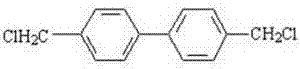

Preparation process for 4,4'-bis(chloromethyl)-1,1'-biphenyl

A technology for preparing biphenyl benzyl dichloride and its preparation technology is applied in the field of preparation technology of biphenyl benzyl dichloride, which can solve the problem of large consumption of catalyst zinc chloride and sulfuric acid, low degree of industrial promotion and application, and low yield of biphenyl benzyl dichloride and other issues to achieve the effect of saving manpower, saving production equipment, process economy and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

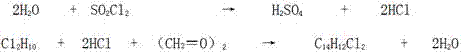

Method used

Image

Examples

Embodiment 1

[0028]A kind of preparation technology of biphenyl benzyl dichloride: the concentrated hydrochloric acid that concentration is 35%, the sulfuryl chloride of 99% are placed in the hydrochloric acid high level tank and the sulfuryl chloride high level tank above the synthetic kettle; Then the concentration is 99% acetic acid , 99% cyclohexane was put into the synthesis kettle, and then the concentration was added successively with 99% anhydrous zinc chloride, 99% paraformaldehyde and 99% biphenyl and stirred for 15 min, the mixed material in the synthesis kettle The stirring speed is 80r / min; the mass ratio of the added acetic acid, cyclohexane, anhydrous zinc chloride, concentrated hydrochloric acid, sulfuryl chloride, paraformaldehyde and biphenyl is 0.64: 1.02: 0.7: 0.29: 0.7: 0.39 :1;. The rate of addition of concentrated hydrochloric acid and sulfuryl chloride is controlled to be 33Kg / hour, 78Kg / hour respectively. After the stirring of the mixed materials in the synthe...

Embodiment 2

[0031] A kind of preparation technology of biphenyl benzyl dichloride: the concentrated hydrochloric acid that concentration is 35%, the sulfuryl chloride of 99% are placed in the hydrochloric acid high level tank and the sulfuryl chloride high level tank above the synthetic kettle; Then the concentration is 99% acetic acid , 99% cyclohexane was put into the synthesis kettle, and then 99% anhydrous zinc chloride, 99% paraformaldehyde and 99% biphenyl were added successively and stirred for 15 min, and the mixture in the synthesis kettle was The stirring speed of the material is 80r / min; the mass ratio of the added acetic acid, cyclohexane, anhydrous zinc chloride, concentrated hydrochloric acid, sulfuryl chloride, paraformaldehyde and biphenyl is 0.64:1.02:0.7:0.29:0.7: 0.39:1; the dropping rate of concentrated hydrochloric acid and sulfuryl chloride is controlled to be 33Kg / hour and 78Kg / hour respectively. After the stirring of the mixed materials in the synthesis kettle is c...

Embodiment 3

[0033] A kind of preparation technology of biphenyl benzyl dichloride: the concentrated hydrochloric acid that concentration is 35%, the sulfuryl chloride of 99% are placed in the hydrochloric acid high level tank and the sulfuryl chloride high level tank above the synthetic kettle; Then the concentration is 99% acetic acid , 99% cyclohexane was put into the synthesis kettle, and then 99% anhydrous zinc chloride, 99% paraformaldehyde and 99% biphenyl were added successively and stirred for 15 min, and the mixture in the synthesis kettle was The stirring speed of the material is 80r / min; the mass ratio of the added acetic acid, cyclohexane, anhydrous zinc chloride, concentrated hydrochloric acid, sulfuryl chloride, paraformaldehyde and biphenyl is 0.64:1.02:0.7:0.29:0.7: 0.39:1; the dropping rate of concentrated hydrochloric acid and sulfuryl chloride is controlled to be 33Kg / hour and 78Kg / hour respectively. After the stirring of the mixed materials in the synthesis kettle is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com