Patents

Literature

40results about How to "Solve shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing thin wall welder cases of revolving body structures

InactiveCN102794610ASolve the structural sizeSolve the coaxial problem of front and rear installation side weldingArc welding apparatusPre deformationEngineering

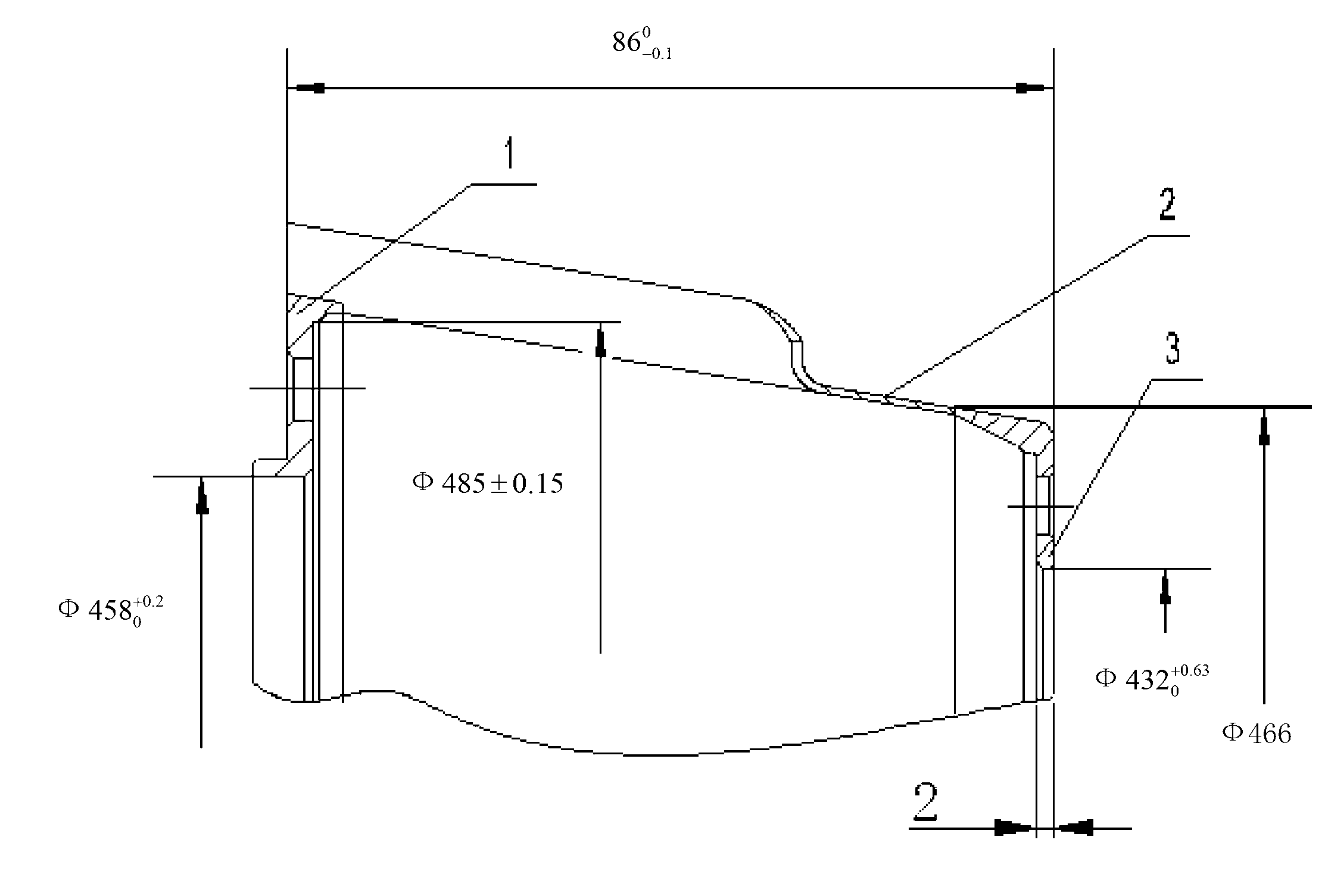

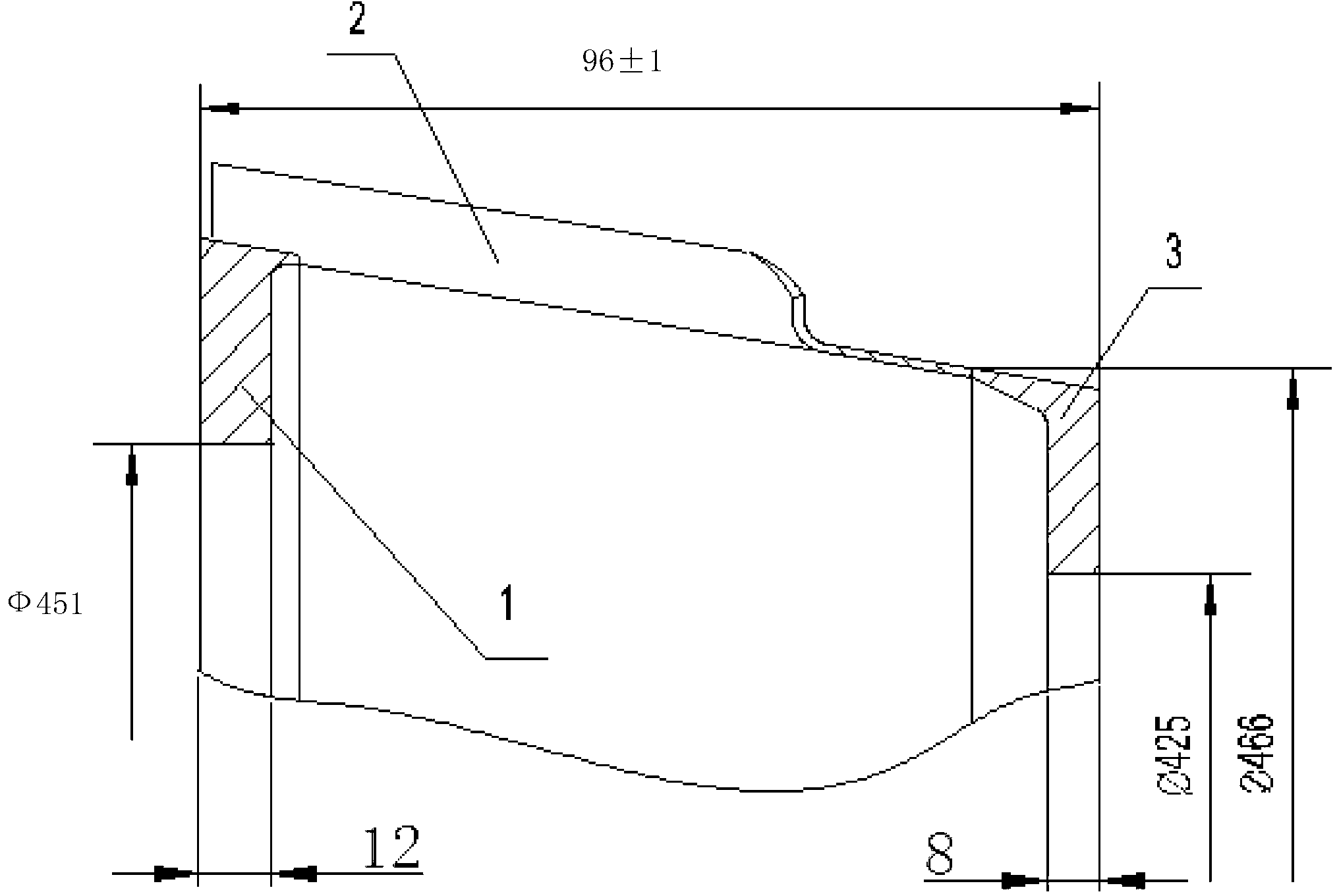

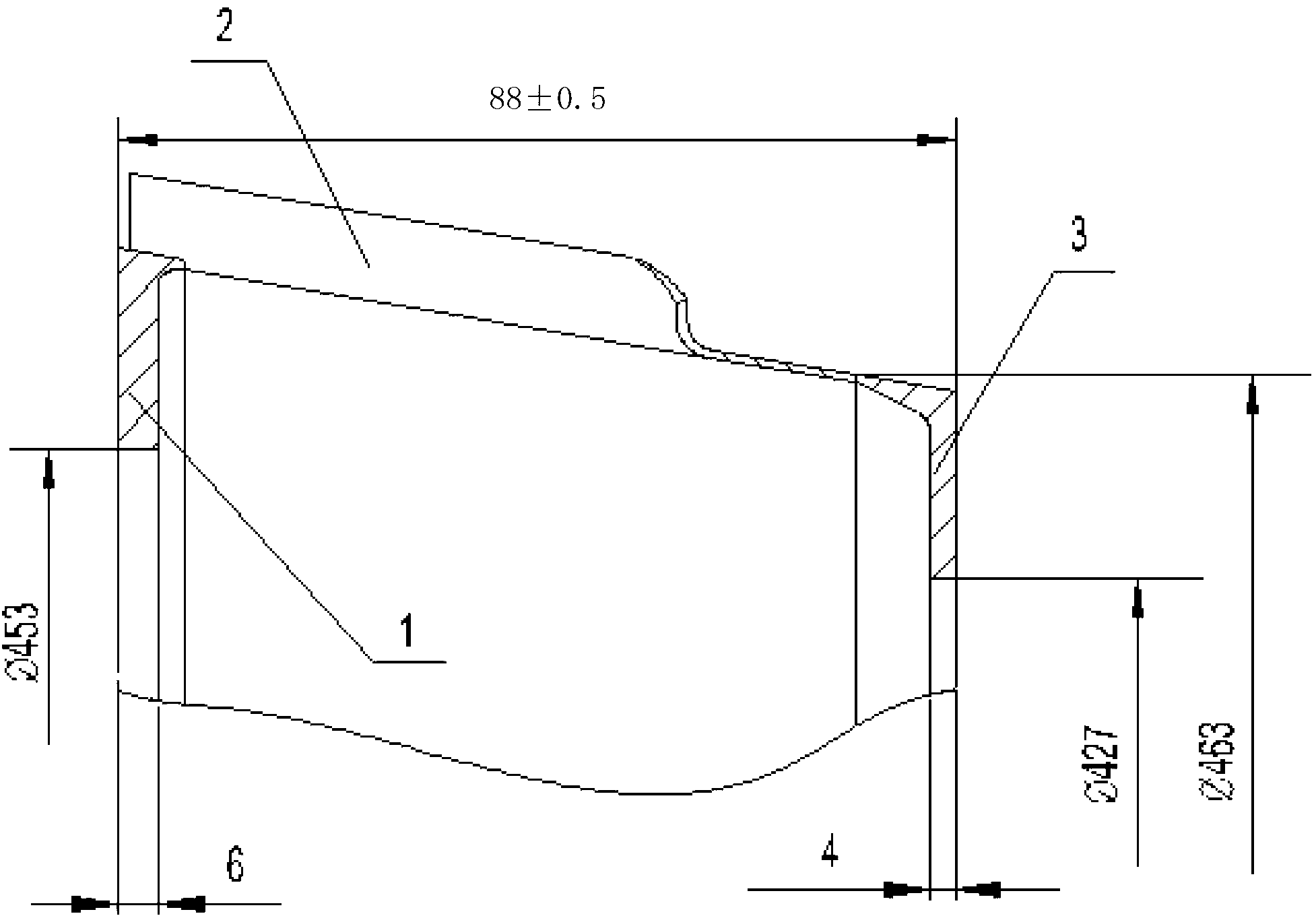

The invention discloses a method for processing thin wall welder cases of revolving body structures, belonging to the technical field of aero-engine metal plate forming and welding. According to the invention, a whole pre-deformation welding / forming method is used for solving the problems that sizes of mounting edges are out of tolerance, coaxiality of front and rear mounting edges with main bodies after welding is out of tolerance and residual stress distribution of welding components is unbalanced. The method provided by the invention comprises the following steps of: carrying out technological structure welding deformation allowance compensation design on a mounting edge and a main body of a thin wall welder case before the welding according to the plastic deformation characteristics of materials; plastically forming an expansion block according to an expander work part, size and final structural size requirement of parts; carrying out automatic argon arc welding on the mounting edge and the main body; assembling the welded welder case and expansion block on the expander work part to carry out expansion plastic forming and controlling the expansion forming size through adjusting pressure of the expander; and unloading the pressure of the expander, recovering the expander work part and unloading the parts to complete the welding / forming process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

