Preparation method for Ga-doped ZnO nanometer material

A nano-material and preparation technology, applied in the field of preparation of Ga-doped nano-ZnO, can solve the problems of irreparable glass substrate, long reaction time, high temperature, etc., and achieve controllable surface morphology, less impurities in the product, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

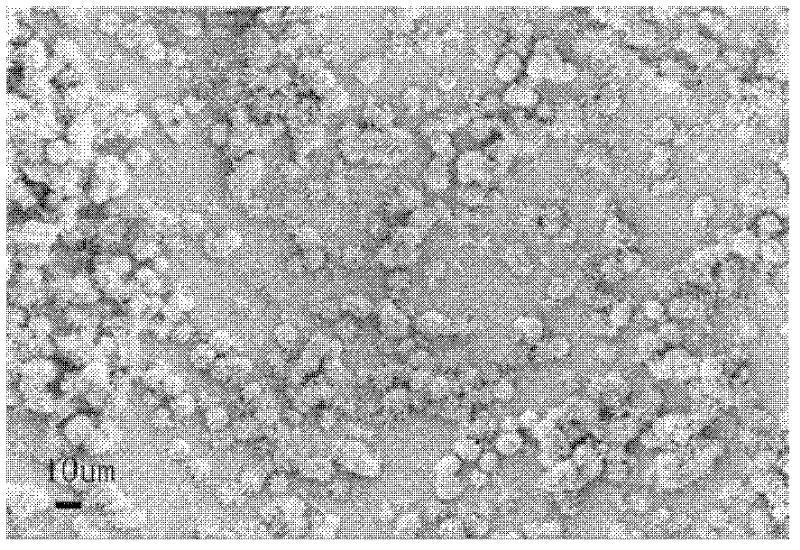

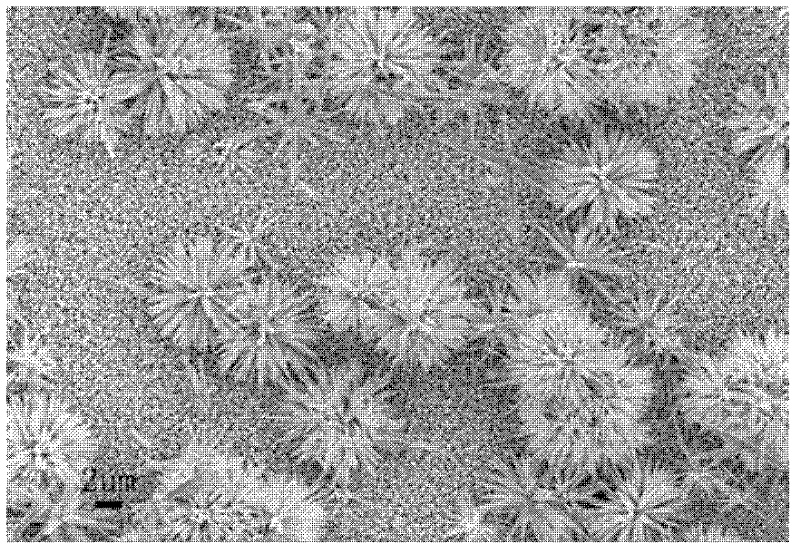

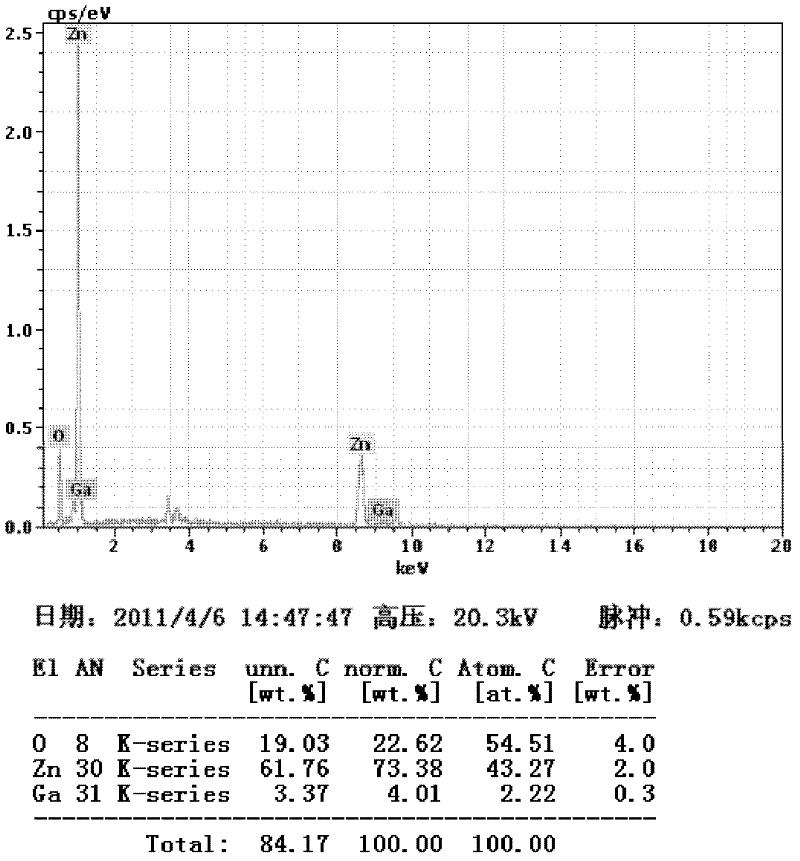

Image

Examples

Embodiment Construction

[0022] Below in conjunction with example technical scheme of the present invention is further described:

[0023] 1. Dissolve zinc nitrate hexahydrate and gallium nitrate with a molar ratio of 1:0.05 in deionized water to prepare a mixed solution of 75ml 0.2mol / L zinc nitrate and 0.01mol / L gallium nitrate, and perform ultrasonic treatment for 1 hour A clear and transparent solution was obtained.

[0024] 2. Measure 2.5ml of ethylenediamine with a graduated cylinder and add it to the solution described above, and then ultrasonicate for half an hour to obtain a milky white reaction precursor.

[0025] 3. Measure the pH value of the reaction precursor solution with a pH meter or pH test paper, and gradually add sodium hydroxide in small amounts to adjust the pH value of the precursor solution to control it within the range of 9~11, and then ultrasonically for half an hour for later use.

[0026] 4. Wash 4 pieces of FTO conductive glass successively through acetone, absolute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com