Patents

Literature

42 results about "Pore interconnectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

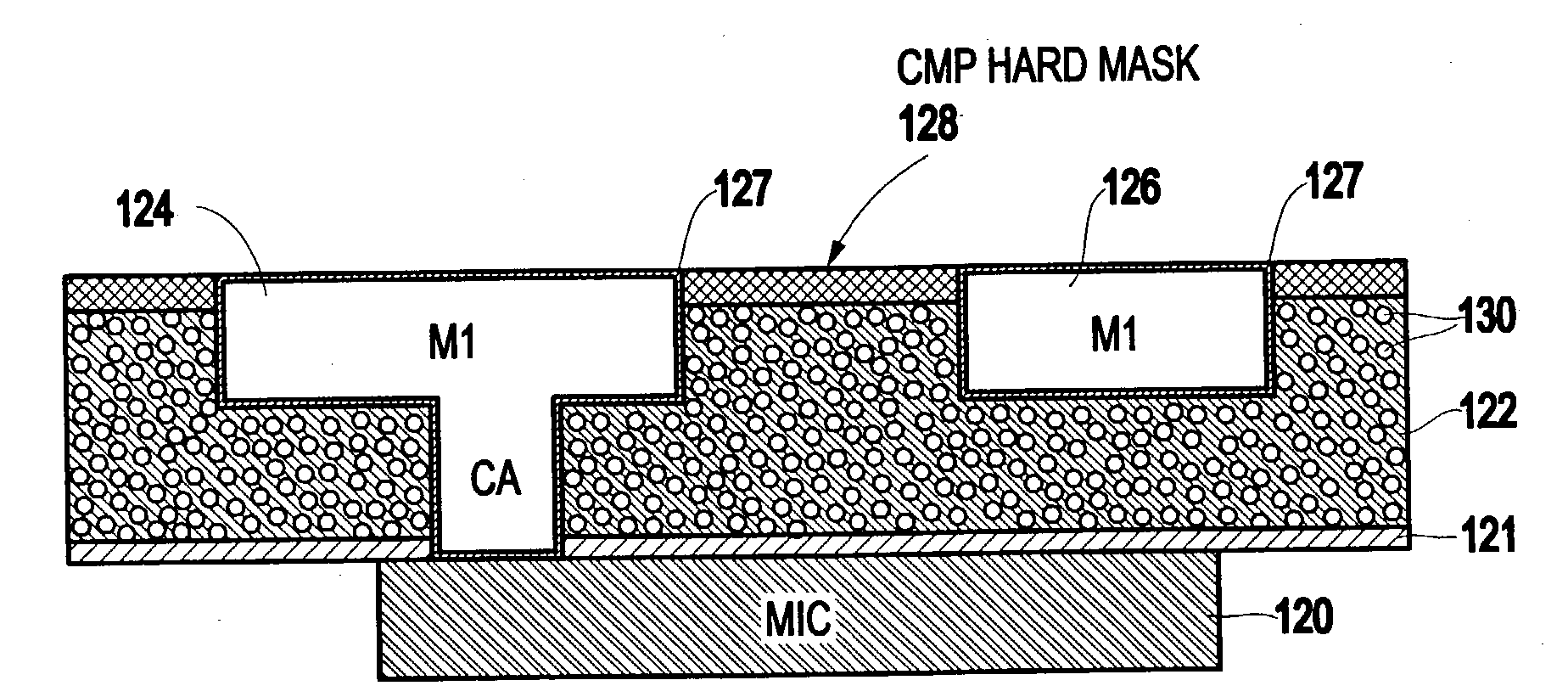

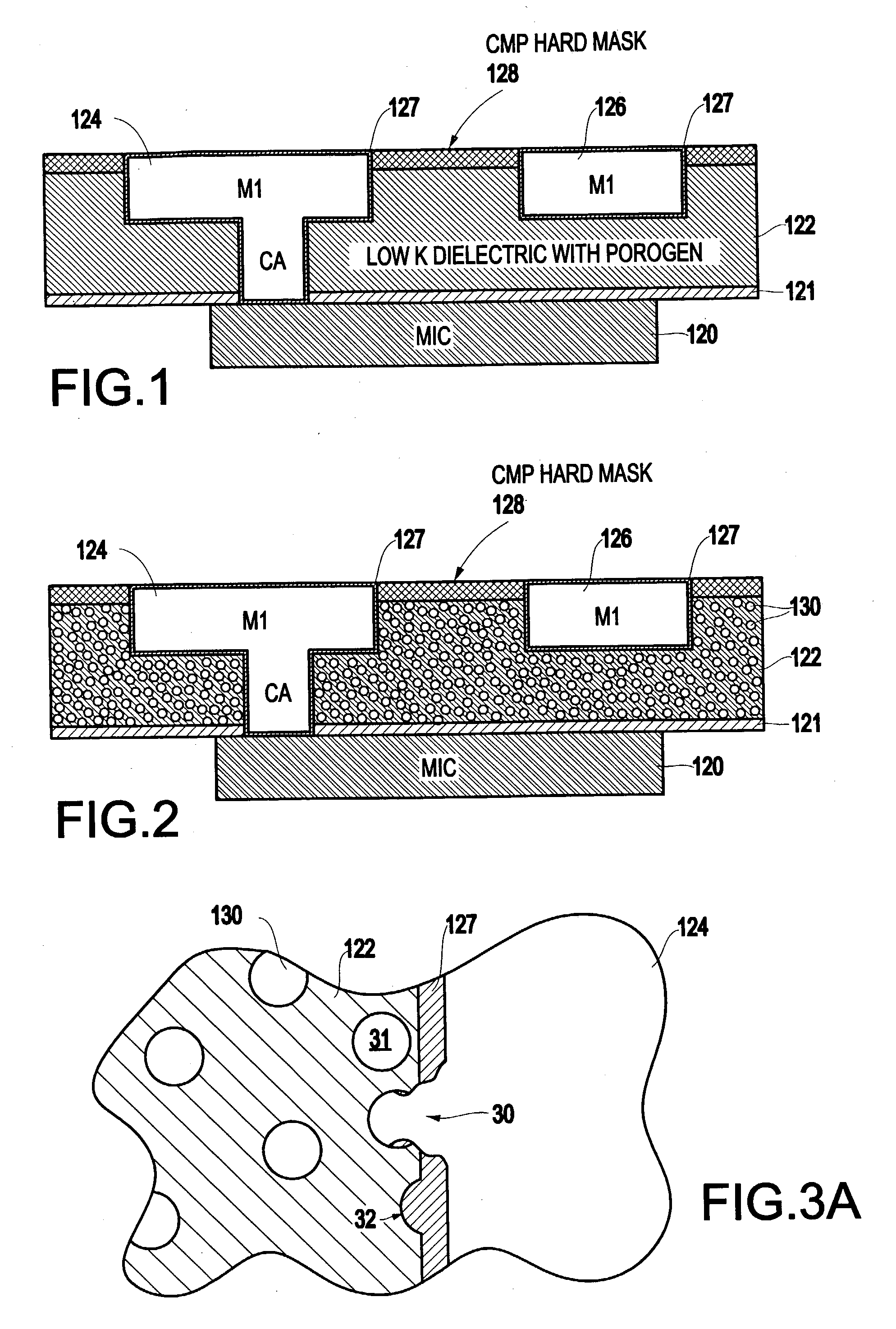

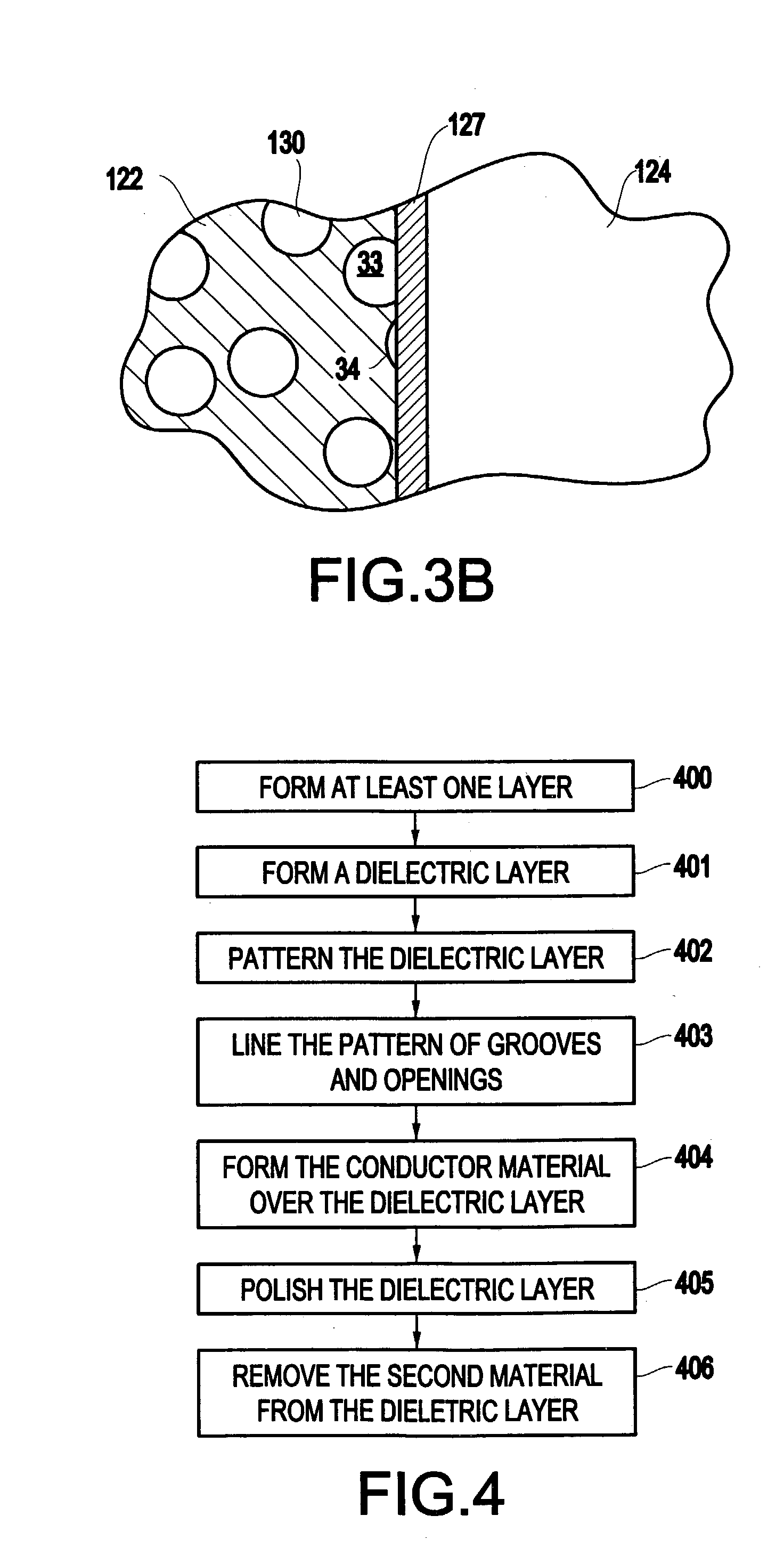

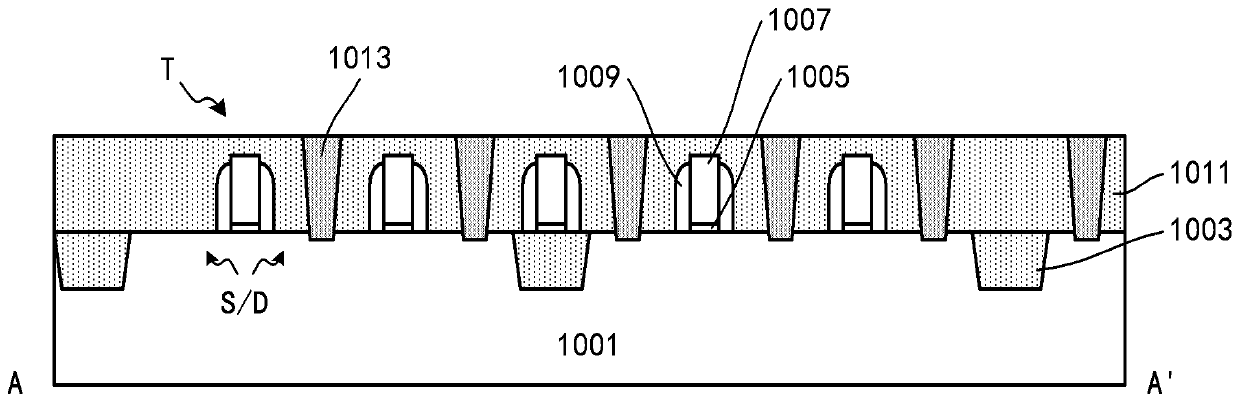

Improved formation of porous interconnection layers

InactiveUS20040130027A1Low dielectric constantInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

A method and structure for forming an integrated circuit structure is disclosed that forms at least one first layer comprising logical and functional devices and forms at least one interconnection layer above the first layer. The interconnection layer is adapted to form electrical connections between the logical and functional devices. The interconnection layer is made by first forming a dielectric layer. The dielectric layer includes a first material and a second material, wherein the second material is less stable at manufacturing environmental conditions (e.g., the processing conditions discussed below) than the first material. The "second material" comprises a porogen and the "first material" comprises a matrix polymer. The invention then forms conductive features in the dielectric layer and removes (e.g., by heating) the second material from the dielectric layer to create air pockets in the interconnection layer where the second material was positioned.

Owner:GLOBALFOUNDRIES INC

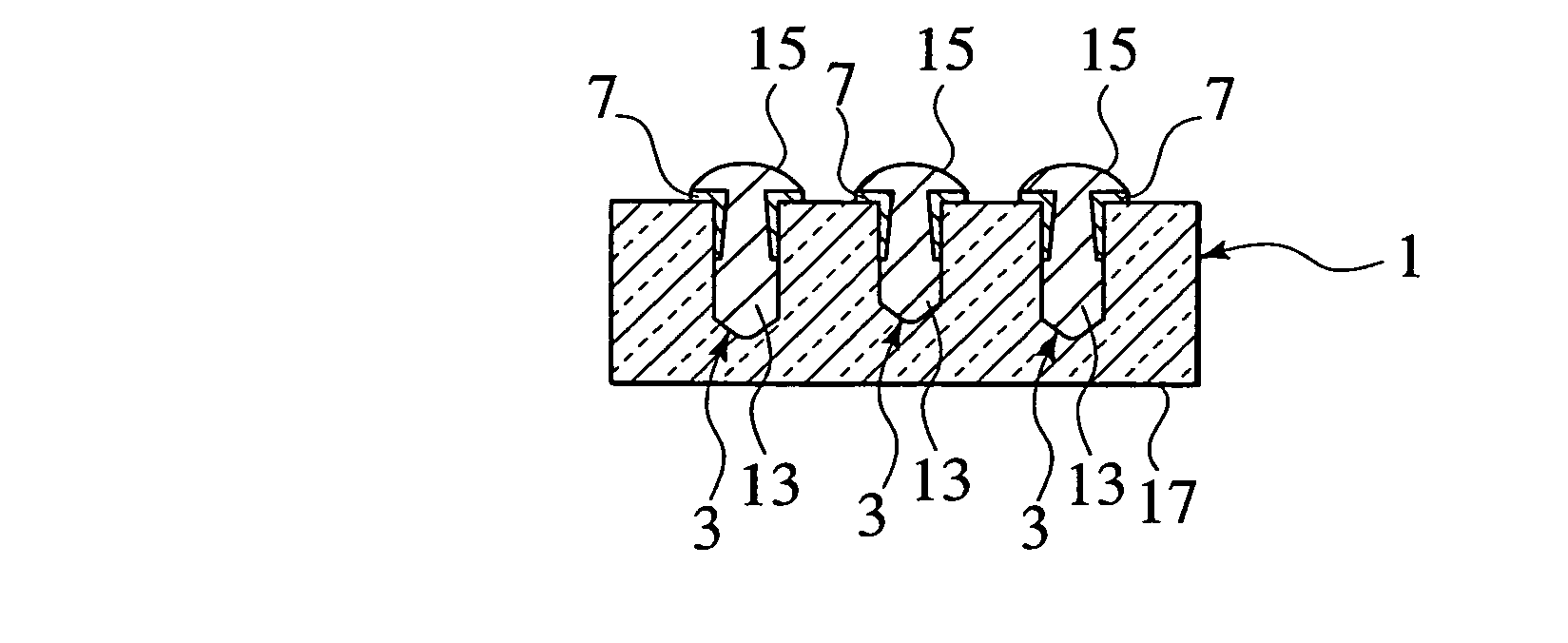

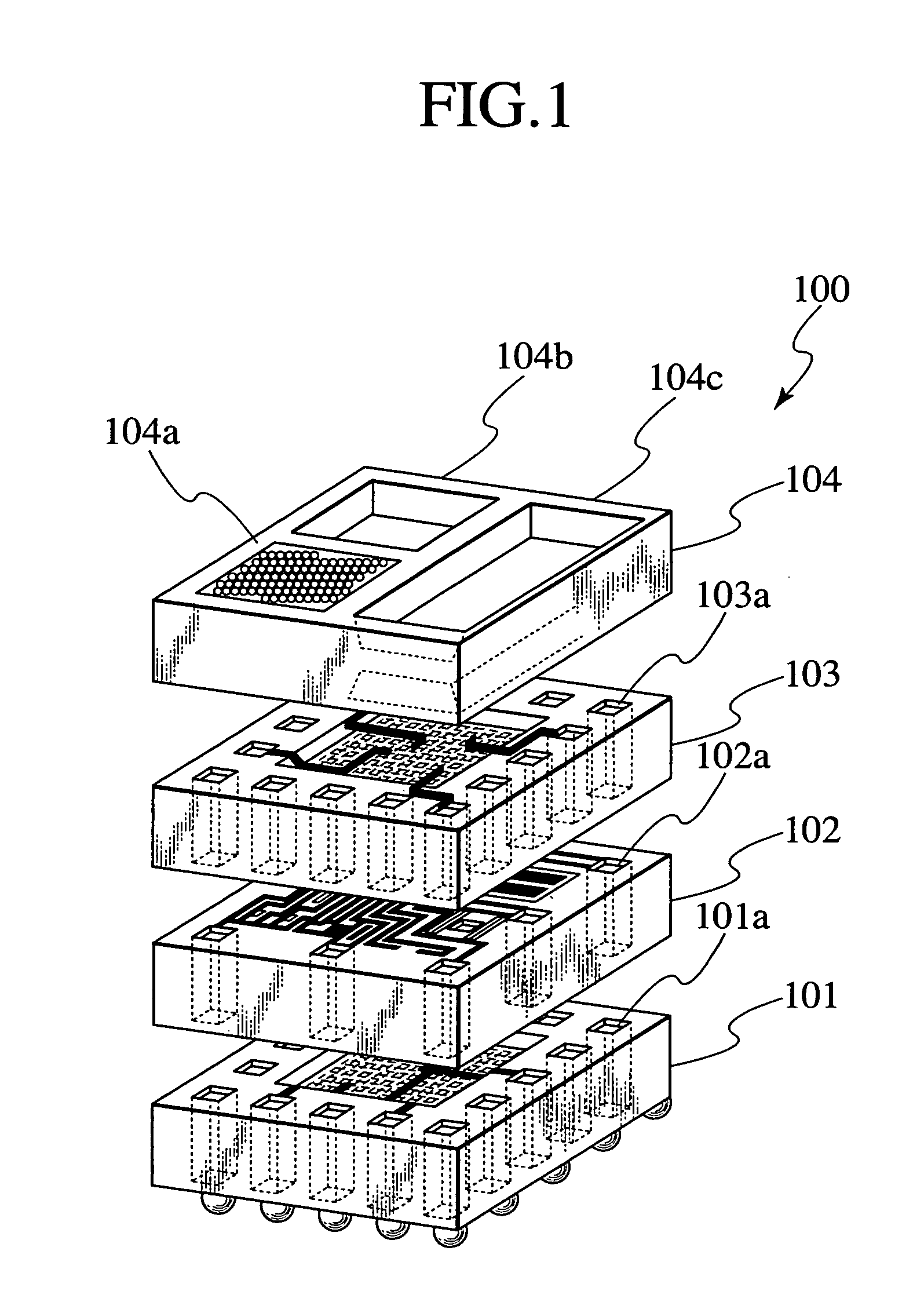

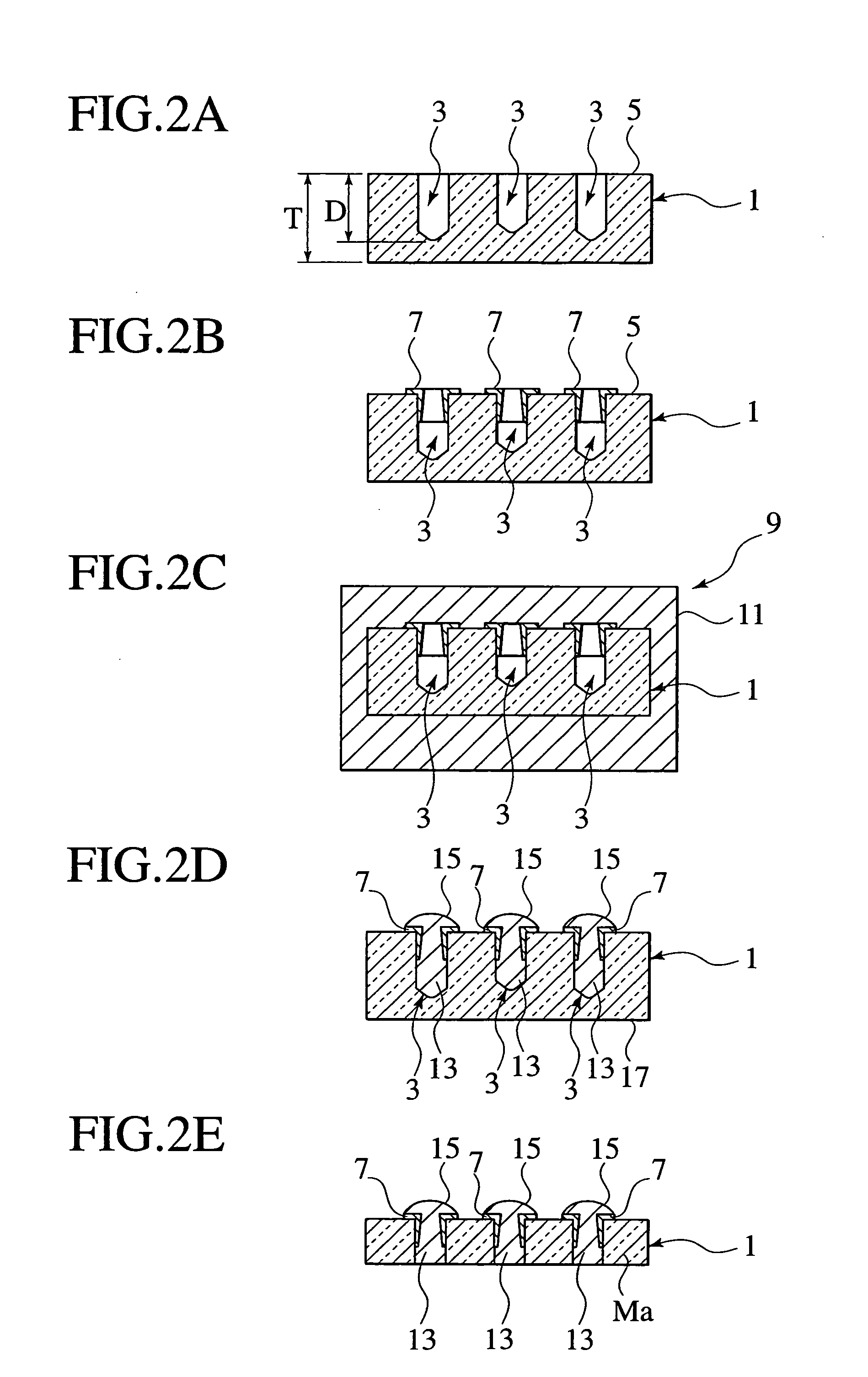

Method for fabricating a through-hole interconnection substrate and a through-hole interconnection substrate

InactiveUS20040092117A1Semiconductor/solid-state device detailsPrinted electric component incorporationElectrical conductorOptoelectronics

A blind hole (3) is formed on a substrate (1) from a first side of the substrate toward a second side of the substrate (1). A conductor (11) is filled in the blind hole (3). The substrate (1) is removed from the opposite side to expose the conductor (13) filled in the blind hole (3).

Owner:THE FUJIKURA CABLE WORKS LTD

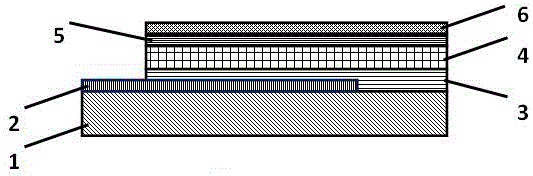

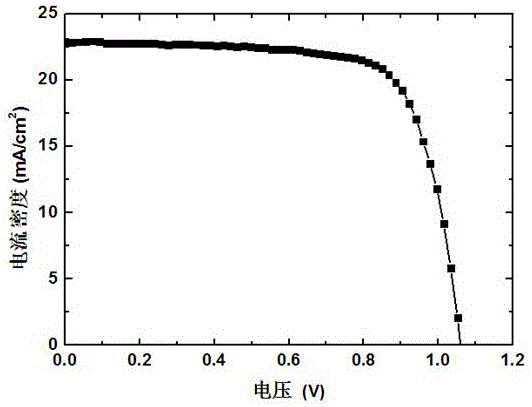

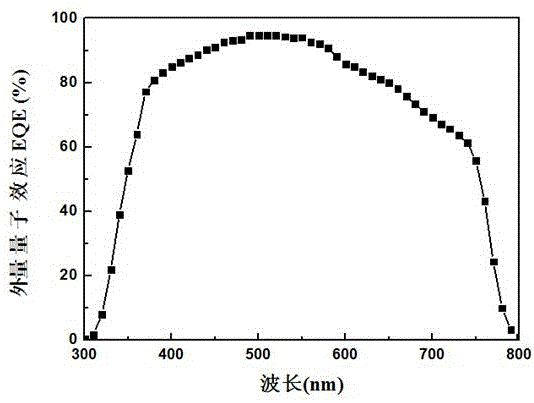

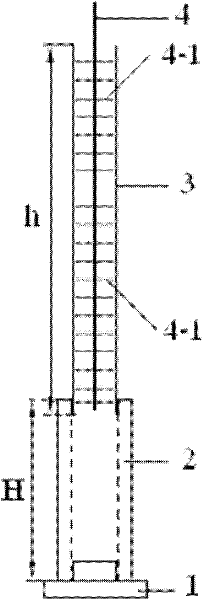

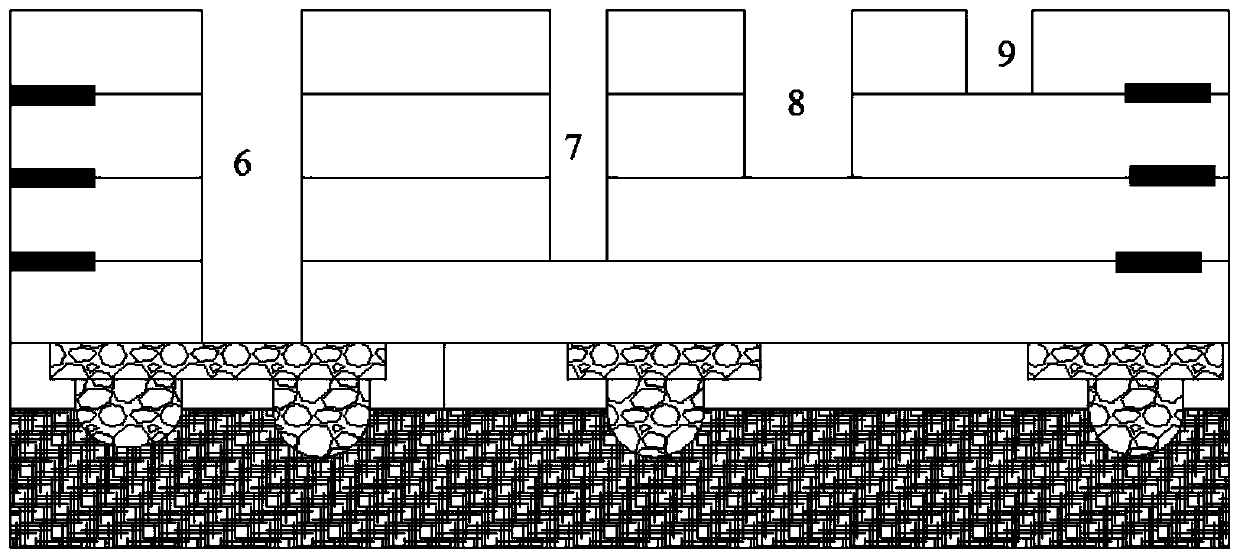

REO (rare earth oxide) down-conversion material perovskite solar cell and preparation method

InactiveCN105957966AReduce difficultySimple processFinal product manufactureSolid-state devicesRare earthSpectral responsivity

The invention discloses an REO (rare earth oxide) down-conversion material full-solid organic-inorganic perovskite solar cell and a preparation method. The method comprises the steps: the preparation of an REO down-conversion nano-material, the preprocessing of a transparent conductive substrate, the preparation of an inorganic metal oxide compact layer, the preparation of an REO down-conversion nano-material porous interconnection film, the preparation of a porous structural organic-inorganic perovskite material structural layer, the preparation of a hole conductive layer structure, and the preparation of electrodes. The method employs an REO down-conversion nano-material porous support structure to replace a conventional titanium dioxide mesoporous structure, enlarges the light absorption and utilization range of the solar cell, and improves the spectrum response density and stability of the cell. The prepared solar cell is high in efficiency, is good in stability, is simple in technology, is good in repeatability, and can be used for scale production.

