Variable-speed response capsule glue-dipping device and method

A technology of dipping glue and capsules, which is applied in the direction of coating, etc., can solve the problems of large difference in grain weight, uneven film thickness, difficulty in hollow capsule grain weight difference, etc., and achieve the effect of small natural grain weight difference and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

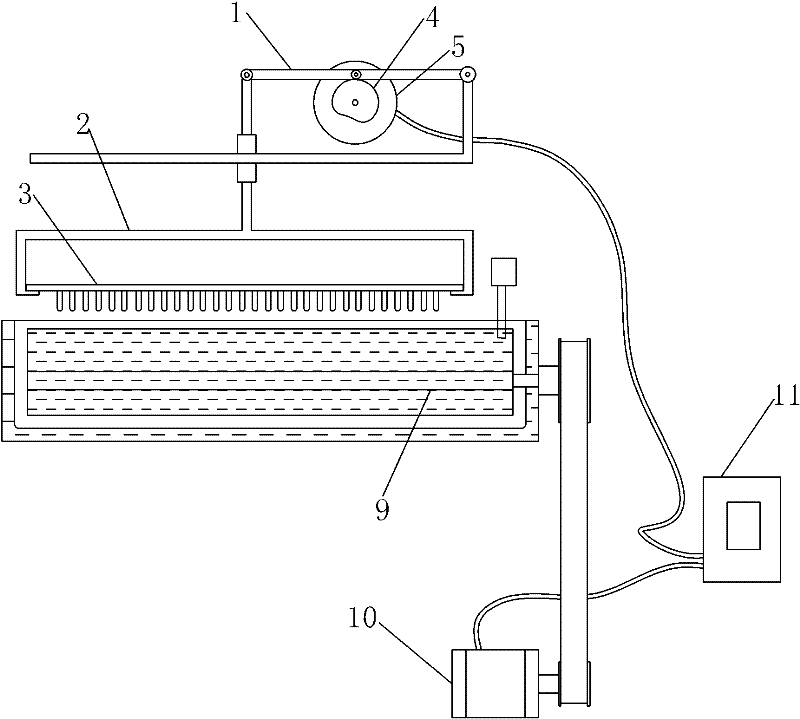

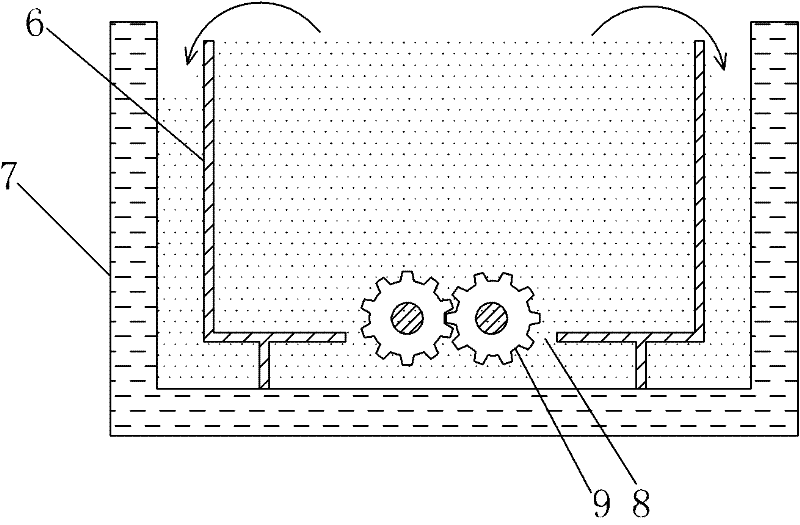

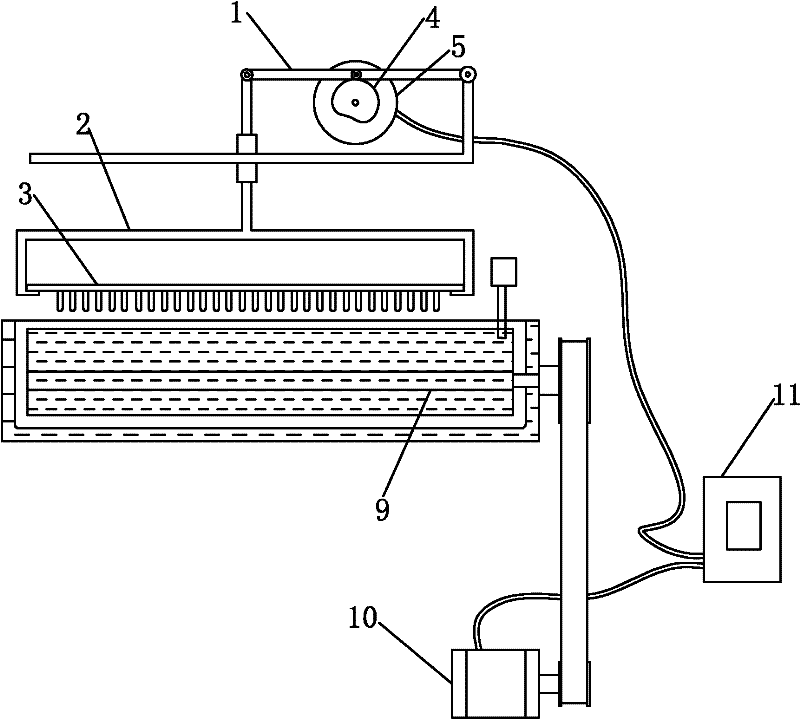

[0016] Example: such as figure 1 As shown, a variable-speed response capsule dipping device includes a dipping device and a dipping tank. The dipping device includes a bracket 1, a dipping hanger 2, a dipping mold 3 and a dipping cam driving device. The dipping cam driving device is composed of a cam 4 and a first motor 5. The cam 4 is arranged on the lower part of the bracket 1 and is in contact with the bracket 1. The upper end of the dipping hanger 2 is connected with the bracket 1. The dipping mold 3 Installed on the lower end of dipping hanger 2; figure 2 As shown, the dipping tank includes an inner tank 6 and an outer tank 7, the bottom of the inner tank 6 and the bottom of the outer tank 7 are kept at a certain distance, and the bottom of the inner tank 6 is provided with a connection between the inner tank 6 and the outer tank 7. Opening 8, a stirring rod 9 is provided at the opening 8, blades are distributed on the stirring rod 9, the stirring rod 9 is horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com