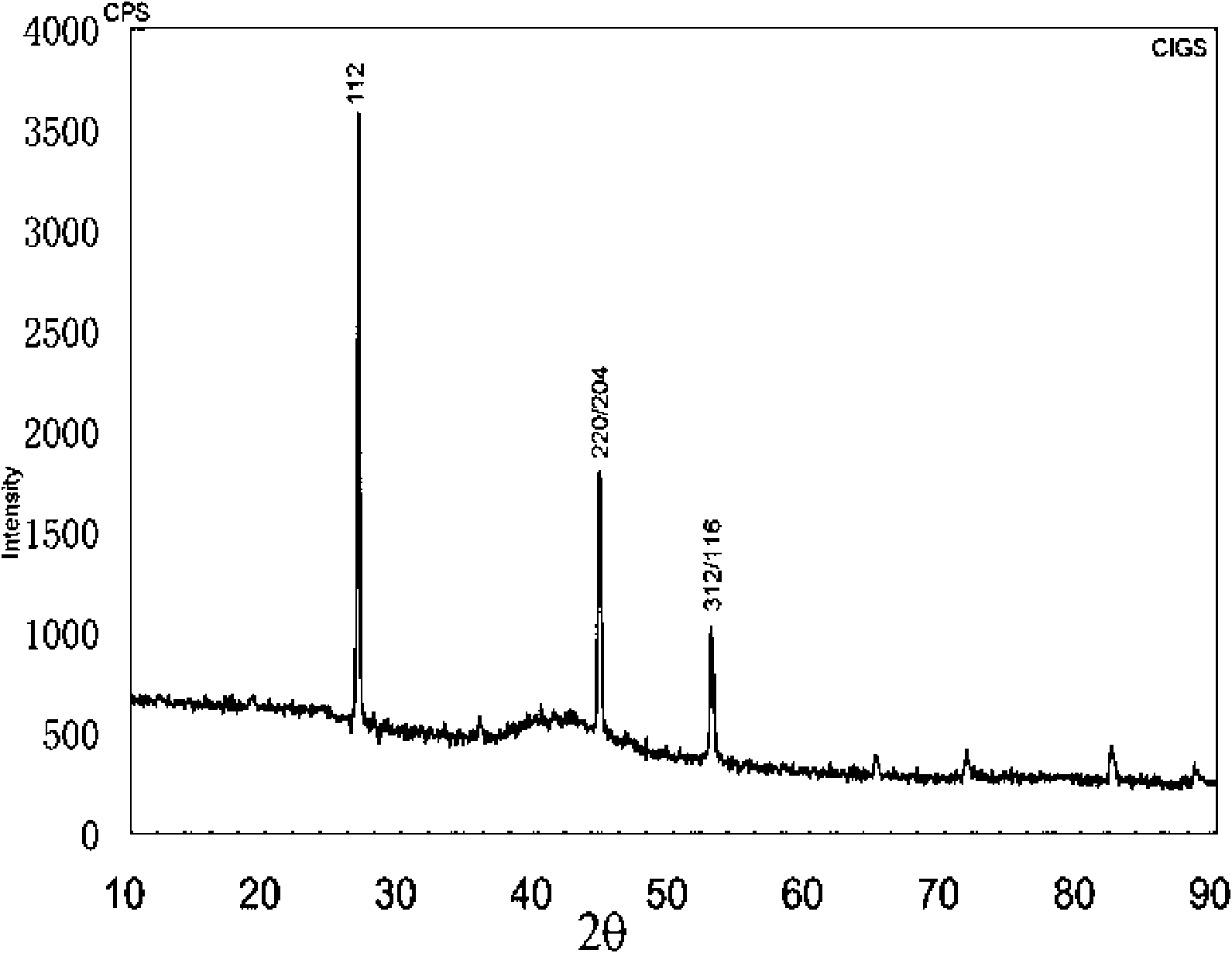

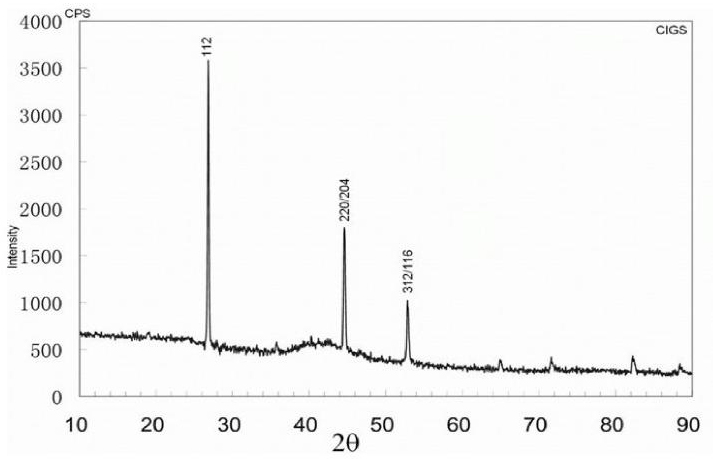

[0038] On the 0.3mm thick 304 stainless steel sheet, use magnetron sputtering to deposit 0.8 micron thick molybdenum Mo metal, and then use the vacuum magnetron sputtering method to sputter the CIGS alloy single target prepared by the vacuum melting method described in patent 200810044210.5 on the molybdenum film material to form the solar cell absorber layer. Sputter the first time with a copper-rich CIGS alloy single target, and then sputter with a copper-poor CIGS alloy single target for the second time. The copper-rich CIGS alloy single target material has a mass ratio of copper atoms of 28%, and the mass ratio of selenium atoms is 45%; the copper-poor CIGS single target material has a mass ratio of copper atoms of 20%, and the mass ratio of selenium atoms The mass ratio of atoms is 53%. The parameter of magnetron sputtering is 3x10 -3 Torr, and doped with 5% O 2 The Ar gas is used, and the temperature of the molybdenum substrate is kept at 350°C to 450°C during the spu...