Owner:EAST CHINA NORMAL UNIV

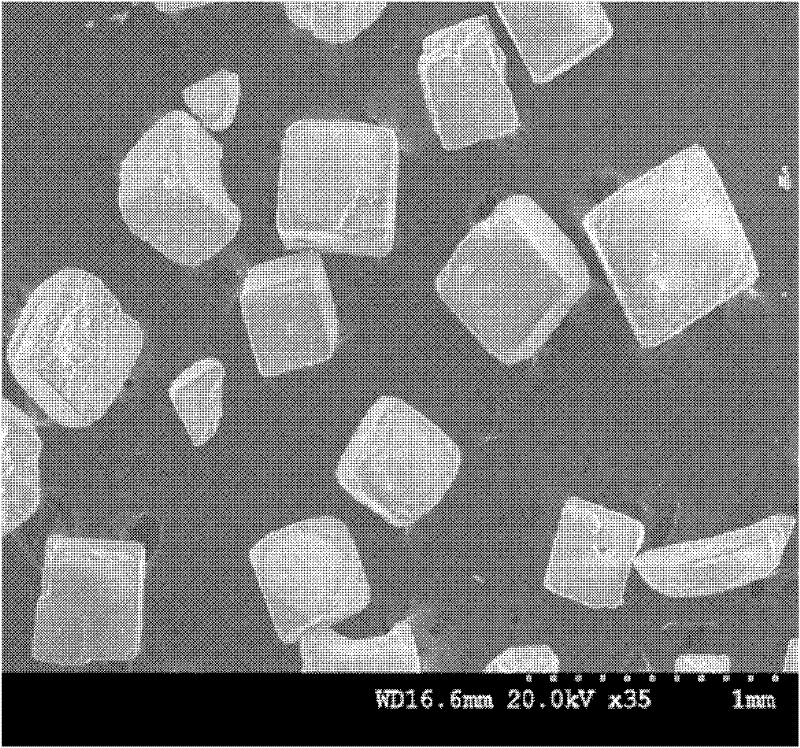

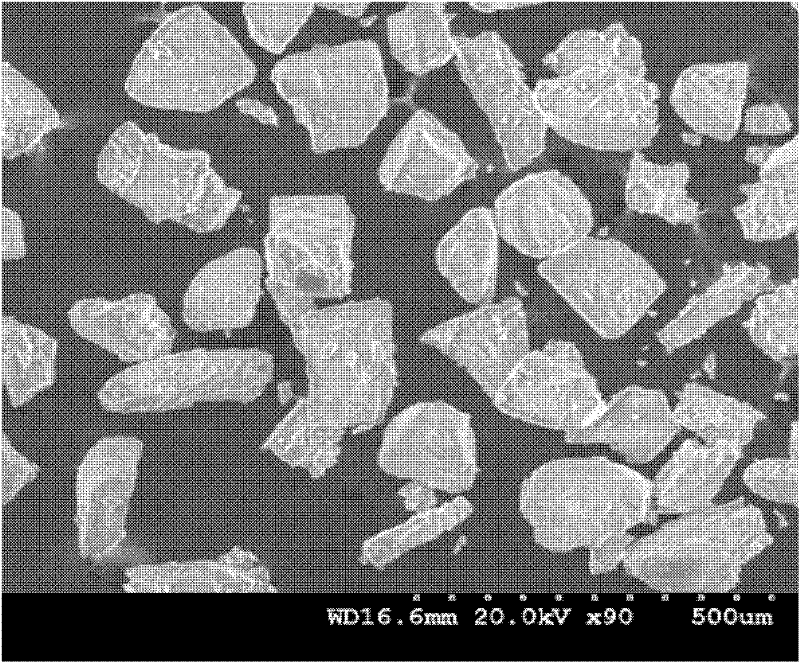

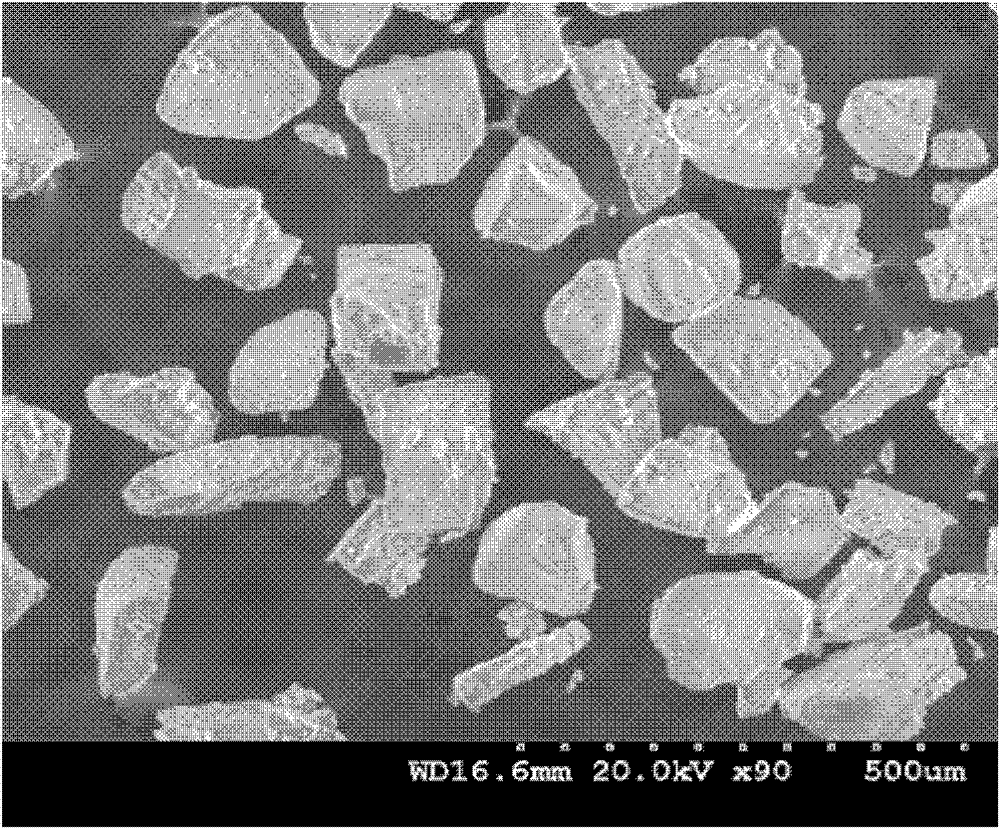

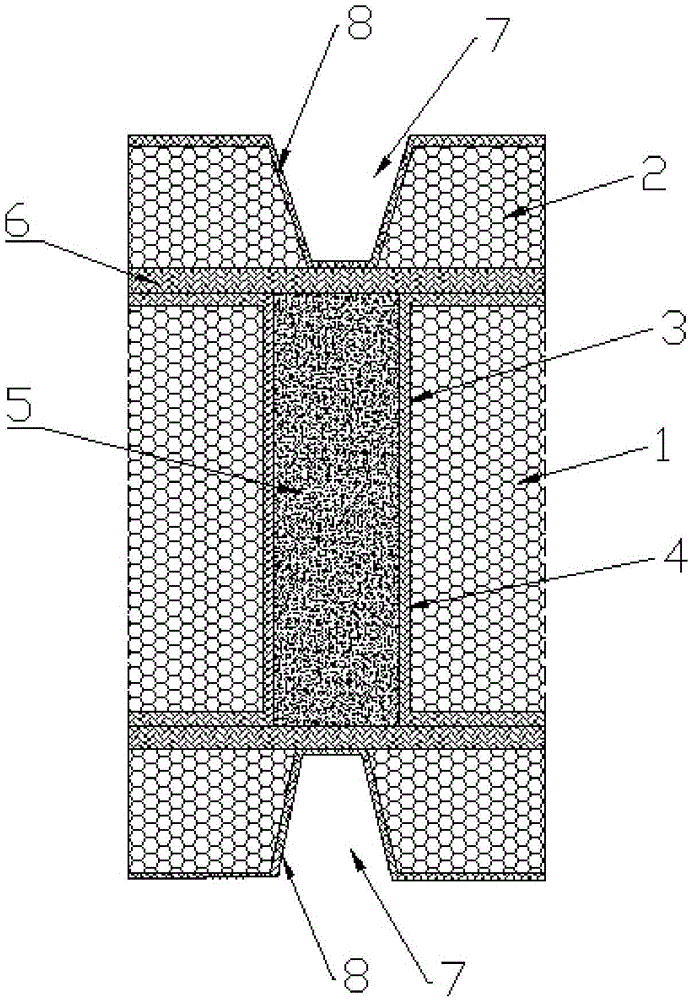

Preparation method of nickel titanium foam alloy with double pore structure

A preparation method of a nickel titanium foam alloy with a double pore structure relates to a preparation method of a nickel titanium foam alloy. The invention solves the problems that the existing nickel titanium foam alloy used for the replacement and repair of the bone tissue has low pore interconnectivity and uneven pore distribution. The method comprises the following steps: respectively weighting several parts of nickel powder, titanium powder, large-particle sodium chloride and small-particle sodium chloride, evenly spreading large-particle sodium chloride and the mixed powder of nickel powder, titanium powder and small-particle sodium chloride in a mould in a laminated mode successively, and then performing cold compressing and forming, cold isostatic pressing, hot pressing sintering and homogenizing treatment in turn. The porosity of the nickel titanium foam alloy is 59.17%-71.71%; and the elastic modulus of the alloy is effectively reduced, which is close to the modulus of the bone tissue. The pore distribution is uniform, and small pores are distributed around large pores to ensure that the large pores are connected to form interconnected pores. By adopting the nickel titanium foam alloy, the bone tissue is controlled to only grow in the large pores; and the nickel titanium foam alloy can be used as the material used for the replacement and repair of the bone tissue.

Owner:HARBIN INST OF TECH

Preparation method of thermal interface material based on high-density graphene interconnection network structure

InactiveCN112457826AImprove densification performanceLow priceHeat-exchange elementsHigh densityNetwork structure

The invention discloses a preparation method of a thermal interface material based on a high-density graphene interconnection network structure. The preparation method mainly comprises the following steps: taking copper powder with micron-scale or nano-scale particle size as a growth substrate, sintering and curing the copper powder by virtue of high temperature to form a porous interconnected foamy copper structure, and growing graphene on the surface of the copper powder by virtue of a chemical vapor deposition method to obtain a graphene-coated composite structure; then, etching the foamy copper frame by virtue of etching liquid to obtain a spongy graphene interconnection network framework; and finally, carrying out glue pouring and mechanical cutting to obtain a graphene / polymer composite thermal interface material. According to the preparation method, the graphene network can be grown in one step simply through the copper powder, then the foamy copper structure formed by the copper powder is etched off to obtain the spongy graphene interconnection network framework with high compactness and high heat conductivity coefficient, and finally, the mechanical strength and the use robustness of the spongy graphene interconnection network framework are improved through composite processing with a polymer. The method has the advantages of low cost, low defects, high heat conductivity coefficient and the like.

Owner:杭州英希捷科技有限责任公司

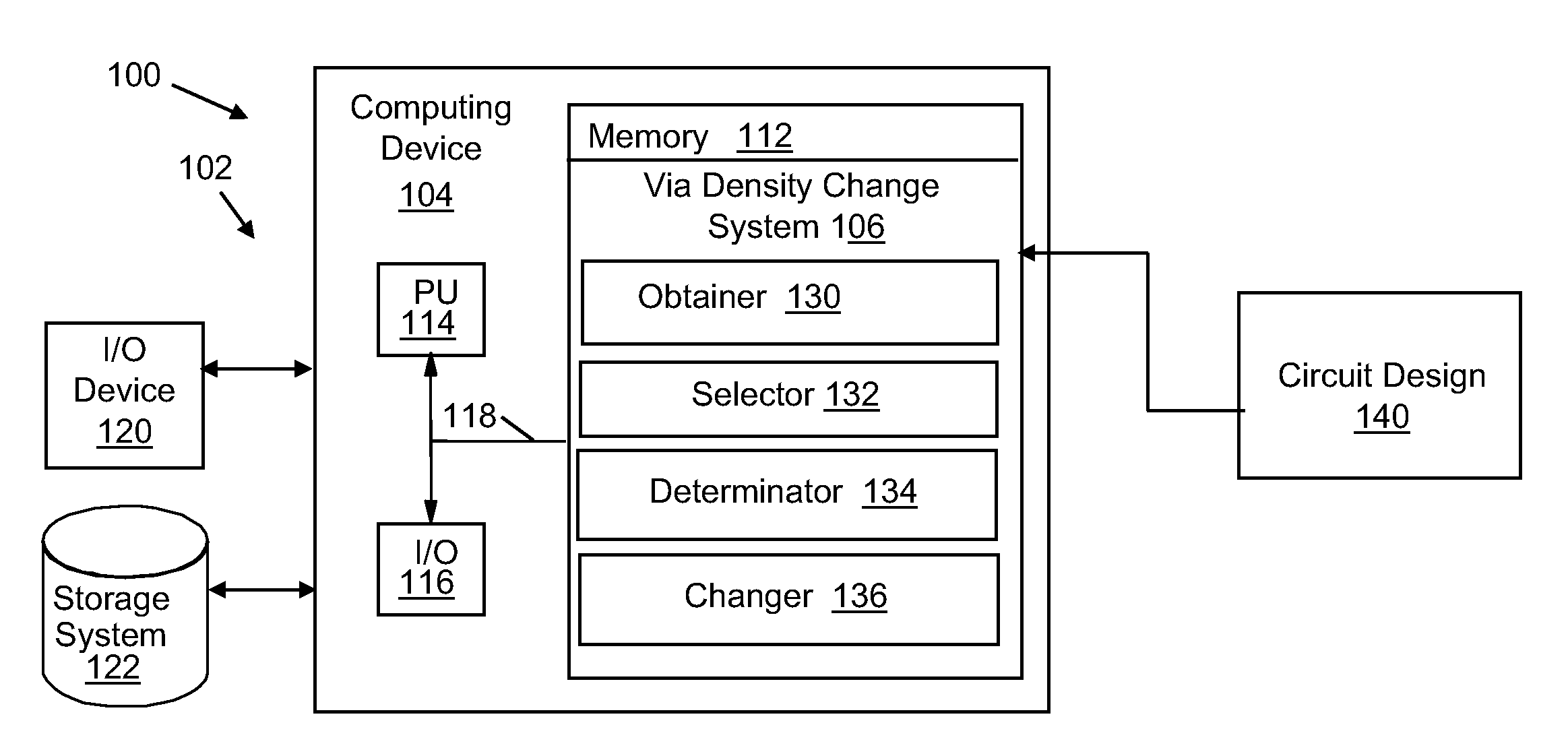

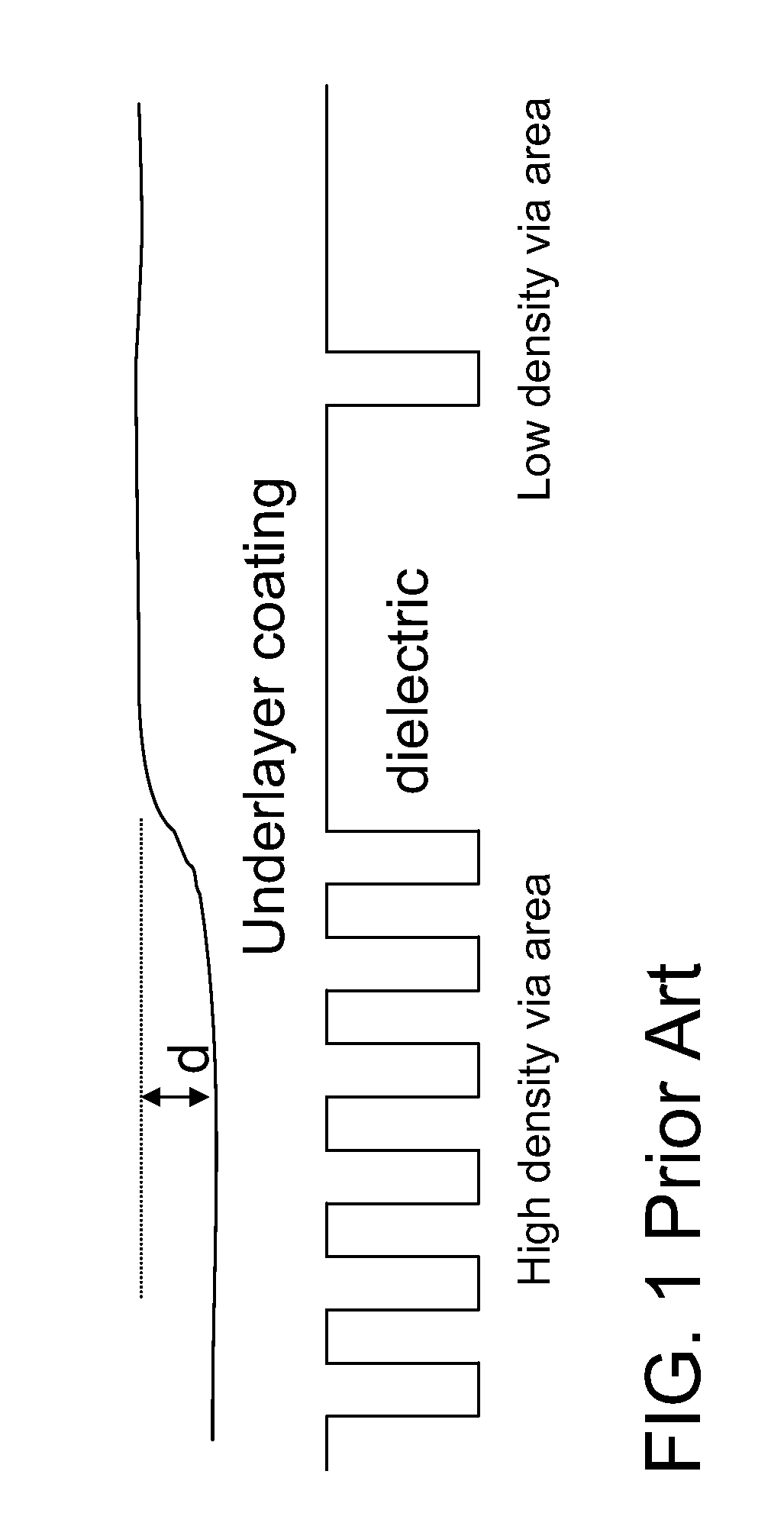

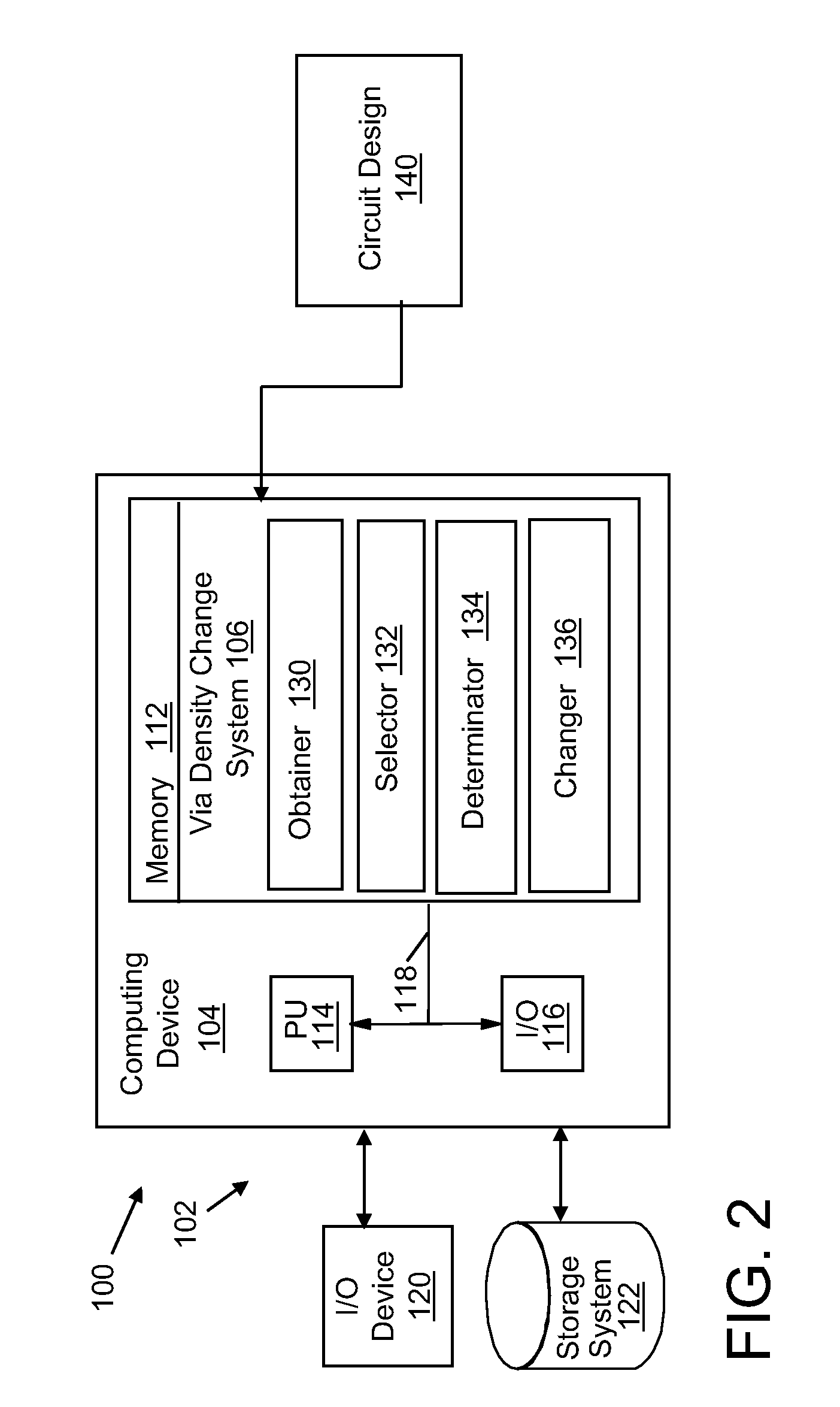

Via density change to improve wafer surface planarity

InactiveUS20100031221A1Improve wafer surface planarityCAD circuit designTotal factory controlEngineeringDensity change

Changing a via density for viafill vias to improve wafer surface planarity for later photolithography is provided, in one embodiment, by obtaining a circuit design including a plurality of viafill vias having differing via density across the circuit design, each viafill via interconnecting non-functional metal fill shapes in different layers of the circuit design; selecting a region of the circuit design to evaluate using an evaluation window; determining a via density within the evaluation window; and changing a number of viafill vias within the region in the circuit design in response to the via density being different than a threshold via density that is selected such that a coating deposited over the plurality of vias presents a substantially planar surface.

Owner:GLOBALFOUNDRIES INC

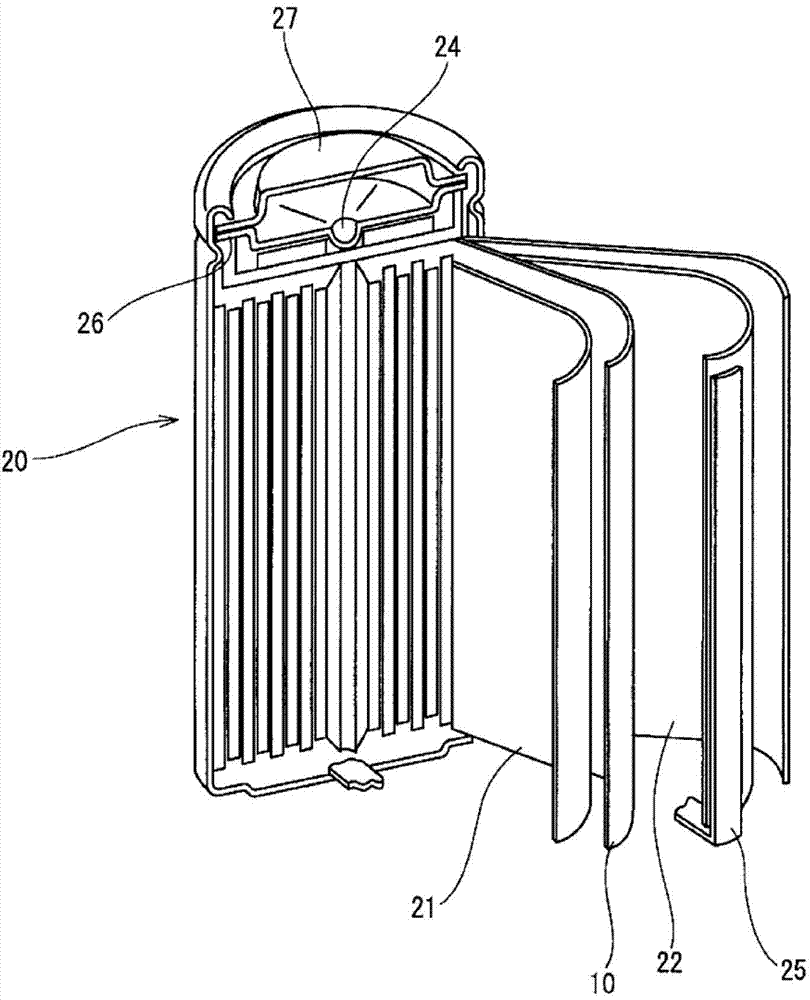

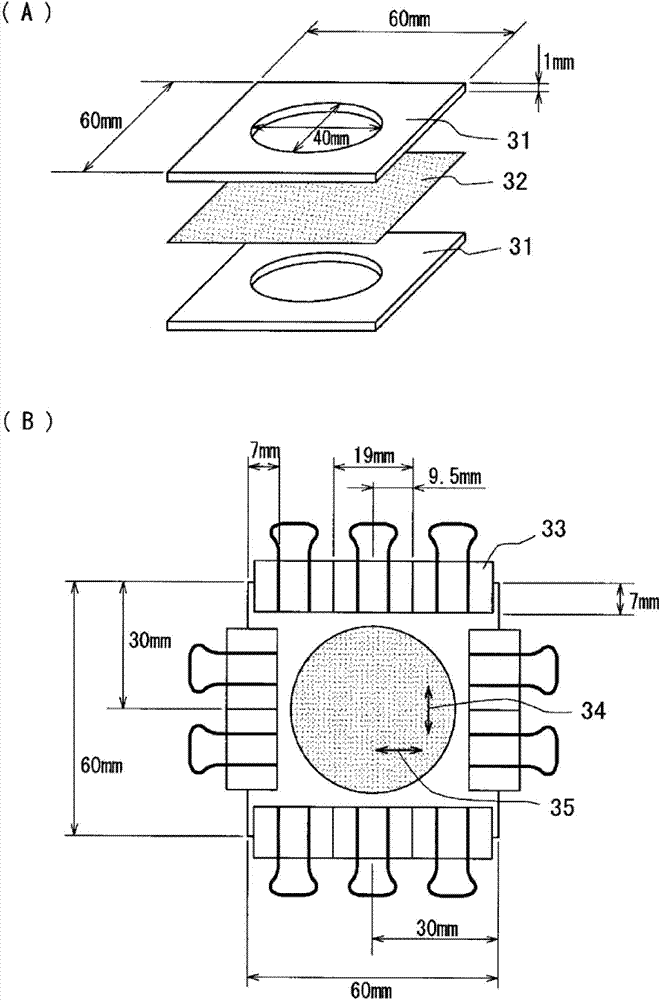

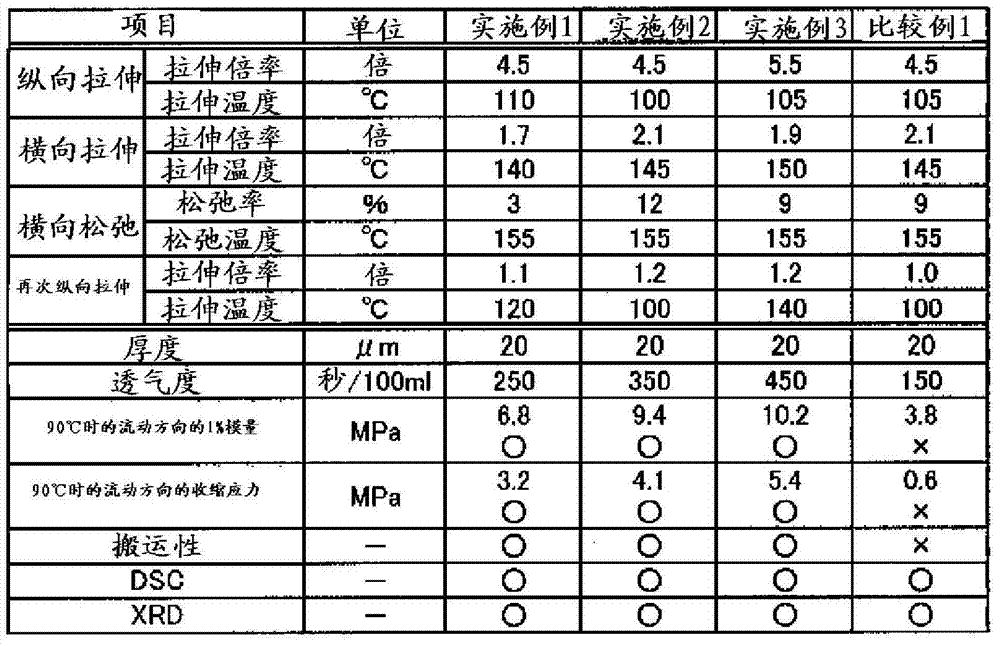

Polyolefin resin porous film

ActiveCN104334619AFull battery performanceHigh precisionCell seperators/membranes/diaphragms/spacersLi-accumulatorsPolyolefinRelative permeability

The purpose of the present invention is to provide a polyolefin resin porous film that maintains pore interconnectivity, has superior air permeability, and that, due to having a high shrinkage stress, is resistant to wrinkling during conveyance processes in high-temperature environments, therefore having a superior coating suitability. The present invention is characterized in that, at 90°C, the 1% modulus in the flow direction is equal to or greater than 4.5MPa, and the air permeability is equal to or less than 800s / 100ml.

