Synthesizing method for growing terbium gallium garnet crystal by pulling method

A technology of terbium gallium garnet and synthesis method, which is applied in the field of synthesis of terbium gallium garnet crystals grown by pulling method, and can solve the problems of blackened crystals, easy cracking and streaks of TGG crystals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (Tb 3 Ga 5 o 12 liquid phase synthesis):

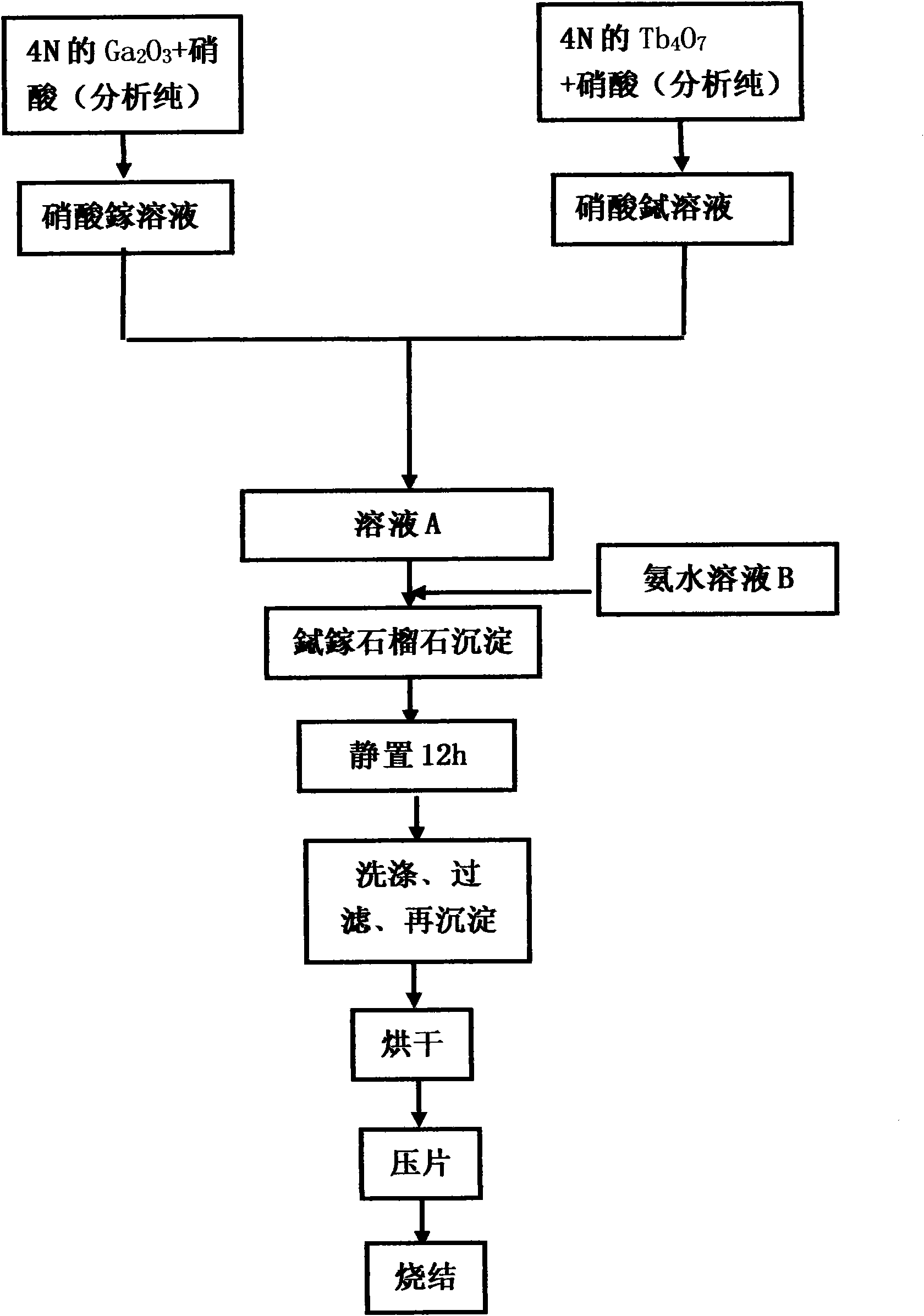

[0036] Ga with a purity of 99.99% 2 o 3 Completely dissolved in concentrated nitric acid solution to obtain Ga(NO 3 ) 3 solution. Will Tb 4 o 7 Completely dissolved in concentrated nitric acid solution to obtain Tb(NO 3 ) 4 solution. Prepare a certain amount of 2.5mol / L ammonia solution B. Ga(NO 3 ) 3 solution and Tb(NO 3 ) 4The solutions were fully mixed according to the molar ratio of 3:5 to obtain the mixed solution A. Prepare a certain amount of 2.5mol / L ammonia solution B. The above-mentioned mixed solution A and ammonia solution B, according to the synthesis route method of the accompanying drawings, flow the A and B solutions into a large container at the same flow rate, and stir for a long time so that the pH value is controlled at about 10. At this time The resulting white precipitate is the terbium gallium garnet precursor. The above-mentioned reactant was aged for 12-24 hours, and the ...

Embodiment 2

[0037] Embodiment 2 (liquid phase synthesis of Ce-doped TGG):

[0038] Ga with a purity of 99.99% 2 o 3 and CeO 2 (the molar percentage of Ce is 1%) completely dissolved in concentrated nitric acid solution to obtain Ga(NO 3 ) 3 solution. Will Tb 4 o 7 Completely dissolved in concentrated nitric acid solution to obtain Tb(NO 3 ) 4 solution. Prepare a certain amount of 2.5mol / L ammonia solution B. Ga(NO 3 ) 3 solution and Tb(NO 3 ) 4 The solutions were fully mixed according to the molar ratio of 3:5 to obtain the mixed solution A. Prepare a certain amount of 2.5mol / L ammonia solution B. The above-mentioned mixed solution A and ammonia solution B, according to the synthesis route method of the accompanying drawings, flow the A and B solutions into a large container at the same flow rate, and stir for a long time so that the pH value is controlled at about 10. At this time The resulting white precipitate is the precursor of cerium-doped terbium gallium garnet (Ce:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com