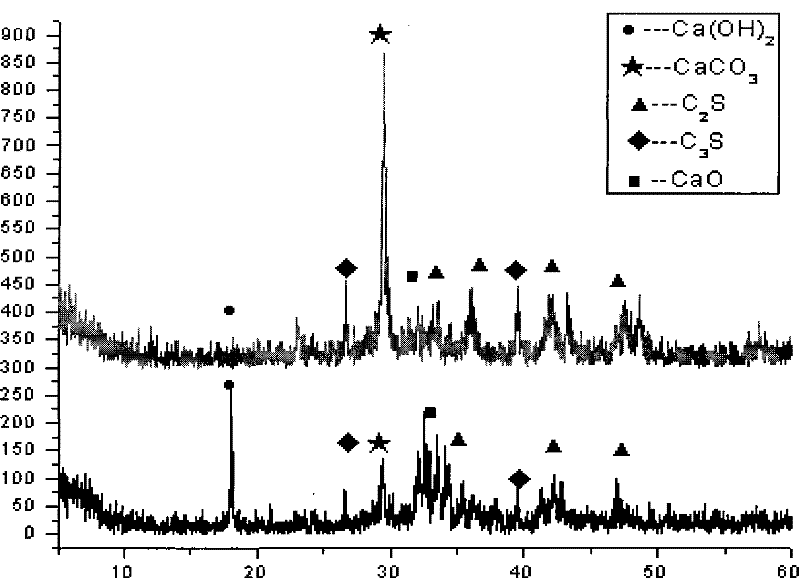

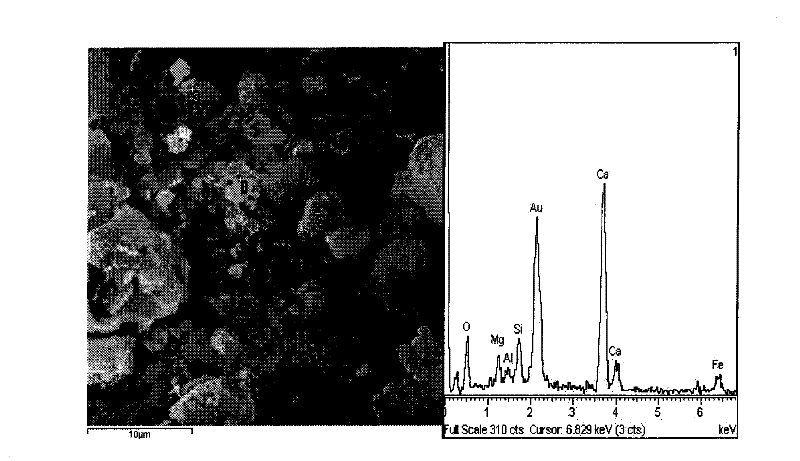

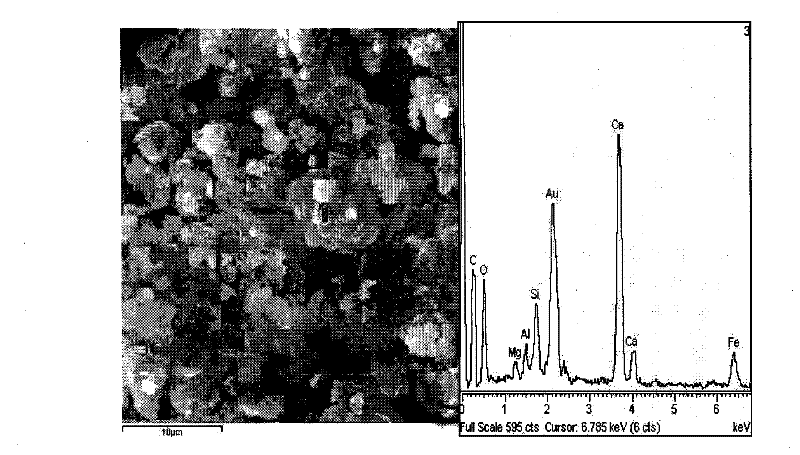

Method for producing architectural materials by using paper making sludge

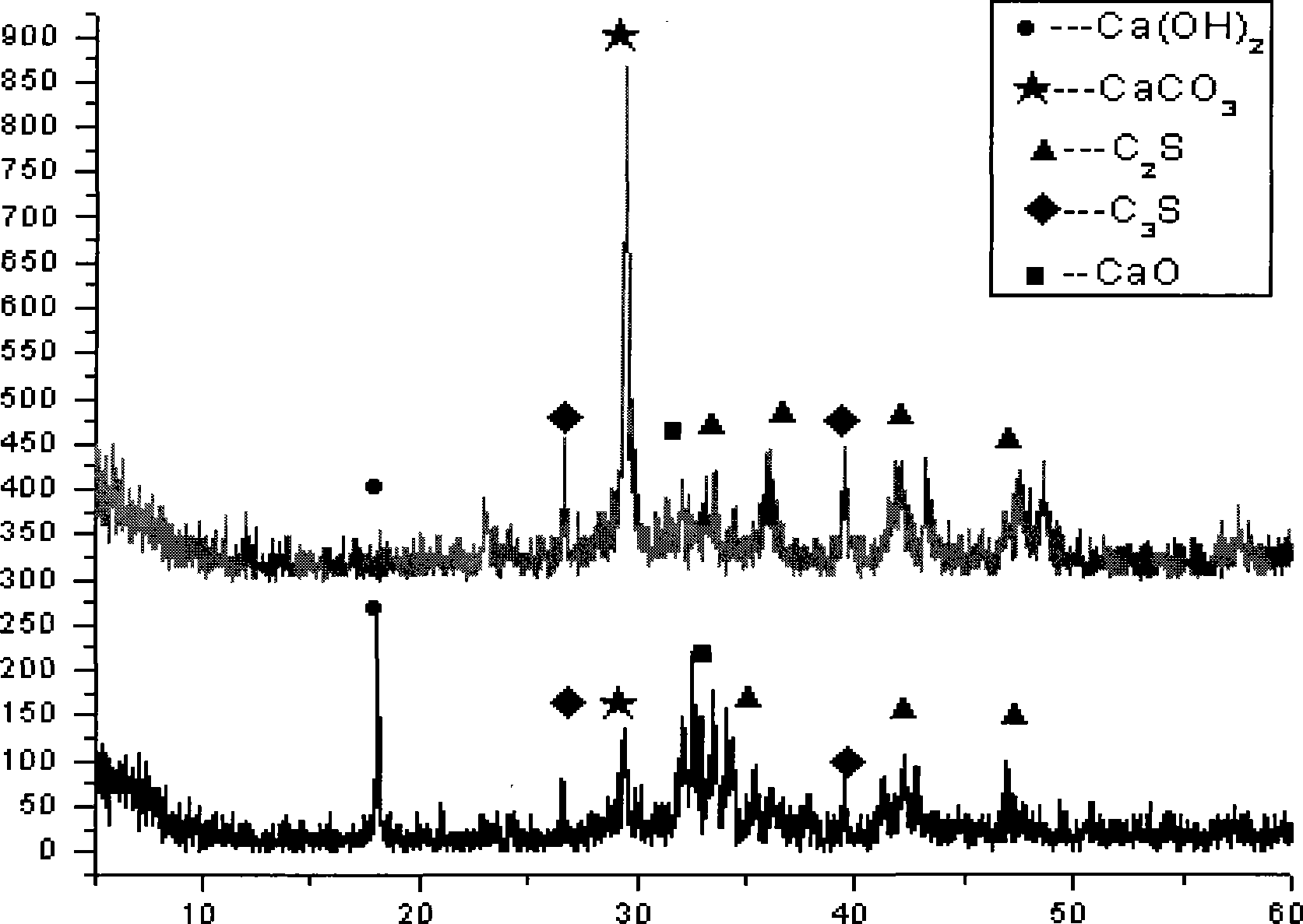

The invention belongs to the technical field of environmental protection, and relates to a method for preparing a building material by using industrial wastes (paper making sludge, different steel slag, furnace cinders, waste concrete) as main raw materials and applying an accelerated carbonation technology, in particular to the method for producing the building material by using the paper making sludge. The method comprises the following steps: according to the weight ratio of between 1 to 0.5 and 1 to 4, mixing the paper making sludge with a carbonized material; adding water into the mixture and mixing the mixture evenly; pressing the mixture into a semi-finished product of the building material; and preparing the semi-finished product of the building material into a finished product of the building material under the curing of accelerated carbonation. The method effectively makes use of the industrial wastes such as the paper making sludge, reduces the emission of the greenhouse gas of carbon dioxide, and prepares the building material with excellent performance and beautiful appearance. The method has the advantages of favorability for waste recycling, environmental protection, energy conservation, and low cost.

Owner:UNIV OF JINAN

High internal phase polyelectrolyte emulsions for the manufacture of superabsorbent polymers and superabsorbent polymers made therefrom

InactiveUS6916864B2Efficient use ofEfficient conversionOther chemical processesPretreated surfacesSuperabsorbent polymerWater soluble

The present invention refers to a high internal phase polyelectrolyte emulsions which are useful for the manufacture of superabsorbent polymers having two phases: i) a continuous oil phase and the ii) a dispersed aqueous phase containing the aqueous monomer solution prior to polymerization and the polyelectrolyte in water-soluble, or water-swellable or very slightly crosslinked form after polymerization, wherein the polymerization occurs in the dispersed aqueous phase and wherein the dispersed aqueous phase contains a high concentration of polyelectrolyte. The present invention also refers to a process for preparing such emulsions and for inverting these emulsions so as to form films or other patterns of the superabsorbent polymer. Absorbent structures containing SAP films or other patterns prepared by the present invention are also contemplated.

