Process for forging rear axle shaft flange of automobile

A technology for automobile rear axle and axle flange, which is applied in vehicle parts, railway car body parts, transportation and packaging, etc., can solve the problems of poor surface quality of forgings, high production cost and low production efficiency, and achieve good surface quality of forgings. , the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0027] Present embodiment is a kind of automobile rear axle semi-shaft flange (such as Figure 6 Shown) forging process, the steps are as follows:

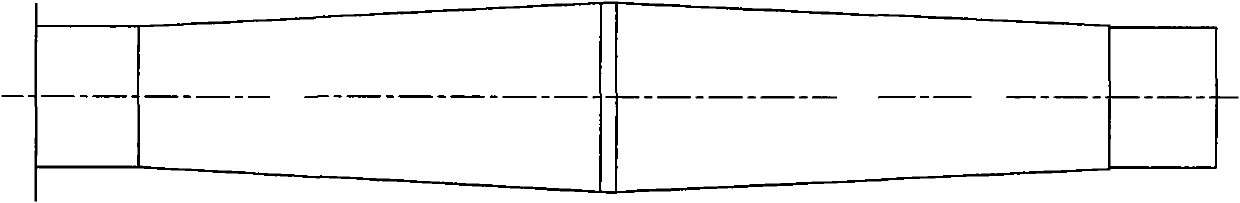

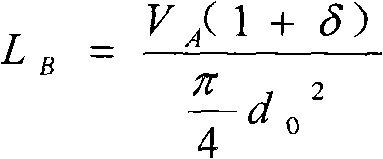

[0028] 1) will be as figure 1 The circular bar shown is heated to 1150 ° C ~ 1250 ° C in an intermediate frequency heating furnace, and then heated in such as Figure 7 The flat forging machine shown uses the conical cavity of the mold to upset the circular bar to form a blank for the rear axle half shaft of the automobile. The shape part 5, the ratio of the length La to the diameter of the frustum-shaped part ranges from 0.9 to 1.5, which ensures that the billet is not easy to be inclined or bent during the rolling process of the subsequent pendulum mill, and the diameter is the average value of the frustum-shaped part diameter (ie Figure 5 The small end diameter d of the frustoconical portion shown n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com