Direct vat set modifier of cast asphalt mixture and preparation method

An asphalt mixture, direct-injection technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of unstable mixture performance and modified asphalt performance, and avoid attenuation, segregation, and high temperature on the road surface. Excellent performance, low temperature resistance and good fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

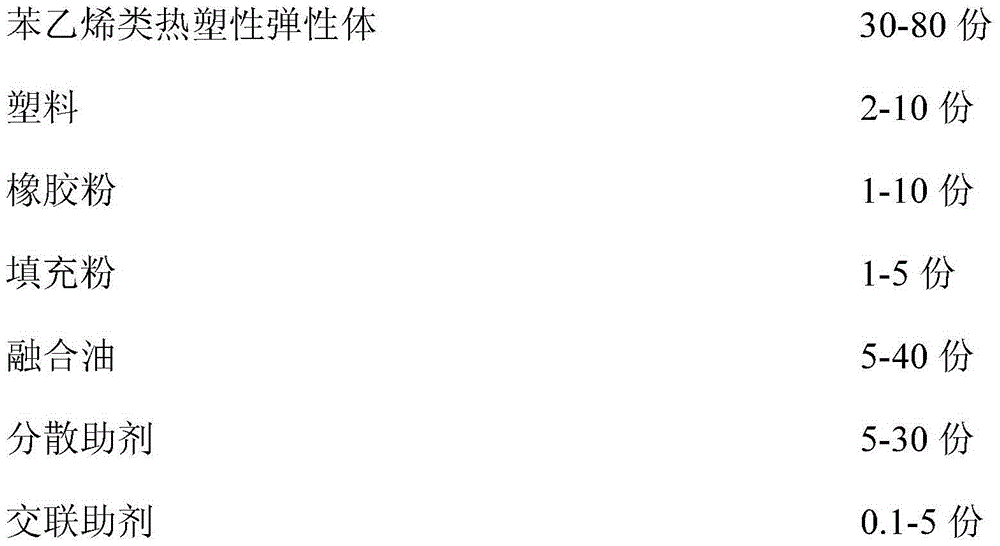

[0018] (1) the preparation of direct throw modifier, described modifier is made up of the following components of parts by weight:

[0019]

[0020] The ethylene styrene copolymer is specifically a mixture of 45 parts of SBS791H produced by Dushanzi and 45 parts of SBS445233 parts of Yanshan Petrochemical;

[0021] The plastic is specifically PVC;

[0022] Described rubber powder is specifically radial tire regenerated rubber powder;

[0023] Described filling powder is specifically ground calcium carbonate;

[0024] Described fusion oil is Hengshui furfural extraction oil;

[0025] Described dispersion aid is calcium stearate;

[0026] Described crosslinking auxiliary agent is maleic anhydride;

[0027] Mix the above components evenly and pour them into a granulator to melt and granulate.

[0028] Castable asphalt mixture is produced according to the following steps:

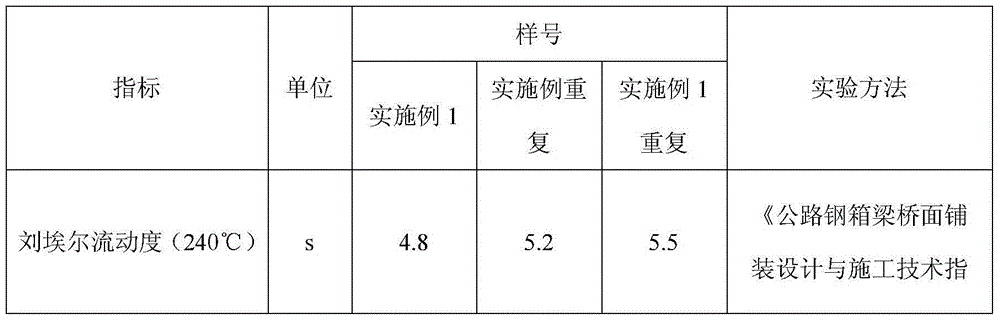

[0029] First, add the mineral material preheated at about 240 degrees (see Table 1 for gradation an...

