Secondary battery

A secondary battery and current collector technology, applied in secondary batteries, battery electrodes, lithium batteries, etc., can solve problems such as battery characteristic degradation, silicon deformation, peeling or micronization, and achieve high capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0042] In this embodiment, an electrolyte and a solvent used for a negative electrode and an electrolytic solution of a secondary battery according to one embodiment of the present invention will be described. In addition, a method for producing the negative electrode will be described.

[0043] (Structure of negative electrode)

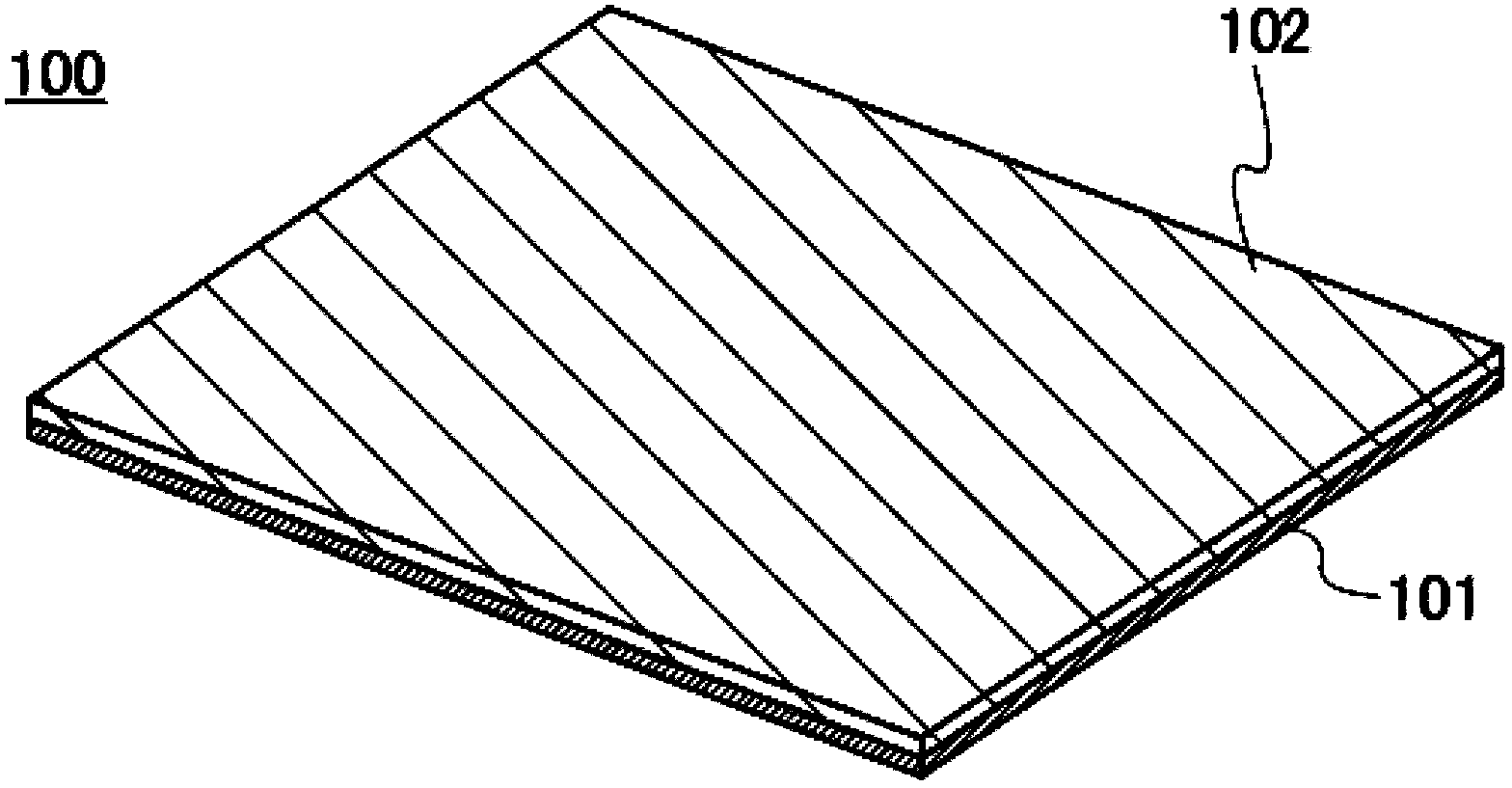

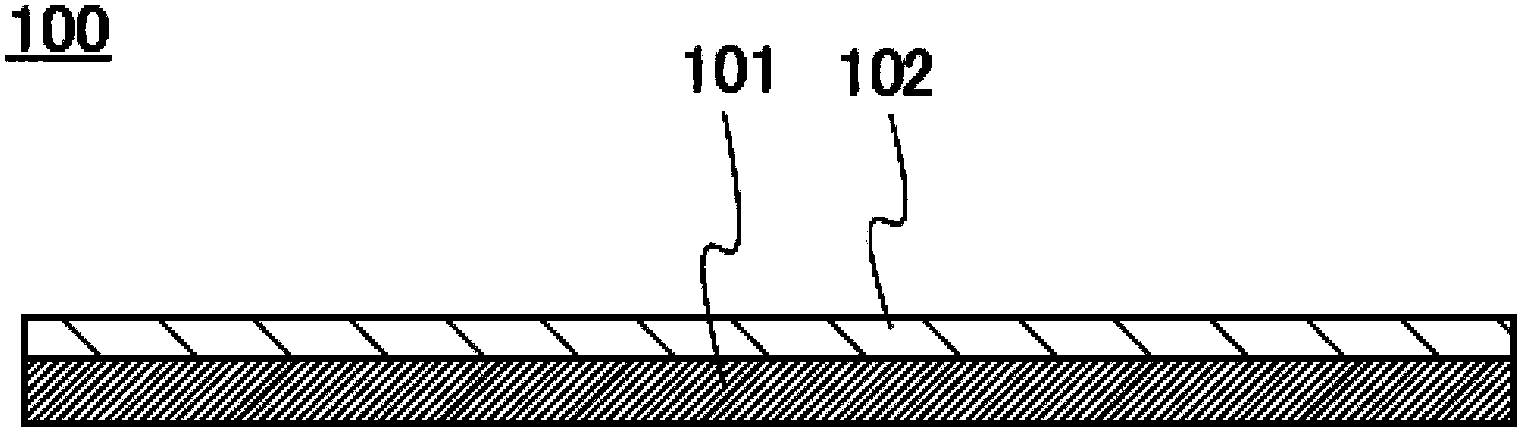

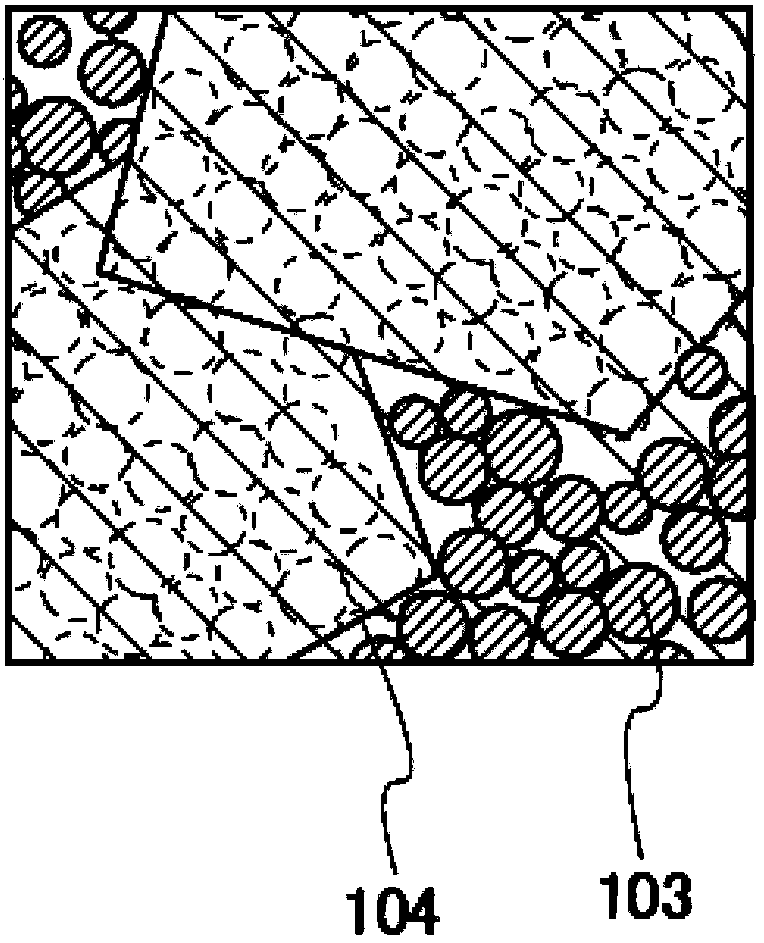

[0044] Figure 1A is a graph looking down on the negative pole, and Figure 1B It is a figure which shows the cross section in the thickness direction of a negative electrode. The negative electrode 100 has a structure in which a negative electrode active material layer 102 is provided on a negative electrode current collector 101 . In addition, although the negative electrode active material layer 102 is provided on only one surface of the negative electrode current collector 101 in the drawings, the negative electrode active material layer 102 may be provided on both surfaces of the negative electrode current collector 101 .

[0045] As the neg...

Embodiment approach 2

[0086] In this embodiment, refer to Figure 2A and 2B as well as Figure 3A and 3B The structure of the secondary battery will be described.

[0087] (Coin type secondary battery)

[0088] Figure 2A This is an external view of a coin-type (single-layer flat type) secondary battery, and partially shows its cross-sectional structure.