Owner:MITSUBISHI CHEM CORP

Polymeric bone defect filler

ActiveUS8338498B2High mechanical strengthImprove interconnectivityBone implantTissue regenerationParticulatesBone defect

Owner:DOCTORS RES GROUP

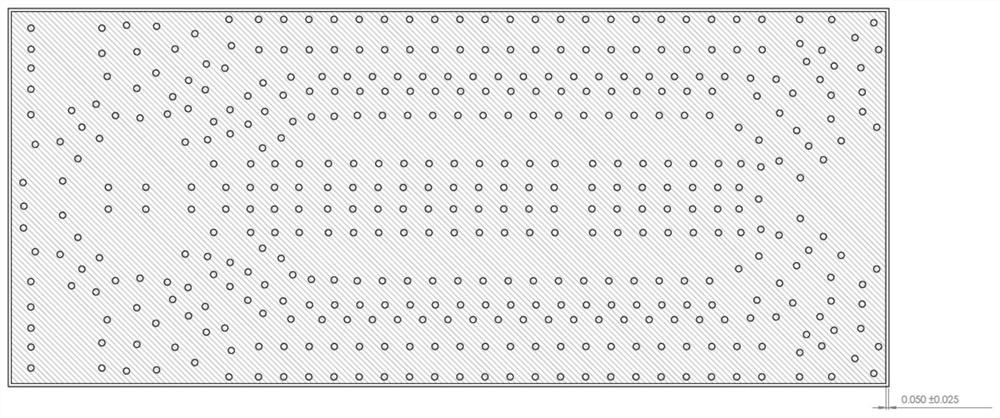

Manufacturing method of double-sided photoelectric substrate with interconnected high-density through holes

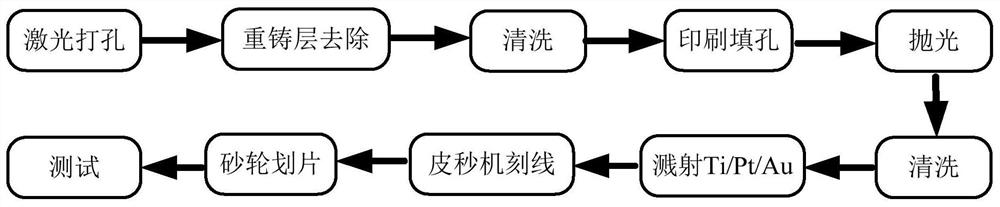

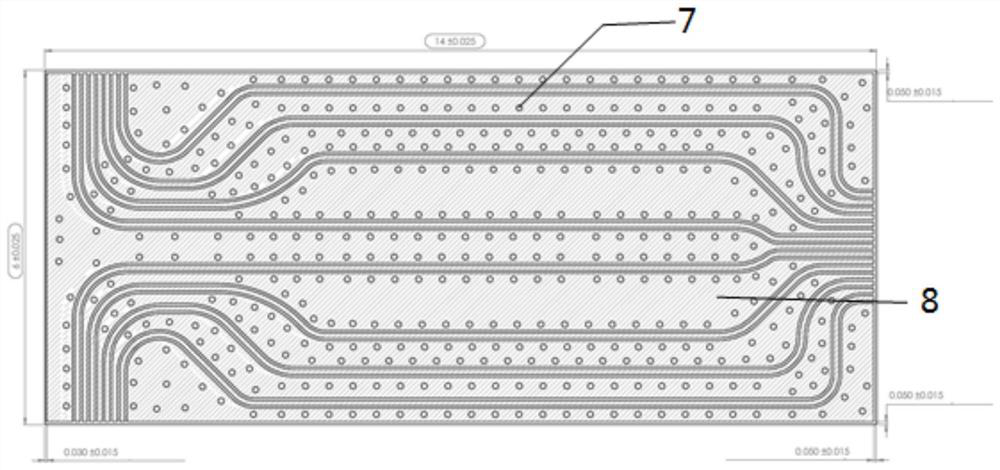

ActiveCN111681965AMeet the needs of the design substrateMeet the design requirementsFinal product manufactureSemiconductor/solid-state device manufacturingLaser processingHigh density

The invention discloses a manufacturing method of a double-sided photoelectric substrate with interconnected high-density through holes. According to the method, the double-sided interconnected photoelectric ceramic substrate with the high-density micro-through holes is manufactured on the basis of the processes of manufacturing the micro-through holes in the ceramic substrate by a laser processing technology, filling the auxiliary through holes, flattening the surface, sputtering a film layer, manufacturing wiring lines and the like. The method is based on a fine processing technology of AlNceramic by laser. The manufacturing technology of the high-density micro-through-hole interconnection photoelectric device is studied, through the high-density micro-through-hole double-face interconnection technology, the double sides of the substrate are connected via the through holes, Au is filled in the through holes, and the problems that the back face of a photoelectric module device circuit needs to have corresponding functions and is connected with a front face graph and reliability is poor are solved. A metal film layer is prepared on the basis of a magnetron sputtering technology, the high-density micro-through-hole interconnection photoelectric device manufacturing technology is realized, a patterning process technology is carried out through a metallization layer, and a thickfilm hole filling process and a thin film patterning process are effectively combined.

Owner:XIAN MICROELECTRONICS TECH INST

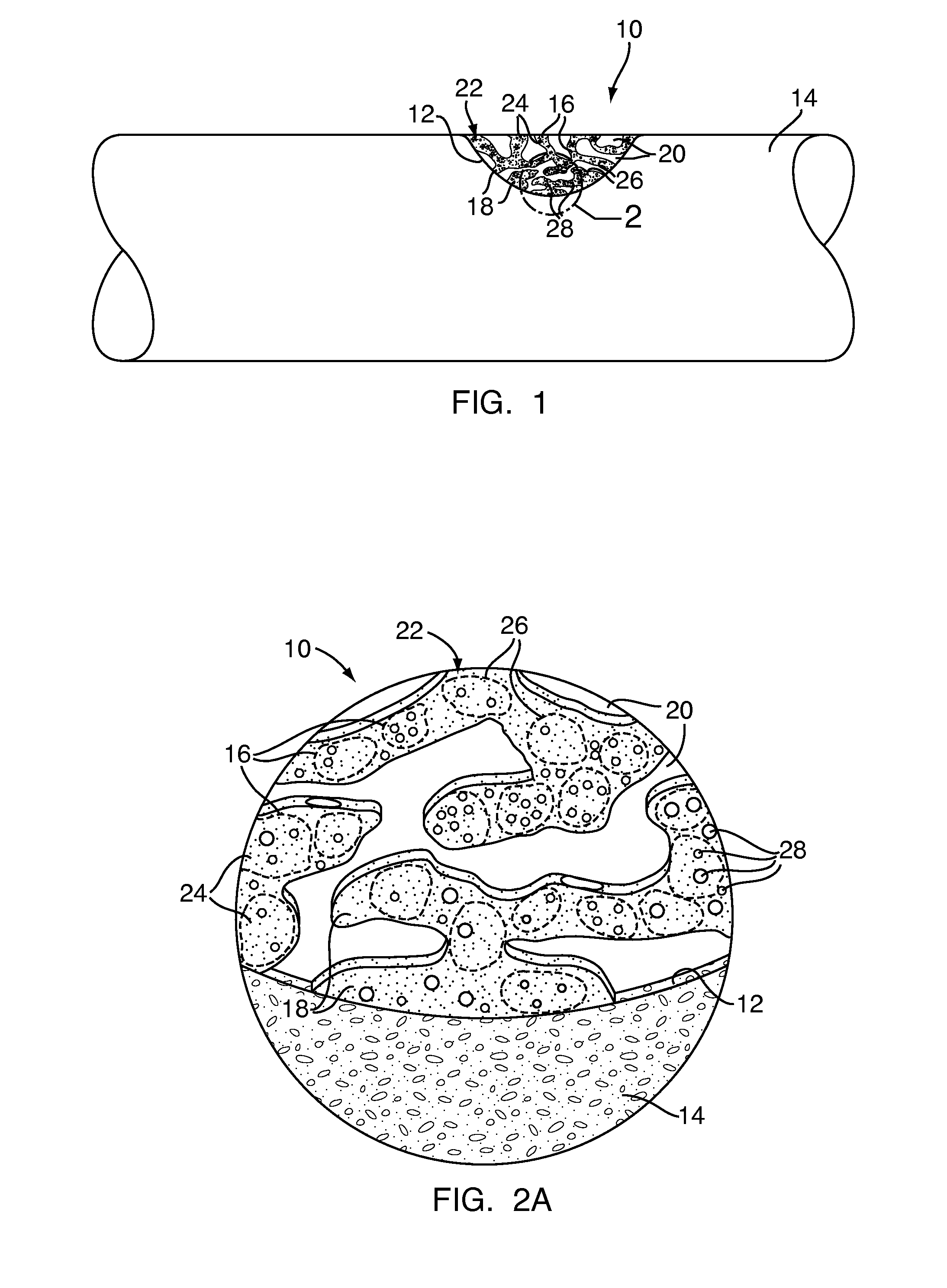

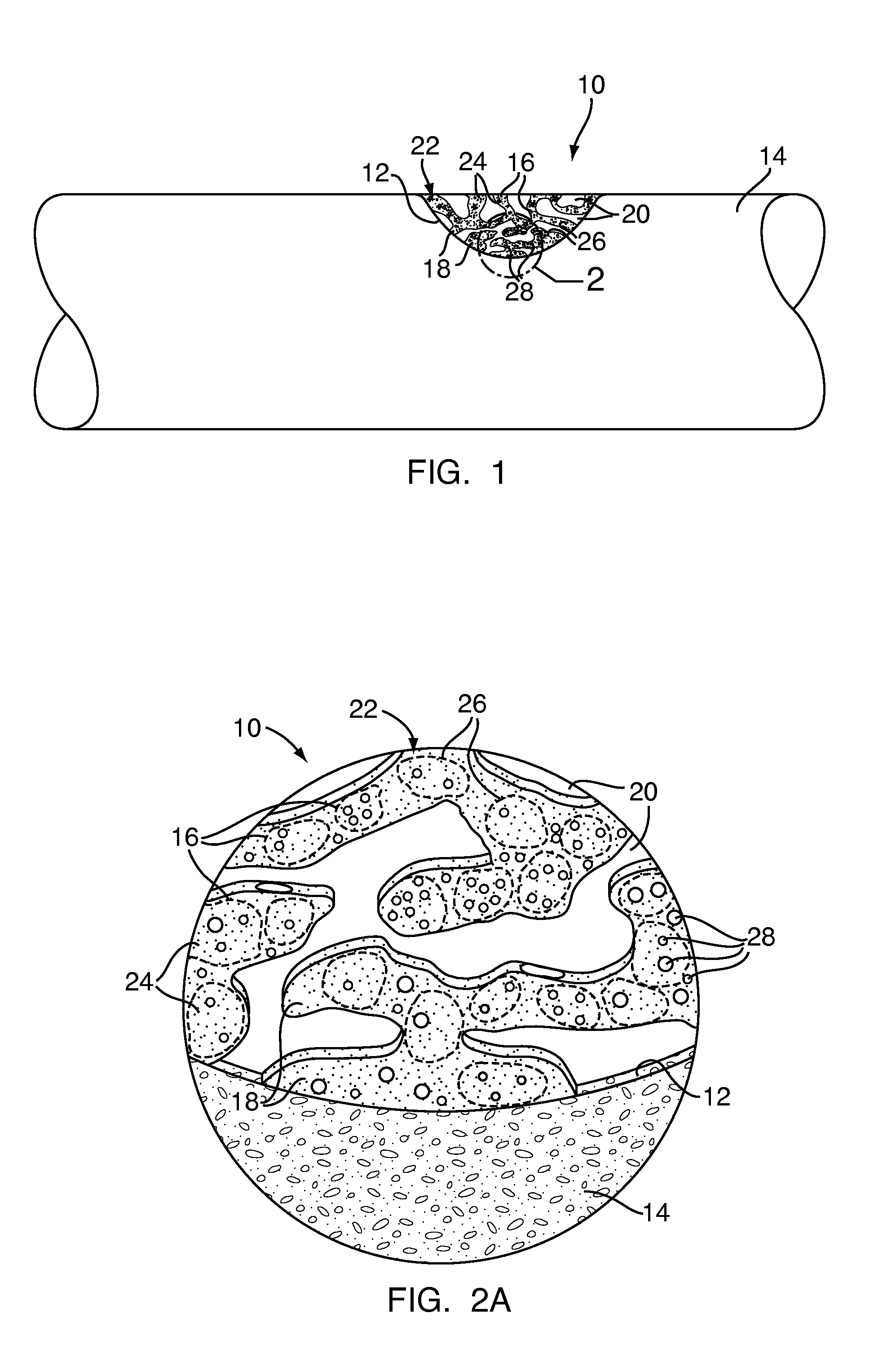

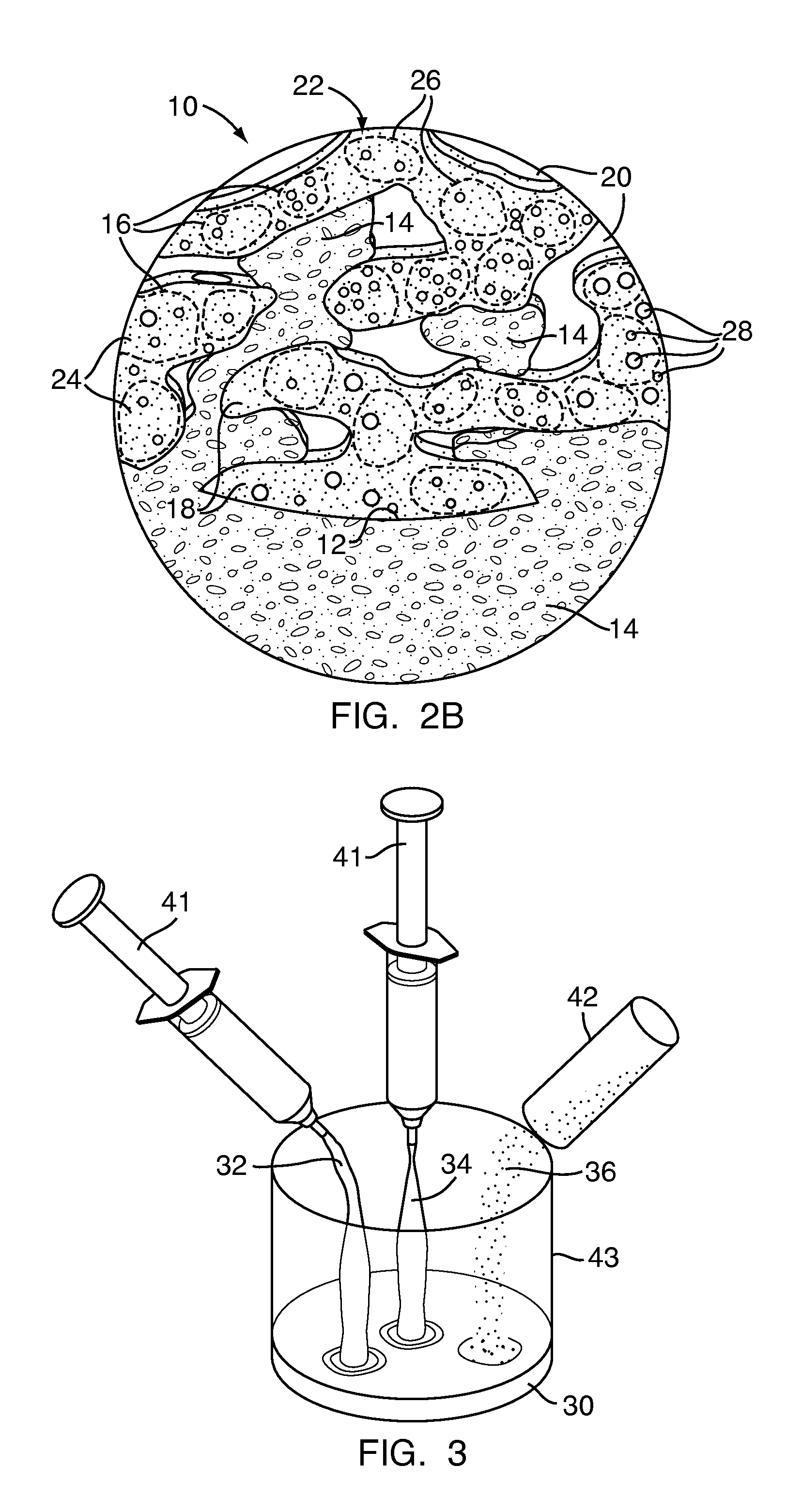

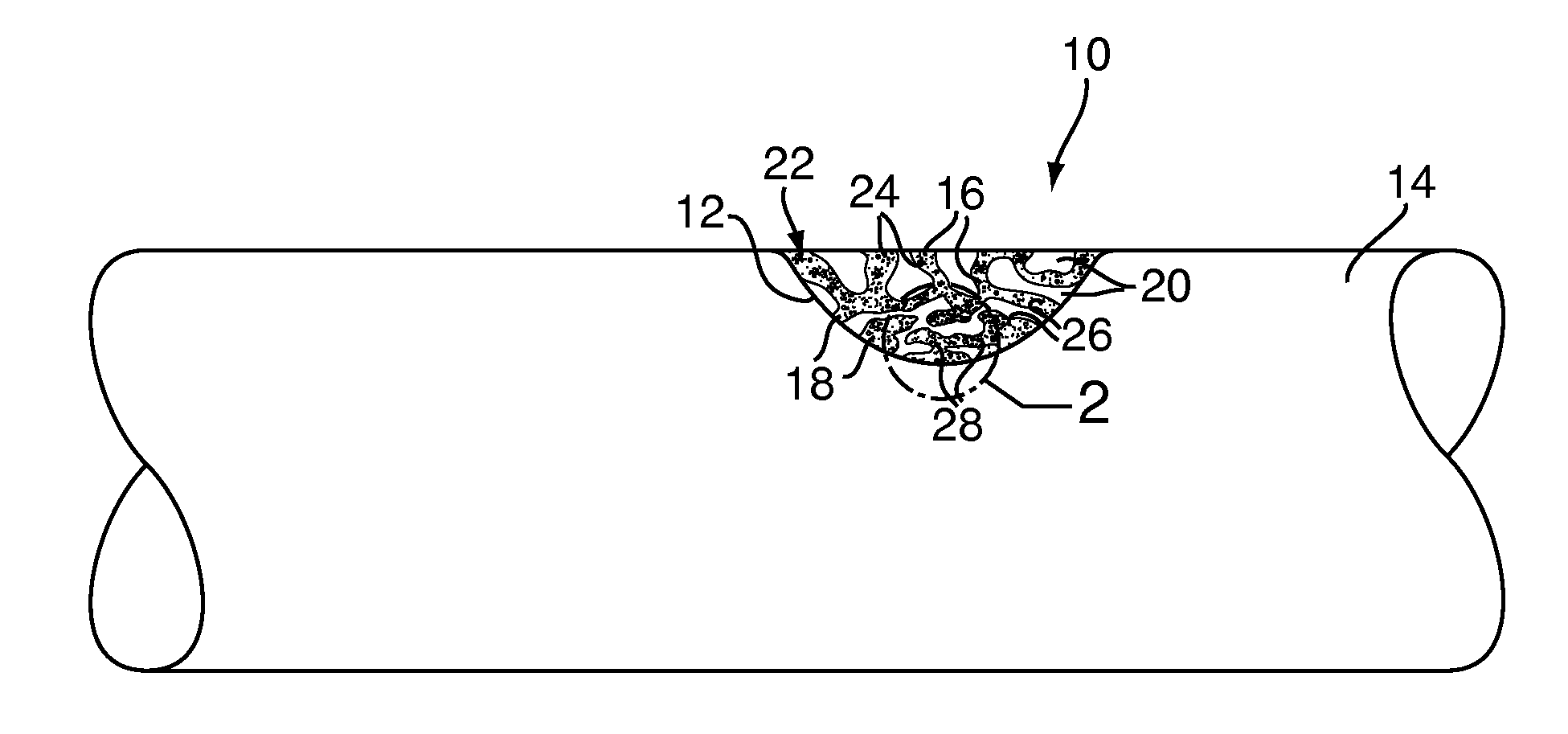

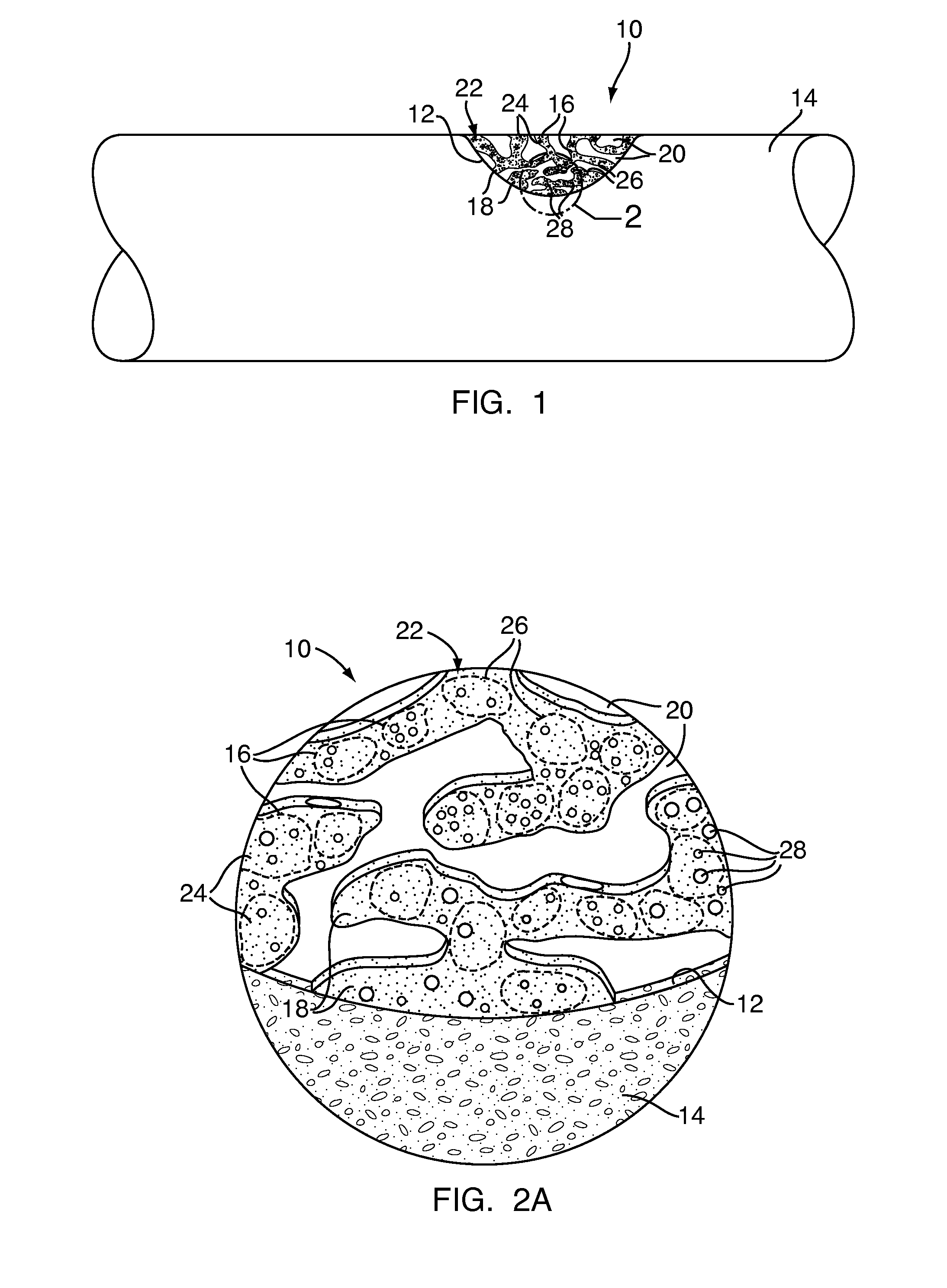

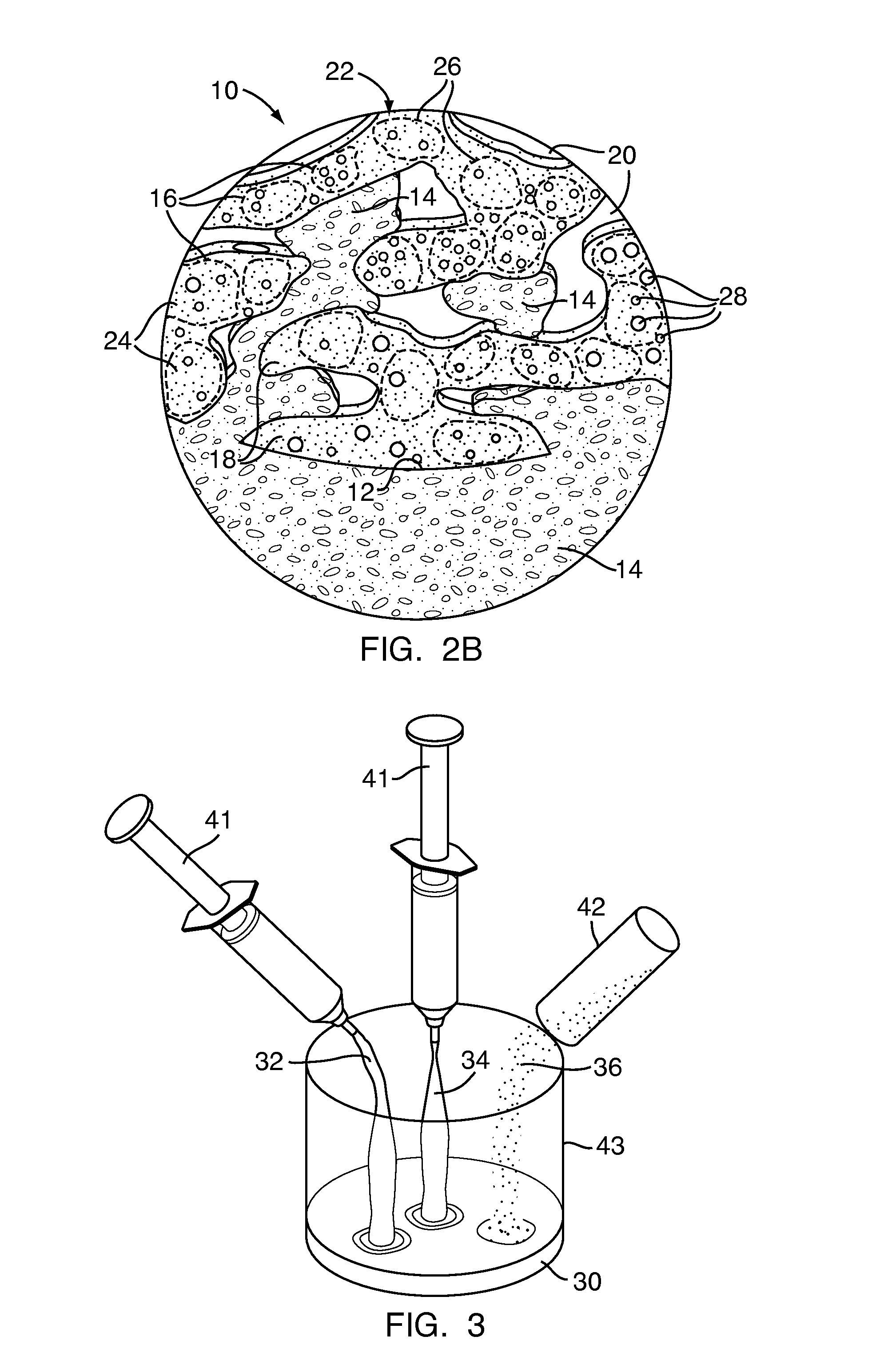

Polymeric bone defect filler

InactiveUS20110201704A1High mechanical strengthImprove interconnectivityPolyureas/polyurethane adhesivesTissue regenerationParticulatesBone defect

