Airflow impurity separation device and manufacturing method of airflow impurity separation device

A separation device and impurity technology, which is applied in the manufacturing field of separation device, impurity separation device in airflow, and impurity separation device in airflow. It can solve problems such as blockage, poor suction, and low collection efficiency, so as to reduce the cost of use and prolong maintenance. The effect of high cycle and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

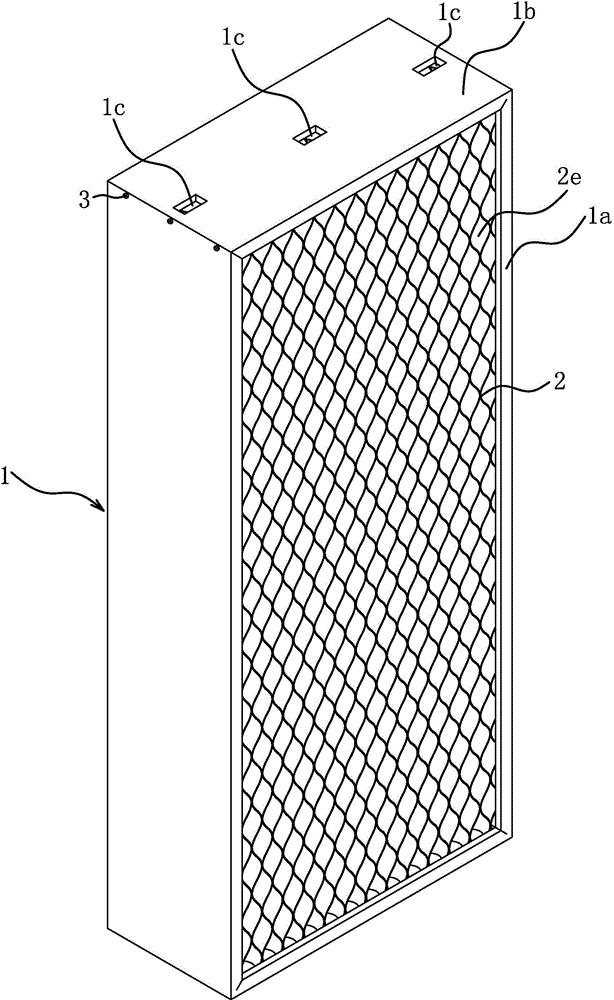

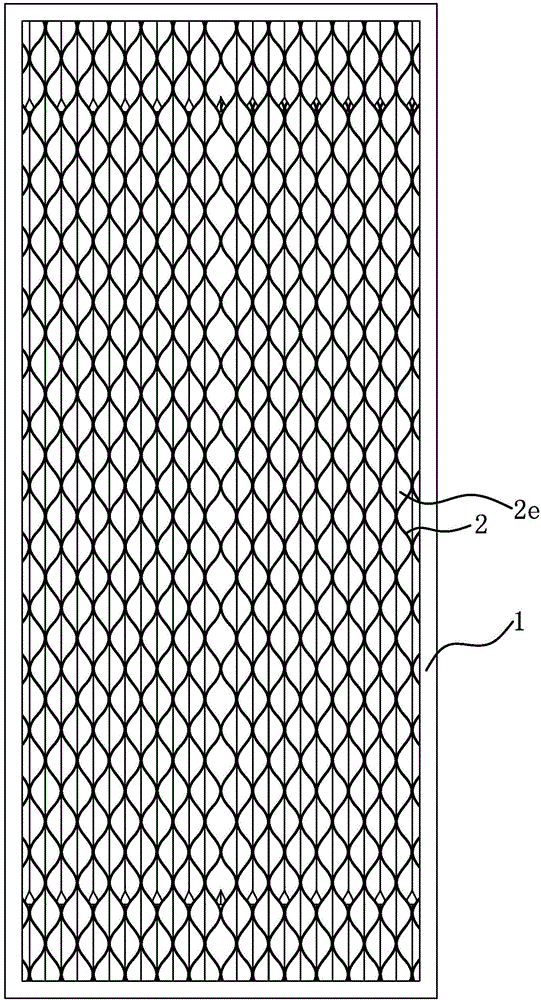

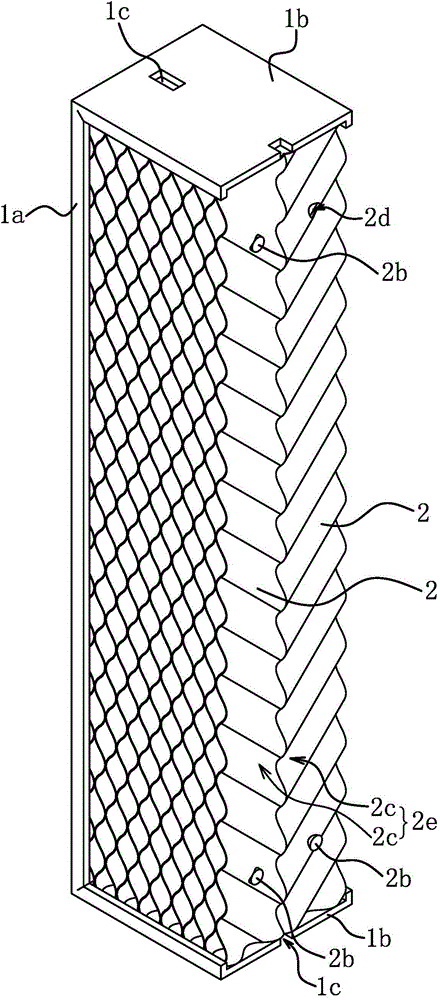

[0036] Such as Figure 1 to Figure 6 As shown, the impurity separation device in the air flow includes two layers of separation filter plates 2 and a frame 1 .

[0037] The separation filter plate 2 includes a plurality of wavy folded plates 2a and two connecting rods 2b. The folded plates 2a have multiple air passages 2a1, and the air passages 2a1 are arranged obliquely relative to the longitudinal line of the folded plates 2a. The two connecting rods 2b pass through all the folded plates 2a, and all the folded plates 2a are stacked in sequence, and the crest of one folded plate 2a abuts against the trough of the adjacent folded plate 2a; Separation channel 2c arranged obliquely relative to the plate surface. The separation channels 2c on the separation filter plate 2 face the same direction.

[0038] Two layers of separation filter plates 2 are stacked together, and the separation channels 2c on the two layers of separation filter plates 2 face opposite directions, such as...

Embodiment 2

[0047] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be redundantly described, and only the differences will be described, and the differences are as follows: Figure 7 and Figure 8 As shown, the air passage 2a1 in the folded plate 2a is V-shaped, and the corners are circular arcs with a gentle transition.

[0048] Such as Figure 9 and Figure 10 As shown, a plurality of folded plates 2a are sequentially stacked to form a layer of separation filter plate 2, and the wave crest in one folded plate 2a of the two adjacent folded plates 2a abuts against the wave trough in the adjacent folded plate 2a. The air passages 2a1 in the two adjacent folded plates 2a are arranged alternately, Figure 10 The dotted line indicates a folded plate 2a, and the solid line indicates a folded plate 2a.

[0049] The method for manufacturing the impurity separation device in the right air flow includes parts pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com