Owner:STOCKHAUSEN GMBH & CO KG

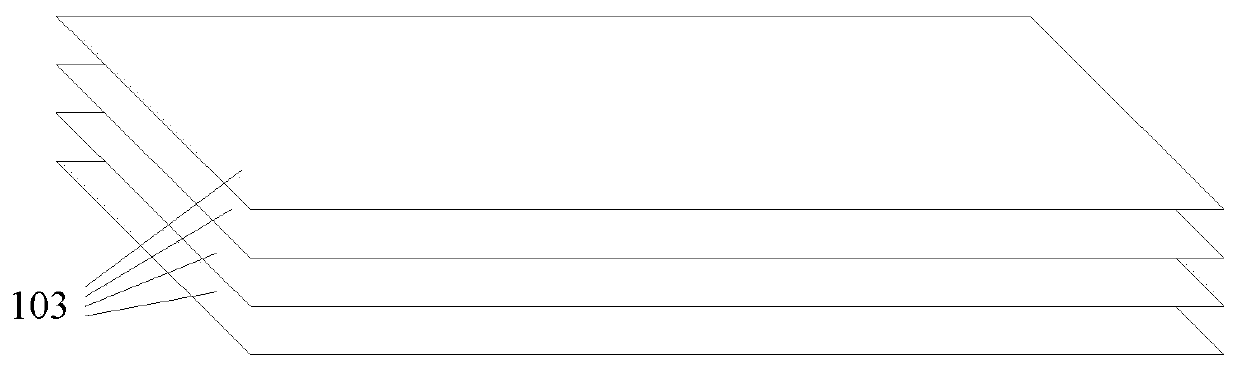

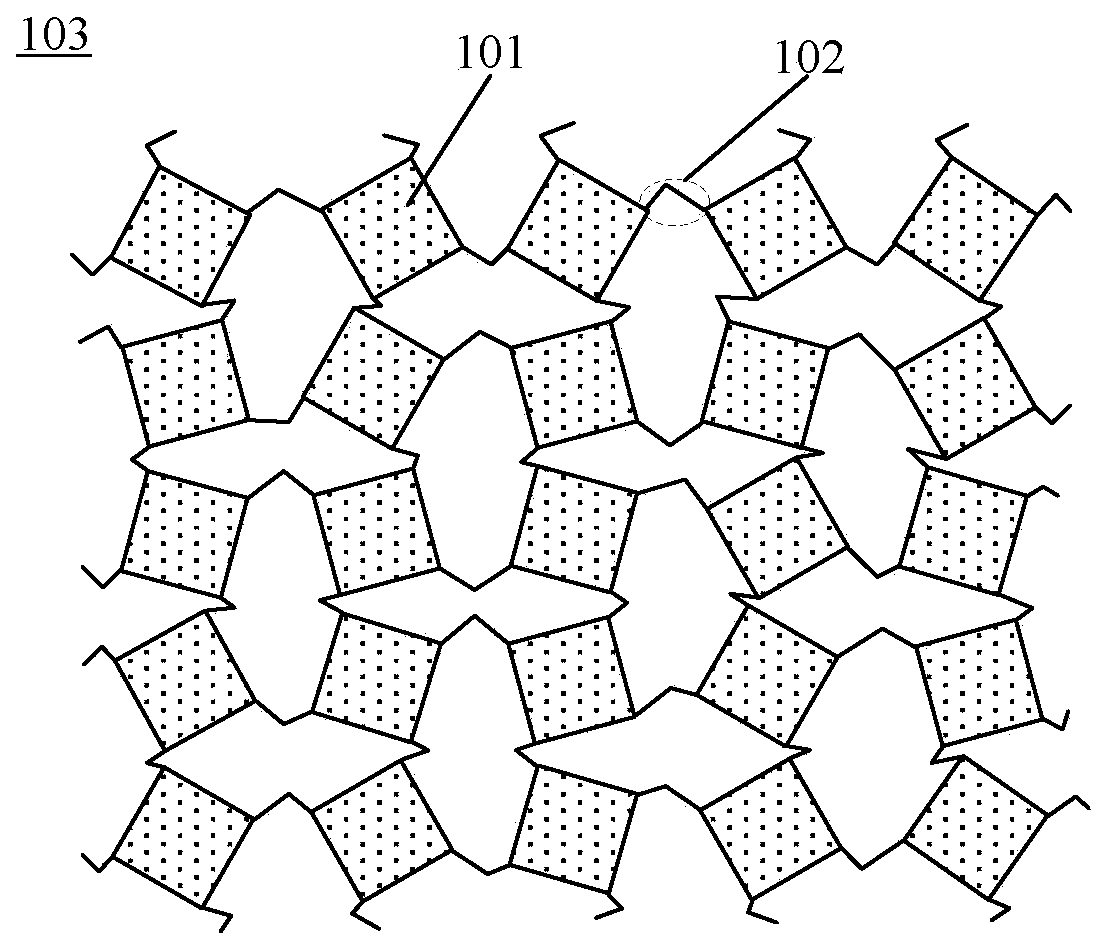

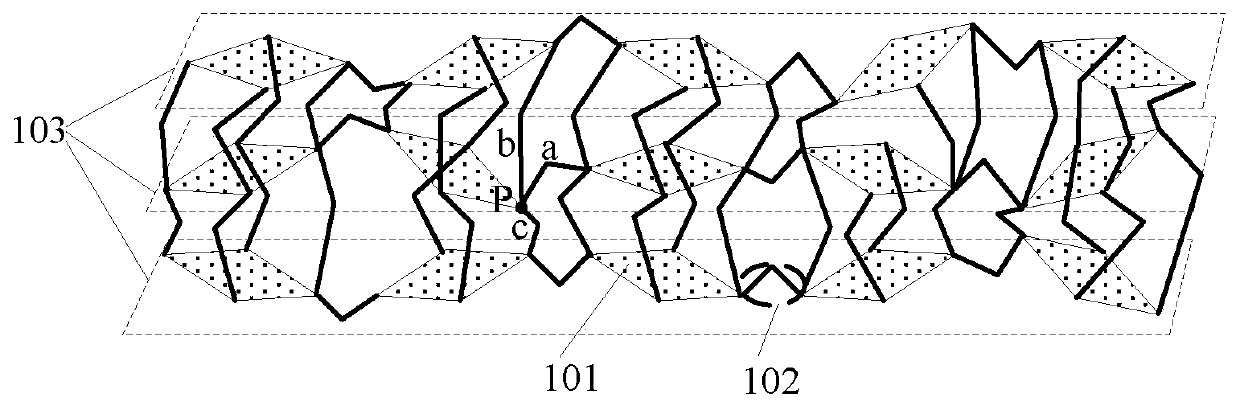

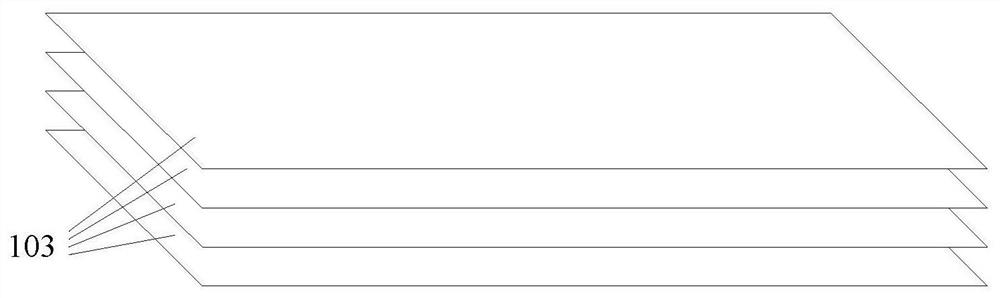

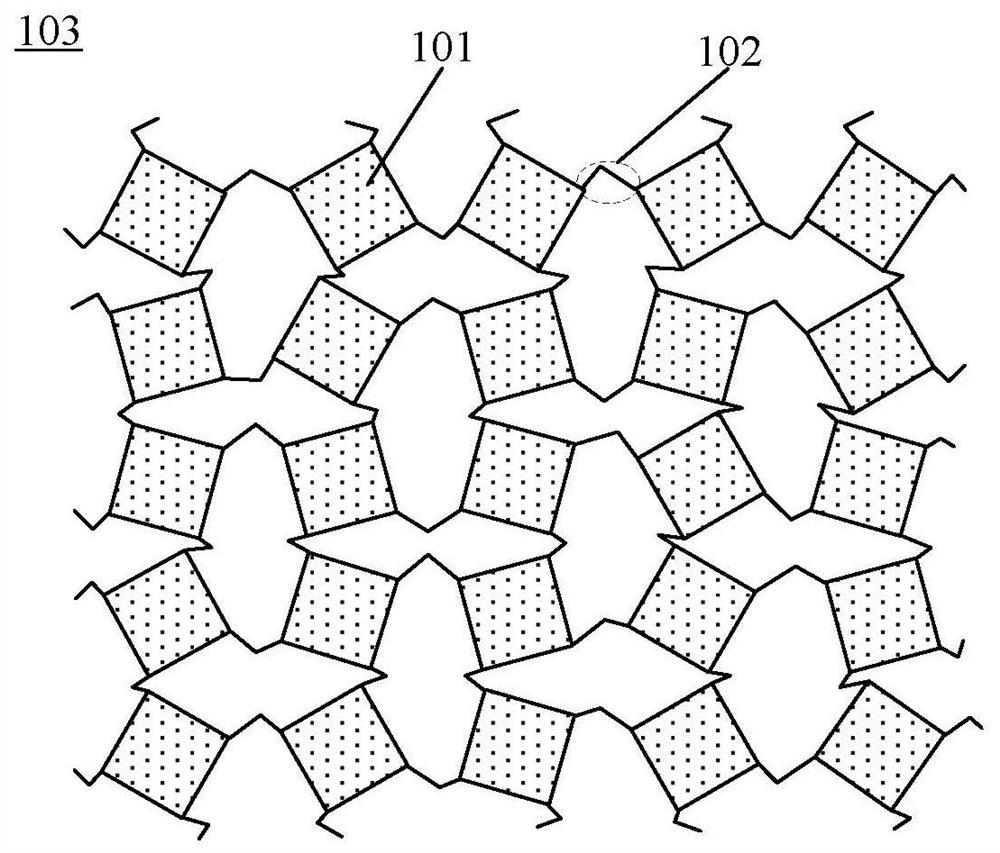

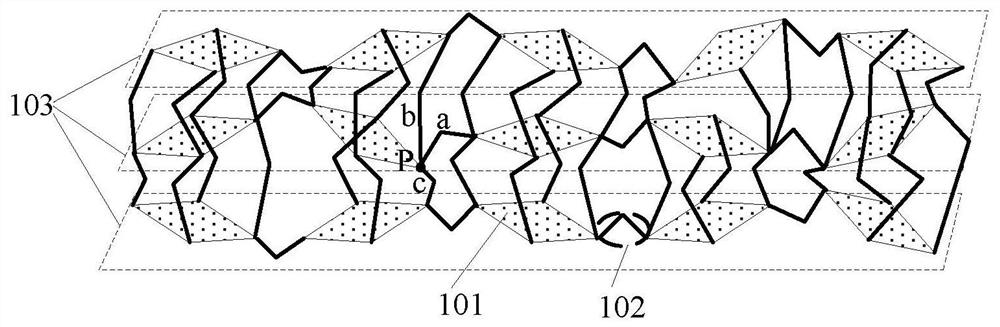

Deformable material, deformable structure, Micro-LED display device and strain sensor