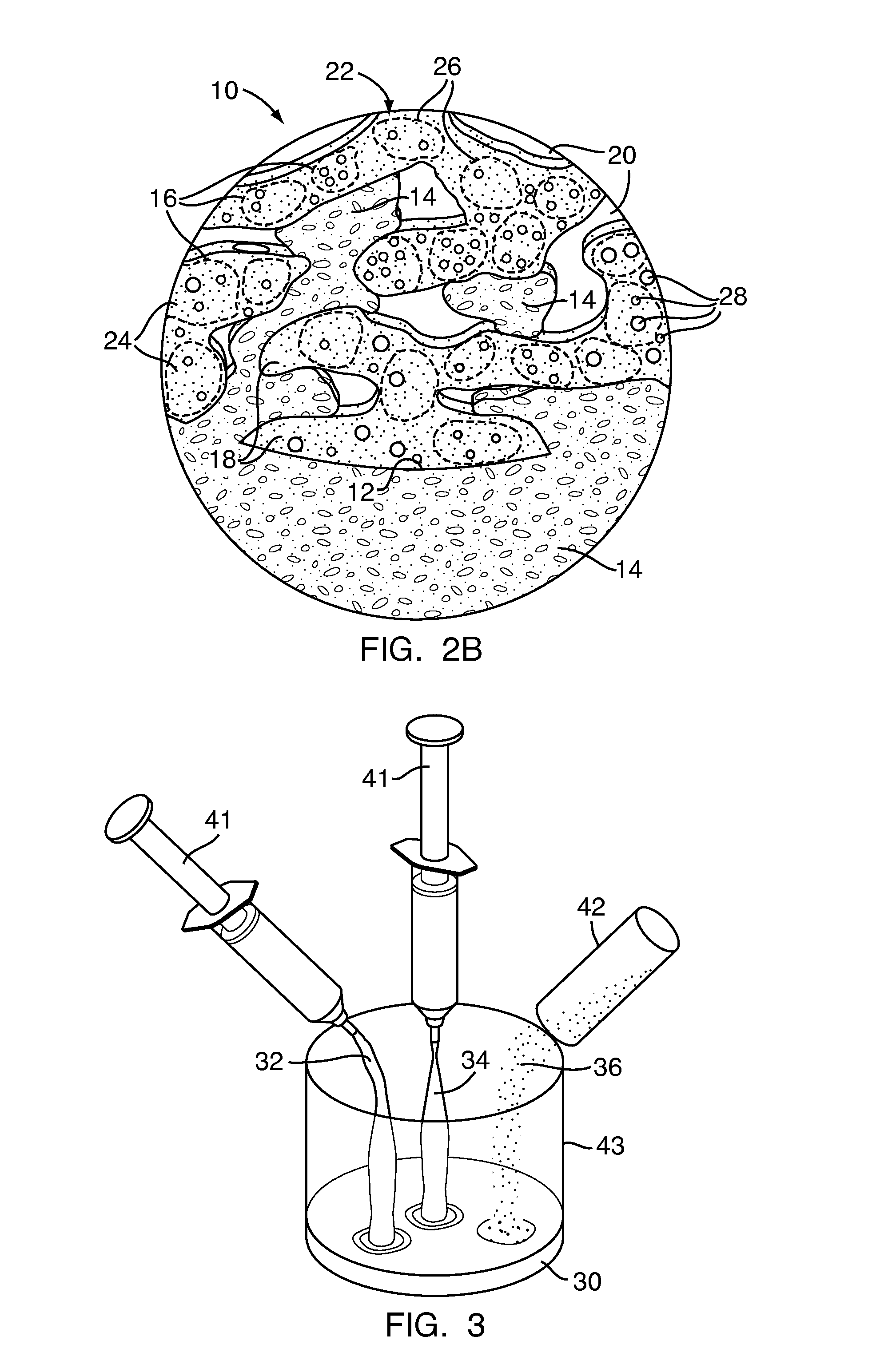

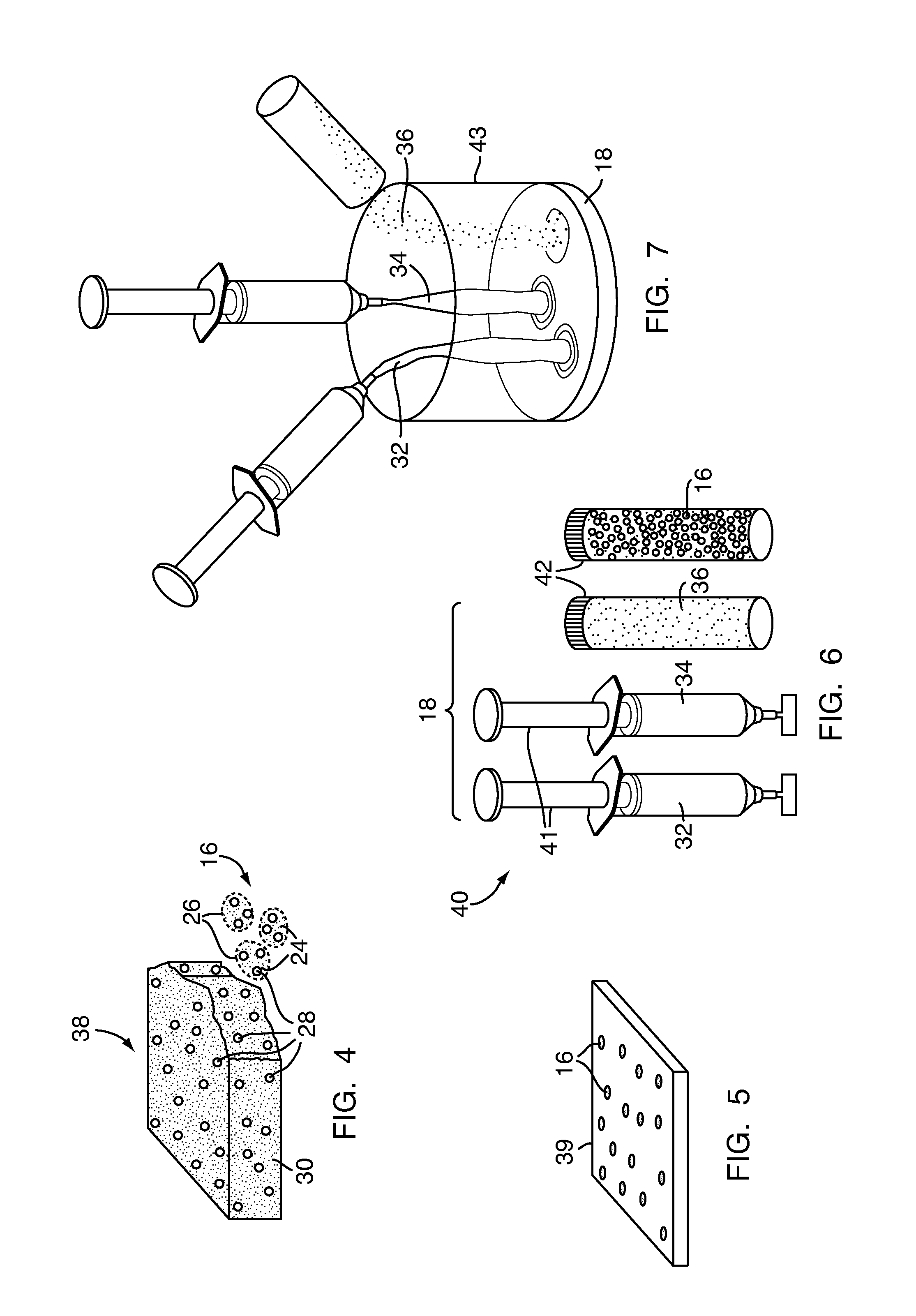

A bone defect filler for implantation in a bone defect of a patient includes a particulate polymer distributed within a polymeric binder. The particulate polymer includes a plurality of particles, which may have substantially the same material composition as the polymeric binder. The particles of the particulate polymer may be formed in a variety of shapes and / or sizes to provide the bone defect filler with improved pore interconnectivity, material expansion and contamination characteristics, while maintaining sufficient mechanical strength and handling characteristics for bone repair applications. The bone defect filler also provides the flexibility to be molded or shaped in situ to fill the bone defect.

Owner:DOCTORS RES GROUP

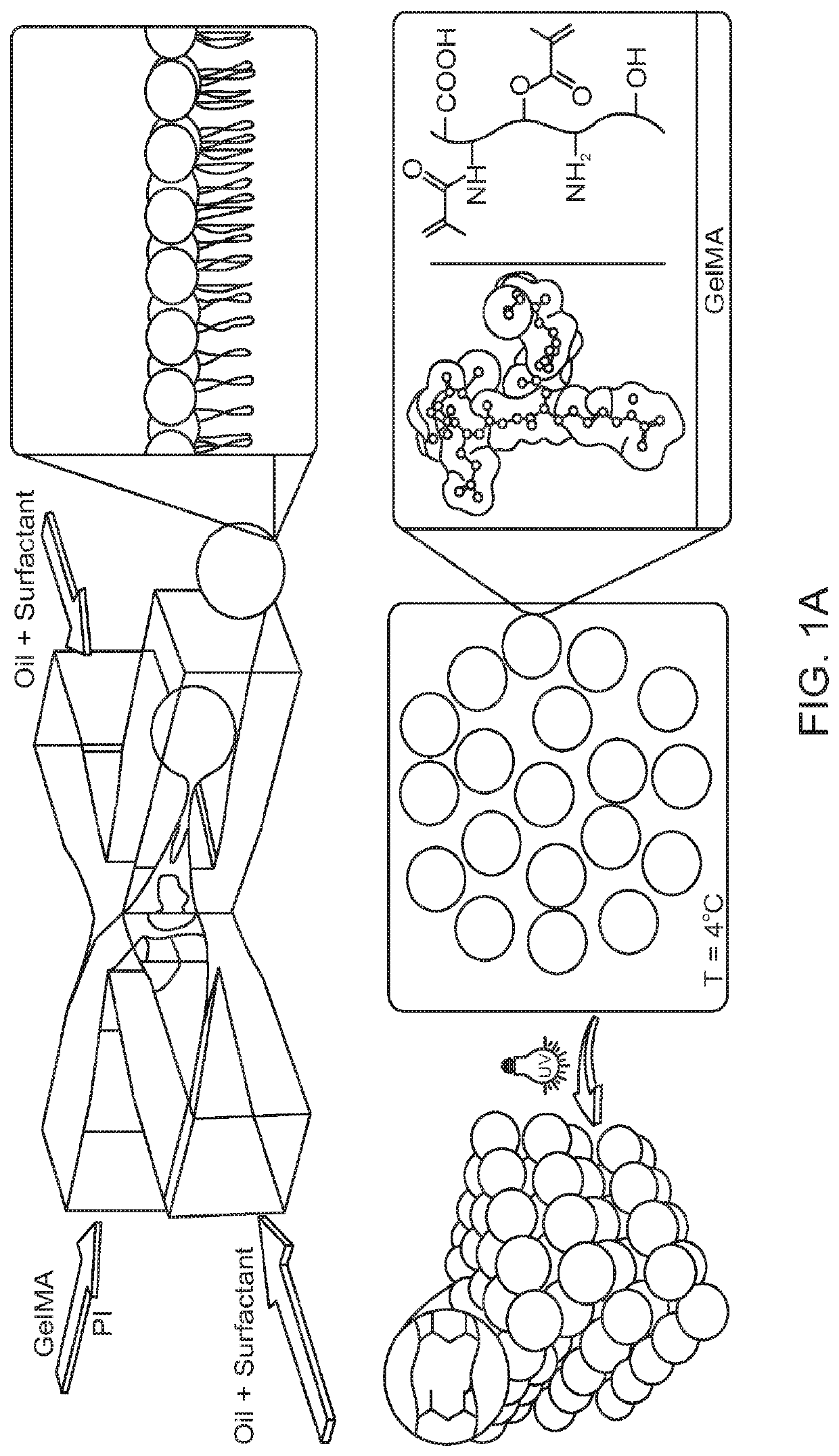

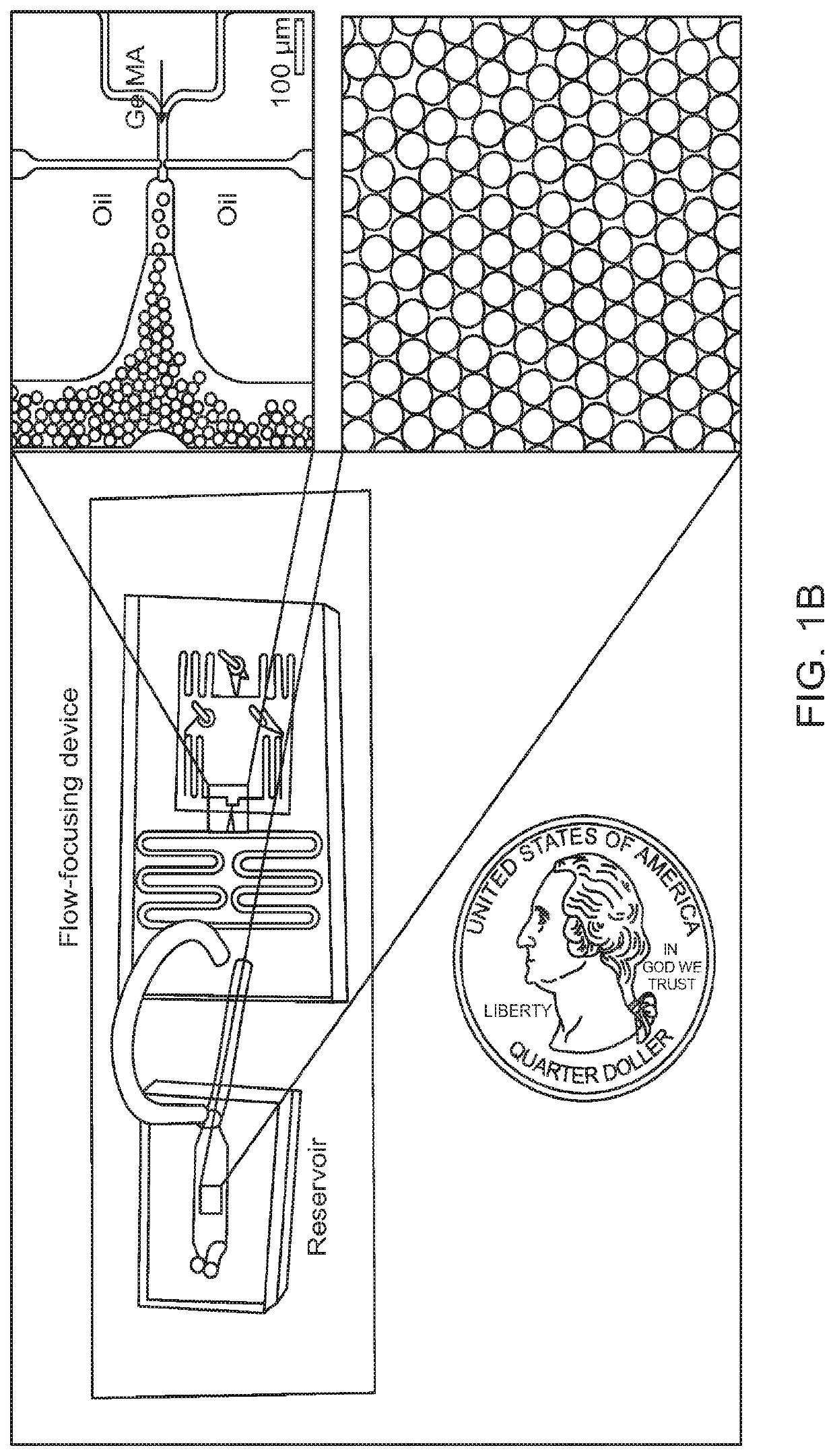

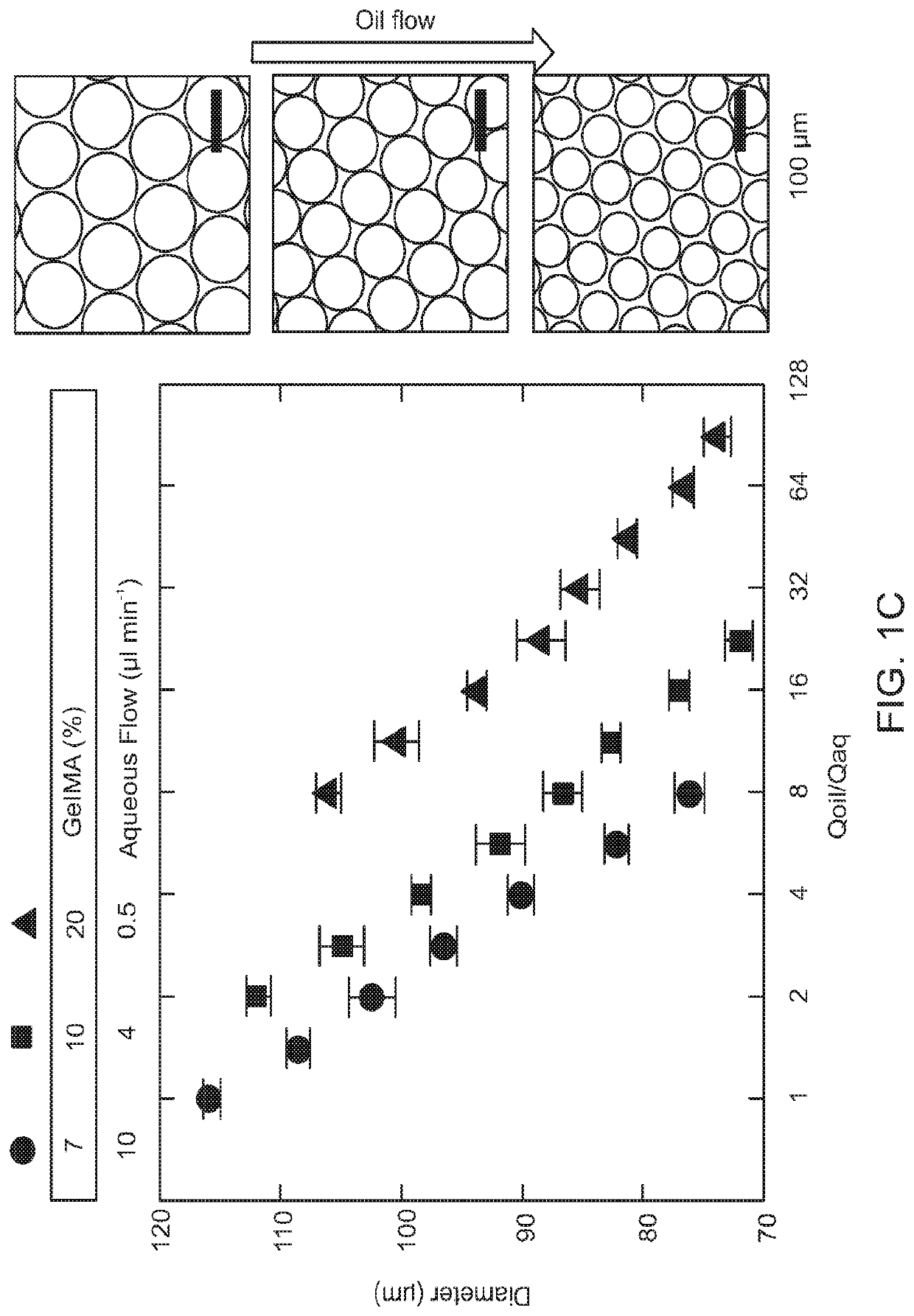

Methods for fabricating modular hydrogels from macromolecules with orthogonal physico-chemical responsivity

PendingUS20210403649A1ExtendingReduce wastePharmaceutical delivery mechanismProsthesisMedicineGelatin

Despite the significant advances in designing injectable bulk hydrogels, the inability to control the pore interconnectivity and decoupling it from the matrix stiffness has tremendously limited the applicability of stiff, flowable hydrogels for 3D cellular engineering. To address this problem, we developed a universal method to convert macromolecules and the like with orthogonal chemical and / or physical responsivity, e.g., thermosensitive macromolecules with chemically-crosslinkable moieties, into annealable building blocks, forming 3D microporous beaded scaffolds in a bottom-up approach. For example, gelatin methacryloyl (GelMA), a widely used biomaterial in tissue engineering, may be converted into physically-crosslinked microbeads using a facile microfluidic approach, followed by flow of the microbead slurry and chemical crosslinking in situ to fabricate microporous beaded GelMA (B-GelMA) scaffolds with interconnected pores, promoting cell functionality and rapid (within minutes) 3D seeding in stiff scaffolds, which are otherwise impossible in the bulk gel counterparts.

Owner:RGT UNIV OF CALIFORNIA

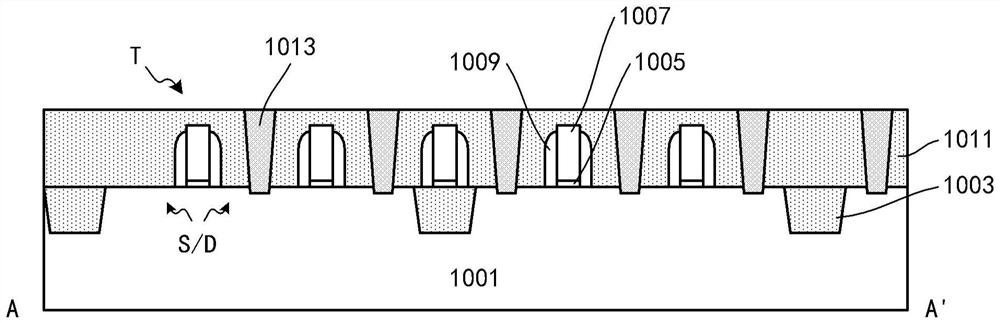

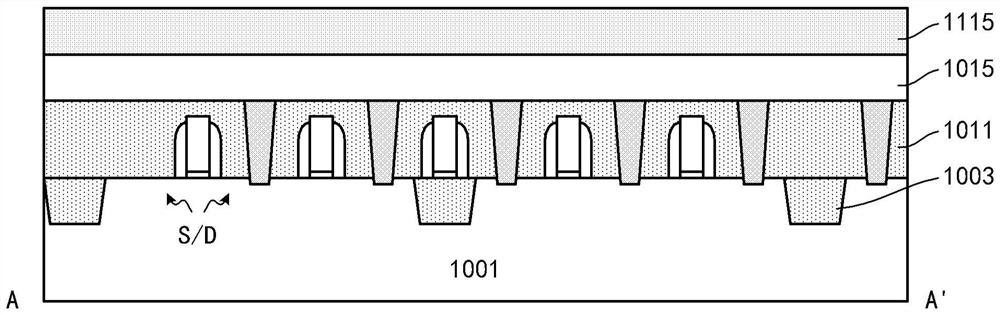

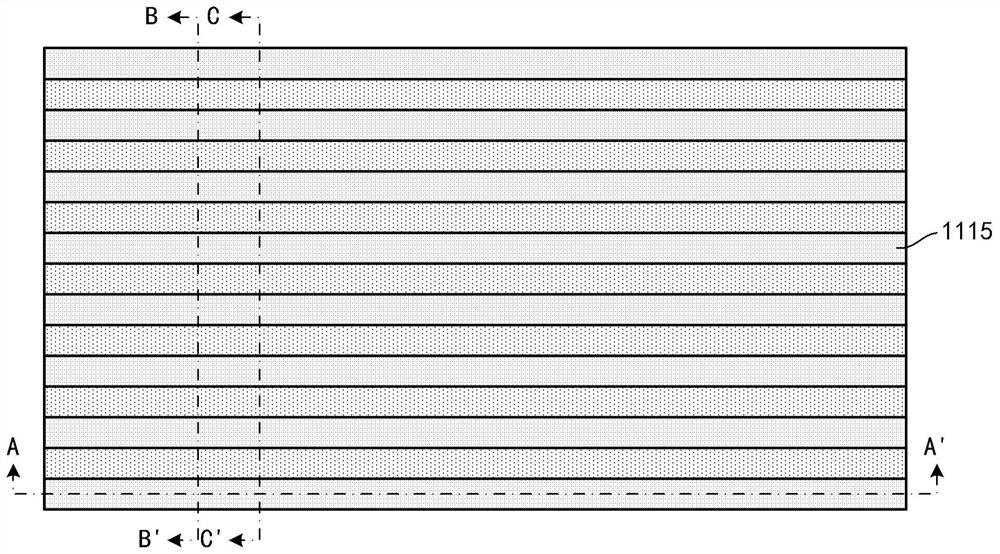

Metallization lamination layer, manufacturing method thereof and electronic equipment comprising metallized laminate

ActiveCN110970379AAvoid stuffing puzzlesReduce line widthSemiconductor/solid-state device detailsSolid-state devicesInterconnectionMechanical engineering

The invention discloses a metallization lamination layer, a manufacturing method thereof and electronic equipment comprising the metallization lamination layer. According to an embodiment, the metallization lamination layer may include at least one interconnect line layer and at least one via hole layer alternately disposed on a substrate. At least one pair of adjacent interconnection line layer and via hole layer in the metallization lamination layer comprises interconnection lines in the interconnection line layer and via holes in the via hole layer. The interconnect line layers are closer to the substrate than the via hole layer. The outer peripheral side wall of the via holes on at least a portion of the interconnect lines does not exceed the outer peripheral side wall of the at leasta portion of the interconnect lines.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

