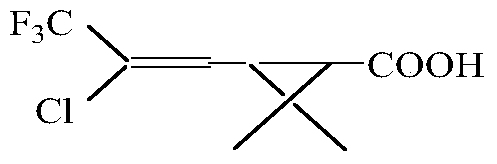

Continuous production method for trifluoro monochloro chrysanthemic acid

A technology of trifluoro-permethrin and a production method, applied in chemical instruments and methods, organic chemistry, carboxylate preparation and other directions, can solve the problem of product yield and quality decline, low yield of trifluoro-permethrin, recovery of Unusable raw materials, etc., to achieve the effect of reducing side reactions, shortening saponification reaction time, and shortening product production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

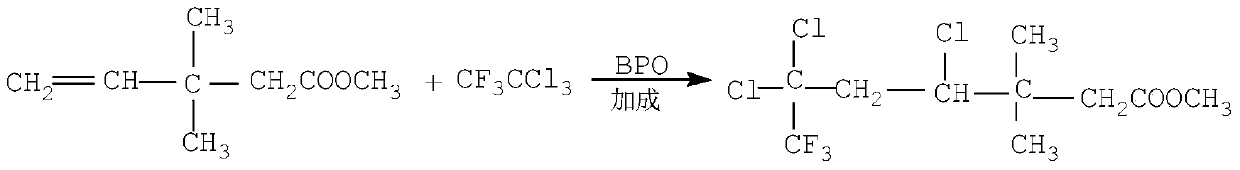

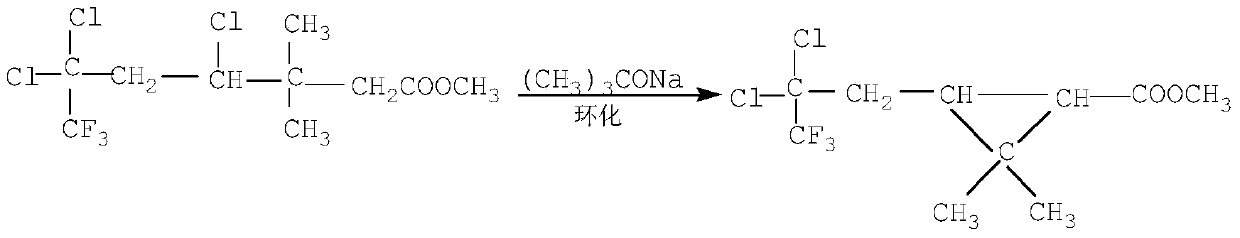

[0034] The synthetic method of trifluoro-permethrin may further comprise the steps:

[0035] a) Process for continuous production of 4,6,6-trichloro-7,7,7-trifluoro-3,3-dimethylheptanoate (adduct):

[0036] From the storage tank area, the methyl perineate, trifluorotrichloroethane, catalyst BPO, and tert-butanol are respectively 1:1.5:0.015:2 (molar ratio), and the mass flowmeter is used to control the metering through the respective pipelines. Static mixer, mix well. Then use the material pump to pump the addition raw material mixture into the pipeline reactor for heating and heat preservation reaction, control the reaction pressure≤0.35MPa, and the reaction temperature≤115°C. Online sampling and analysis of the content of methyl bentinate in the reaction material≤0.2%, determine The residence time of the reactant pipe reactor, after the online sampling test is qualified, the material is continuously discharged to the intermediate tank, and then rectified to continuously sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com