Microwave heating device for heating cold-rolling pickling process medium

A microwave heating device and medium heating technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve environmental pollution, waste and other problems, and achieve less production equipment, less floor space, energy utilization and heating high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

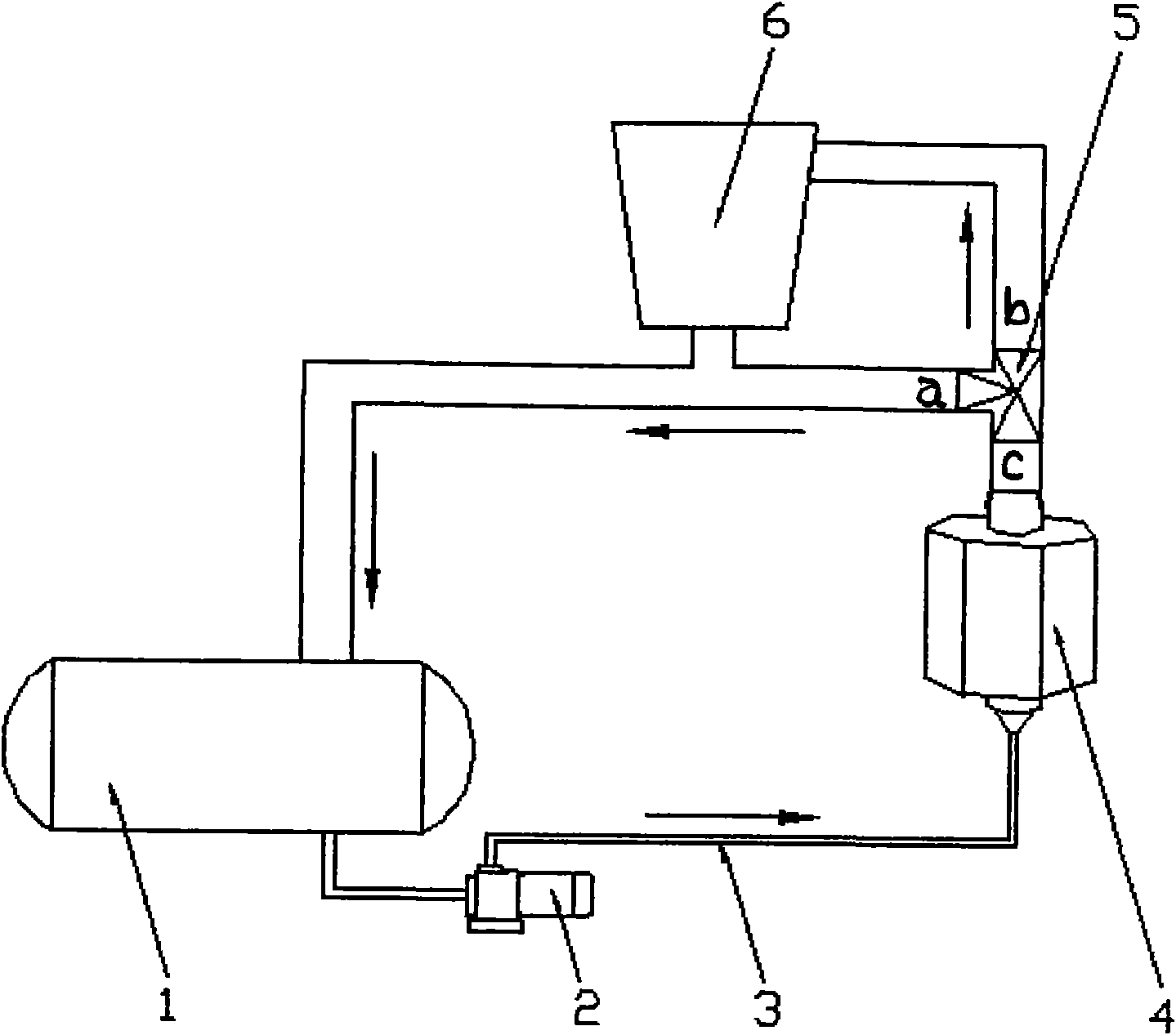

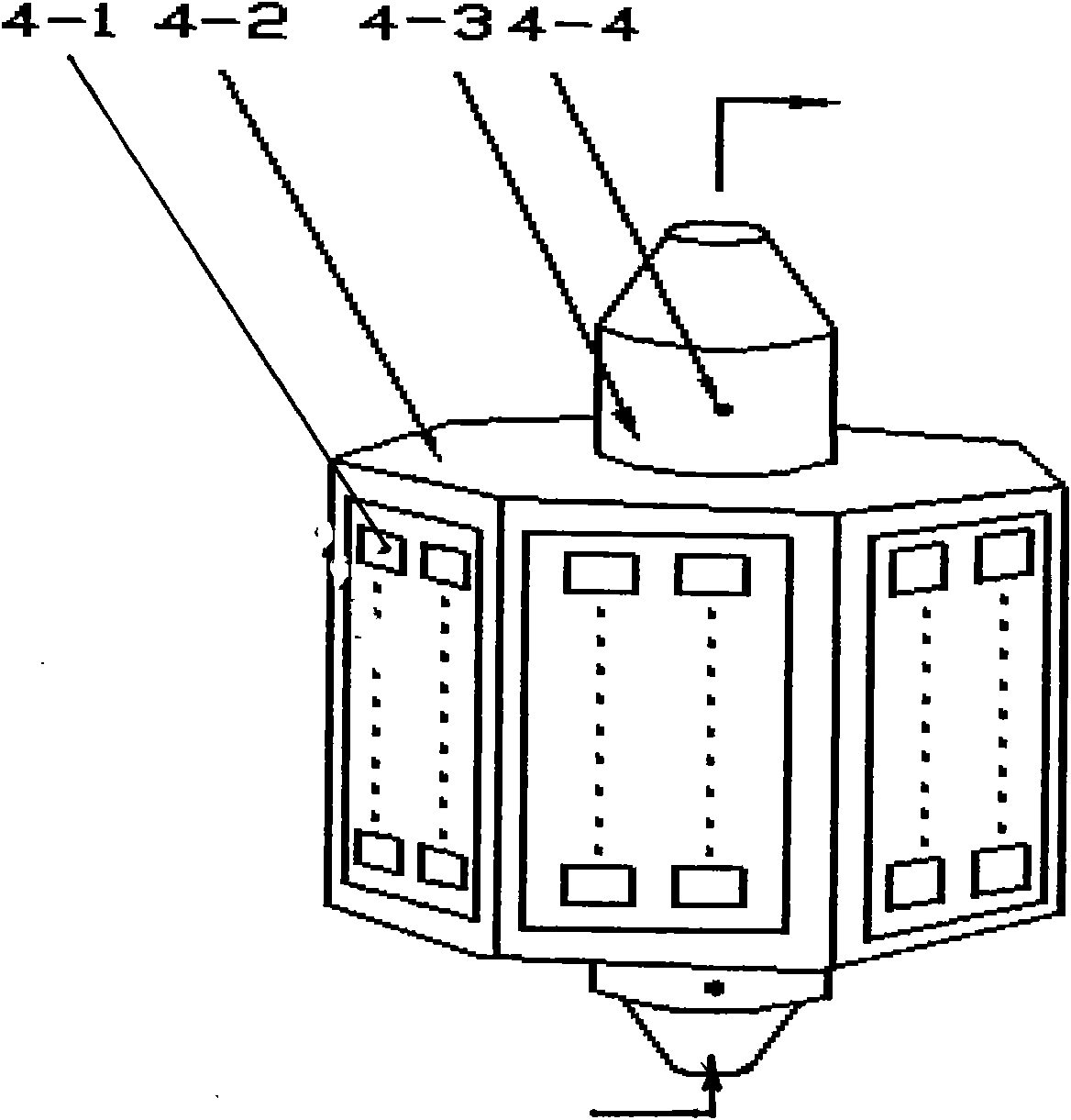

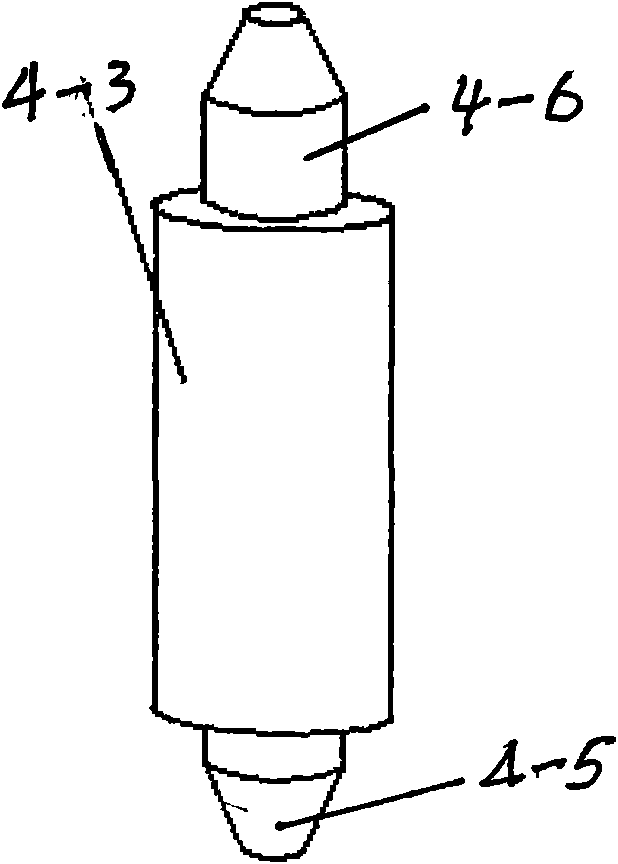

[0012] Embodiment: a kind of device that is used for the microwave heater heating titanium strip cleaning acid solution of titanium strip cold rolling pickling process, it comprises circulation tank 1, circulation pump 2, pipeline 3, microwave heating device 4, three-way valve 5, Pickling tank 6; microwave heating device 4 includes microwave heater 4-1, cavity 4-2, heating pipe 4-3, temperature sensor 4-4, heating pipe input port 4-5, heating pipe output port 4- 6. The circulation tank 1 and the circulation pump 2 are connected with the heating pipe input port 4-5 of the microwave heating device 4 through the pipeline 3, and the heating pipe output port is connected with the pickling tank 6 through the pipeline, between the microwave heater 4 and the pickling tank 6 The pipeline is provided with a three-way valve 5, and the pickling tank 6 is connected with the circulation tank 1 through a pipeline; the cavity 4-2 is designed to be an equipolyhedron shape, and the microwave he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com