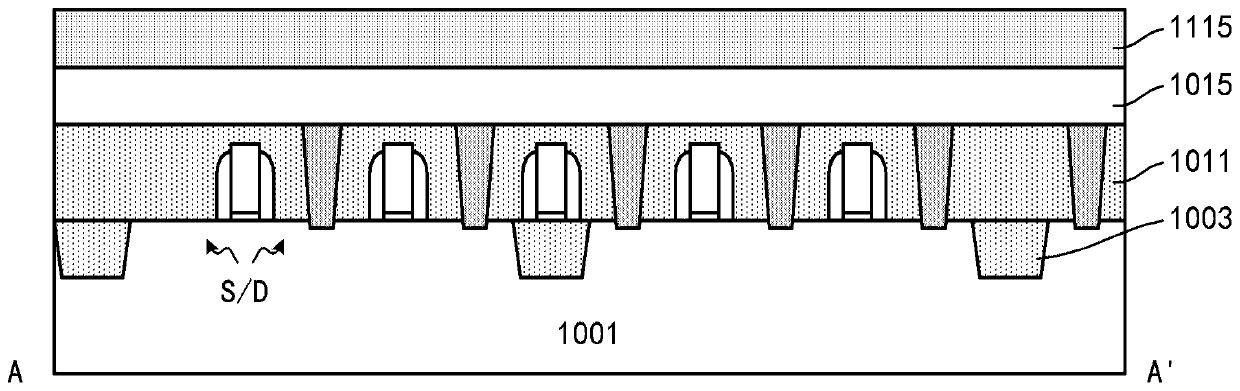

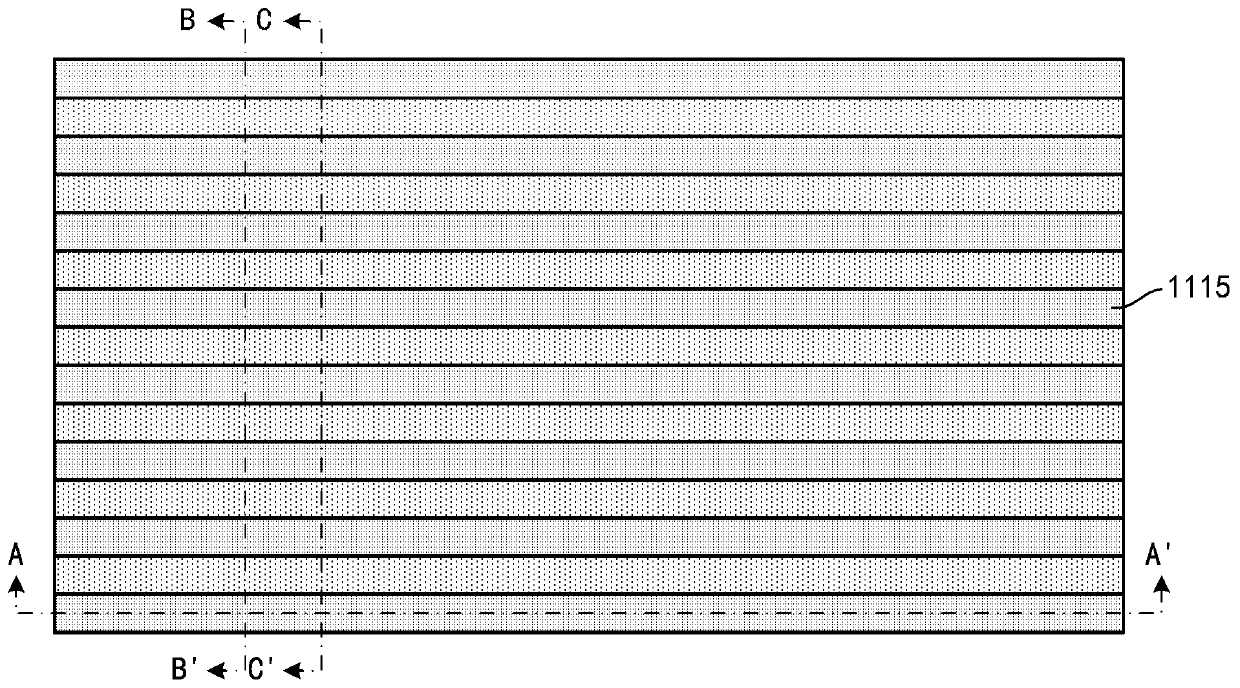

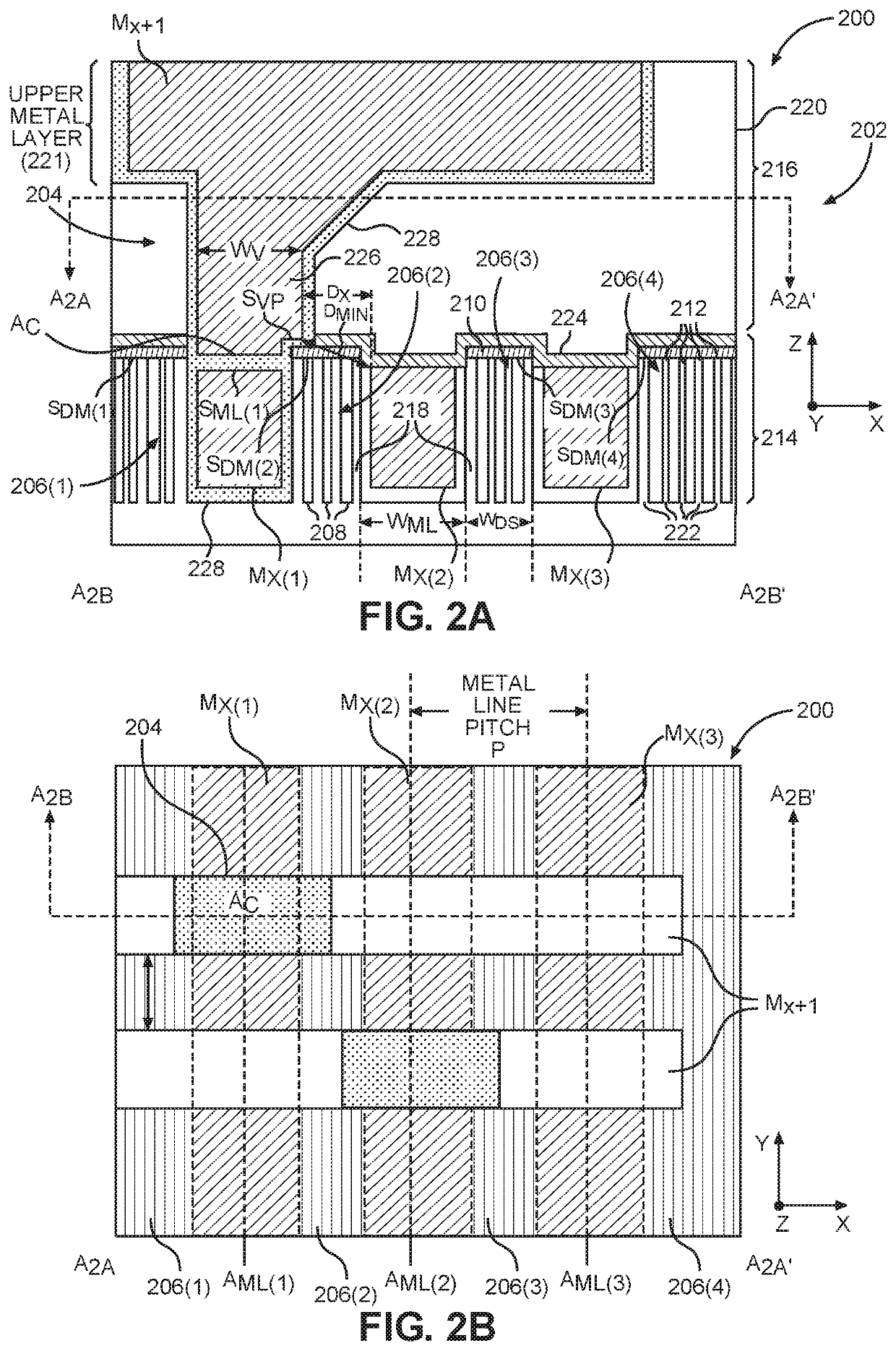

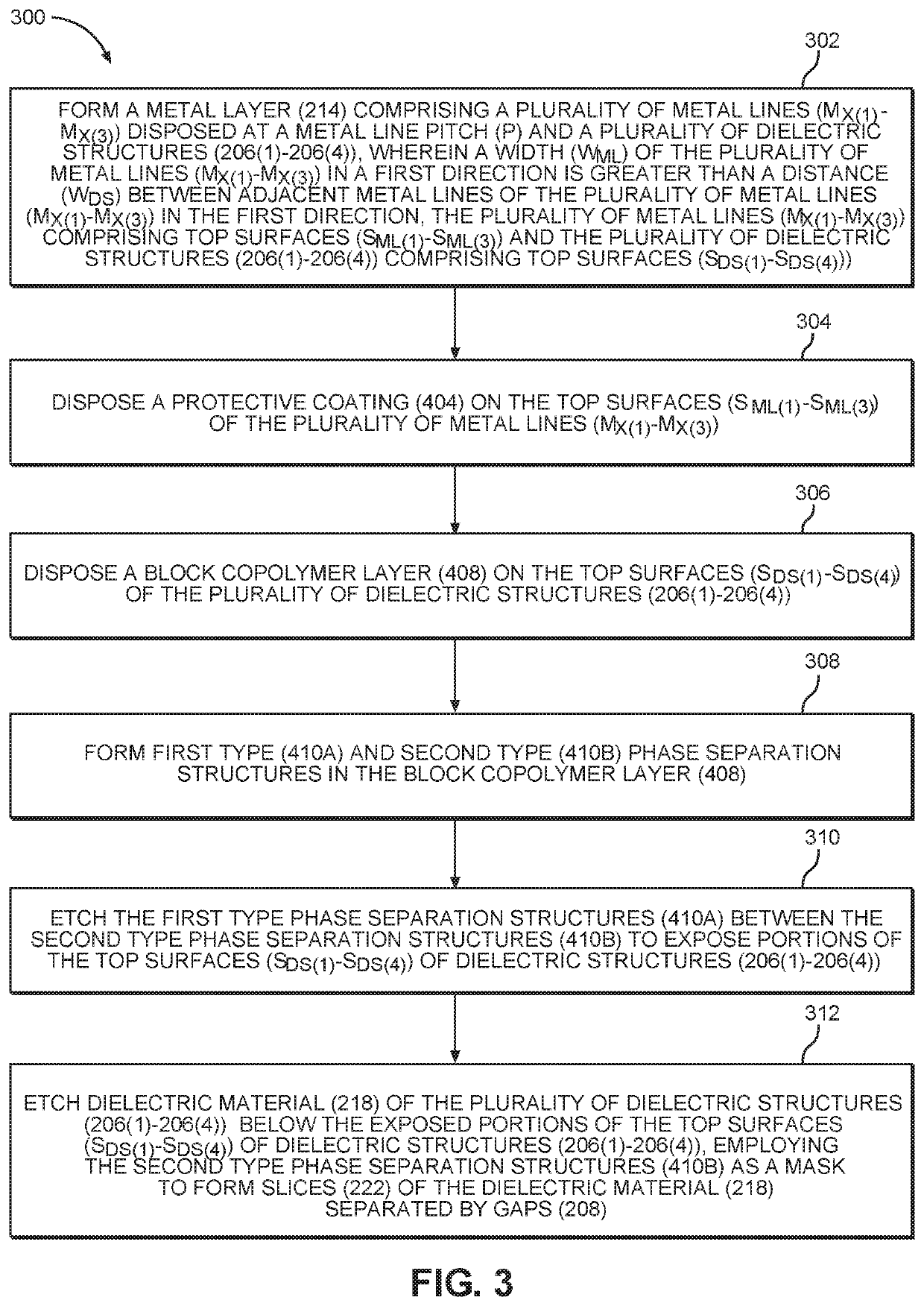

Integrated circuit (IC) interconnect structure having a metal layer with asymmetric metal line-dielectric structures supporting self-aligned vertical interconnect accesses (VIAS)

ActiveUS10651122B1Improve connectivityPrevent metal line shortingSemiconductor/solid-state device detailsSolid-state devicesCapacitanceElectrical resistance and conductance

An integrated circuit (IC) interconnect structure may include a metal layer with asymmetric metal line-dielectric structures supporting fully self-aligned vertical interconnect accesses (vias). The interconnect structure includes metal lines spaced at a metal line pitch and dielectric structures disposed between adjacent metal lines. The width of the metal lines is asymmetric to the width of dielectric structures, providing an asymmetric width relationship that allows a metal line to have a greater cross-sectional area for reducing electrical resistance without having to increase metal line pitch. The via pattern is self-aligned to an upper metal opening at the top and an underlayer metal recess opening at the bottom, allowing the maximum contact area to reduce via resistance. To reduce capacitive coupling between adjacent metal lines, the adjacent interconnect structures include a plurality of gaps formed in a dielectric material of the dielectric structure.

Owner:QUALCOMM INC

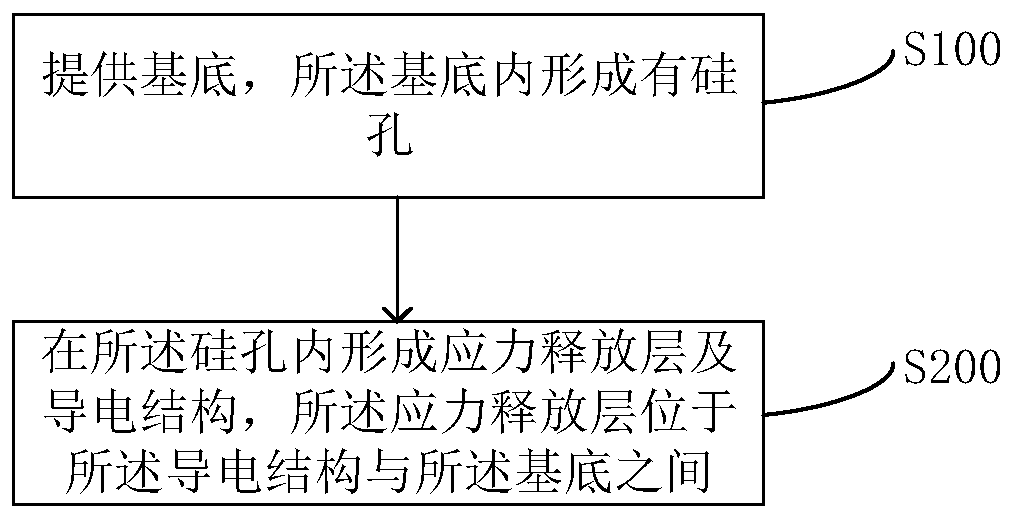

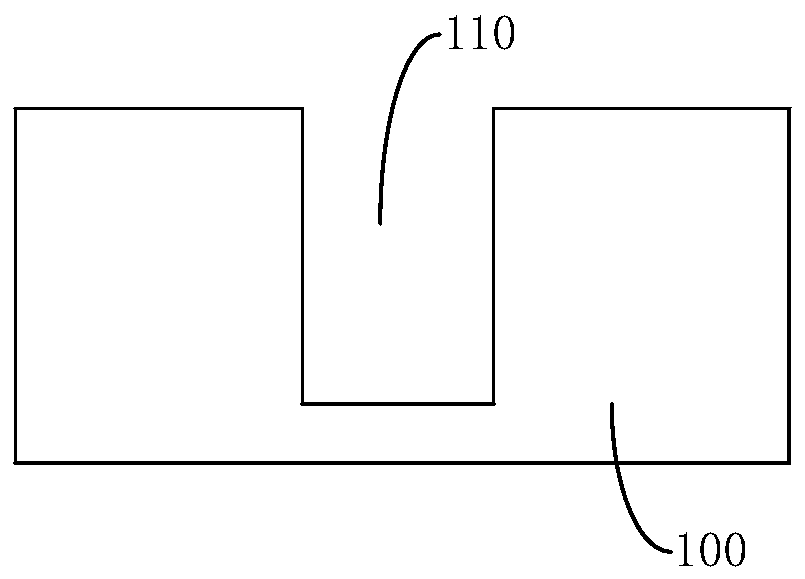

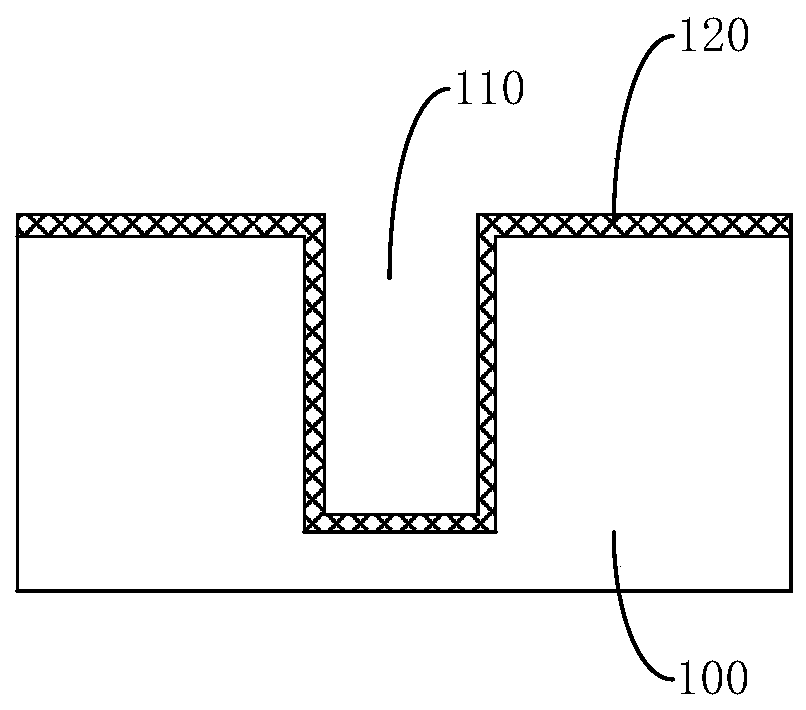

Silicon through hole interconnection structure and preparation method thereof

PendingCN111180387AAvoid breakingSemiconductor/solid-state device detailsSolid-state devicesInternal stressThrough-silicon via

The invention relates to a silicon through hole interconnection structure and a preparation method thereof. The preparation method comprises the steps of: providing a substrate, and forming a siliconhole in the substrate, and forming a stress release layer and a conductive structure in the silicon hole, the stress release layer being located between the conductive structure and the substrate. According to the preparation method of the silicon through hole interconnection structure, after a barrier layer is formed, the stress release layer grows on the surface of the barrier layer. After the conductive structure is formed in the silicon hole, the conductive structure expands due to the thermal effect in the subsequent thermal process, and the stress release layer can absorb the stress generated by the expansion of the conductive structure at the moment, thereby preventing the wafer from being broken due to too much internal stress of the wafer in the annealing process or the thinning process.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

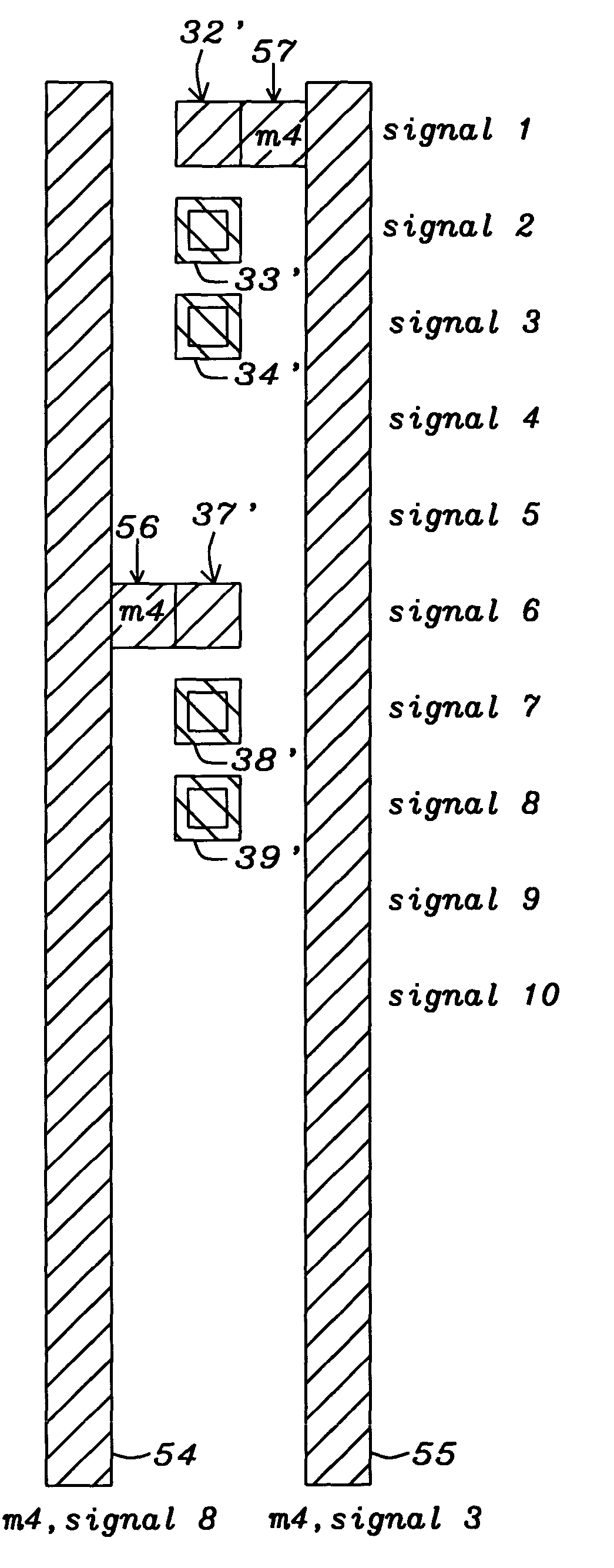

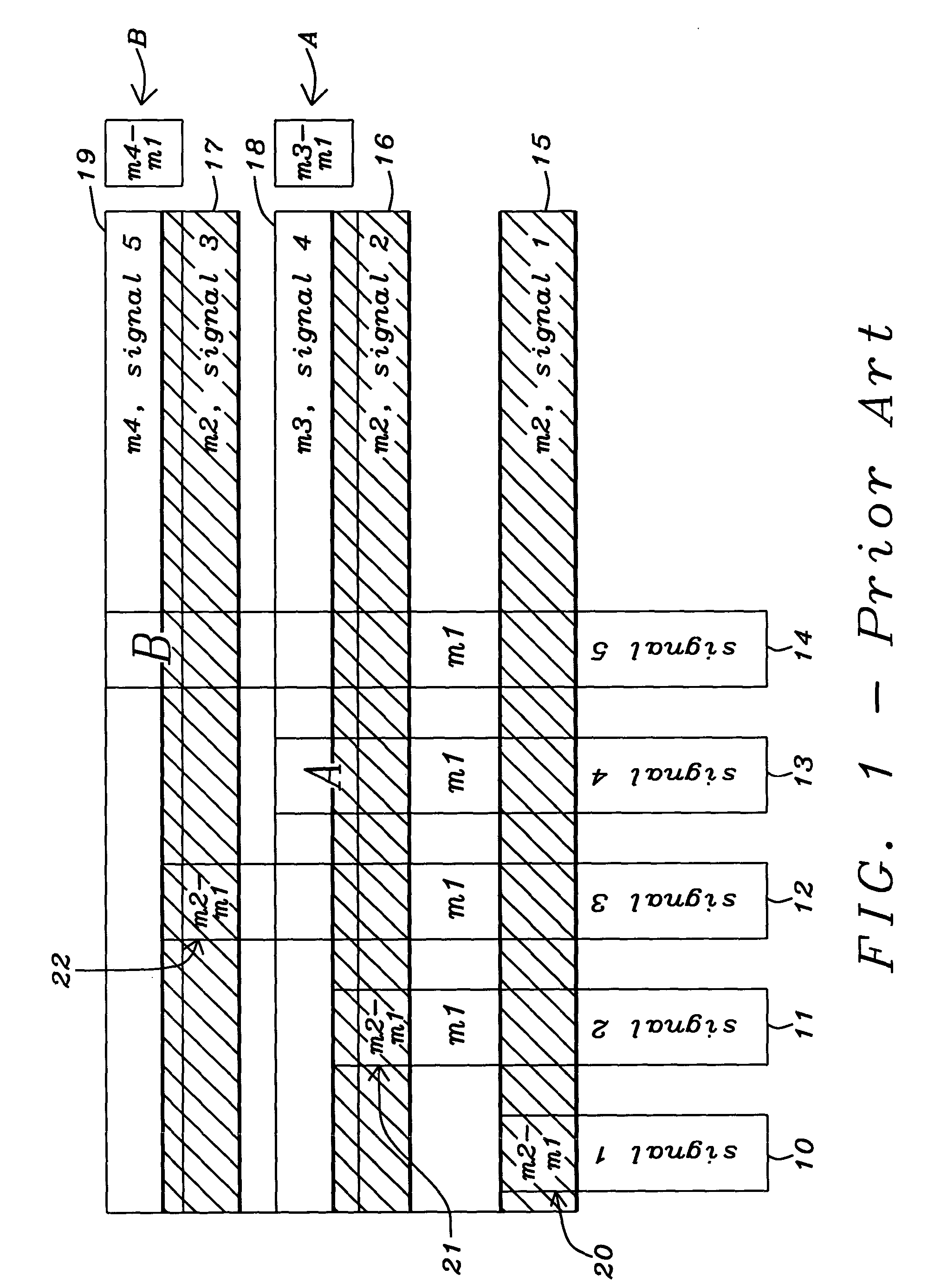

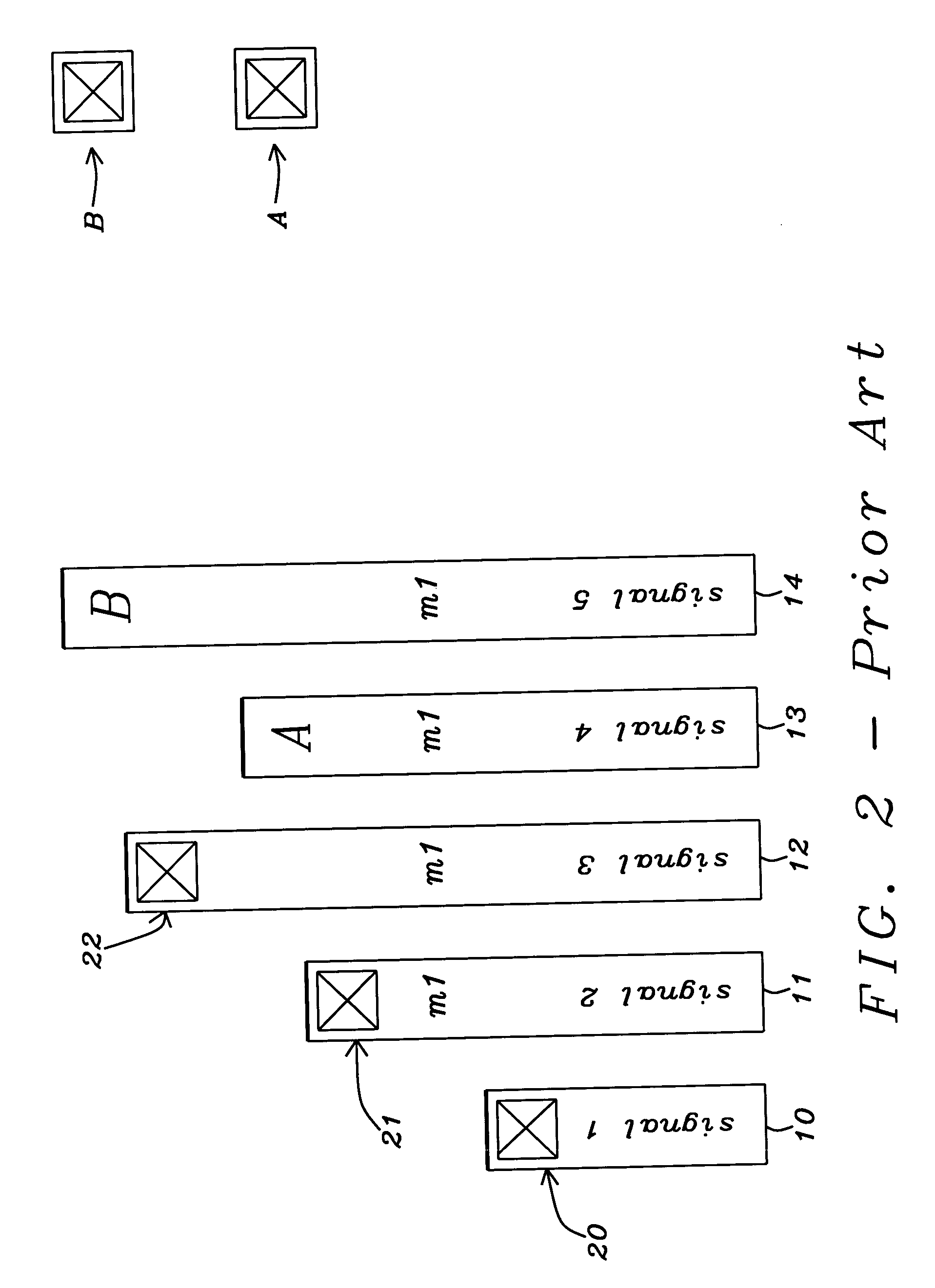

Multi-layered metal routing technique

ActiveUS20050056936A1Semiconductor/solid-state device detailsSolid-state devicesInterconnectionMetal

In accordance with the objectives of the invention a new method and structure is provided for the creation of multiple overlying layers of interconnect metal. A channel is reserved for the creation of via interconnects, no vias are placed on metal lines. The metal lines are stacked and parallel, whereby a space is provided between lines that is reserved for the creation of vias for layer interconnection. This structure can be repeated, the vias are placed on the therefore reserved channel, interconnections are provided to the interconnect traces.

Owner:TAIWAN SEMICON MFG CO LTD

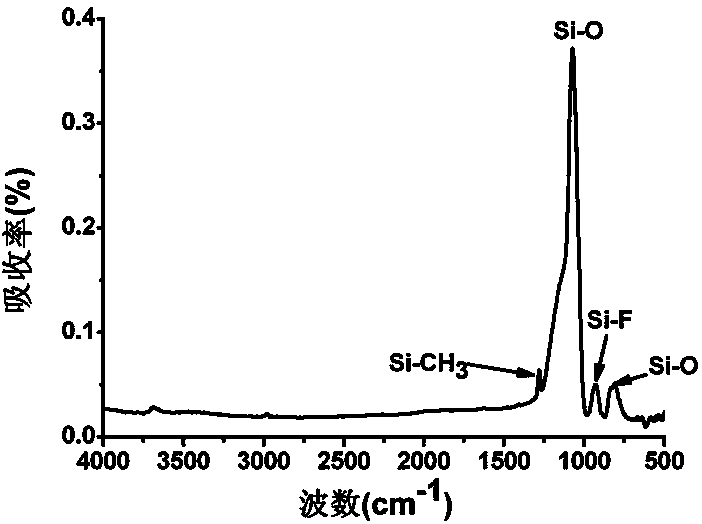

Thin film used for hole sealing of porous interconnection dielectric surface and preparing method of thin film

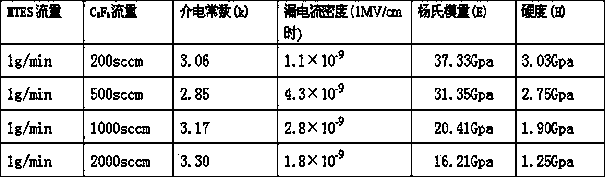

InactiveCN103956331AImprove uniformityEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesElectrical field strengthPorous medium

The invention belongs to the technical field of super-large-scale integrated circuits, and particularly relates to a method for preparing a material for hole sealing of a porous interconnection dielectric surface. An organic liquid state source MTES is taken as a liquid source and enters a cavity along with He carrier gas after being vaporized to be mixed with C2F6 gas, a plasma enhanced chemical vapor deposition (PECVD) process is adopted, and a thin film is deposited on the porous low-dielectric-constant interconnection dielectric surface. The dielectric constant of the thin film is 2.8-3.3, the order of magnitude of the leakage current density is 10-9 A / cm2 under the electric field strength of 1 MV / cm, the Young modulus is 16.21-37.33 GPa, and the hardness is 1.25-3.03 GPa. The thin film can be used for hole sealing of the porous interconnection dielectric surface in super-large-scale integrated circuit rear-end interconnection, and meanwhile performs the function of improving adhesion strength between a porous dielectric layer and a cap layer or a diffusion impervious layer.

