Method for realizing interconnection of front and back surface patterns of thick film substrate

A front and back, thick film technology, applied in the direction of printing devices, printing, electrical components, etc., can solve the problem that the graphics on the front and back sides cannot be interconnected, achieve good practicality and economic value, improve interconnection, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

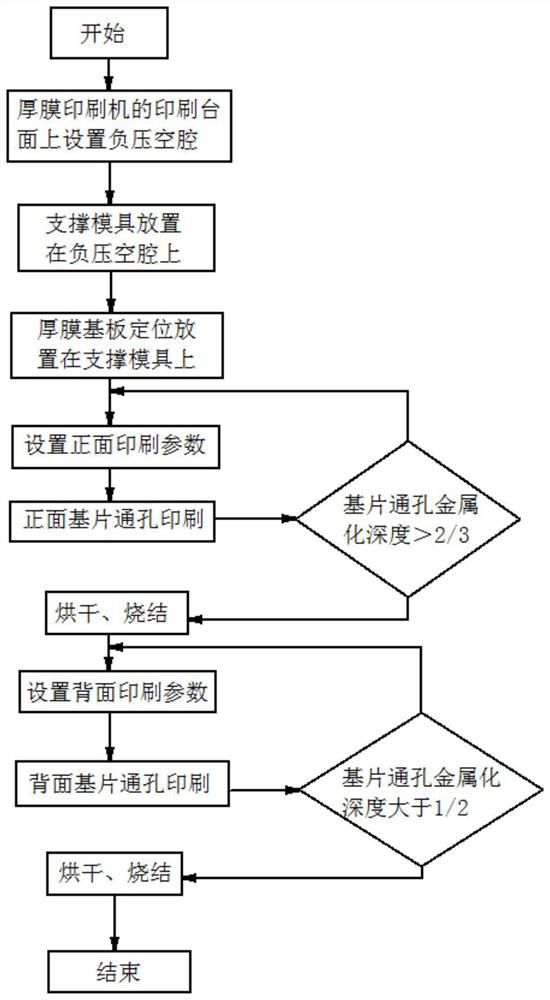

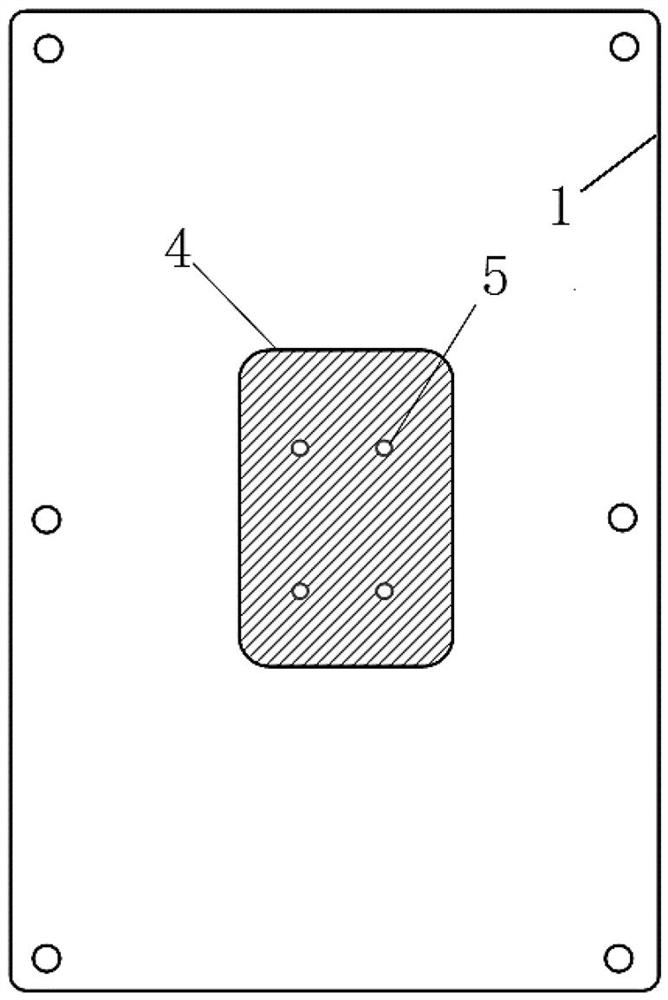

[0047] Step 1, Renovation of Printing Mesa 1:

[0048] The air holes of the printing table of the ordinary printing machine can only be used for substrate positioning in the printing process. The printing table 1 of the thick film printing machine is modified, and a negative pressure chamber 4 of 50mm×50mm×2mm is made in the middle area of the printing table 1. A cavity is formed below the film substrate 3, and the cavity structure consists of figure 1 with figure 2 As shown, it is beneficial to the gas flow in the negative pressure channel, so that the slurry forms adhesion on the side wall of the through hole of the substrate.

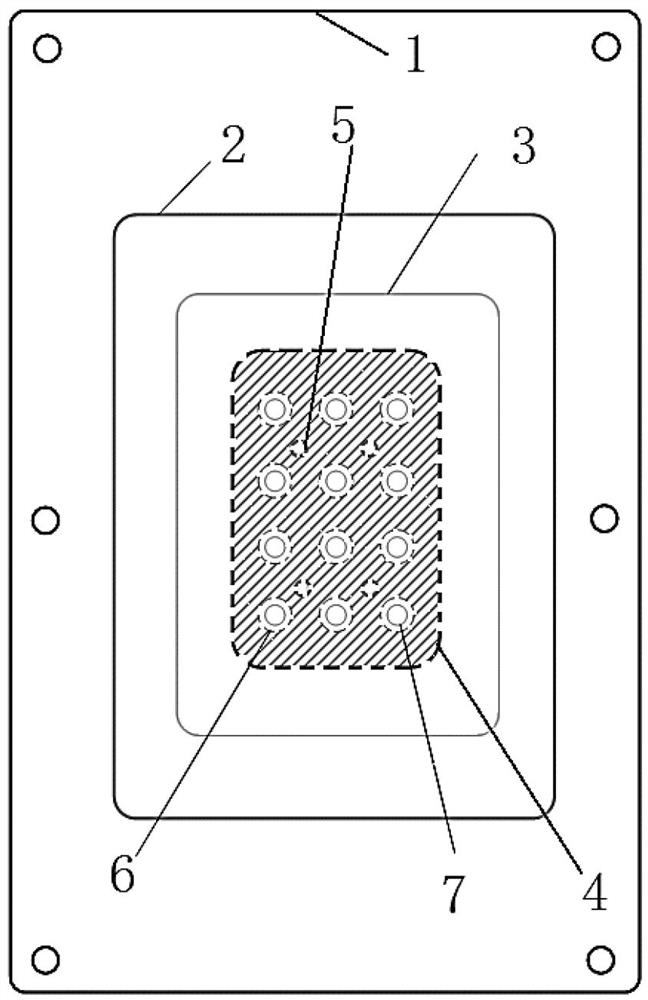

[0049] Step 2, production of supporting mold:

[0050] The support mold 2 corresponding to the thick film substrate 3 is fixed above the negative pressure chamber 4, so that the cavity for the adsorption of the substrate through hole 7 of the thick film substrate 3 is completed, and the support mold 2 is also used as the thick film substrate 3 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com