Fast precise semi-axle casing extruding formation process

A semi-shaft casing and a new process technology, applied in the direction of manufacturing tools, metal processing equipment, other manufacturing equipment/tools, etc., can solve the problems of shrinking application range, inability to form forgings, and low material utilization rate, so as to improve labor productivity , Improve material utilization, reduce the effect of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following examples illustrate the implementation process of the present invention, and further illustrate the technical characteristics of the present invention.

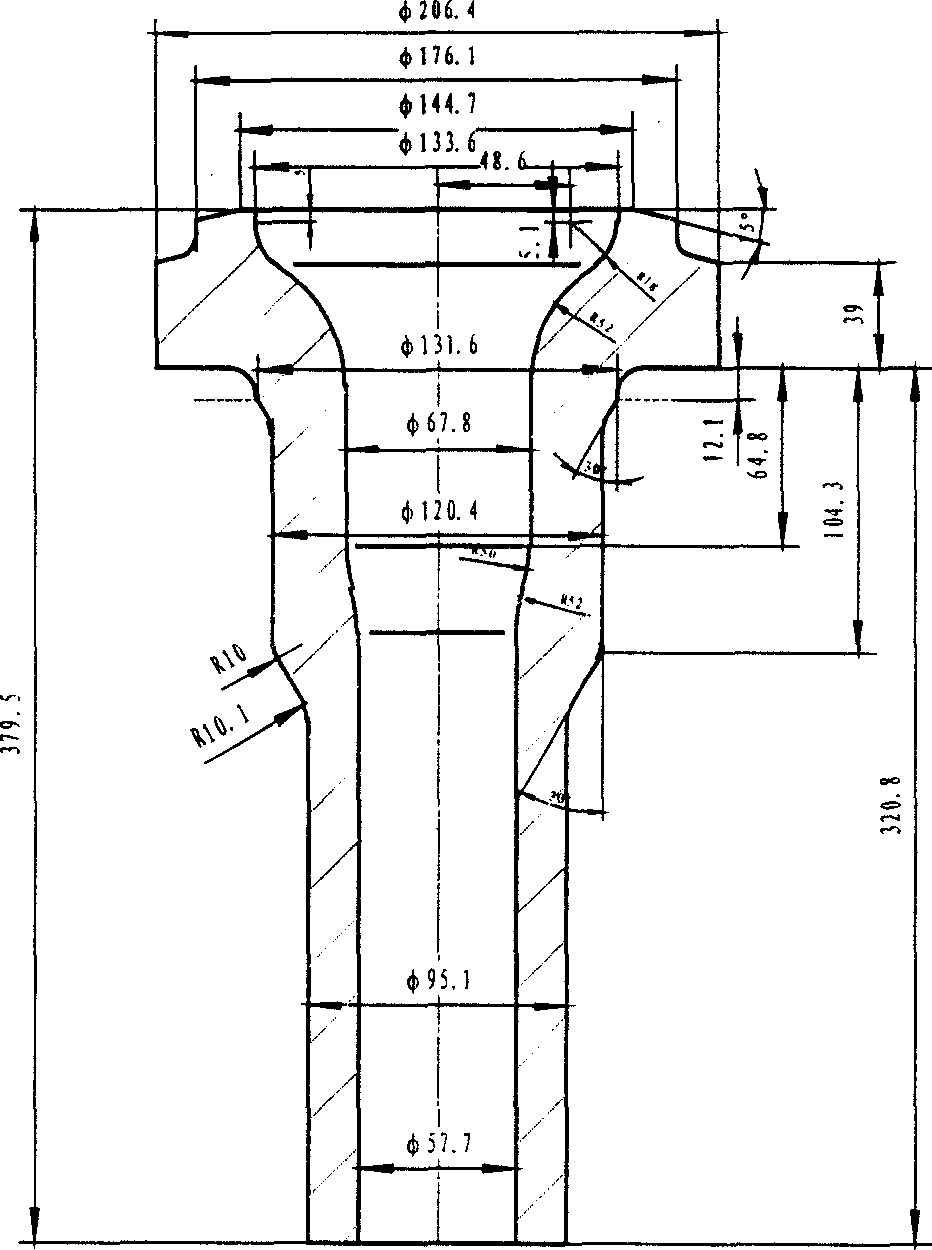

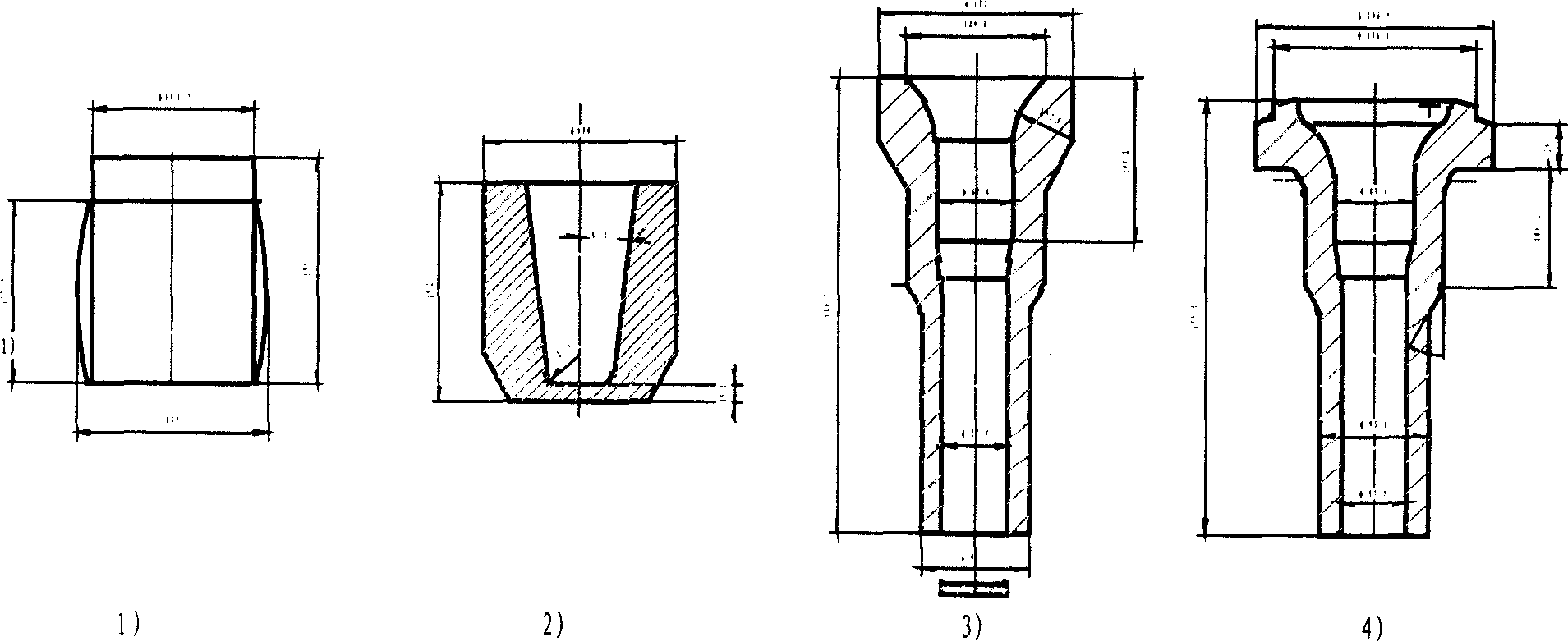

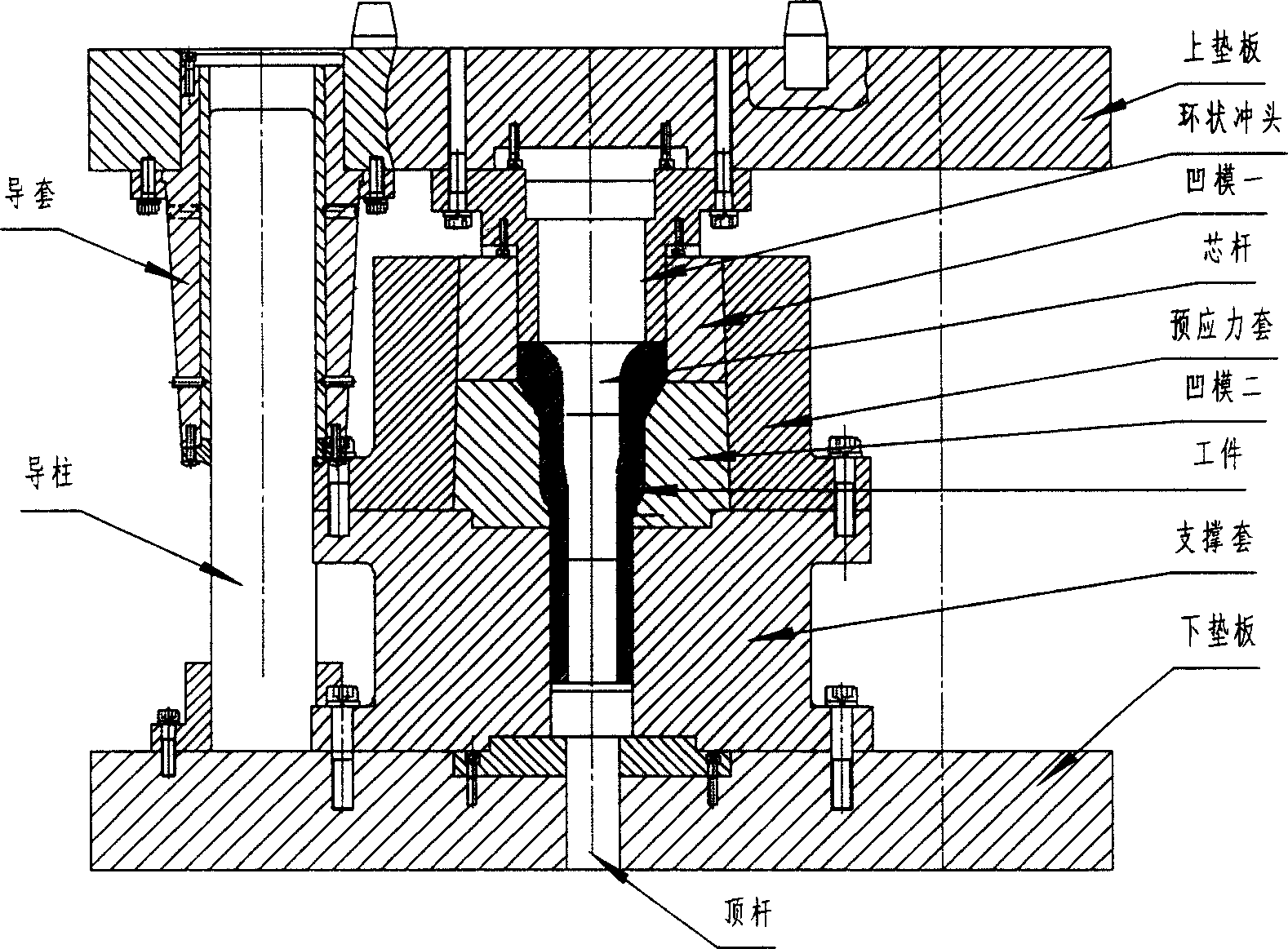

[0010] Figure 1 is a diagram of a half-shaft casing forging. The precision grade is the precision grade in GB12362 "Steel Die Forging Tolerance and Machining Allowance". The height of the forging is 380mm, and the head has a flange. Extrusion is used, and the working stroke of the press should be at least twice the height of the workpiece. This is because in addition to the stroke required for extrusion, the stroke required to remove the workpiece after it is ejected from the die must also be considered. In addition to the height of the mold system, the opening height of the press should be greater than 4 times the height of the workpiece. General mechanical presses cannot meet this requirement, but hydraulic presses are easier to meet this requirement, so it is more reasonable to choose hydraulic pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com