Owner:FUDAN UNIV

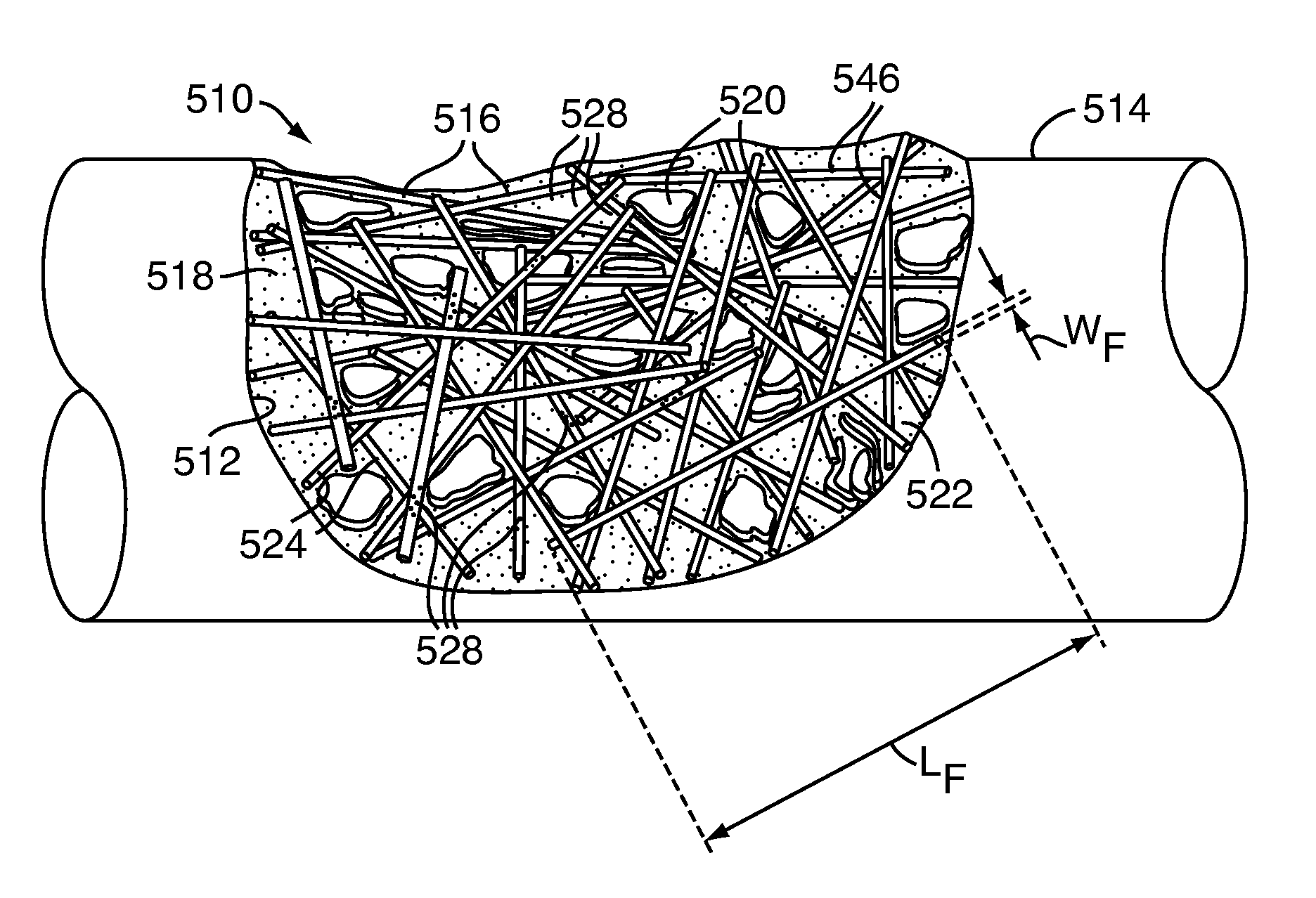

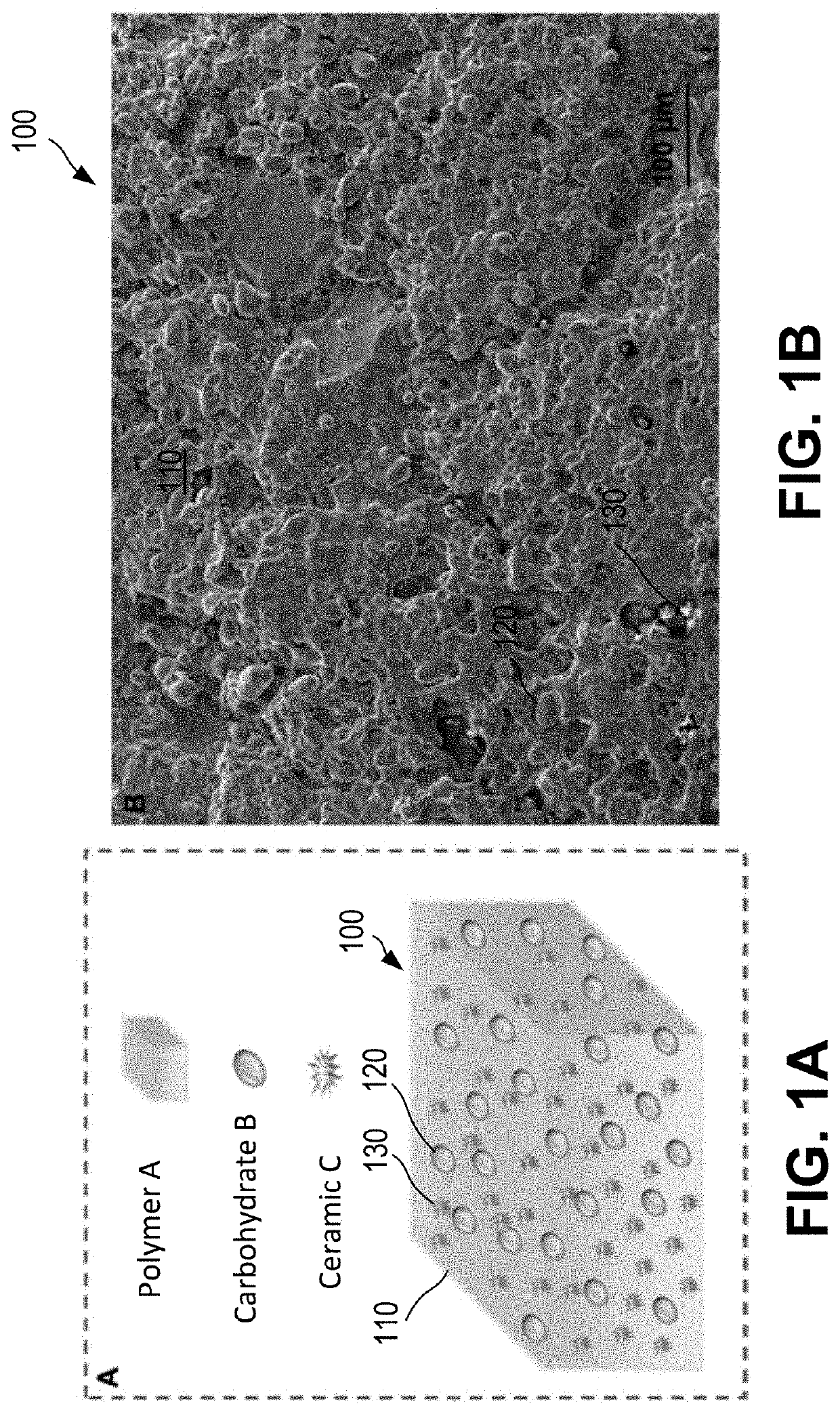

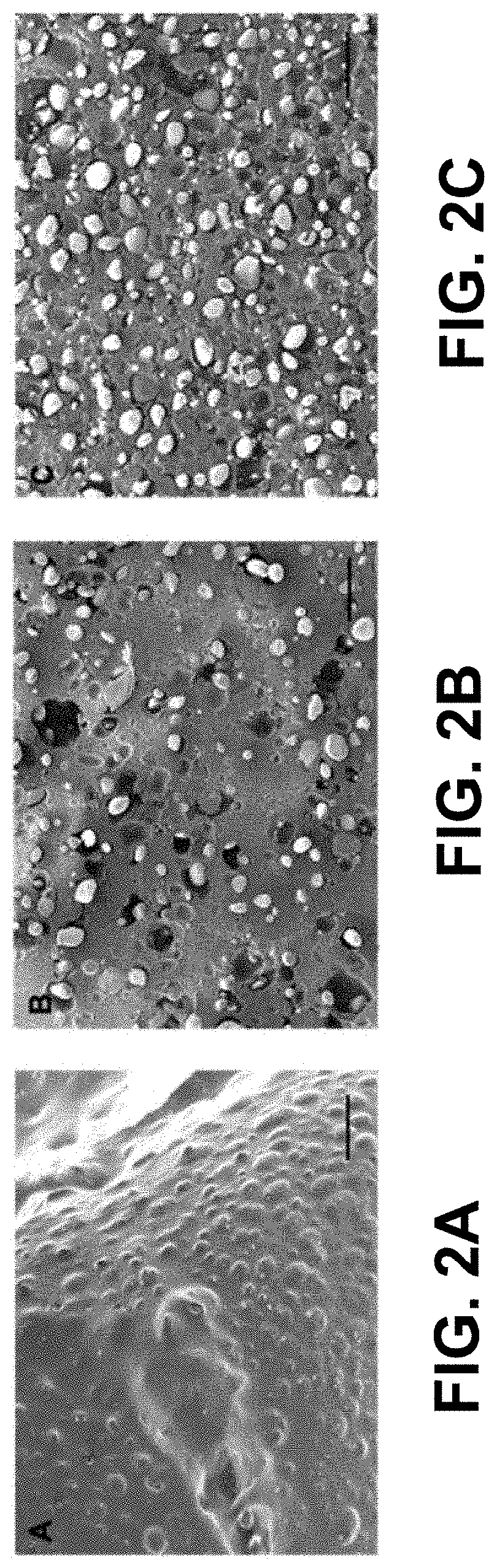

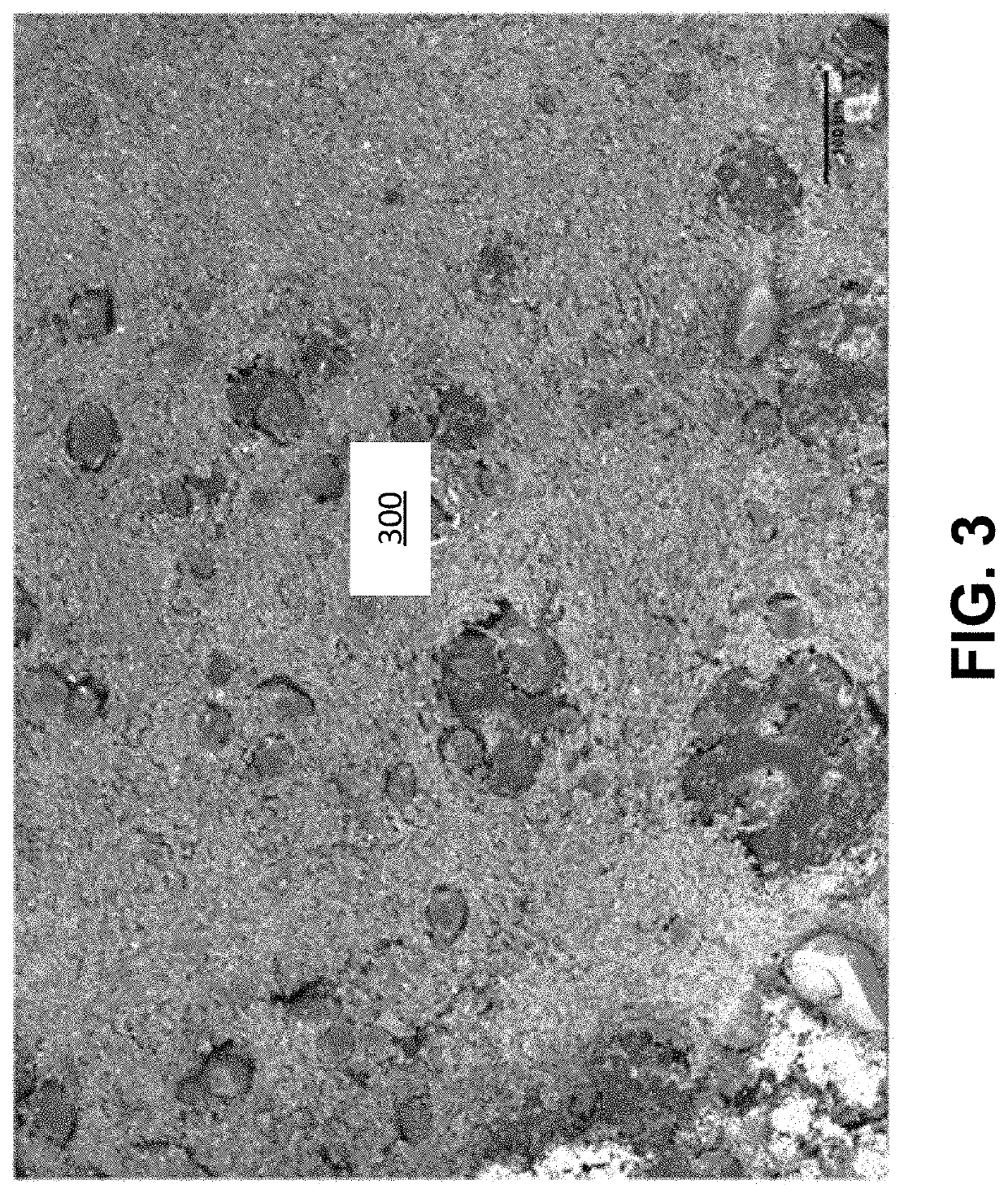

Bioresorbable implant with inside-out resorption for enhanced bone ingrowth and tissue integration and method of manufacturing thereof

PendingUS20210236693A1Easy to integratePromote osseointegrationTissue regenerationProsthesisOsteoblastBone ingrowth

Disclosed is a bioresorbable implant with enhanced bone ingrowth and tissue integration utilizing an inside-out resorption mechanism and a method to manufacture a bioresorbable implants for use in osteotomies and bone-soft tissue reconstruction surgeries. The bioresorbable implant includes a polymer A (e.g., an aliphatic polymer matrix) and / or poly(propylene fumarate)), a carbohydrate B (e.g., a bioresorbable natural carbohydrate filler) and a ceramic C. The implant may be a porous scaffold structures with suitable porosity, pore size, pore interconnectivity, and mechanical properties for enhanced osteoblast penetration and bone formation to fabricate tissue integrating bioresorbable implants. The implant may be shaped as wedges, bone void fillers, and soft tissue fixation implant like screws, rods and / or anchors. In some embodiments, the implant may be a putty.

Owner:SDIP INNOVATIONS PTY LTD

Shape memory bone repairing stent and preparation method thereof

InactiveCN110025831AExcellent shape memory performanceReduce the risk of disconnectionPharmaceutical delivery mechanismTissue regenerationManufacturing technologyMass ratio

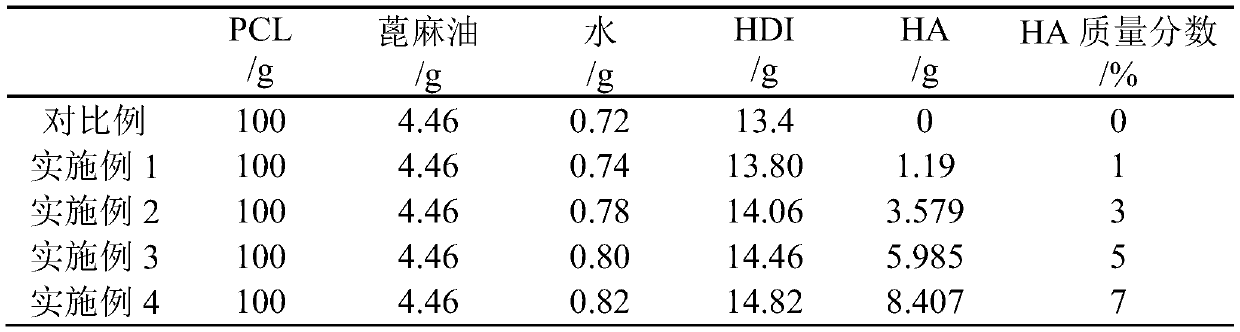

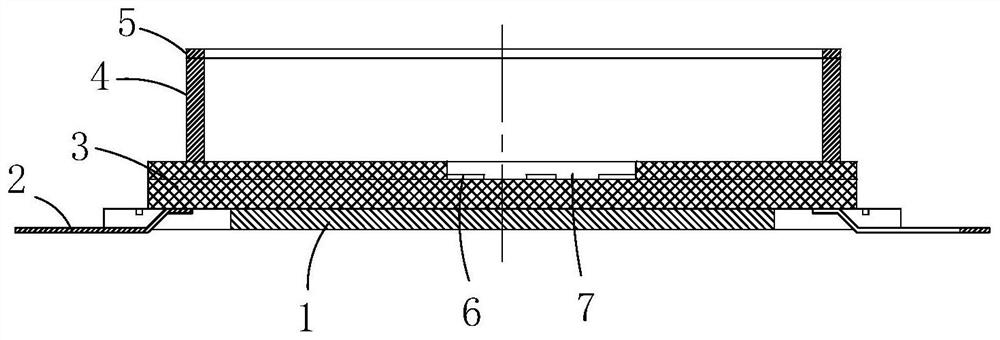

The present invention discloses a shape memory bone repairing stent for bone defect repair. The shape memory bone repairing stent comprises the following raw materials: HA, HDI, castor oil, PCL and water, wherein mass of the HA mass is 1%-7% of a total mass of the shape memory bone repairing stent raw materials, a sum mass of the HA, the HDI and the castor oil is 17-35% of the total mass of the raw materials, a mass ratio of the castor oil, the HA to the PCL is (4.46-6):(1.1-8.4):100; a mass ratio of the water to the HDI is 1:(18-19); and the shape memory bone repairing stent has a pore diameter of 534 [mu]m-797 [mu]m, a porosity is 50%-60%, and pore interconnectivity is 95%-99%. The shape memory bone repairing stent is prepared by using a pre-polymer foaming method, has pore structure andmechanical properties similar to bone tissues, at the same time has high shape memory property, biocompatibility and biodegradability, is not limited to mold shapes, manufacturing technology and bonedefect shapes, can be highly compatible with bone defect sites, and promotes formations of new bones and new blood vessels.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

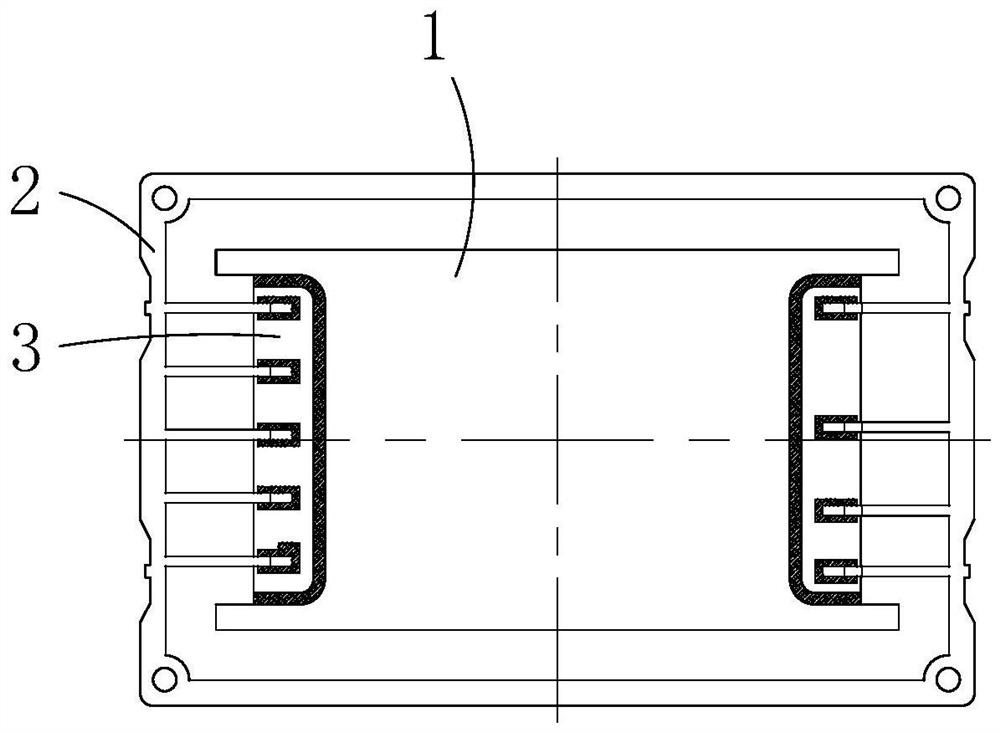

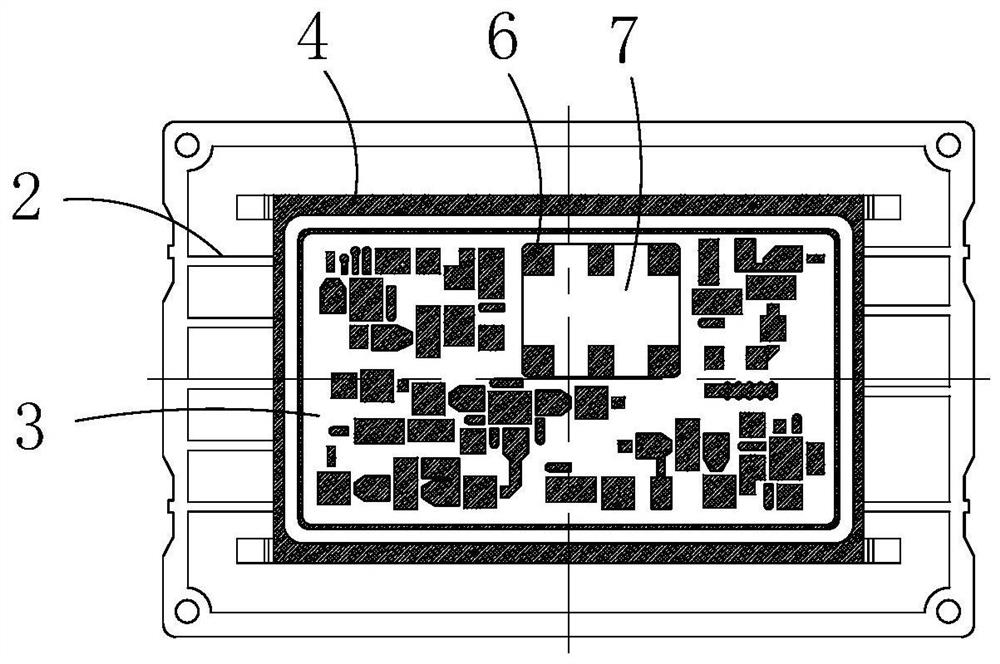

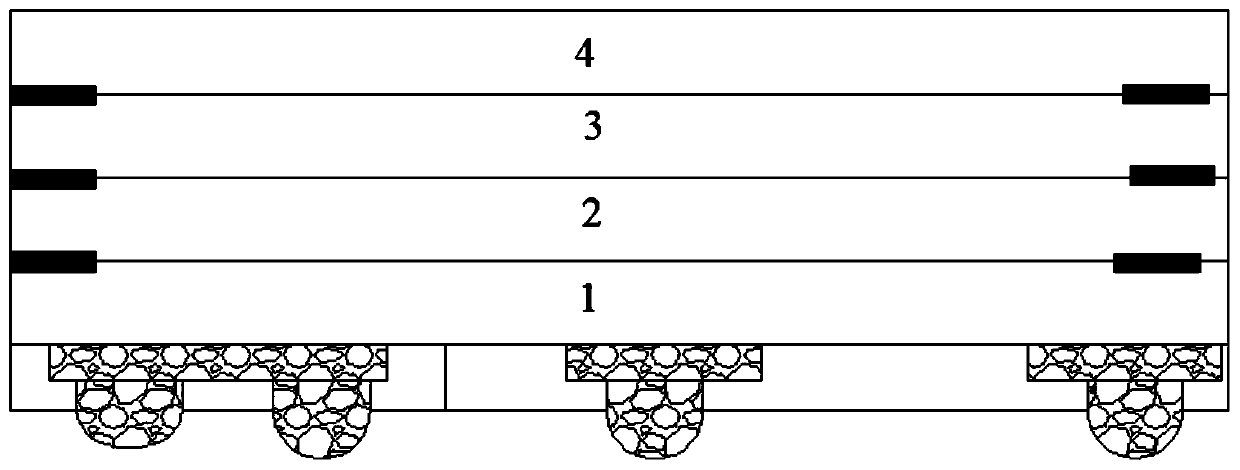

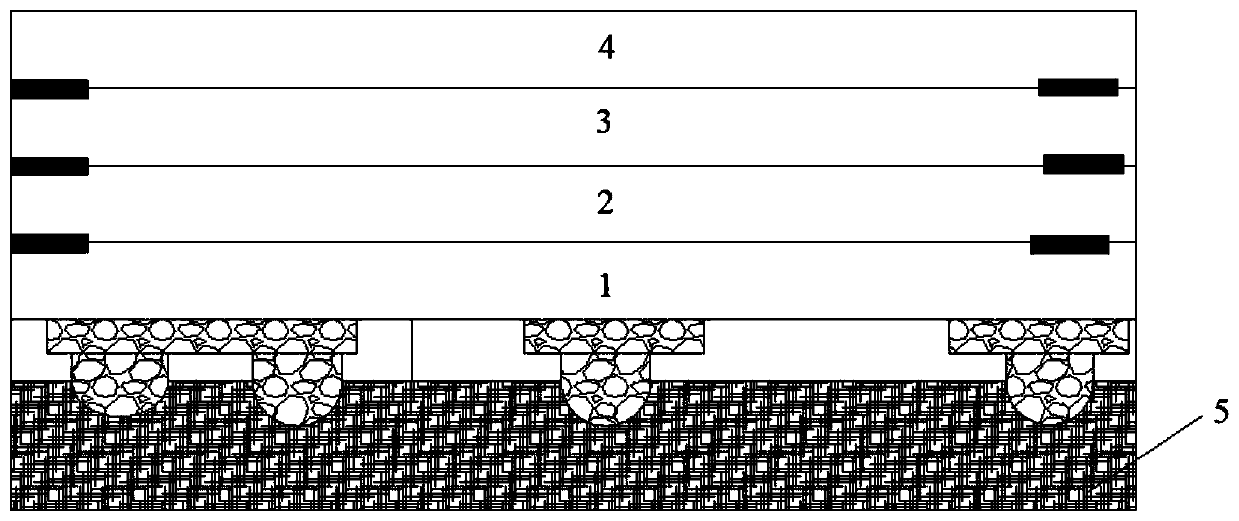

CSOP type ceramic shell, amplification filter and manufacturing method

PendingCN114050130AImprove air tightnessImprove toleranceImpedence networksSemiconductor/solid-state device detailsLead frameCo-fired ceramic

The invention provides a CSOP type ceramic shell, an amplification filter and a manufacturing method, and belongs to the technical field of ceramic packaging, the CSOP type ceramic shell comprises a ceramic substrate, a metal wall body, a metal chassis and a lead frame; the ceramic substrate is provided with interconnection holes, and metal tungsten columns are arranged in the interconnection holes; the metal wall body is arranged on the front surface of the ceramic substrate and forms a packaging cavity with the ceramic substrate; the metal chassis is arranged on the back surface of the ceramic substrate; the lead frame is connected to the back surface of the ceramic substrate and is connected with the metal tungsten columns; the ceramic substrate is made of aluminum oxide high-temperature co-fired ceramic. According to the CSOP type ceramic shell provided by the embodiment of the invention, the high-temperature co-fired ceramic is adopted to replace low-temperature co-fired ceramic, the high-temperature co-fired ceramic substrate and the lead frame are welded together during welding, and then the ceramic substrate, the metal chassis and the metal wall body are welded together by adopting the high-temperature welding flux, so that the processing cost and the processing difficulty are reduced; and the requirements of high-density wiring, batch, miniaturization, low cost, high reliability of an assembly process and the like can be met.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Preparation method of silicon through hole interconnection structure

