Method for preparing gallium lanthanum niobate series nano powder

A nano-powder, gallium lanthanum niobate technology, applied in chemical instruments and methods, niobium compounds, gallium/indium/thallium compounds, etc., can solve the problems of easy volatility, high growth cost, and difficulty in controlling the uniformity of growth crystal components, etc. problem, achieve the effect of improving the uniformity of components, solving the volatilization of components, and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

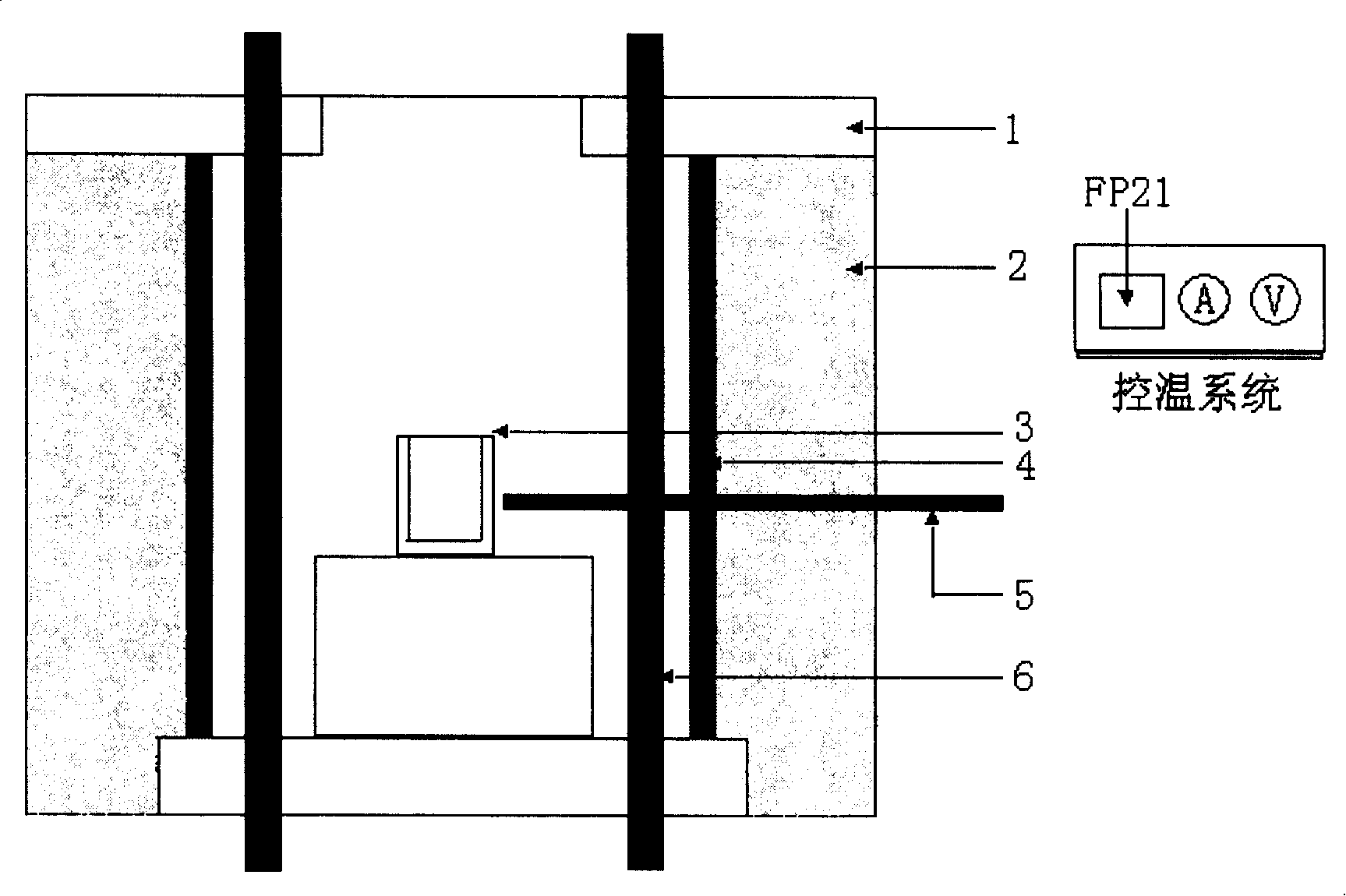

Method used

Image

Examples

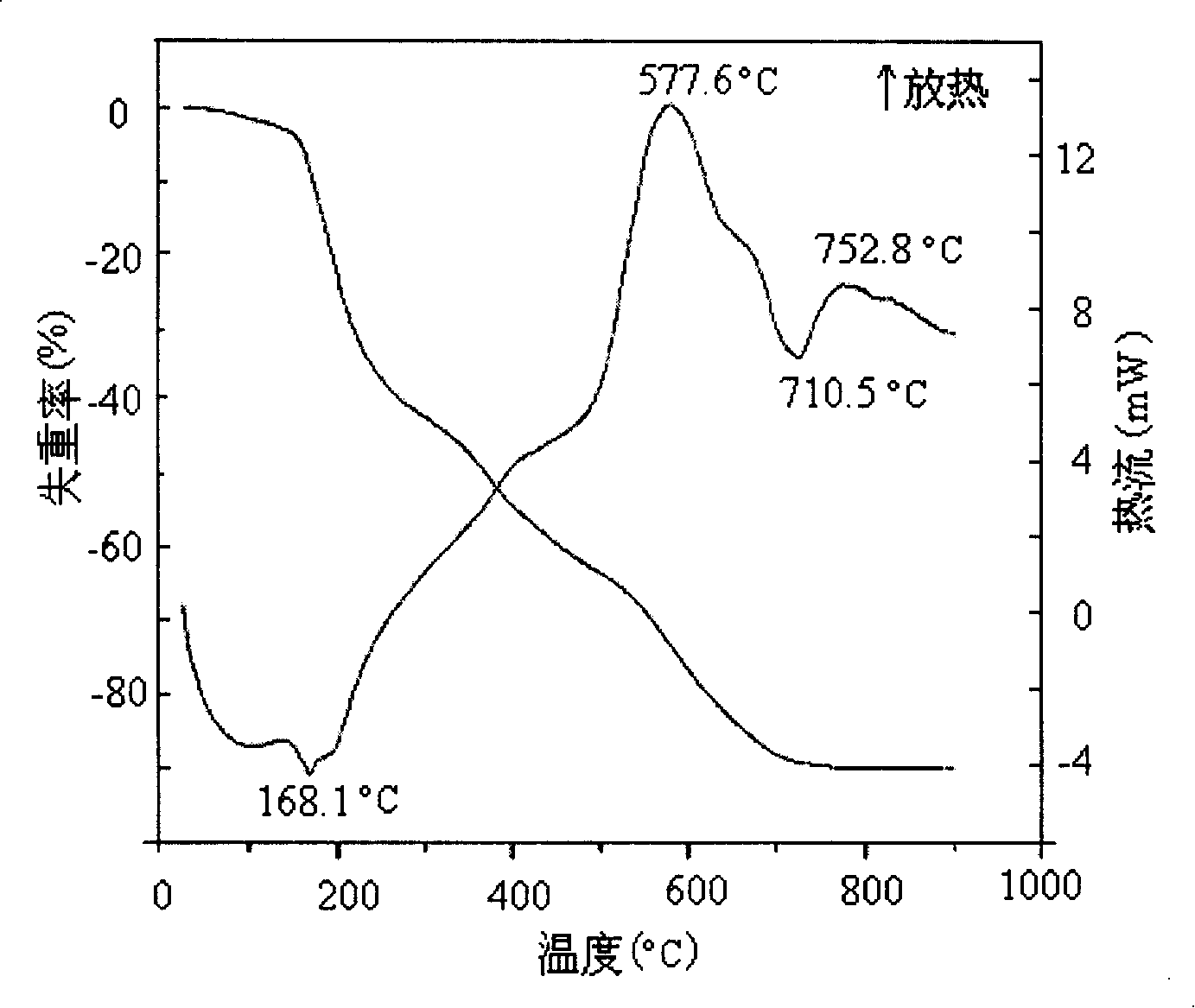

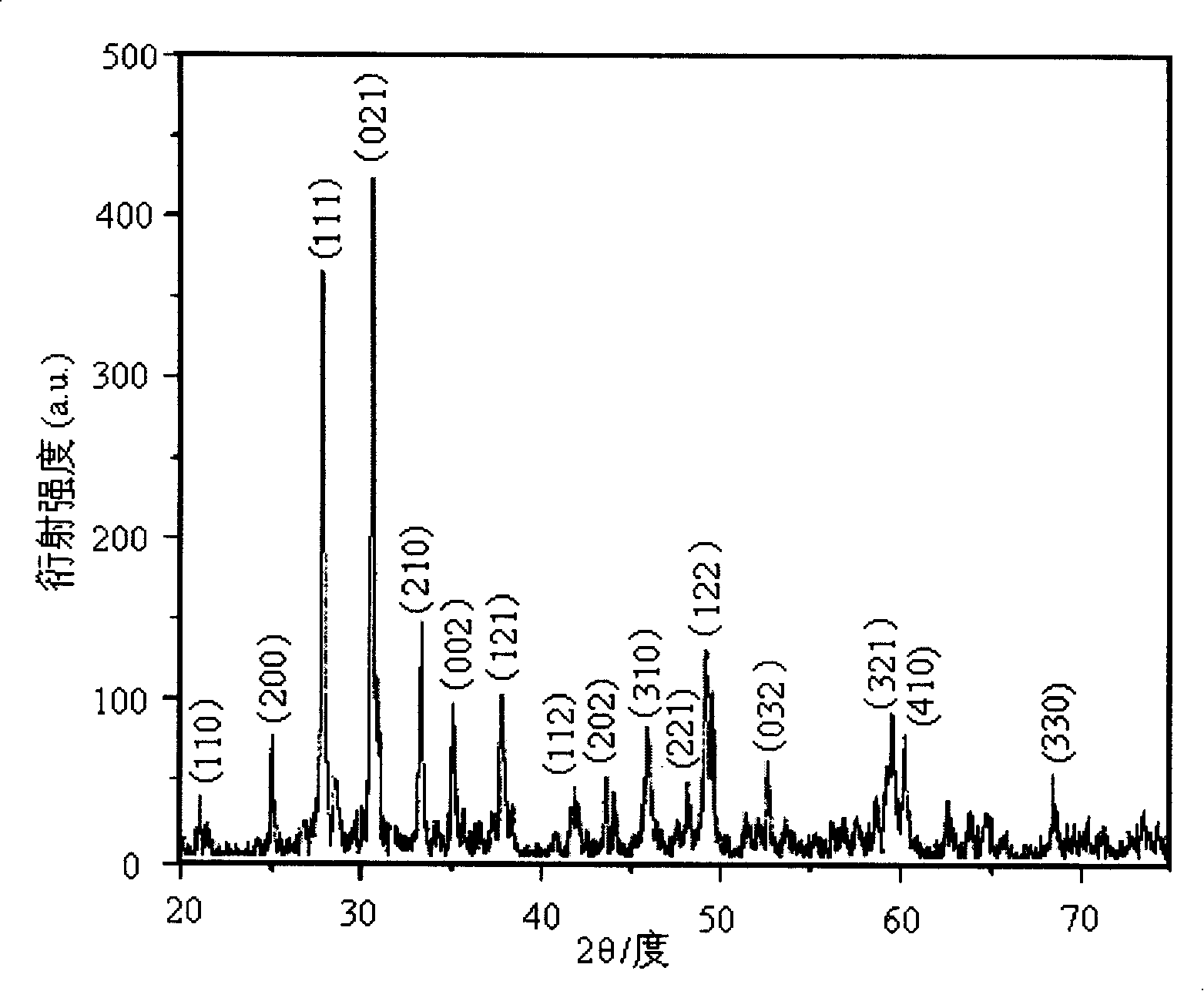

