Method for preparing Ga*O*-Al*O* catalyst for reduction of nitrogen oxide

A ga2o3-al2o3, nitrogen oxide technology, applied in the field of nitrogen oxide reduction catalyst preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

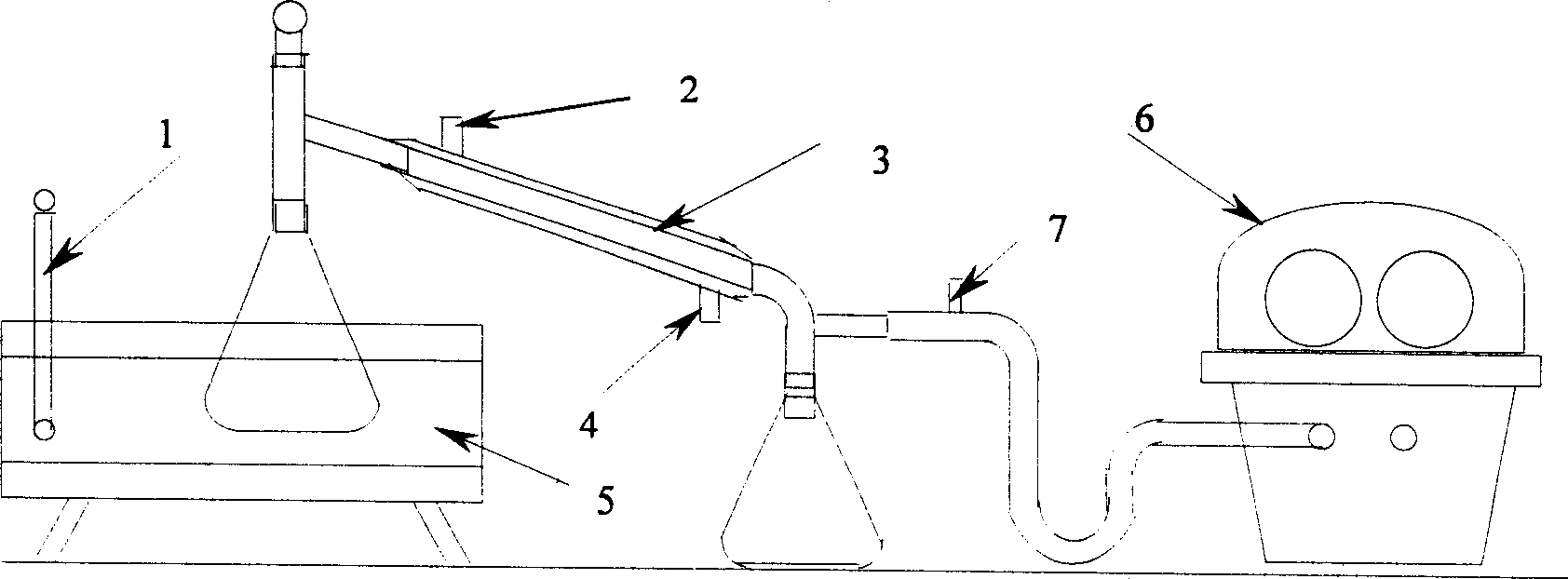

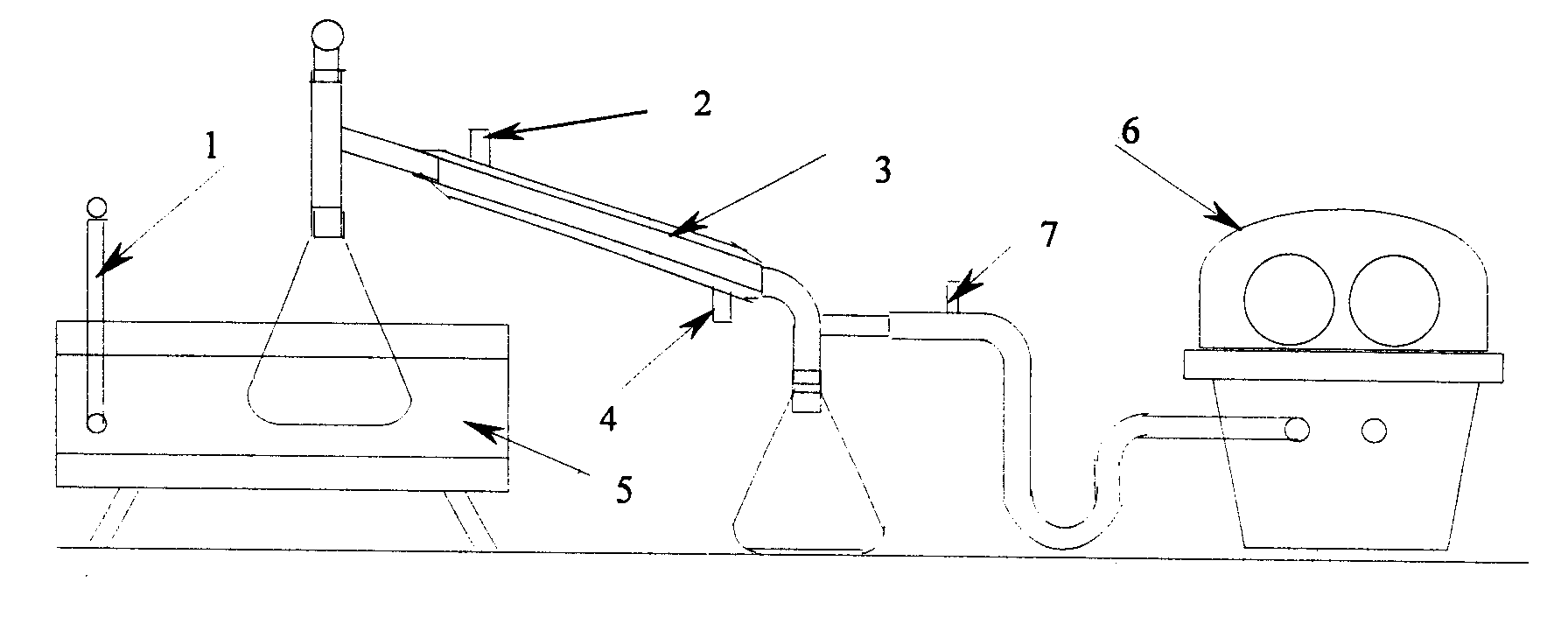

Image

Examples

Embodiment 1

[0019] a. Preparation of gallium nitrate: Take 0.01 moles of gallium oxide and add it to 0.09 moles of concentrated nitric acid, stir and place it on the heating mantle for a few minutes, then add deionized water to start heating and evaporating, concentrate, add water, and concentrate again. Process 15 hours, until the solution has no obvious irritating smell,

[0020] b. After the solution is cooled, add 0.20 moles of ethylene glycol to the solution;

[0021] c. Preparation of boehmite: Add 20.423g of aluminum isopropoxide to 160ml of deionized water at a temperature of 92°C, stir and hydrolyze for 1 hour, then add 18ml of dilute nitric acid (the molar ratio of nitric acid to aluminum isopropoxide 0.3:1) aqueous solution, then vigorously stirred at 92°C for 1 hour to form a transparent sol,

[0022] d. Then, add the mixed solution of gallium nitrate and ethylene glycol obtained in b into the boehmite sol dropwise, then stir at room temperature for 24 hours,

[0023] e. Aft...

Embodiment 2

[0027] a. Preparation of gallium nitrate: Take 0.01 moles of gallium oxide and add it to 0.12 moles of concentrated nitric acid, stir and place it on the heating mantle for a few minutes, then add deionized water to start heating and evaporating, concentrate, add water, and concentrate again. Process 12 hours, until the solution has no obvious irritating smell,

