Blind-buried hole interconnecting structure and processing method therefor

A technology of conduction structure and blind buried via, which is applied in the direction of electrical connection of printed components, formation of electrical connection of printed components, printed circuit components, etc., can solve the problems of poor conduction/isolation, high processing cost, and high metallization process requirements. , to solve the high risk of reliability testing, reduce alignment requirements, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

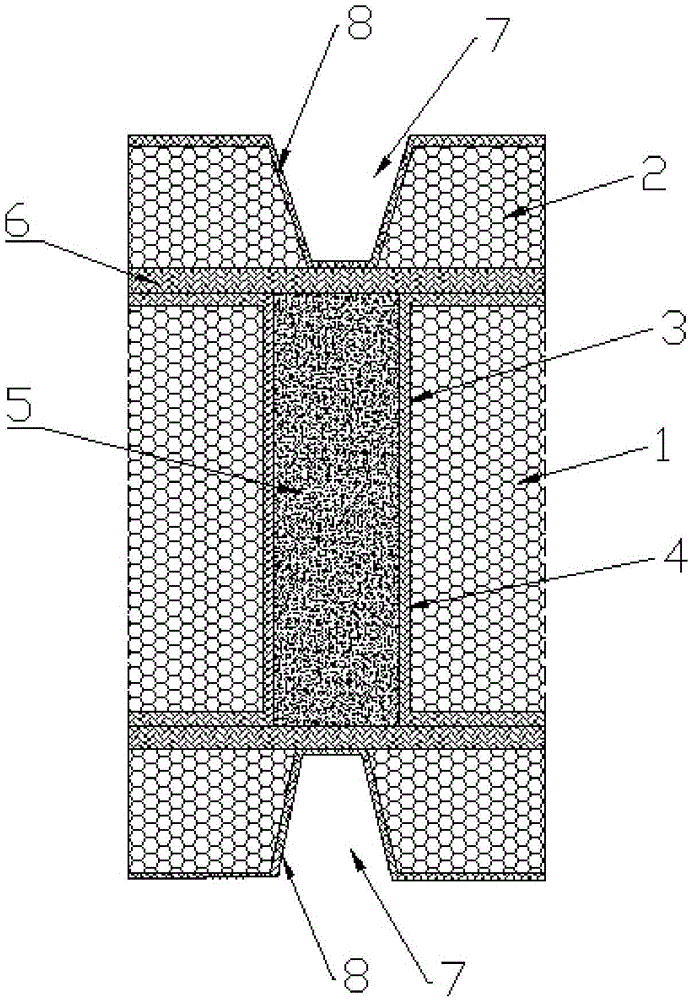

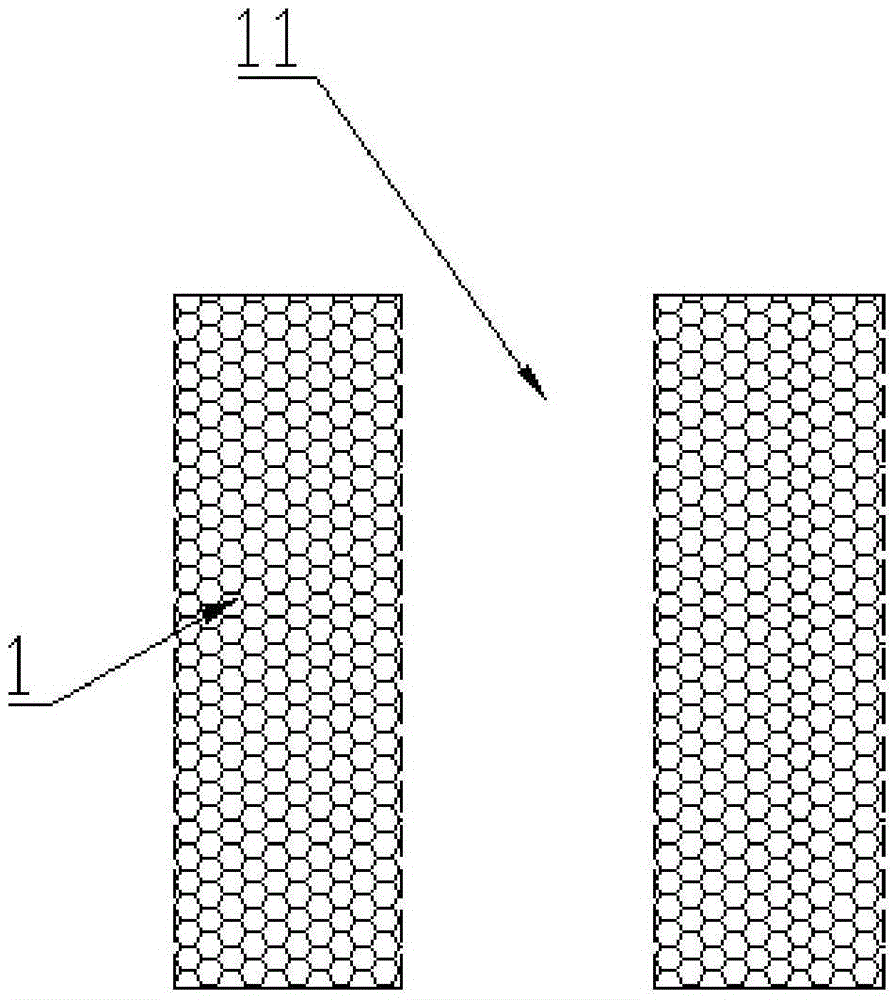