Embodiment 2

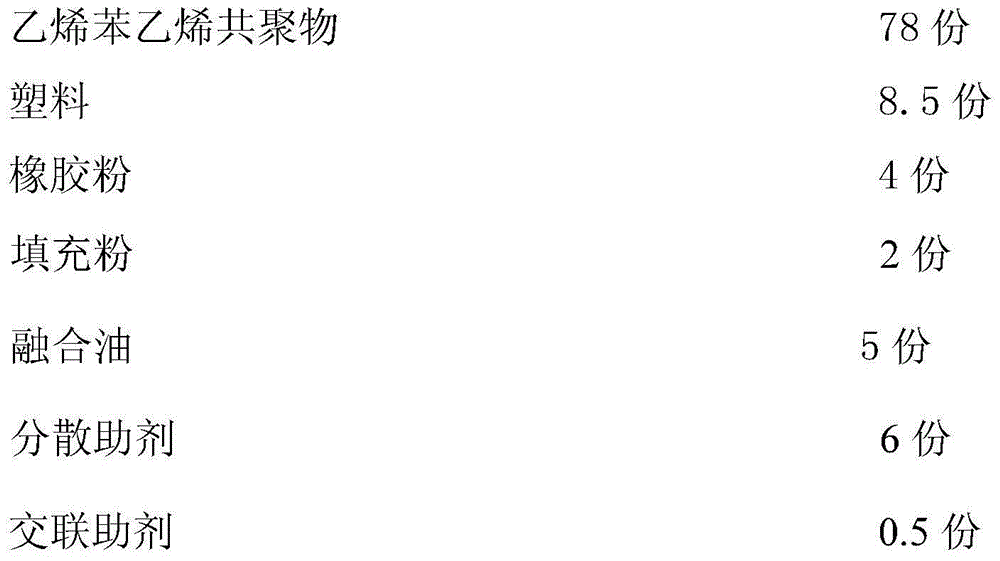

[0041] The preparation of direct throw modifier, it is made up of the following components of parts by weight:

[0042]

[0043] The ethylene styrene copolymer is specifically formed by mixing 20 parts of Dushanzi SBS791H and 10 parts of Yanshan Petrochemical SBS4452;

[0044] The plastic is specifically Dongguan Juntai HDPE;

[0045] Described rubber powder is specifically radial tire regenerated rubber powder;

[0046] Described fusion oil is aromatic hydrocarbon oil;

[0047] Described dispersing aid is Fischer-Tropsch wax;

[0048] Described crosslinking auxiliary agent is isocyanate;

[0049] Mix the above components evenly and pour into the granulator to melt and granulate.

[0050] Castable asphalt mixture is produced according to the following steps:

[0051] First, add the mineral material preheated at about 240 degrees (see Table 3 for gradation and origin) into the mixing tank and mix evenly.

[0052] Second, add the weighed base asphalt (the ratio of aspha...

Embodiment 3

[0063] (1) Take various components by weighing the following parts by mass to prepare the direct-throwing modifier:

[0064]

[0065] The styrene-based thermoplastic elastomer is SEBS, which is a linear three-block copolymer with polystyrene as the end segment and ethylene-butene copolymer obtained by hydrogenation of polybutadiene as the middle elastic block.

[0066] The plastic is specifically Shuangdi Trading LLDPE;

[0067] Described rubber powder is specifically radial tire regenerated rubber powder;

[0068] The filler powder is specifically talcum powder;

[0069] Described fusion oil is rubber filler oil;

[0070] Described dispersing aid is vinyl stearic acid amide (EBS);

[0071] Described cross-linking auxiliary agent is sulfur powder;

[0072] Mix the above components evenly and pour into the granulator to melt and granulate.

[0073] Castable asphalt mixture is produced according to the following steps:

[0074] First, add the mineral material preheated at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com