ActiveCN110065267ASolve shapeProtective equipmentSynthetic resin layered productsLED displayDisplay device

The embodiment of the invention provides a deformable material, a deformable structure, a Micro-LED display device and a strain sensor, and relates to the technical field of flexibility. The problem is solved that when the deformable structure is deformed, the shape before deformation is different from the shape after deformation. The deformable material comprises a multi-layer sheet structure, each layer of sheet structure comprises a plurality of zymohexases, the shape of the zymohexases is square, and amino acid residues at the four corners of each zymohexase are connected with the amino acid residues of the four zymohexases around the zymohexase through four disulfide bonds. The amino acid residues of the zymohexases in adjacent sheet structures are connected together through disulfidebonds.

Owner:BOE TECH GRP CO LTD +1

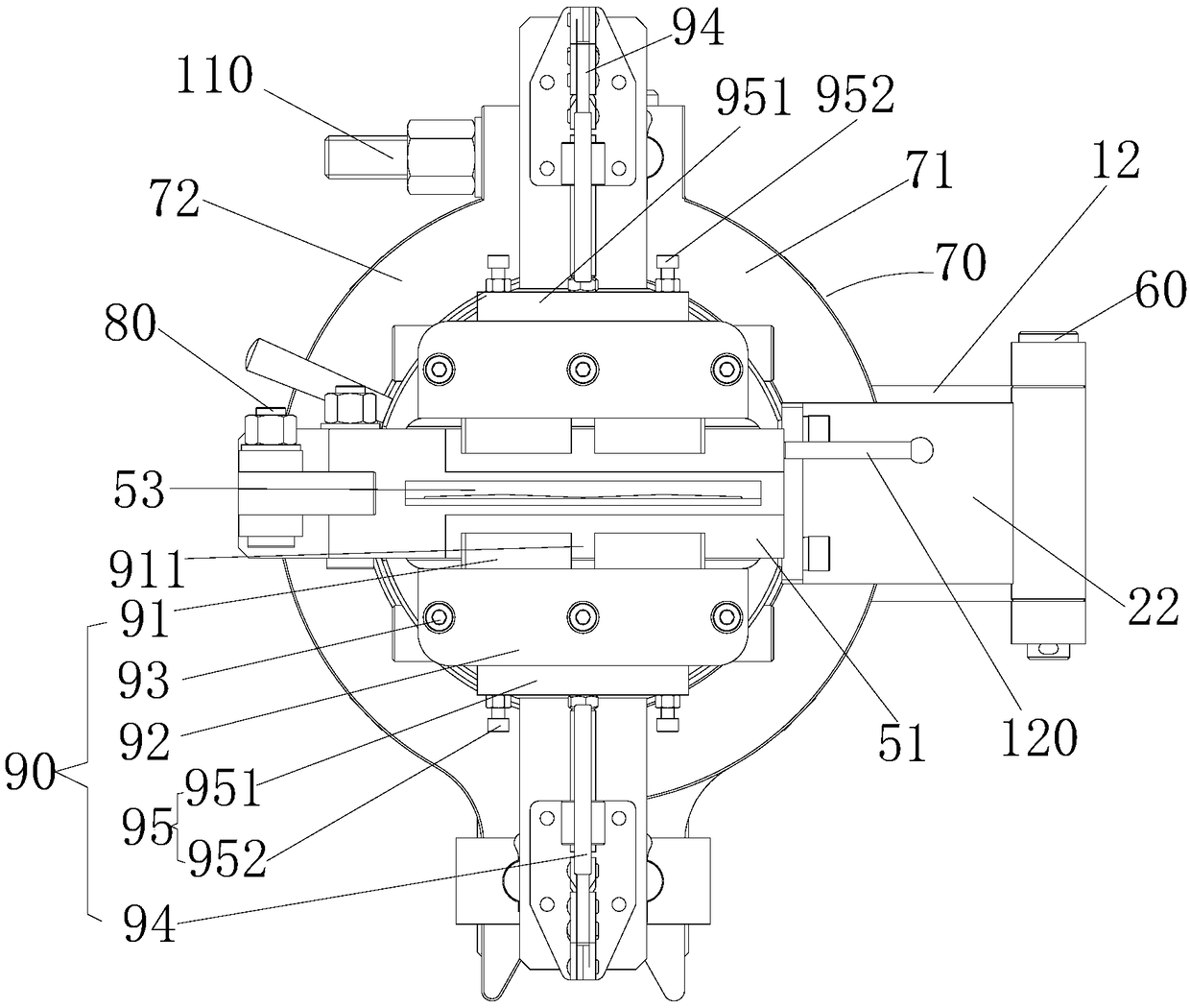

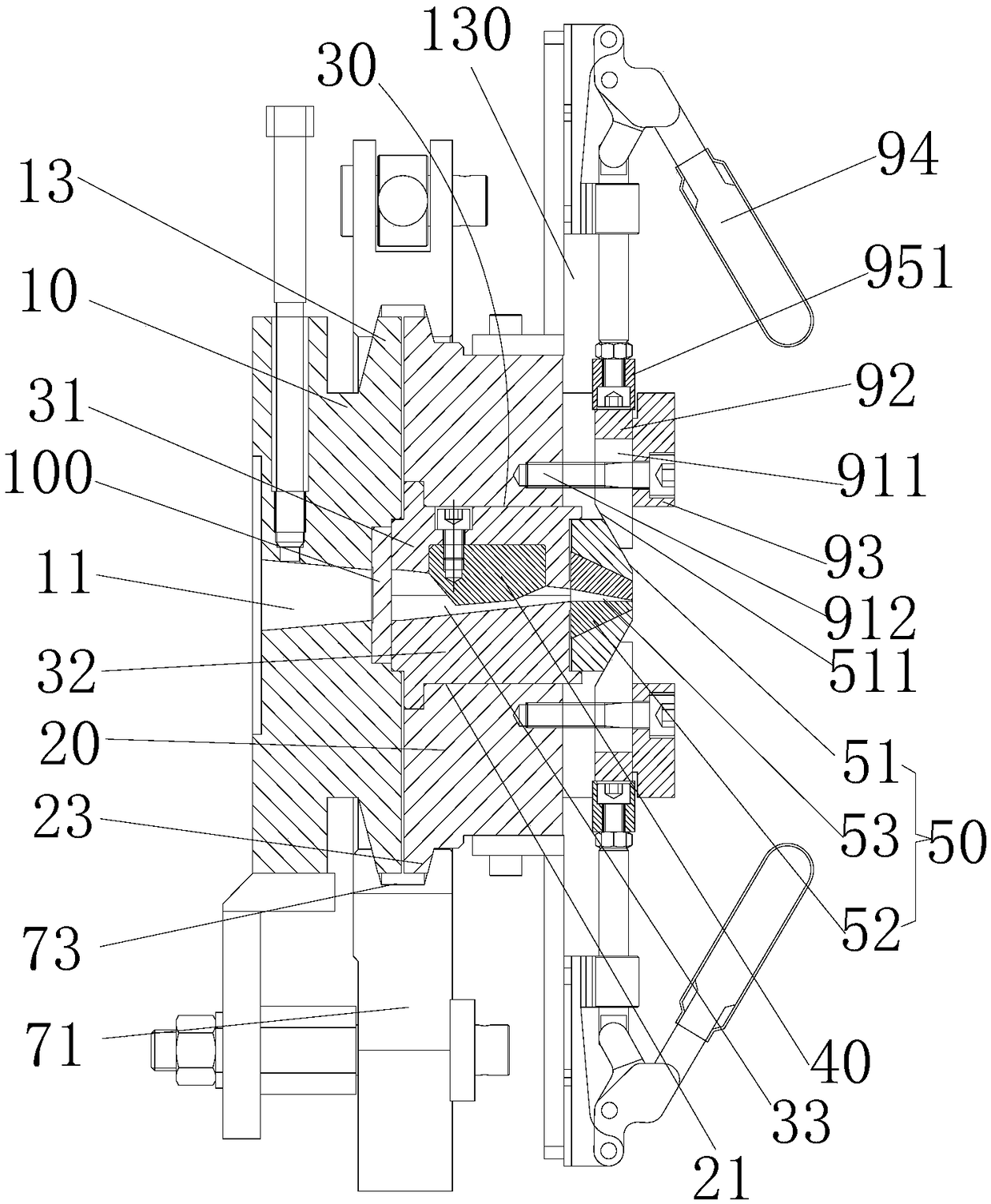

Electrolytic copper crane sling

The invention discloses an electrolytic copper crane sling, which aims to solve the problem that the shape and position of polar plate lifting lugs are required to be frequently and pertinently changed in the prior art. According to the technical scheme I, the electrolytic copper crane sling is characterized by comprising an anode hanger, a cathode hanger, a cathode adjustment driving device and a balancing arm, wherein the anode hanger and the cathode hanger respectively have a frame structure; the anode hanger is positioned at the periphery of the cathode hanger; and the cathode hanger is connected with the anode hanger through a cathode hanger lifting device. The electrolytic copper crane sling with the technical scheme has the characteristics that due to a horizontal guide device between the anode hanger and the cathode hanger, a conductive rod of a cathode plate is prevented from interfering with an anode hook in the polar plate lifting process, human assistance is not required, anode and cathode polar plates are sequentially discharged or filled, and the target is lifted, thereby achieving the aim of improving the working efficiency of an electrolytic copper crane.

