Method for manufacturing electricity storage device and electricity storage device obtained using said method

A technology for an electrical storage device and a manufacturing method, which is applied in the manufacture of electrolyte batteries, electrodes of non-aqueous electrolyte batteries, and battery electrodes, and can solve problems such as the inability to contribute to the miniaturization of an electrical storage device and the inability to form a rocking-chair type secondary battery, etc., to achieve The effect of excellent capacity density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

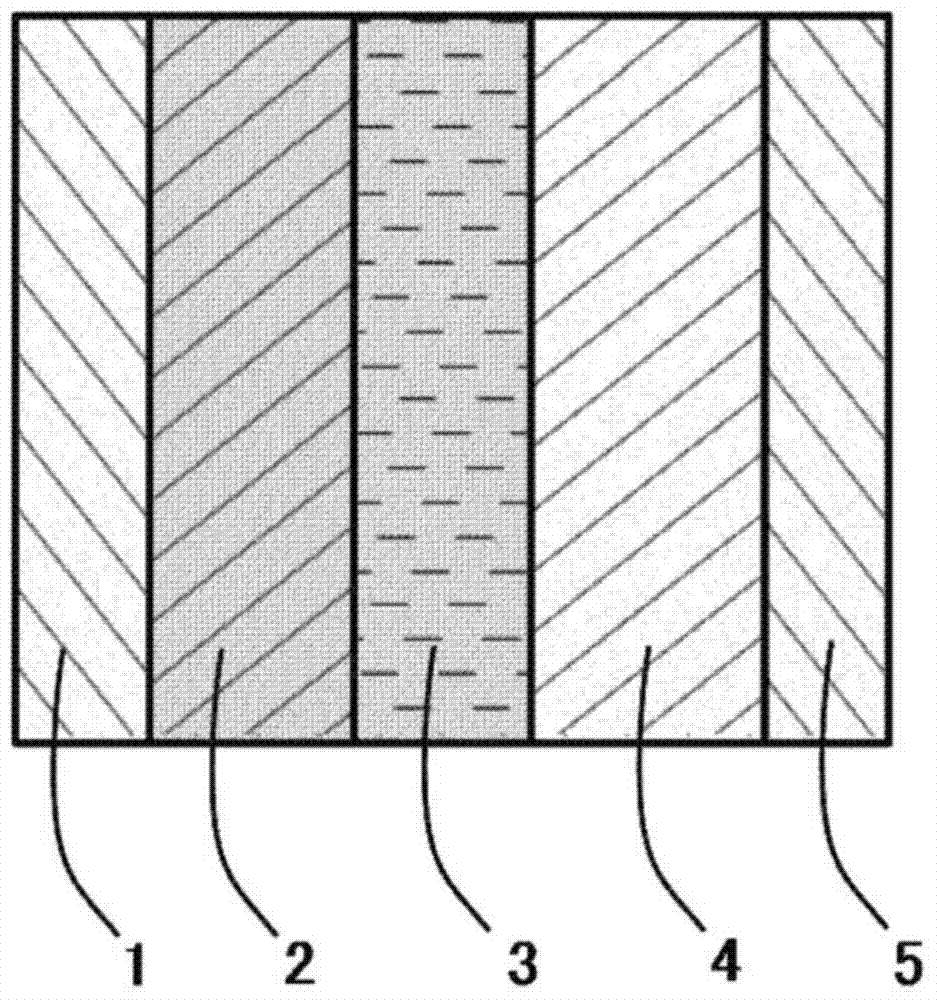

[0102] [Example 1]( figure 1 )

[0103]

[0104] The conductive polyaniline powder in the doped state obtained by the above is dropped into 2 mol / L sodium hydroxide aqueous solution, stirred in a 3L detachable flask for 30 minutes, and the tetrafluoroboric acid of the dopant is neutralized by neutralization reaction. de-doping. The dedoped polyaniline was washed with water until the filtrate became neutral, then stirred and washed in acetone, filtered under reduced pressure using a Buchner funnel and a suction bottle, and dedoped polyaniline powder was obtained on No. 2 filter paper. This was vacuum-dried at room temperature for 10 hours to obtain a brown polyaniline powder in an undoped state.

[0105]

[0106] Next, the polyaniline powder in the dedoped state was put into an aqueous methanol solution of phenylhydrazine, and a reduction treatment was performed for 30 minutes while stirring. The color of the polyaniline powder changed from brown to gray due to reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com