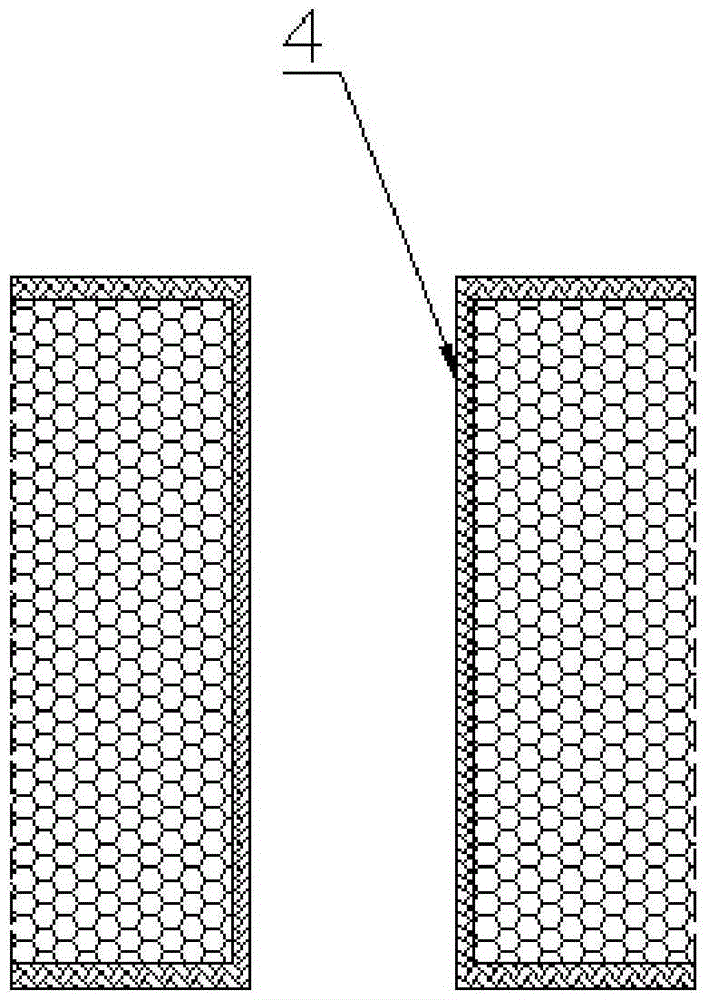

[0038] Such as figure 1 As shown, a blind buried hole interconnection conduction structure includes an inner core board 1 and two side boards 2 located on both sides of the inner core board, and the inner core board is formed by mechanical drilling to form a central buried Hole 3, the hole wall of the central buried hole is metallized to form a metal conduction layer 4 in the central hole, the hole of the central buried hole is filled with non-conductive material 5 epoxy resin, the two hole ports of the central buried hole And the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com