Owner:重庆寿丰科技有限公司

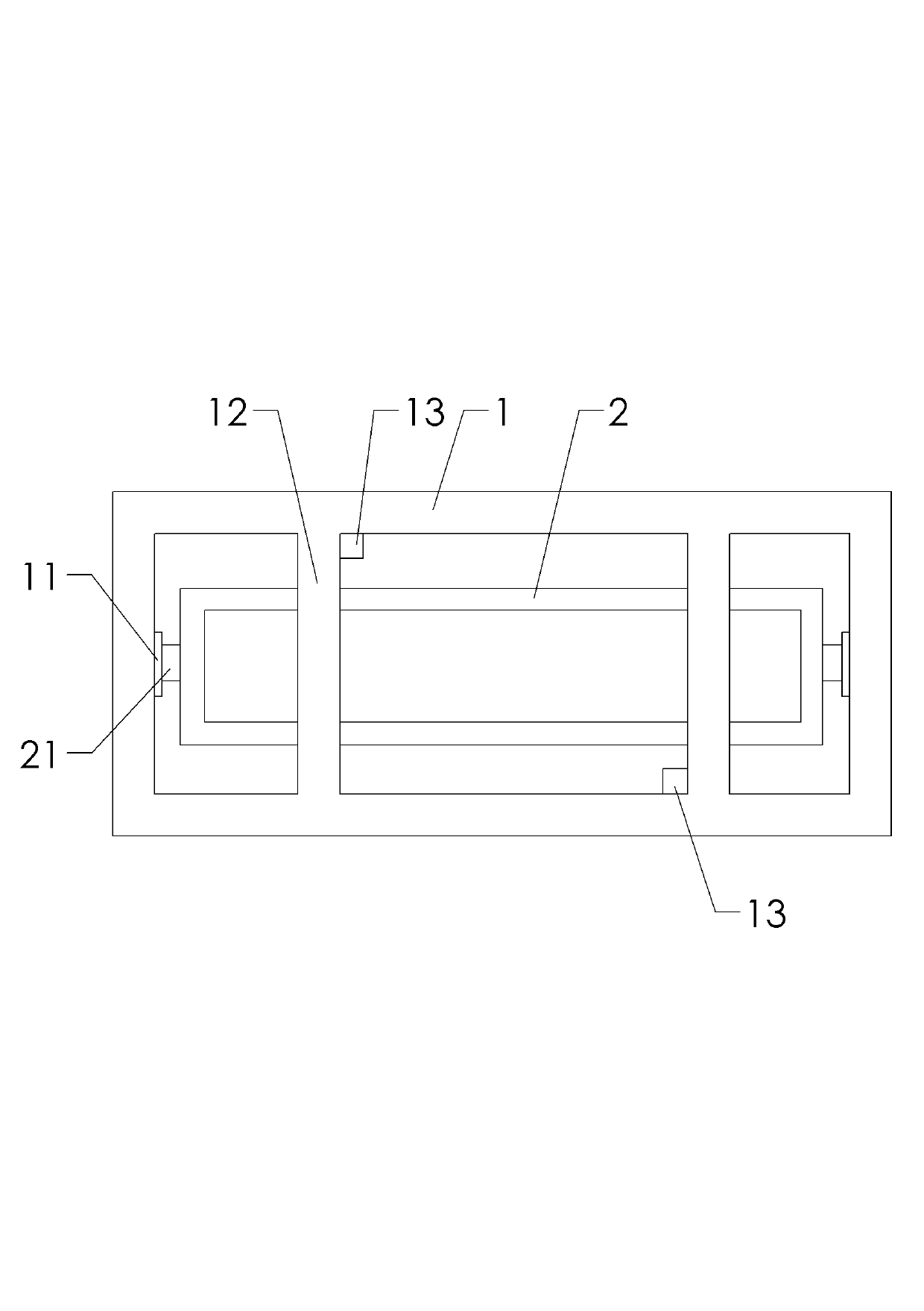

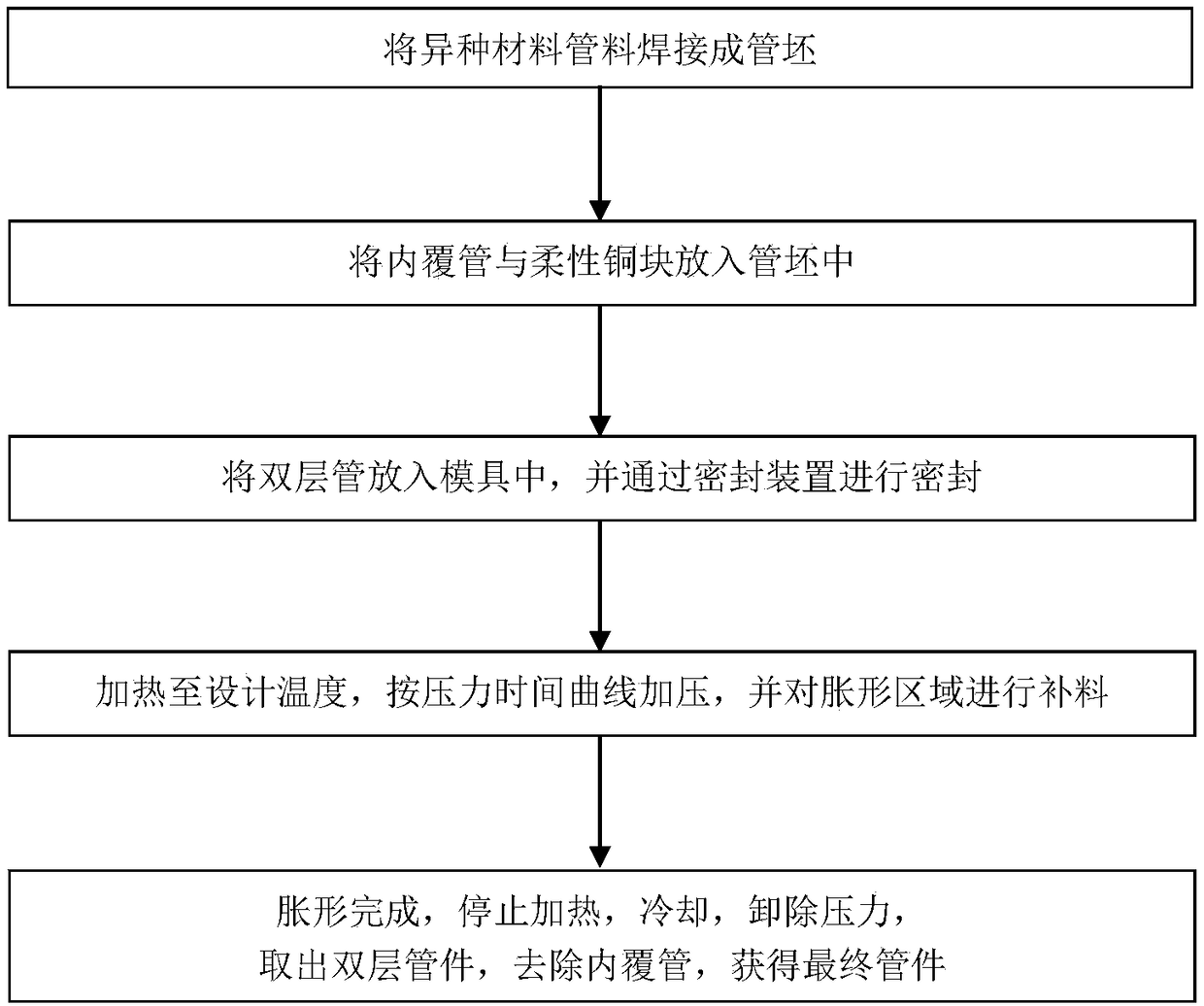

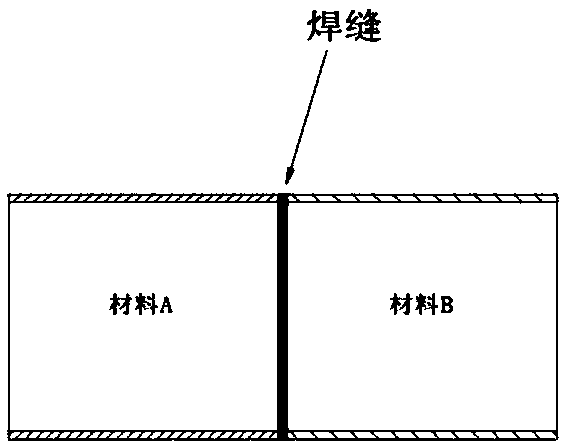

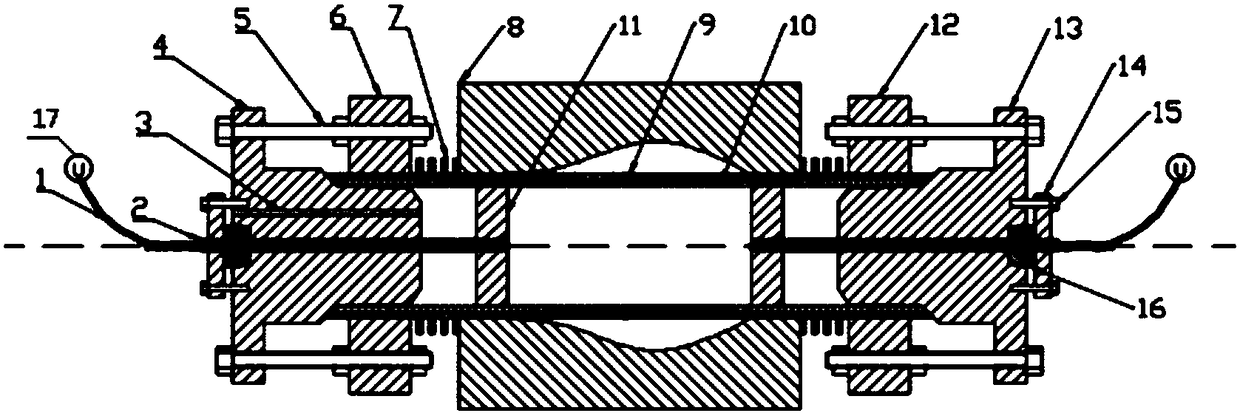

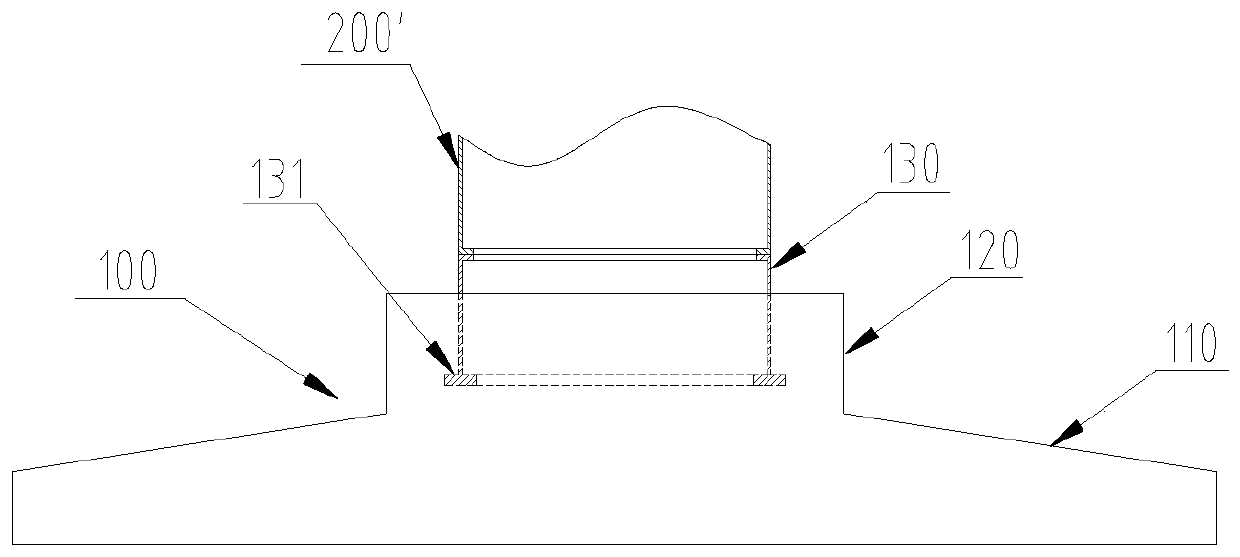

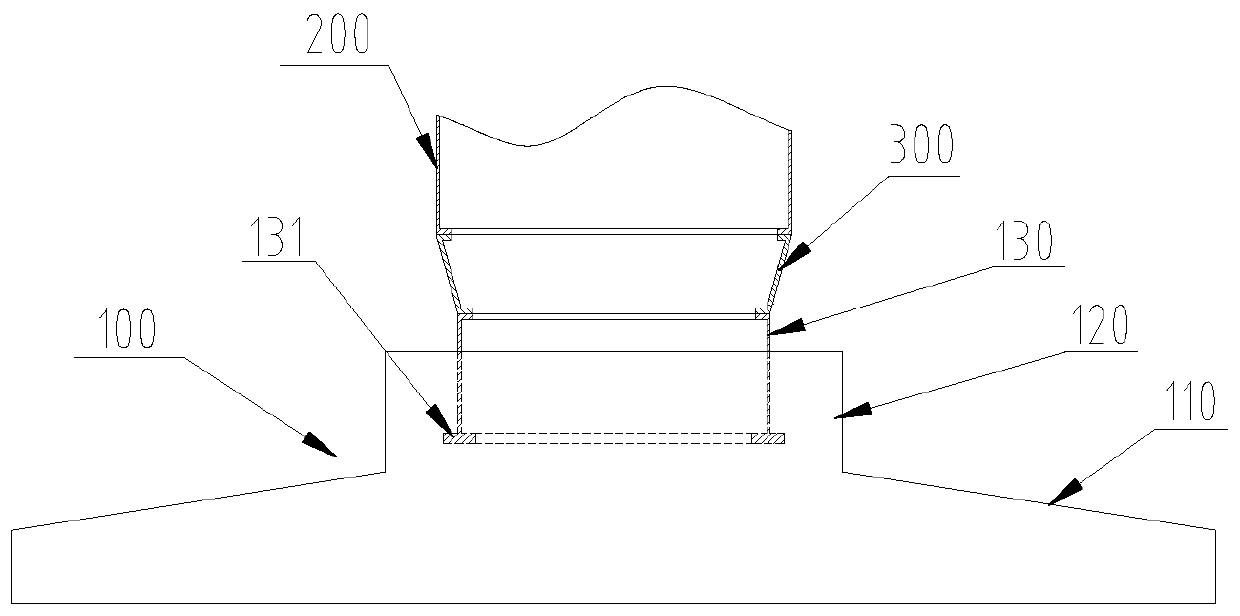

Electric assistant heating forming device and method for dissimilar material complicated section pipe fittings

The invention discloses an electric assistant heating forming device and method for dissimilar material complicated section pipe fittings. Pipe blanks welded by dissimilar material pipes and inner coating pipes positioned in the pipe blanks are positioned in an air expansion forming mold; two ends of the pipe blanks are sealed through sealing push heads and elastic sealing blocks; the positions offlexible copper blocks are adjusted by using advancement and retreating of push rods to realize local area heating; high-pressure gas is injected in the inner coating pipes to enable the pipe blanksto quickly bond on molds; meanwhile, the push heads are pushed for feeding; after formation, the heating is stopped; the high-pressure gas in the pipe blanks is relieved; formed double-layer pipe fittings are taken out; and the inner coating pipes are removed through acid washing to obtain final pipe fittings. The device and the method are suitable for expansion of the dissimilar material pipes, solve the problems of inharmonious deformation in expansion of traditional dissimilar material pipe blanks and rupture of welding lines through local heating and coating plate expansion, also can be used for gradual formation of pipe fittings in multiple expansion areas, meet urgent demands in such fields as aerospace, and achieve high practical value.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

