Method for preparing doped graphene from supercritical fluid

A supercritical fluid and supercritical flow technology, applied in the field of graphene, can solve the problems of high magazine content, large equipment investment, cumbersome steps, etc., and achieve the effects of simple process, low environmental pollution, and few production equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

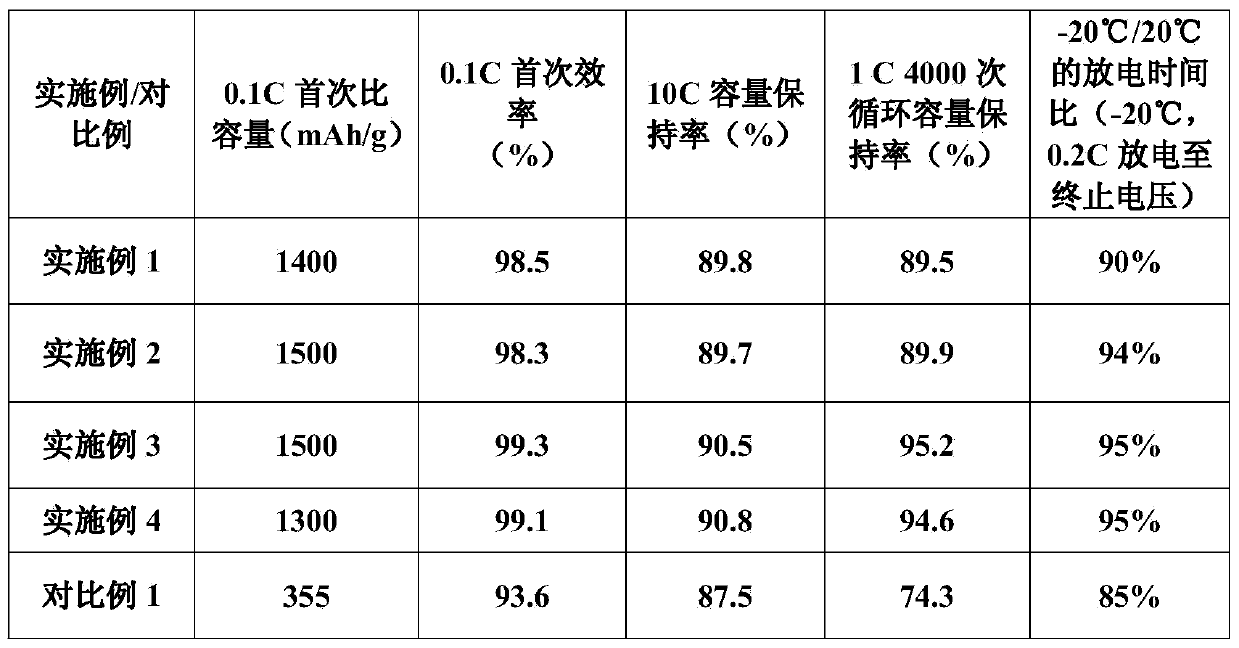

Examples

Embodiment 1

[0021] A method for preparing doped graphene by supercritical fluid, comprising the steps of:

[0022] 1) preparation of graphene oxide:

[0023] Add graphite into the mixture of strong oxidizing acid and nitrate, after mixing evenly, add a strong oxidizing agent containing potassium, raise the temperature of the system to 35°C, and continue stirring for 12 hours, then slowly add a certain amount of water, raise the temperature of the system to 80°C and Keep it for 30 minutes, then add water and a certain amount of hydrogen peroxide, after fully stirring the reaction, wash repeatedly with dilute acid solution and deionized water to remove various ions in the system, and then collect the solid by vacuum drying to obtain graphene oxide; The mass ratio of reactants is strong oxidizing acid: nitrate: potassium-containing strong oxidizing agent: hydrogen peroxide: graphite=10:5:2:5:1.

[0024] 2) Preparation of doped graphene

[0025] Put the graphene oxide obtained above and the...

Embodiment 2

[0030] A method for preparing doped graphene by supercritical fluid, comprising the steps of:

[0031] 1) preparation of graphene oxide:

[0032] Add graphite into the mixture of strong oxidizing acid and nitrate, after mixing evenly, add a strong oxidizing agent containing potassium, raise the temperature of the system to 40°C, and continue stirring for 4 hours, then slowly add a certain amount of water, raise the temperature of the system to 60°C and Keep it for 60 minutes, then add water and a certain amount of hydrogen peroxide, after fully stirring the reaction, wash repeatedly with dilute acid solution and deionized water to remove various ions in the system, and then collect the solid by vacuum drying to obtain graphene oxide; The mass ratio of reactants is strong oxidizing acid: nitrate: potassium-containing strong oxidizing agent: hydrogen peroxide: graphite=40:1:8:1:1.

[0033] 2) Preparation of doped graphene

[0034] Put the graphene oxide obtained above and the ...

Embodiment 3

[0039] A method for preparing doped graphene by supercritical fluid, comprising the steps of:

[0040] 1) preparation of graphene oxide:

[0041] Add graphite into the mixture of strong oxidizing acid and nitrate, after mixing evenly, add a strong oxidizing agent containing potassium, raise the temperature of the system to 36°C, and continue stirring for 8 hours, then slowly add a certain amount of water, raise the temperature of the system to 70°C and Keep it for 50 minutes, then add water and a certain amount of hydrogen peroxide, after fully stirring the reaction, wash repeatedly with dilute acid solution and deionized water to remove various ions in the system, and then collect the solid by vacuum drying to obtain graphene oxide; The mass ratio of reactants is strong oxidizing acid: nitrate: potassium-containing strong oxidizing agent: hydrogen peroxide: graphite=20:3:5:4:1.

[0042] 2) Preparation of doped graphene

[0043] Put the graphene oxide obtained above and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com