[0089] In the coin-type secondary battery 200, a positive electrode can 201 serving as a positive terminal and a negative electrode can 202 serving as a negative terminal are insulated by using a gasket 203 formed of polypropylene or the like. and sealed. The positive electrode 204 is formed of a positive electrode current collector 205 and a positive electrode active material layer 206 provided in contact therewith. In addition, the negative electrode 207 is formed of a negative electrode current collector 208 and a negative electrode active material layer 209 provided in contact therewith. A separator 210 and an electrolyte (not shown) ...

Embodiment approach 3

[0129] A secondary battery according to one aspect of the present invention can be used as a power source for various electronic devices driven by electricity. In particular, the secondary battery according to one aspect of the present invention is suitable for electronic devices that are expected to be used in low-temperature environments such as cold regions.

[0130] Specific examples of electronic equipment using the secondary battery according to one aspect of the present invention include display devices such as televisions and monitors, lighting devices, desktop or notebook personal computers, word processors, playback and storage on DVD (Digital Versatile Disc (Digital Versatile Disc) Image reproduction devices for still images or moving images on recording media such as digital versatile discs), portable CD players, radios, tape recorders, headphones, stereos, desk clocks, wall clocks, cordless telephone handsets, walkie-talkies , portable wireless devices, mobile pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com