Heat exchanger beneficial to discharge of condensate water

A heat exchanger and condensate technology, applied in heat exchange equipment, evaporators/condensers, refrigerators, etc., can solve problems such as slow airflow, affecting system ventilation and heat transfer, and restricting application fields, and achieve less production equipment. , the effect of saving investment and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

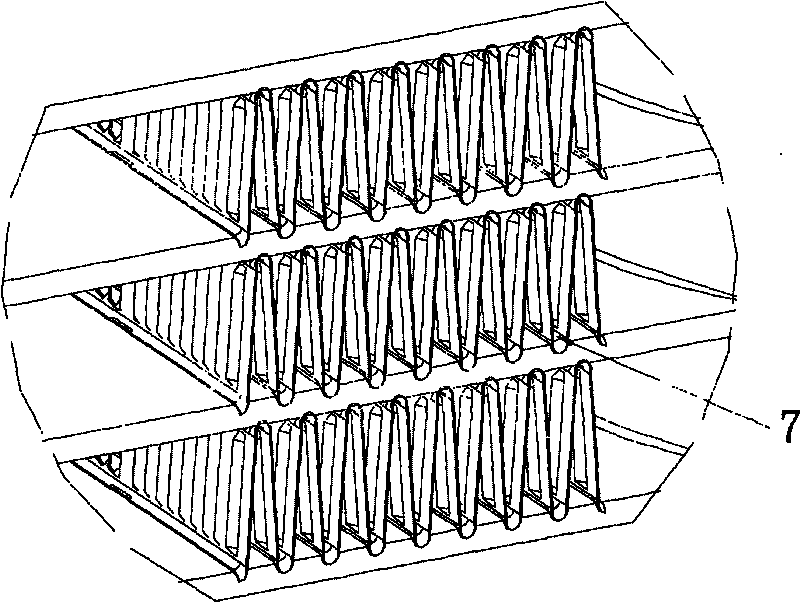

[0020] figure 1 It is a schematic diagram of the connection structure between rolled pleated fins and flat tubes in the prior art, and is composed of figure 1 In mark 7, it can be seen that the small concave arc at the bottom of the rolled pleated fin is a horizontal straight section. In the case of condensed water, the condensed water gathers in the small concave arc 7 and frosts and freezes, which affects the normal ventilation of the system. heat exchange.

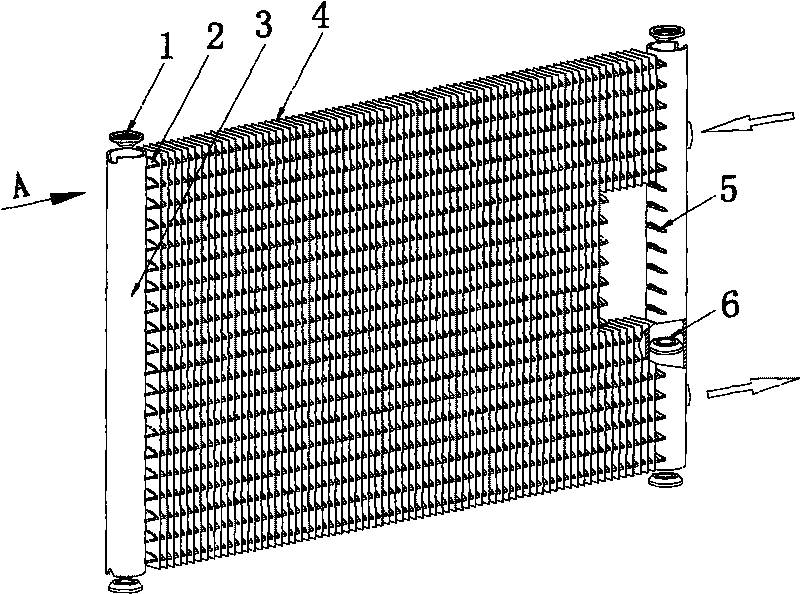

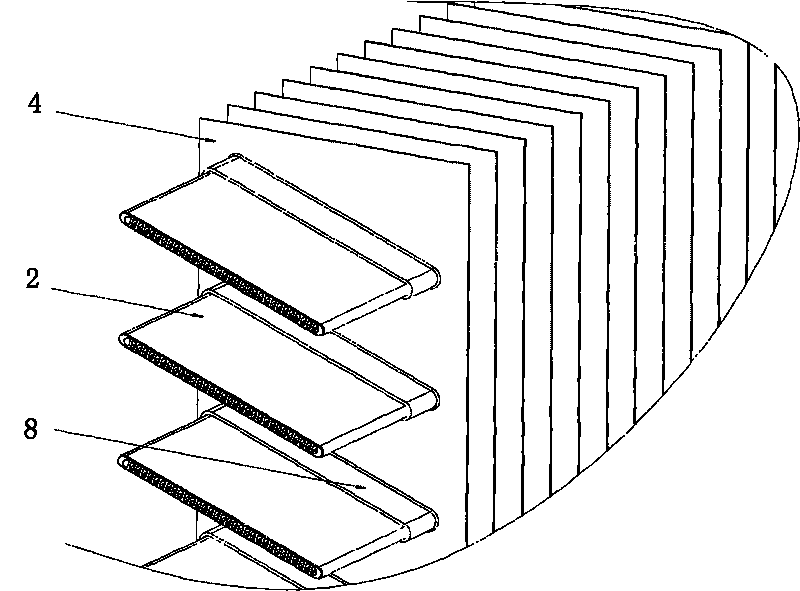

[0021] Depend on figure 2 and image 3 It can be seen that a heat exchanger that facilitates the discharge of condensed water includes a header 3, a blocking cover 1 placed at the end of the header 3, a spacer 6 placed inside the header 3, and the The flat tube 2 connected to the collector 3, and the fins 4 connected to the flat tube 2 are characterized in that: one side of the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com