InactiveCN110648963AAchieve conductionImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineering physicsMaterials science

Owner:NAT CENT FOR ADVANCED PACKAGING

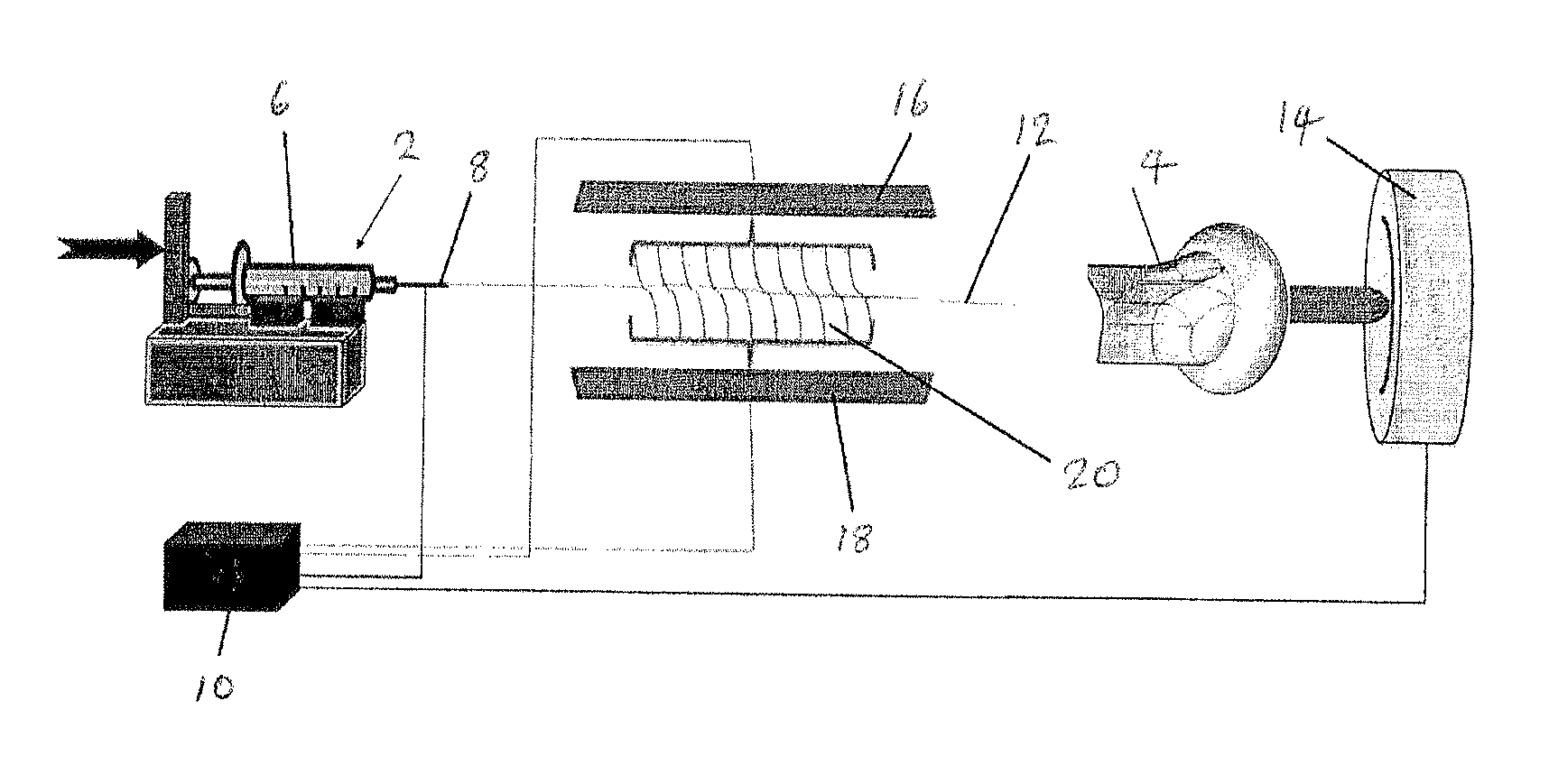

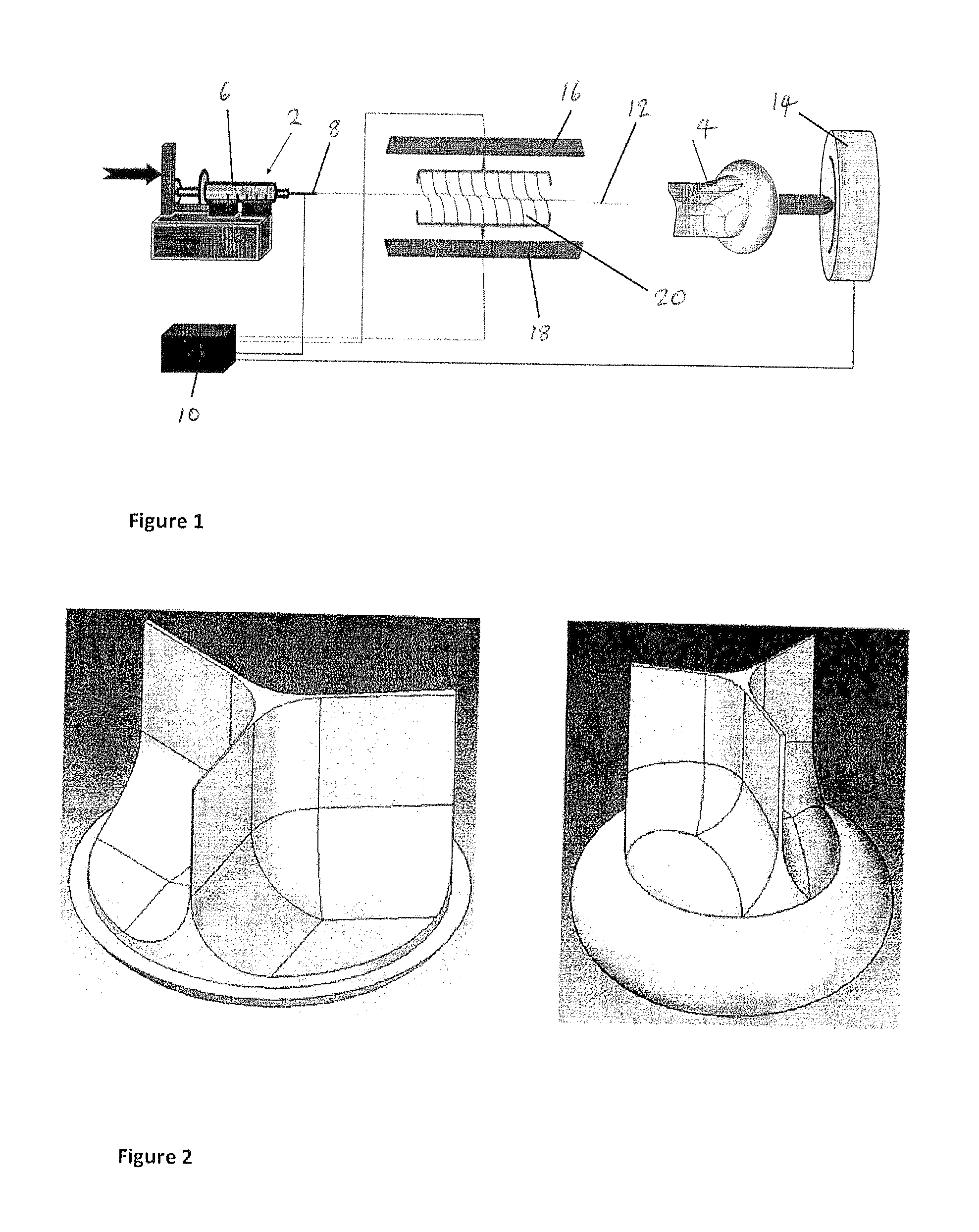

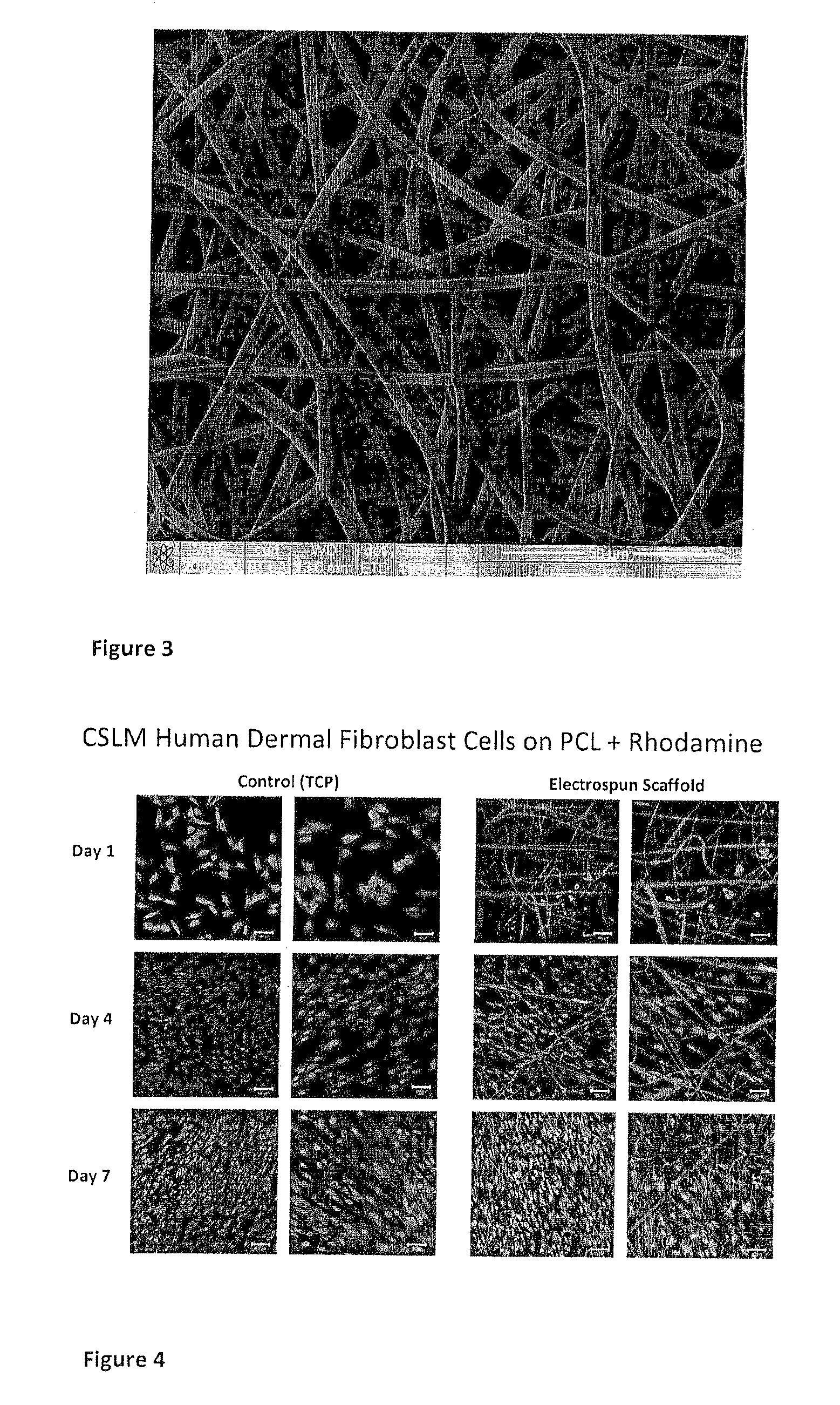

Method of forming a tissue scaffold

ActiveUS9463082B2Function increaseIncreasing cell adhesion and attachment and migration and proliferationHeart valvesLayered productsFiberElectrospinning

A process of forming a tissue scaffold is described, the process comprising electrospinning polymer fibers from a spinneret onto a tissue scaffold template. In embodiments, the fibers are plasma-treated between the spinneret and the template. The scaffold may be constructed of alternating layers of aligned and randomly oriented fibers. The scaffold may be heat treated to control the mechanical properties of the scaffold, such as density, pore size and pore interconnectivity.

Owner:UNIVERSITY OF ULSTER

Polymeric bone defect filler

ActiveUS20110201711A1High mechanical strengthImprove interconnectivityBone implantTissue regenerationParticulatesBone defect

A bone defect filler for implantation in a bone defect of a patient includes a particulate polymer distributed within a polymeric binder. The particulate polymer includes a plurality of particles, which may have substantially the same material composition as the polymeric binder. The particles of the particulate polymer may be formed in a variety of shapes and / or sizes to provide the bone defect filler with improved pore interconnectivity, material expansion and contamination characteristics, while maintaining sufficient mechanical strength and handling characteristics for bone repair applications. The bone defect filler also provides the flexibility to be molded or shaped in situ to fill the bone defect.

Owner:DOCTORS RES GROUP

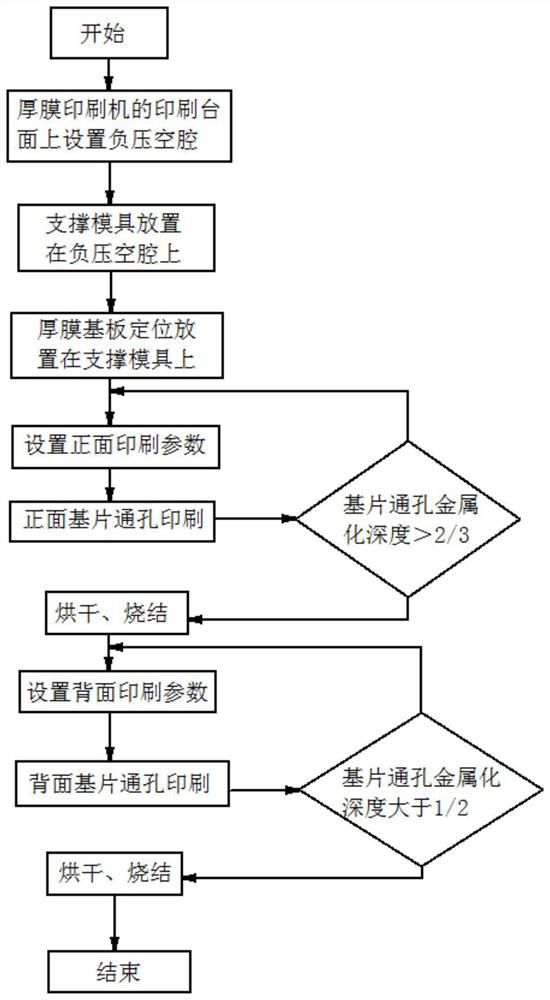

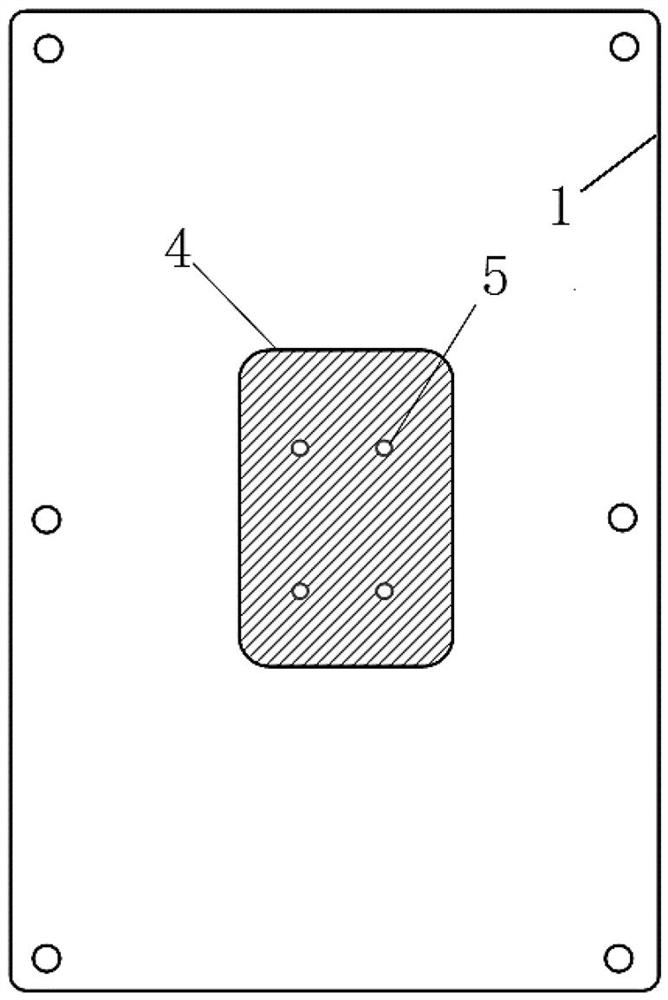

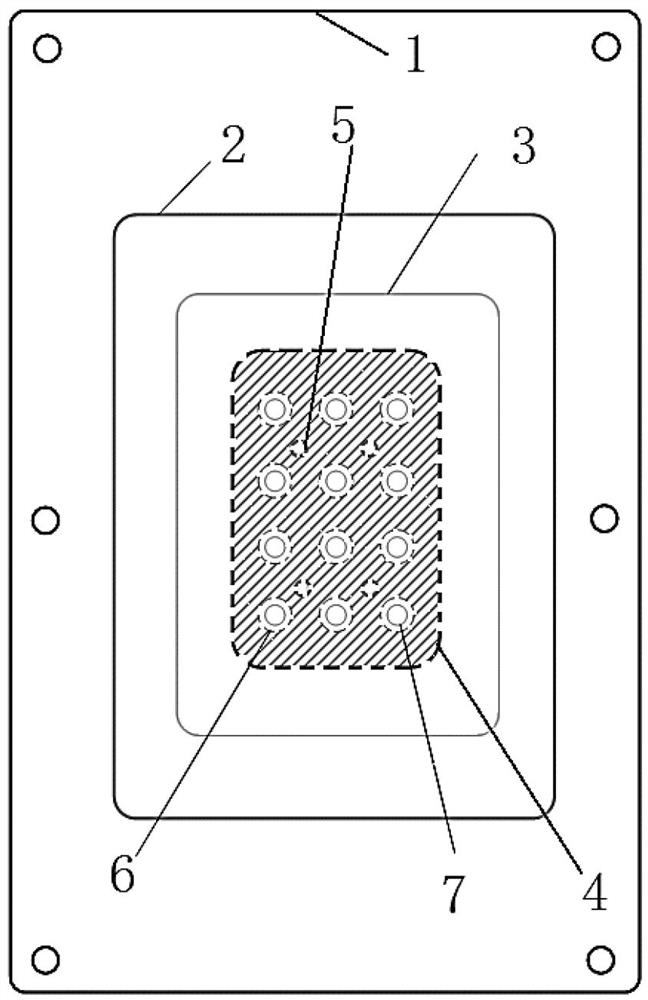

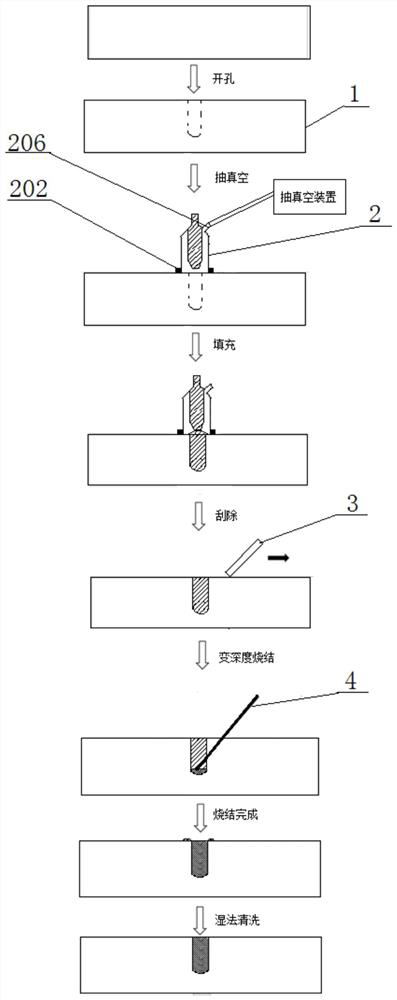

Method for realizing interconnection of front and back surface patterns of thick film substrate

PendingCN113643985AImprove interconnect performanceInterconnection consolidationSemiconductor/solid-state device manufacturingOther printing apparatusSurface patternPrinting press

The invention provides a method for realizing interconnection of front and back surface patterns of a thick film substrate. Interconnection through holes can be manufactured through a common printing machine, through hole interconnection is achieved while the patterns on the front surface and the back surface of the thick film substrate are manufactured, and the production efficiency can be improved. According to the invention, the substrate through holes on the front and back surfaces of the thick film substrate are respectively printed; and the interconnection of the metalized positive and negative lines on the side wall of the substrate through holes is consolidated, and the interconnectivity between the metalized positive and negative lines on the side wall of the substrate through holes is improved. Meanwhile, a process platform is built for manufacturing other through hole interconnection substrates, the method can be quickly and effectively popularized to other products by replacing a supporting mold, and good practicability and an economic value are achieved.

Owner:XIAN MICROELECTRONICS TECH INST

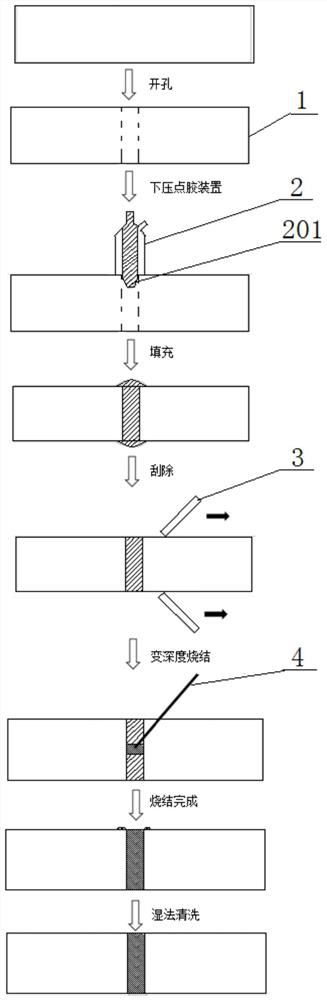

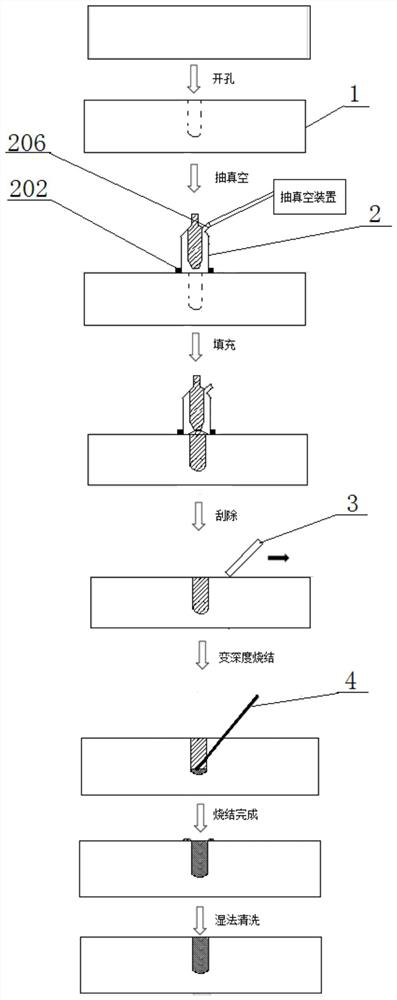

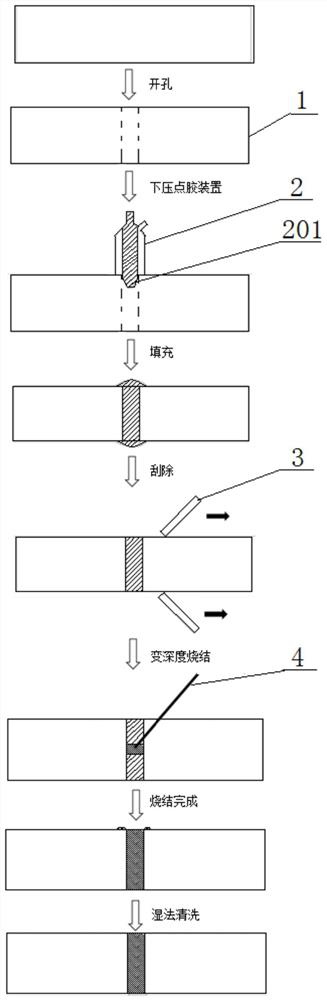

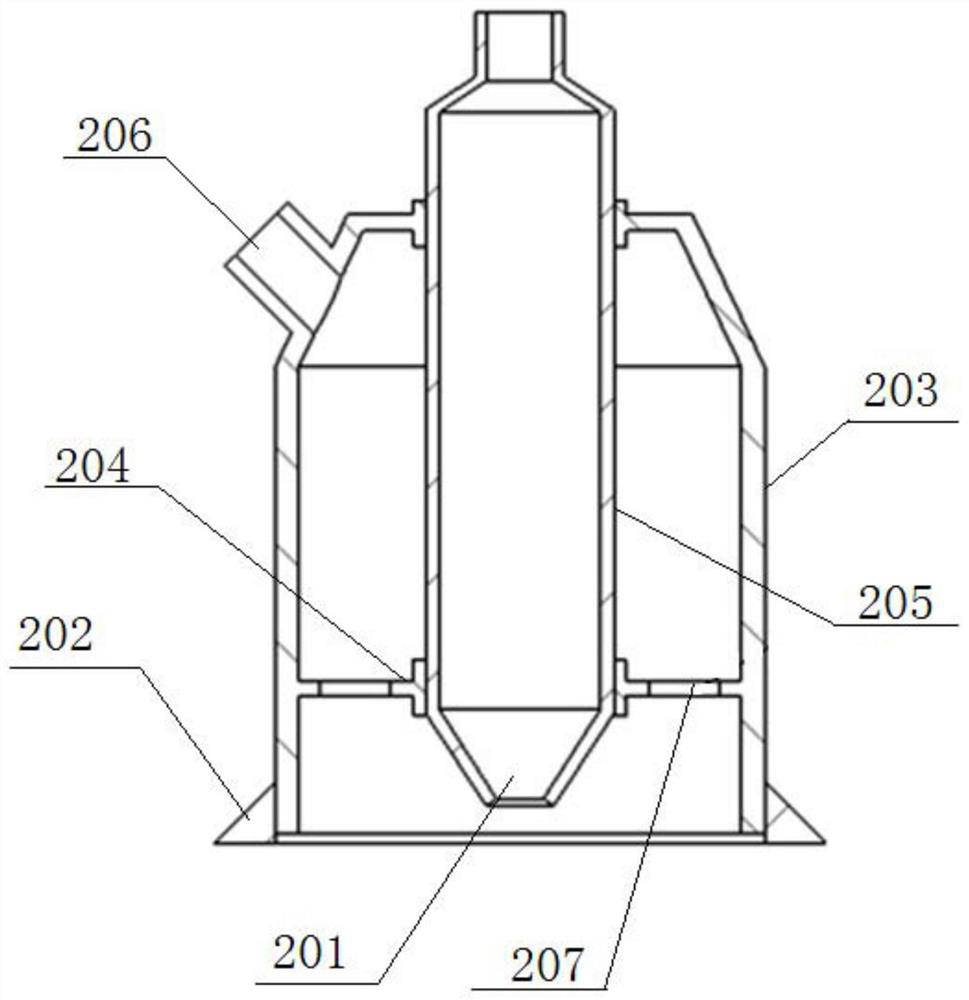

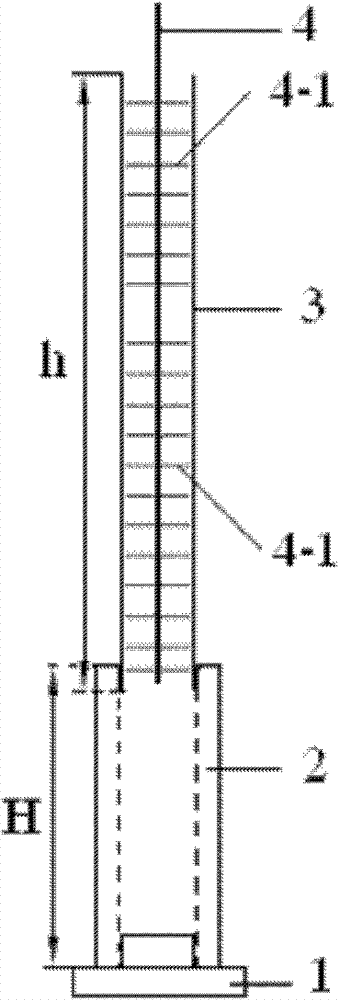

Preparation method of deep hole interconnection structure based on nano-metal

ActiveCN112786531AAvoid pollutionSemiconductor/solid-state device manufacturingNanotechnologyElectrical conductorMetallurgy

The invention discloses a preparation method of a deep hole interconnection structure based on nano-metal. The preparation method comprises the following steps: firstly, forming a deep hole in a glass plate on which the deep hole interconnection structure is to be formed; filling the deep hole with the nano metal paste through a dispensing device; after filling is completed, scrapping off residual nano metal particles overflowing from the surface of the glass plate; then carrying out variable-depth sintering forming on the filled nano metal; and finally, carrying out wet cleaning on the glass plate to remove residual nano metal particles, thereby completing the preparation of the deep hole interconnection structure on the glass plate. According to the invention, the deep hole is filled with the nano-metal, then the deep hole interconnected conductor structure is formed through sintering, a copper electroplating mode does not need to be adopted, and pollution to the environment is avoided.

