Polyolefin resin porous film

A polyolefin-based resin and porous film technology, which is applied in the direction of separators/films/diaphragms/spacers, structural parts, battery pack parts, etc., can solve the problem of coatings that cannot be coated in a thick thickness and do not meet the requirements of coating adaptation Sex and other issues, to achieve the effect of full battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

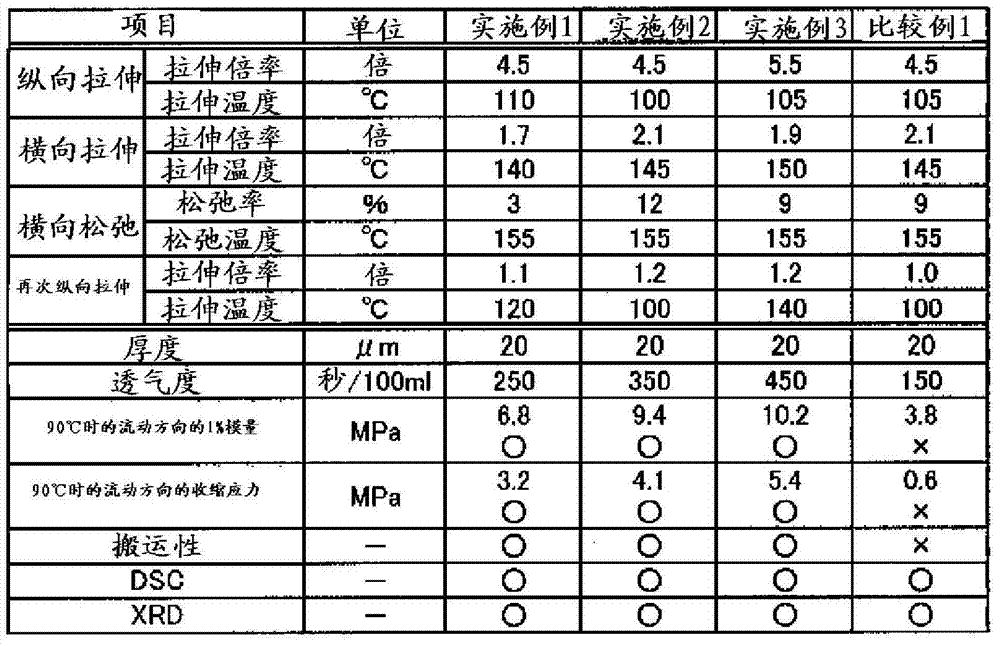

[0144] Examples and comparative examples are shown below, and the polyolefin-based resin porous film of the present invention will be described in detail, but the present invention is not limited to these examples.

[0145] The obtained polyolefin-based resin porous membrane was measured and evaluated for various characteristics as follows, and the results are summarized in Table 1.

[0146] (1) Thickness

[0147] The measurement was performed at 10 positions in an unspecified plane with a dial gauge of 1 / 1000 mm, and the average value was taken as the thickness.

[0148] (2) Air permeability

[0149] The air permeability (sec / 100ml) was measured in a 20°C environment based on JIS P8117.

[0150] (3) 1% modulus in flow direction at 90°C

[0151] Based on JIS K7127, the tensile force at 1% elongation in the flow direction at 90°C was measured, and the 1% modulus in the flow direction at 90°C was calculated based on the following formula. In addition, the results of evaluati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage stress | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com