[0028] b. After the solution is cooled, add 0.26 moles of ethylene glycol in the solution;

[0029] c. Preparation of boehmite: Add 20.423g of aluminum isopropoxide to 170ml of deionized water at a temperature of 90°C, stir and hydrolyze for 1 hour, then add 18ml of dilute nitric acid (the molar ratio of nitric acid to aluminum isopropoxide 0.25:1) aqueous solution, then vigorously stirred at 90°C for 1 hour to form a transparent sol,

[0030] d. Then, add the mixed solution of gallium nitrate and ethylene glycol prepared in a dropwise into the boehmite sol, and then stir at room temperature for 12 hours,

[0031] e...

Embodiment 3

[0034] a. Preparation of gallium nitrate: Take 0.01 moles of gallium oxide and add it to 0.15 moles of concentrated nitric acid, stir and place it on the heating mantle for a few minutes, then add deionized water to start heating and evaporating, concentrate, add water, and concentrate again. Process 10 hours, until the solution has no obvious irritating smell,

[0035] b. After the solution is cooled, add 0.28 moles of ethylene glycol in the solution;

[0036] c. Preparation of boehmite: Add 20.423g of aluminum isopropoxide to 175ml of deionized water at a temperature of 88°C, stir and hydrolyze for 1 hour, then add 18ml of dilute nitric acid dropwise (the molar ratio of nitric acid to aluminum isopropoxide 0.20:1) aqueous solution, then vigorously stirred at 90°C for 1 hour to form a transparent sol,

[0037] d. Then, the mixed solution of gallium nitrate and ethylene glycol prepared in (1) was added dropwise into the boehmite sol, and then stirred at room temperature for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com