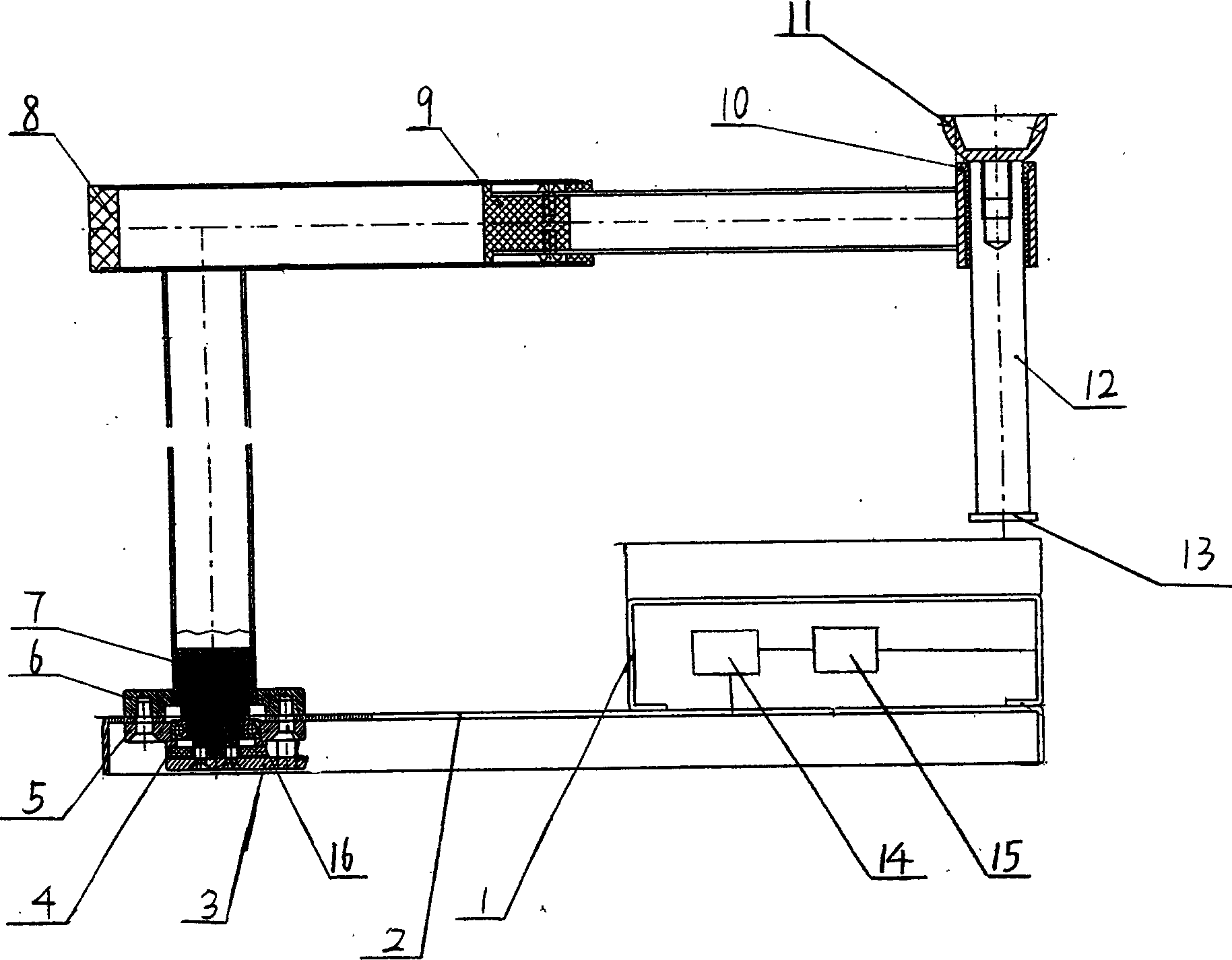

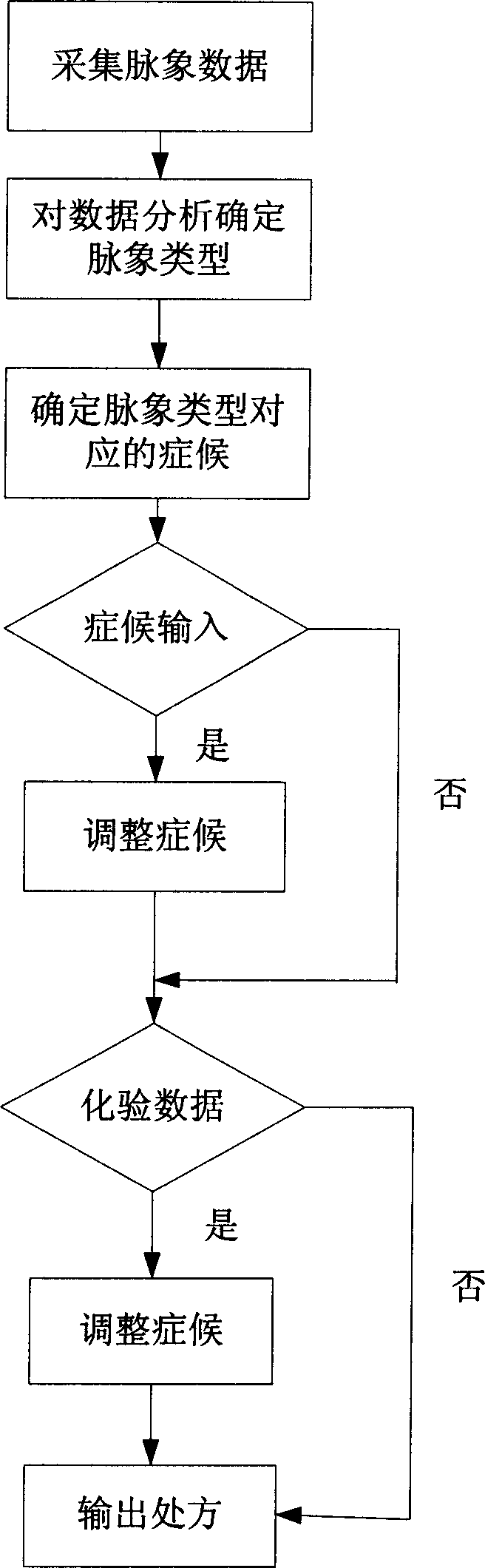

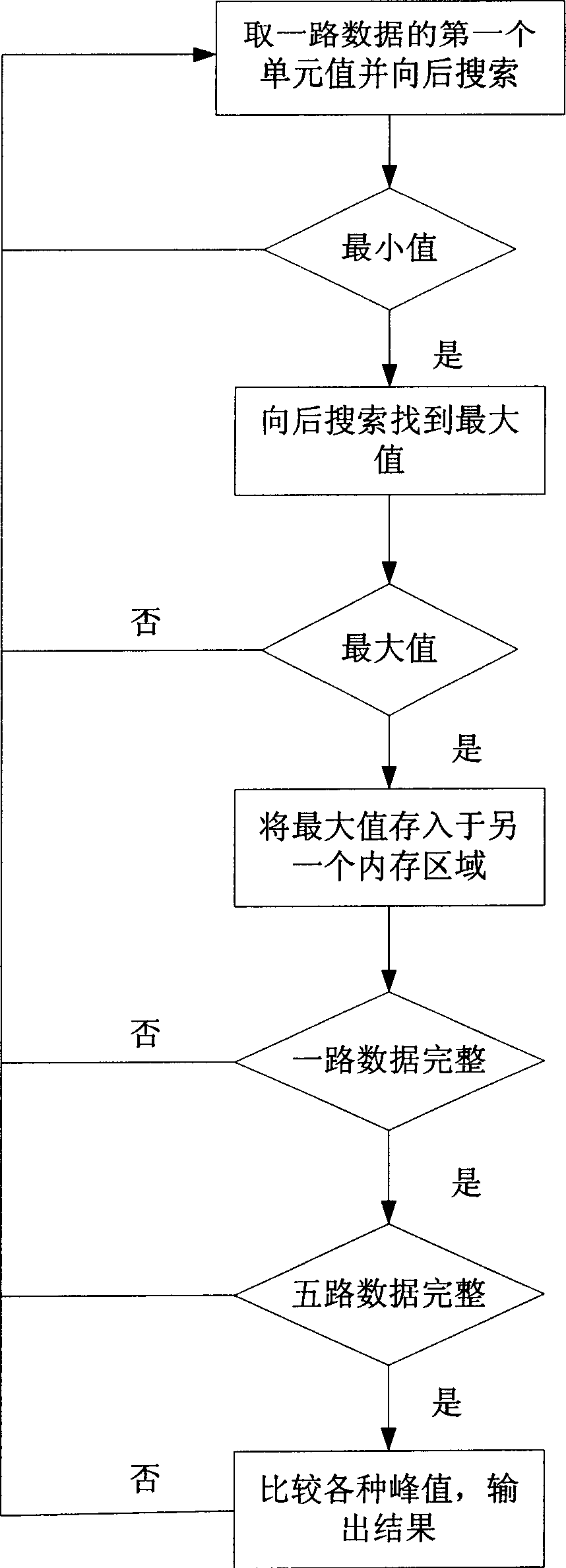

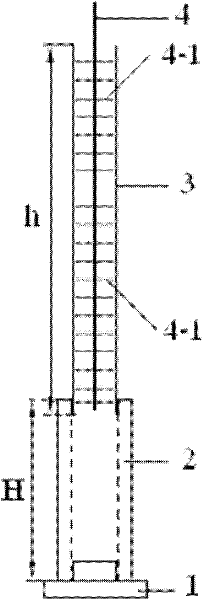

Digital TCM stent-type pulse condition collecting system and pulse condition treating diagnosing method

InactiveCN1813627AGet rid of interventionAchieve automationMeasuring/recording heart/pulse rateSpecial data processing applicationsAudio power amplifierBiochemical engineering

The present invention discloses a digital Chinese medicine support frame type pulse condition collection system which can be used for analyzing pulse condition data, processing pulse condition data, defining type of pulse, making diagnosis, outputting prescription and making the above-mentioned all processes implement digitalization. Said system includes the following several portions: supporting platform, cantilever beam. T-shaped support frame main body, horizontal pulling bar, hollow tube, vertical slide way, counterweight platform, vertical pulling bar, pulse condition sensor, amplifier and A / D converter. Said invention also provides their connection mode and working principle of said pulse condition collection system.

Owner:刘福水

Step-by-step facsimileing writing-skill training method based on writing brush and hard pen

InactiveCN105513457ASolve shapeSolve the rhythm problemTeaching apparatusOperational systemSimulation

The invention relates to a step-by-step facsimileing writing-skill training method based on a writing brush and a hard pen. A desk serves as a carrier, step-by-step facsimileing writing is carried out in sequence under display indication of a display screen, the step-by-step facsimileing training method is guided through good tools from theories to practical application, and a trainer can be accurately trained according to steps. According to the step-by-step facsimileing writing-skill training method, technical training theories of sport events such as