High-temperature co-firing ceramic slurry and preparation method thereof

A technology of high-temperature co-fired ceramics and slurry, applied in the field of semiconductor manufacturing, can solve the problems of limited range of resistance temperature coefficient, difficult to meet different requirements of different resistance electronic components, etc., and achieve the effect of less production equipment and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] 1) Prepare the ceramic powder A by performing 24-hour dry powder ball milling on the inorganic additives in proportion;

[0021] 2) Dry porcelain powder A, tungsten powder and molybdenum powder in proportion, sieve, and quickly ball mill for 1 hour to obtain mixed powder B;

[0022] 3) Add the organic vehicle to the mixed powder B in proportion, and roll it into a slurry through a three-roll mill.

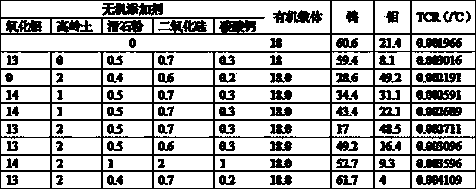

[0023] The high temperature co-fired ceramic slurry formula and test temperature coefficient of resistance (TCR) are as follows:

[0024]

[0025] Note: The test temperature range of TCR is 25℃-600℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com