Embodiment 1

[0028] 1. Accurately weigh 0.1329g Nb 2 o 5 (0.001mol) dissolved in 5ml of concentrated hydrofluoric acid (analytical grade) solution, magnetically stirred at 70°C in a water bath for 2h until Nb 2 o 5 completely dissolved.

[0029] 2. Prepare 4g of ammonium oxalate into an aqueous solution, add it to the solution described in 1, and stir to mix evenly.

[0030] 3. Add ammonia water to the above solution to form white Nb(OH) 5 Precipitate, until the precipitation is complete, the detection pH value is about 10.

[0031] 4. Add 2 g of citric acid until the citric acid is fully dissolved to form a pale yellow Nb-citric acid solution.

[0032] 5. Accurately weigh 0.9774gLa 2 o 5 Dissolved in nitric acid (analytical grade) to form La(NO 3 ) 3 (0.006mol) solution, weigh 3.2048gGa(NO 3 ) 3 ·xH 2O (Ga%=23.93%) was formulated into a solution, and the above two solutions were mixed and then added to the Nb-citric acid solution.

[0033] 6. Add 9.3476g of citric acid into t...

Embodiment 2

[0043] As described in Example 1, the difference is that the calcination temperature is 750° C. to obtain nanoscale LGN powder.

Embodiment 3

[0045] As described in Example 1, the difference is that the ratio of metal cations to citric acid is 1:4 to obtain nanoscale LGN powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com