weightlifting and boxing are used for reference, and set facsimileing movement patterns are throughout repeated in a great circle mode; all kinds of effective elements contained in a traditional copying method and a traditional tracing method are extracted and are subjected to reintegration, scientific allocation and digesting, and a novel skill training operation system is formed.

Owner:潘茂生

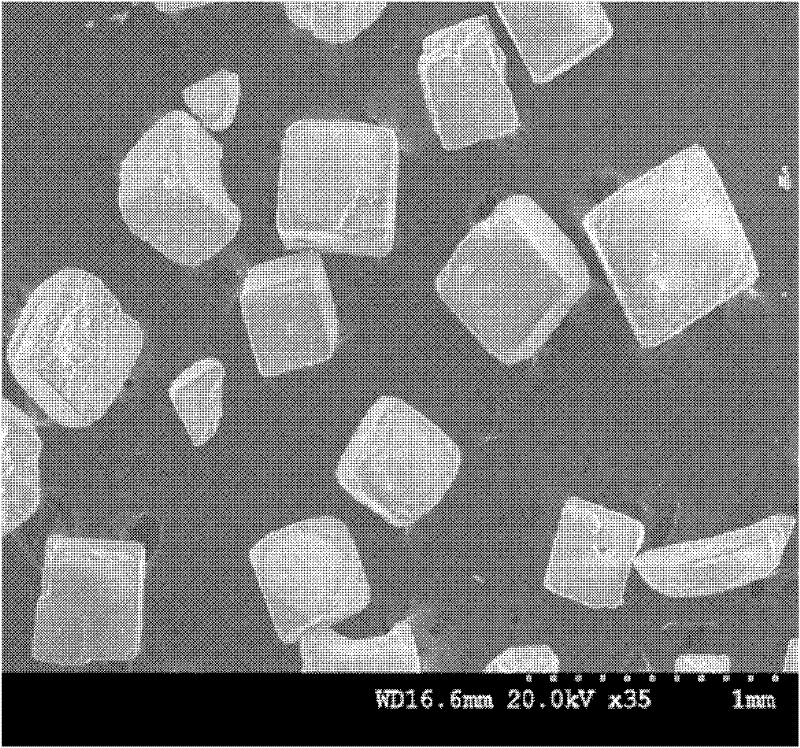

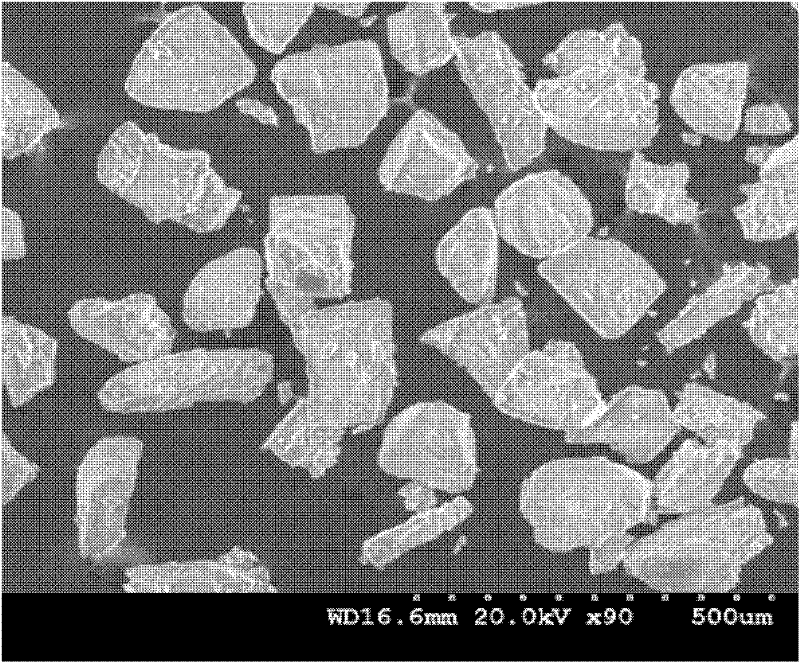

Preparation method of nickel titanium foam alloy with double pore structure

A preparation method of a nickel titanium foam alloy with a double pore structure relates to a preparation method of a nickel titanium foam alloy. The invention solves the problems that the existing nickel titanium foam alloy used for the replacement and repair of the bone tissue has low pore interconnectivity and uneven pore distribution. The method comprises the following steps: respectively weighting several parts of nickel powder, titanium powder, large-particle sodium chloride and small-particle sodium chloride, evenly spreading large-particle sodium chloride and the mixed powder of nickel powder, titanium powder and small-particle sodium chloride in a mould in a laminated mode successively, and then performing cold compressing and forming, cold isostatic pressing, hot pressing sintering and homogenizing treatment in turn. The porosity of the nickel titanium foam alloy is 59.17%-71.71%; and the elastic modulus of the alloy is effectively reduced, which is close to the modulus of the bone tissue. The pore distribution is uniform, and small pores are distributed around large pores to ensure that the large pores are connected to form interconnected pores. By adopting the nickel titanium foam alloy, the bone tissue is controlled to only grow in the large pores; and the nickel titanium foam alloy can be used as the material used for the replacement and repair of the bone tissue.