Owner:GUANGDONG UNIV OF TECH

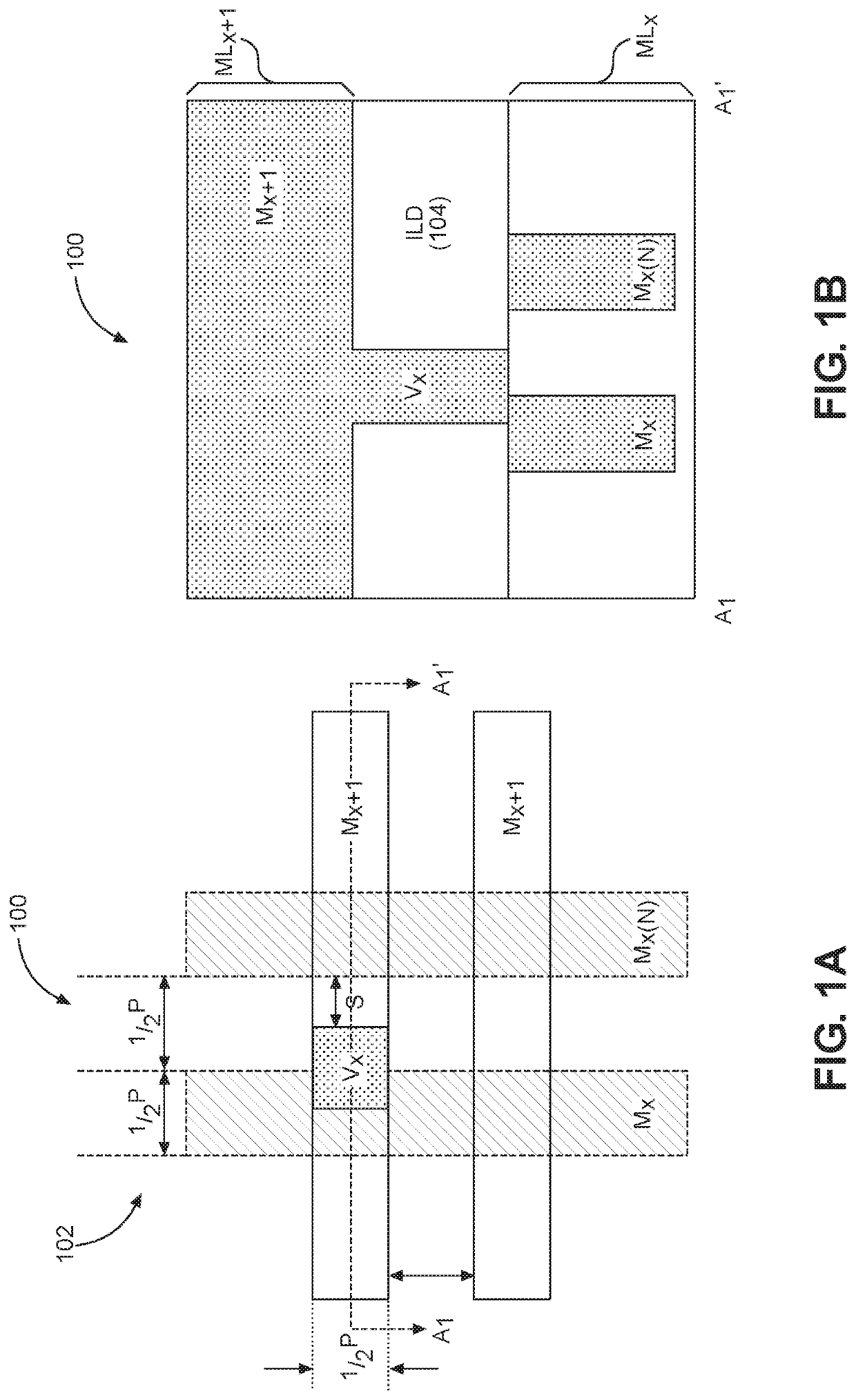

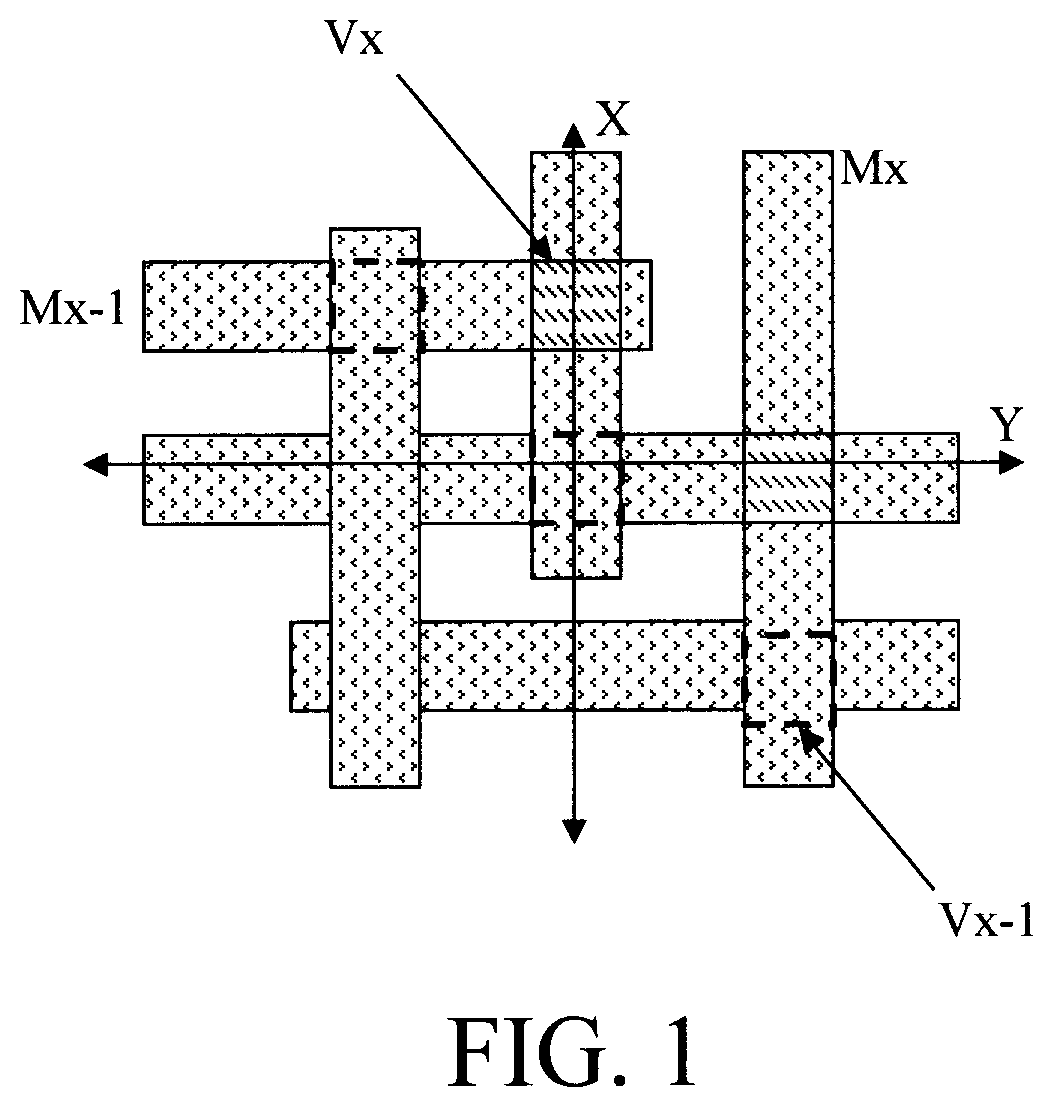

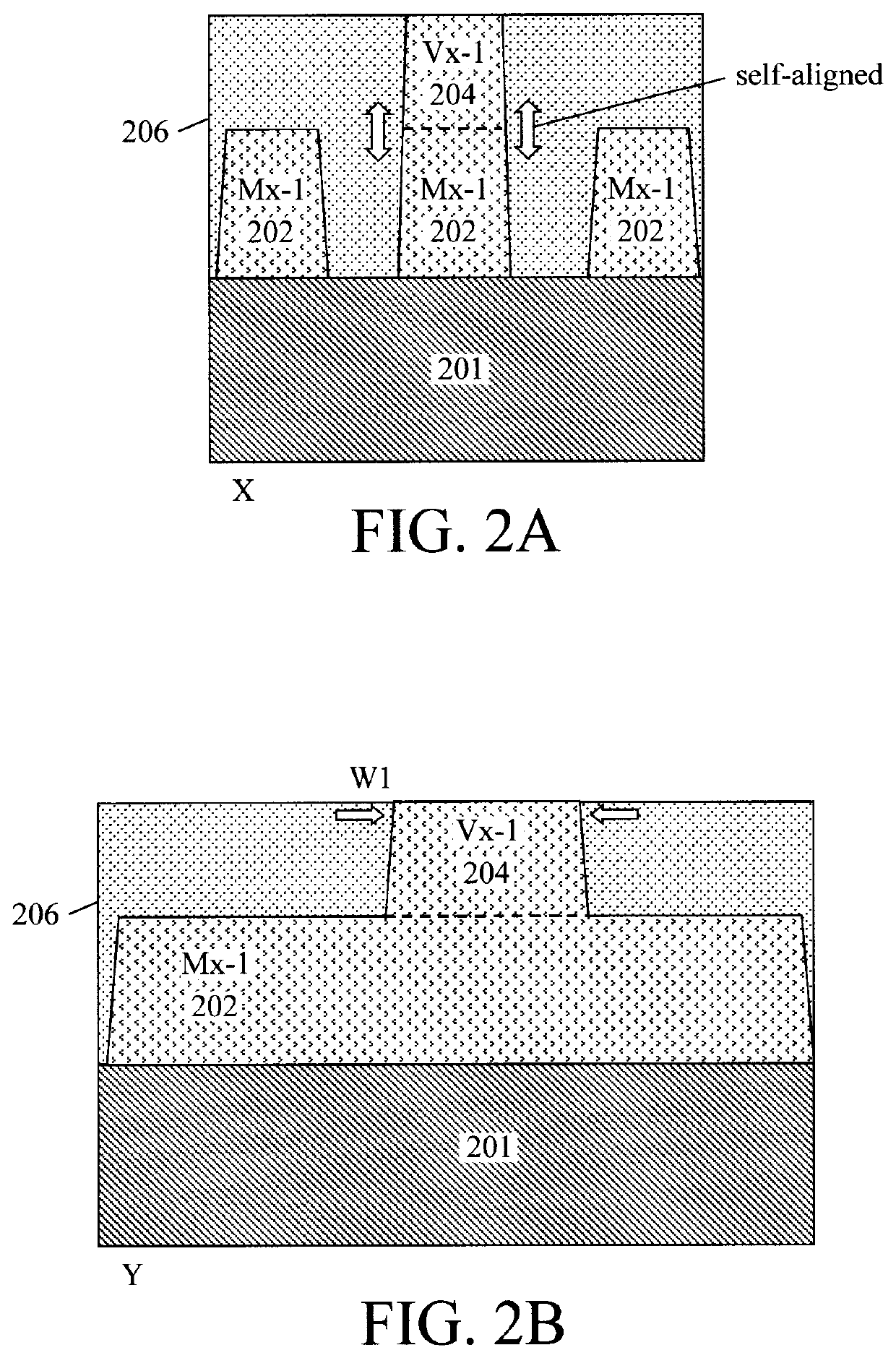

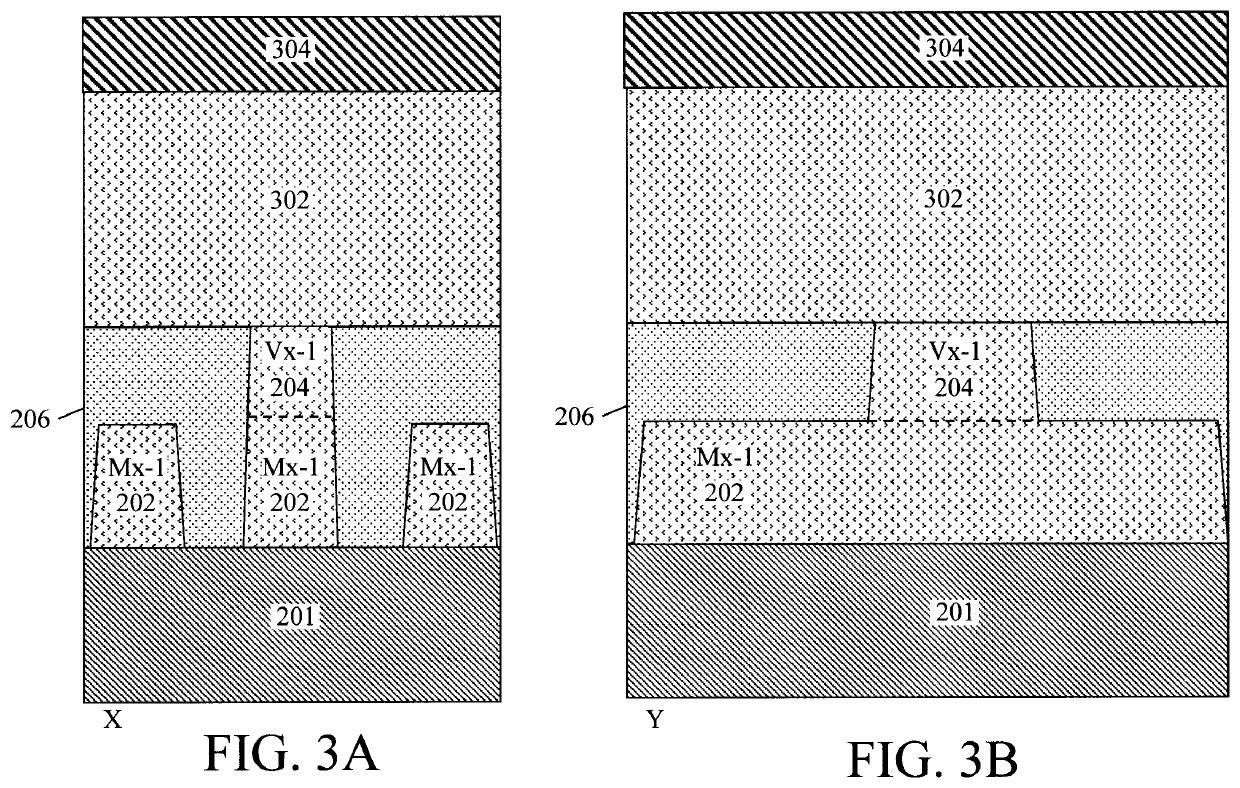

Fully aligned via for interconnect

ActiveUS11495538B2Semiconductor/solid-state device detailsSolid-state devicesMechanical engineeringAtomic physics

A fully aligned via interconnect structure and techniques for formation thereof using subtractive metal patterning are provided. In one aspect, an interconnect structure includes: metal lines Mx−1; metal lines Mx disposed over the metal lines Mx−1; and at least one via Vx−1 fully aligned between the metal lines Mx−1 and the metal lines Mx, wherein a top surface of at least one of the metal lines Mx−1 has a stepped profile. In another aspect, another interconnect structure includes: metal lines Mx−1; metal lines Mx disposed over the metal lines Mx−1; at least one via Vx−1 fully aligned between the metal lines Mx−1 and the metal lines Mx; and sidewall spacers alongside the metal lines Mx. A method of forming an interconnect structure is also provided.

Owner:INT BUSINESS MASCH CORP

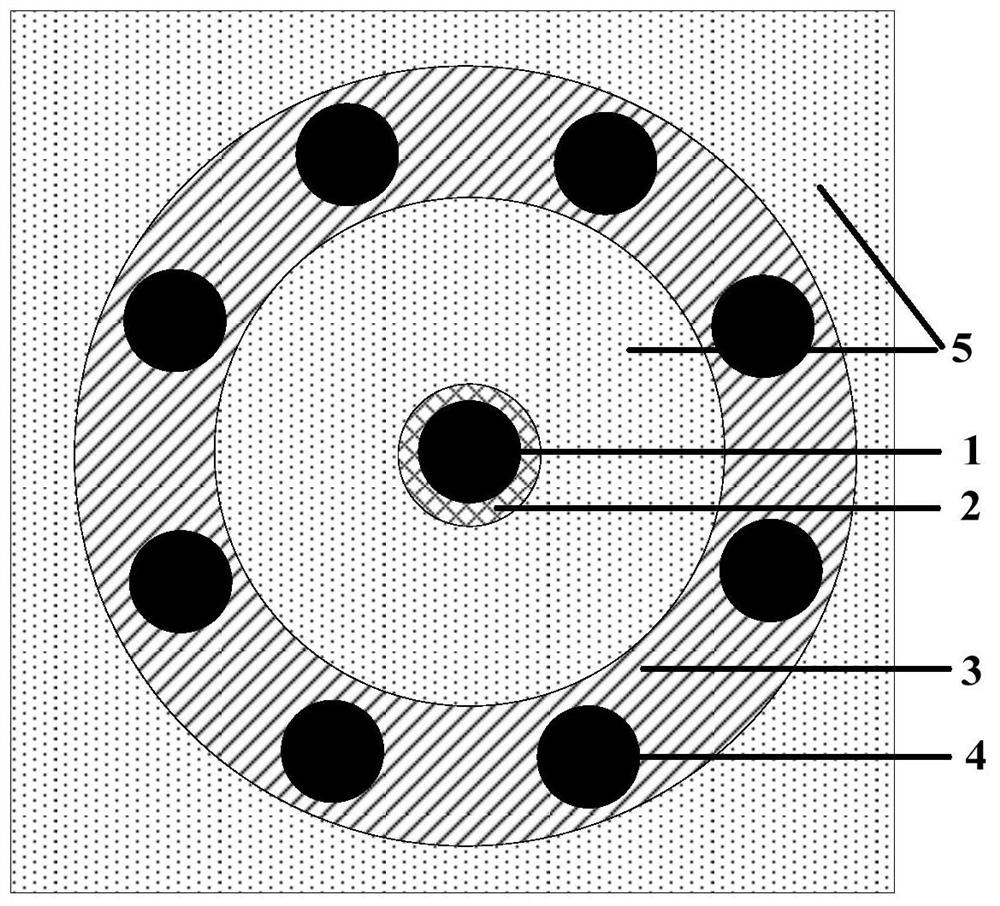

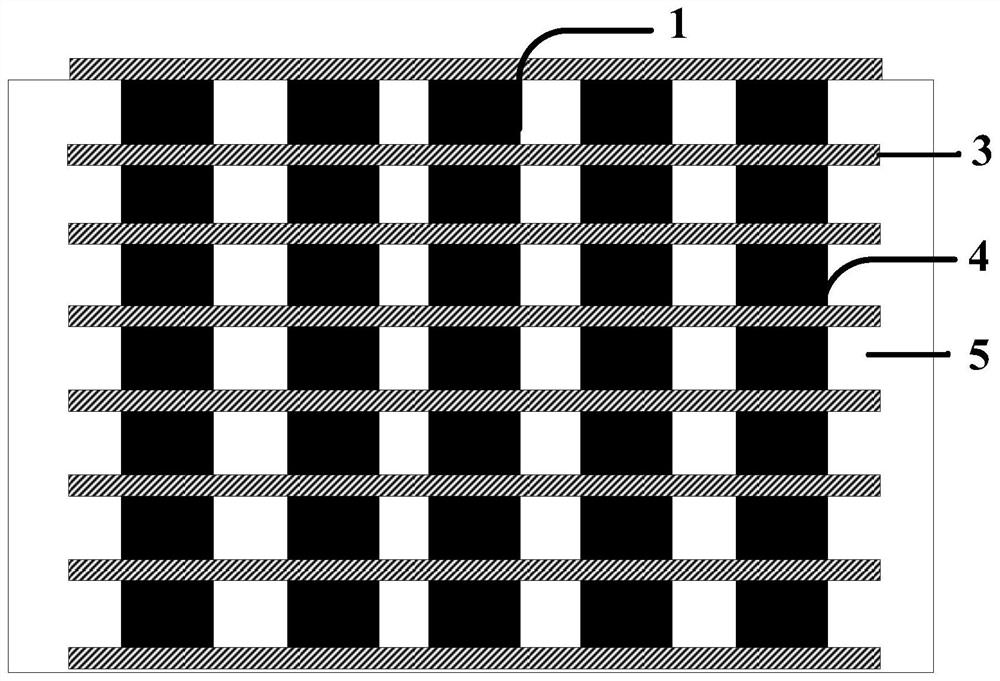

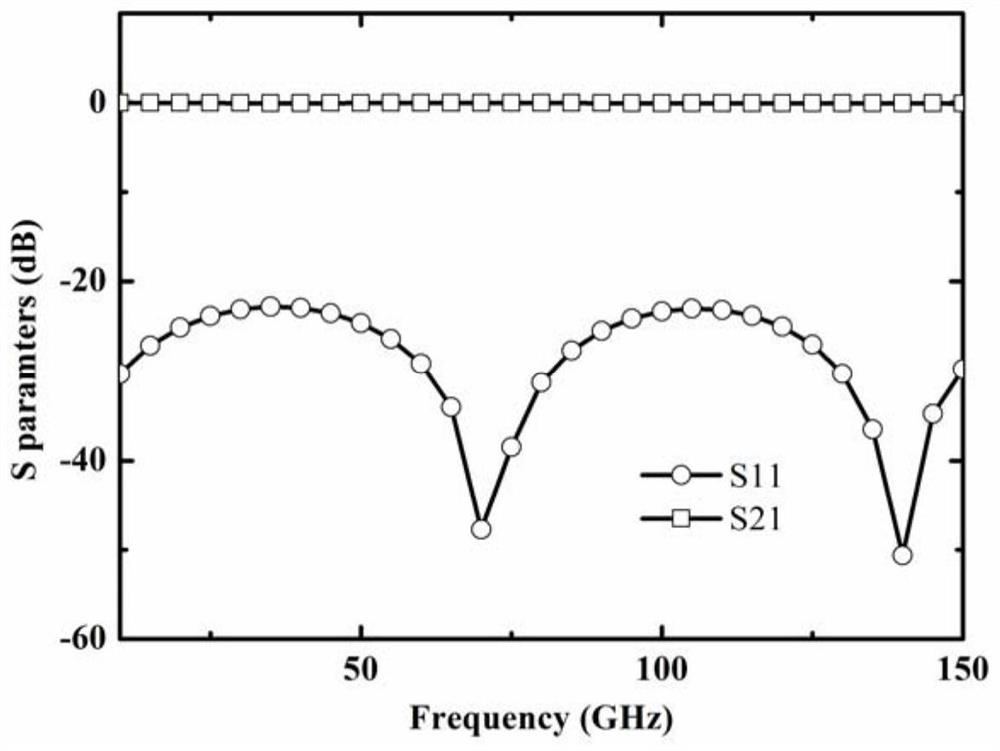

Design and manufacture method of millimeter wave 3D coaxial transmission line

ActiveCN108258379BMany design parametersGuaranteed positioning accuracyWaveguidesElectrical conductorEngineering

The invention provides a millimeter wave 3D coaxial transmission line design and manufacturing method based on the LTCC technology. The LTCC technology is the multilayer wiring and stereoscopic interconnection technology and can realize sintering of 100 layers of ceramic wafers. The low-loss Ferro A6M ceramic material in the millimeter wave band is used as the wafer, the through holes of great collimation and morphology are processed on the single layer wafer by using the laser process, high-precision alignment is performed on multiple through holes by using the laser alignment technology, andmultiple single layer through holes filled with metal paste are interconnected by using a circular protection welding pad and superposed into long through holes of the required height. The peripherallong through holes are interconnected by using an annular protection welding pad, and the long through holes form a mesh structure through enclosing to act as an external conductor so as to constructthe 3D structure millimeter wave coaxial transmission line. The simulation result indicates that the novel high-reliability coaxial transmission line can work to 300 GHz.

Owner:SHANGHAI PRECISION METROLOGY & TEST RES INST +1

A preparation method of deep hole interconnection structure based on nanometer metal

ActiveCN112786531BAvoid pollutionSemiconductor/solid-state device manufacturingNanotechnologyElectrical conductorGlass sheet

The invention discloses a method for preparing a deep-hole interconnection structure based on nanometer metal. Firstly, a deep hole is formed on a glass plate to be formed with a deep-hole interconnection structure; After the completion, scrape off the residual nano-metal particles overflowing from the surface of the glass plate; then carry out variable-depth sintering on the filled nano-metal; The joint structure is prepared. In the present invention, the deep holes are filled with nanometer metals, and then sintered to form a conductor structure interconnected in the deep holes, without the need for electroplating copper, thereby avoiding environmental pollution.

Owner:GUANGDONG UNIV OF TECH

Preparation method of nickel titanium foam alloy with double pore structure

A preparation method of a nickel titanium foam alloy with a double pore structure relates to a preparation method of a nickel titanium foam alloy. The invention solves the problems that the existing nickel titanium foam alloy used for the replacement and repair of the bone tissue has low pore interconnectivity and uneven pore distribution. The method comprises the following steps: respectively weighting several parts of nickel powder, titanium powder, large-particle sodium chloride and small-particle sodium chloride, evenly spreading large-particle sodium chloride and the mixed powder of nickel powder, titanium powder and small-particle sodium chloride in a mould in a laminated mode successively, and then performing cold compressing and forming, cold isostatic pressing, hot pressing sintering and homogenizing treatment in turn. The porosity of the nickel titanium foam alloy is 59.17%-71.71%; and the elastic modulus of the alloy is effectively reduced, which is close to the modulus of the bone tissue. The pore distribution is uniform, and small pores are distributed around large pores to ensure that the large pores are connected to form interconnected pores. By adopting the nickel titanium foam alloy, the bone tissue is controlled to only grow in the large pores; and the nickel titanium foam alloy can be used as the material used for the replacement and repair of the bone tissue.

Owner:HARBIN INST OF TECH

Metallization stack, method of making same, and electronic device including metallization stack

ActiveCN110970379BAvoid stuffing puzzlesReduce line widthSemiconductor/solid-state device detailsSolid-state devicesEngineeringCondensed matter physics

A metallization stack, a method of making the same, and an electronic device including the metallization stack are disclosed. According to an embodiment, the metallization stack may include at least one interconnect layer and at least one via layer alternately arranged on the substrate. At least one pair of adjacent interconnect and via layers in the metallization stack includes interconnect lines in the interconnect layer and vias in the via layer. The interconnect layer is closer to the substrate than the via layer. The peripheral sidewall of the via on at least a portion of the interconnect line does not extend beyond the peripheral sidewall of the at least one portion of the interconnect line.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Blind-buried hole interconnecting structure and processing method therefor

InactiveCN105636354AReduce manufacturing difficultyReduce manufacturing costPrinted circuit aspectsElectrical connection printed elementsEngineeringInterconnection

The invention discloses a blind-buried hole interconnecting structure and a processing method therefor. Laser blind hole and mechanical buried hole interconnection is adopted to replace the conventional mechanical through hole, so that the alignment requirement of layers of a circuit board part is lowered, and the manufacturing difficulty is lowered; a high aspect ratio of a deep through hole is converted to a low aspect ratio of a mechanical buried hole; the buried hole in an inner layer core plate and the blind hole in a side plate are subjected to metallization processing in different steps; the metallization process is simple, and the thickness controllability is high, so that the technical problem that the center of a deep hole cannot be metalized is solved; the technical problem of high reliability test risk caused by insufficient metallization thickness of the deep through hole is solved consequently; the yield is improved and the product quality is ensured; the technical problem that the flexible design specific to a circuit board cannot be realized caused by limitation of the conventional mechanical through hole is solved; therefore, the production cost is lowered and the production efficiency is improved; the processing method is suitable for processing various circuit boards greater than or equal to 3L needing to be conducted through the mechanical through holes; and the processing method particularly has obvious advantages in processing of deep through hole circuit boards with the aspect ratio of greater than 10:1.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com