Embodiment 2

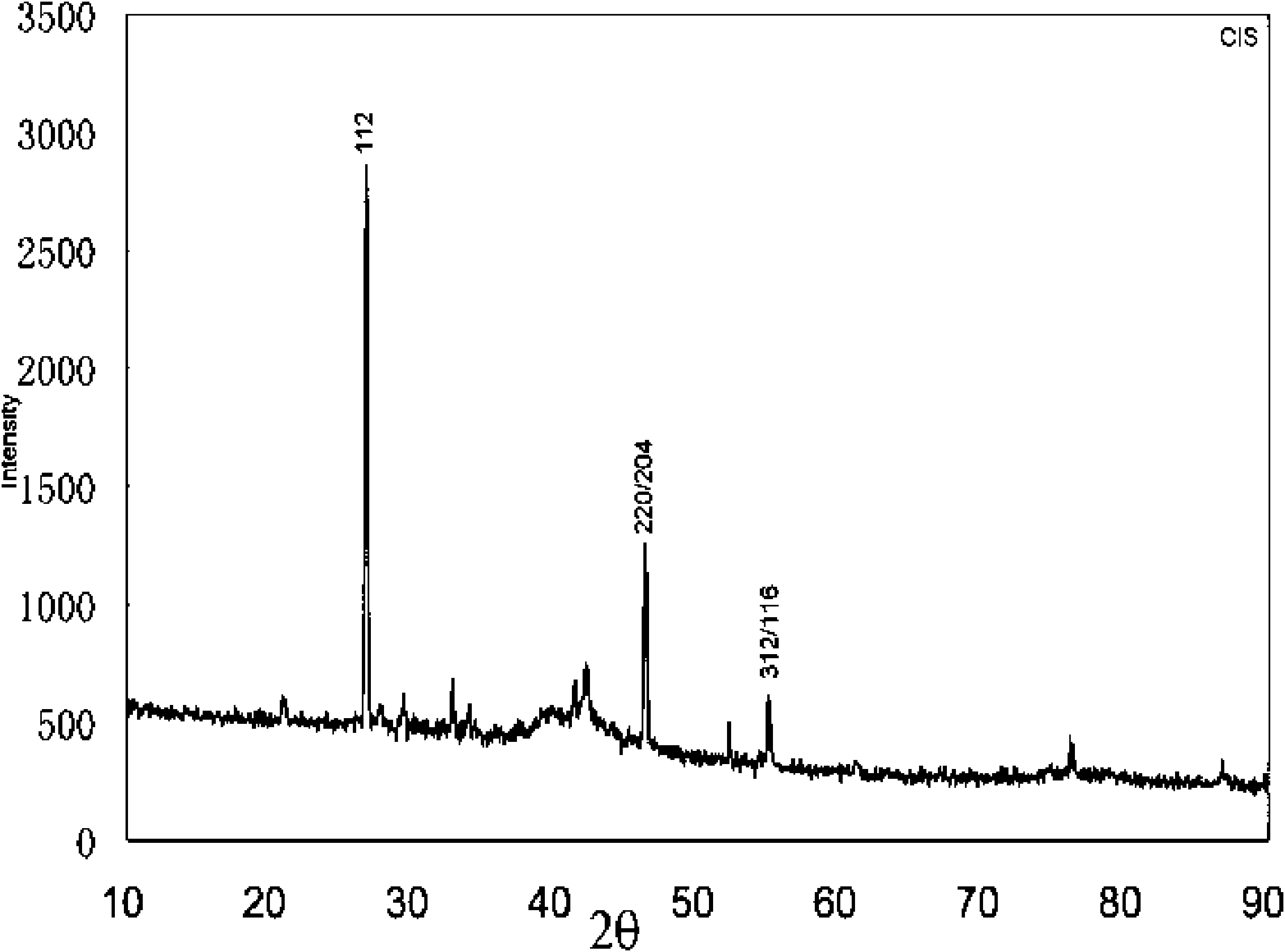

[0046] Magnetron sputtering is used to deposit 0.8 micron thick molybdenum Mo metal on a 3mm thick soda lime glass sheet, and then vacuum magnetron sputtering is used to sputter CIS (CuInS) prepared by the vacuum melting method described in patent 200810044210. 2 ) alloy single target to form the solar cell absorber layer. Sputter the first time with a copper-rich CIS alloy single target, and then sputter with a copper-poor CIS alloy single target for the second time. The copper-rich CIS alloy single target material has a mass ratio of copper atoms of 28%, and the mass ratio of selenium atoms is 45%; the copper-poor CIS single target material has a mass ratio of copper atoms of 20%, and the mass ratio of selenium atoms The mass ratio of atoms is 53%. The parameter of magnetron sputtering is 3x10 -3 Torr, and doped with 5% O 2 Ar gas was used, and the temperature of the molybdenum substrate was kept at 350 °C during the sputtering process. The deposition thickness of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com