Owner:HARBIN INST OF TECH

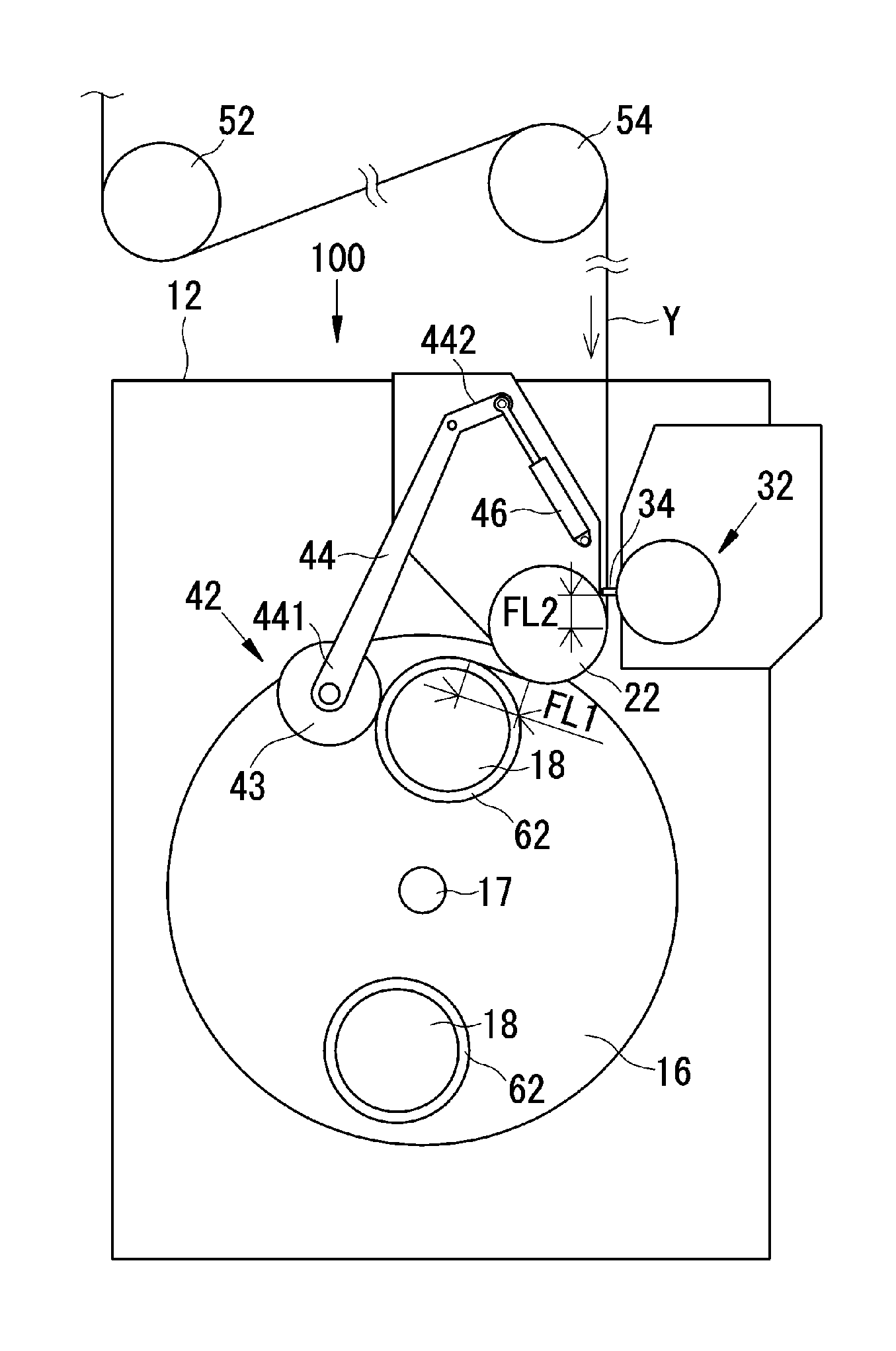

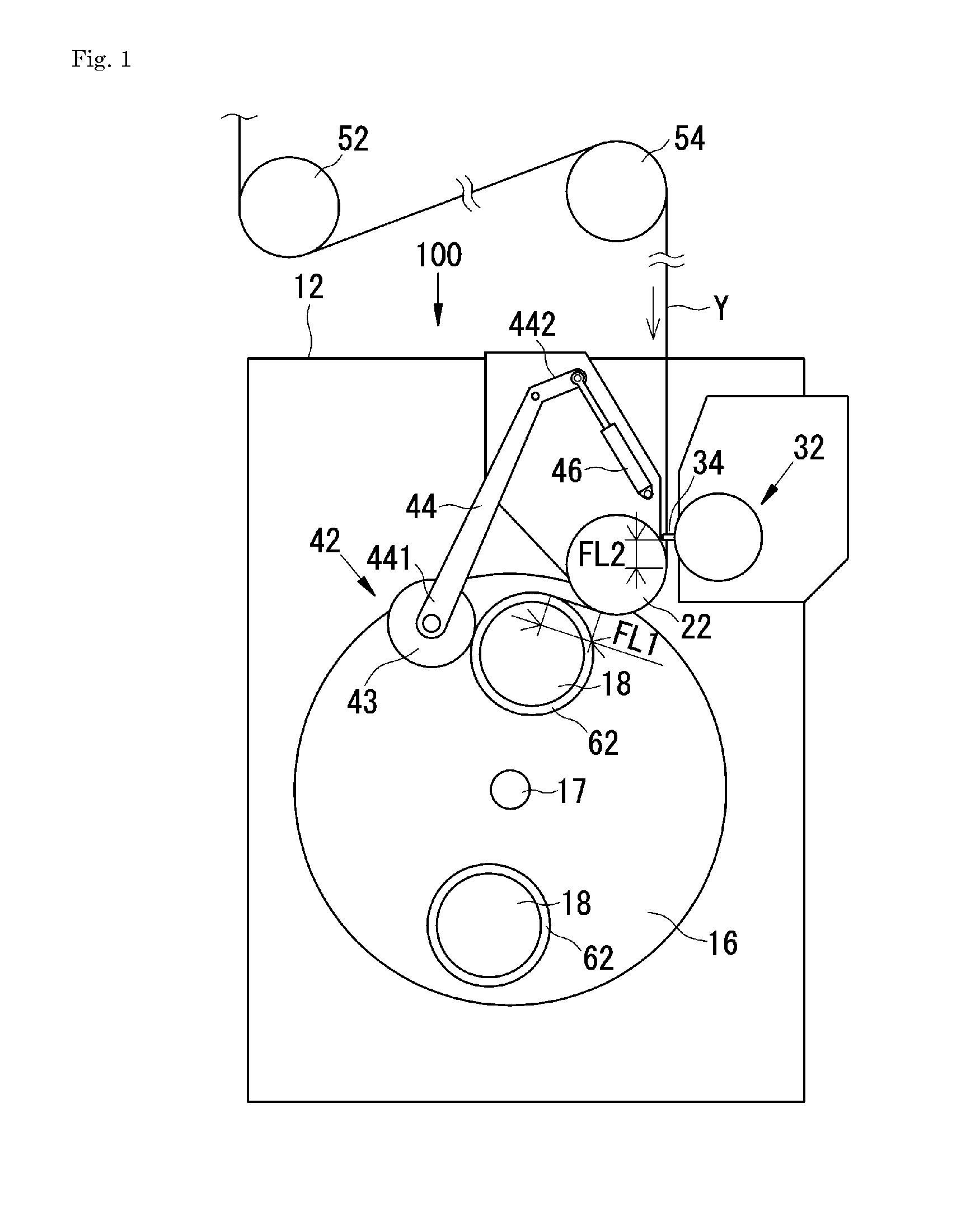

Spun yarn winding device and spun yarn winding facility

A spun yarn winding device includes a machine body; a turret; a feeding roller that is fixed to the machine body, is not in contact with winding bobbins, and feeds yarns to the winding bobbins at a speed equal to or faster than a winding speed; a traverse device fixed at an upstream side of an advance direction of the yarns relative to the feeding roller and which traverses the yarns; a peripheral speed detection unit that detects a peripheral speed of the winding bobbins; and a control unit that is arranged and programmed to perform a basic operation to maintain a free length of the yarns at a standard length by controlling a rotational angle of a turret during a yarn winding period, the free length of the yarns being located between the feeding roller and the winding bobbins.

Owner:TMT MACHINERY INC

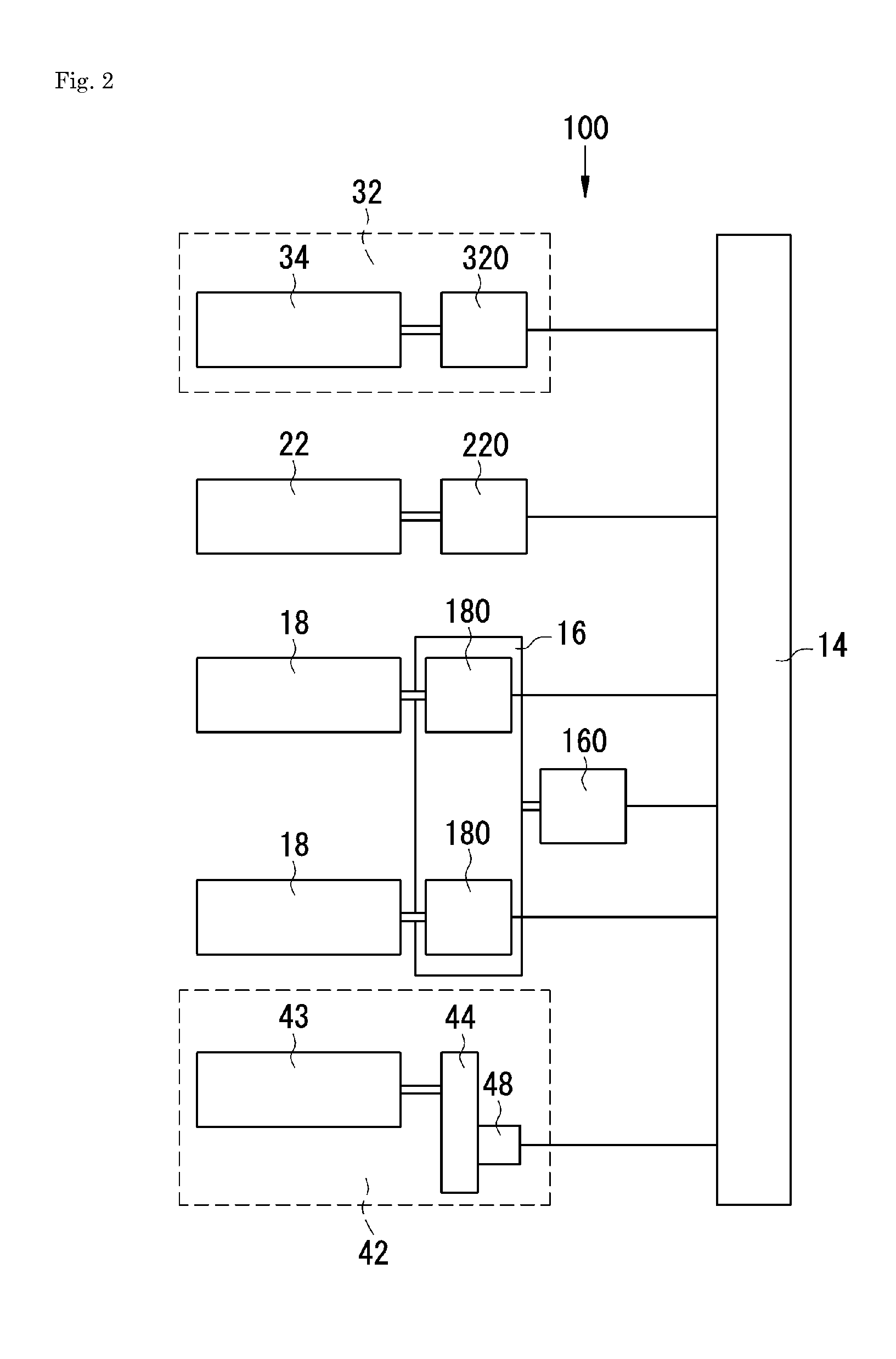

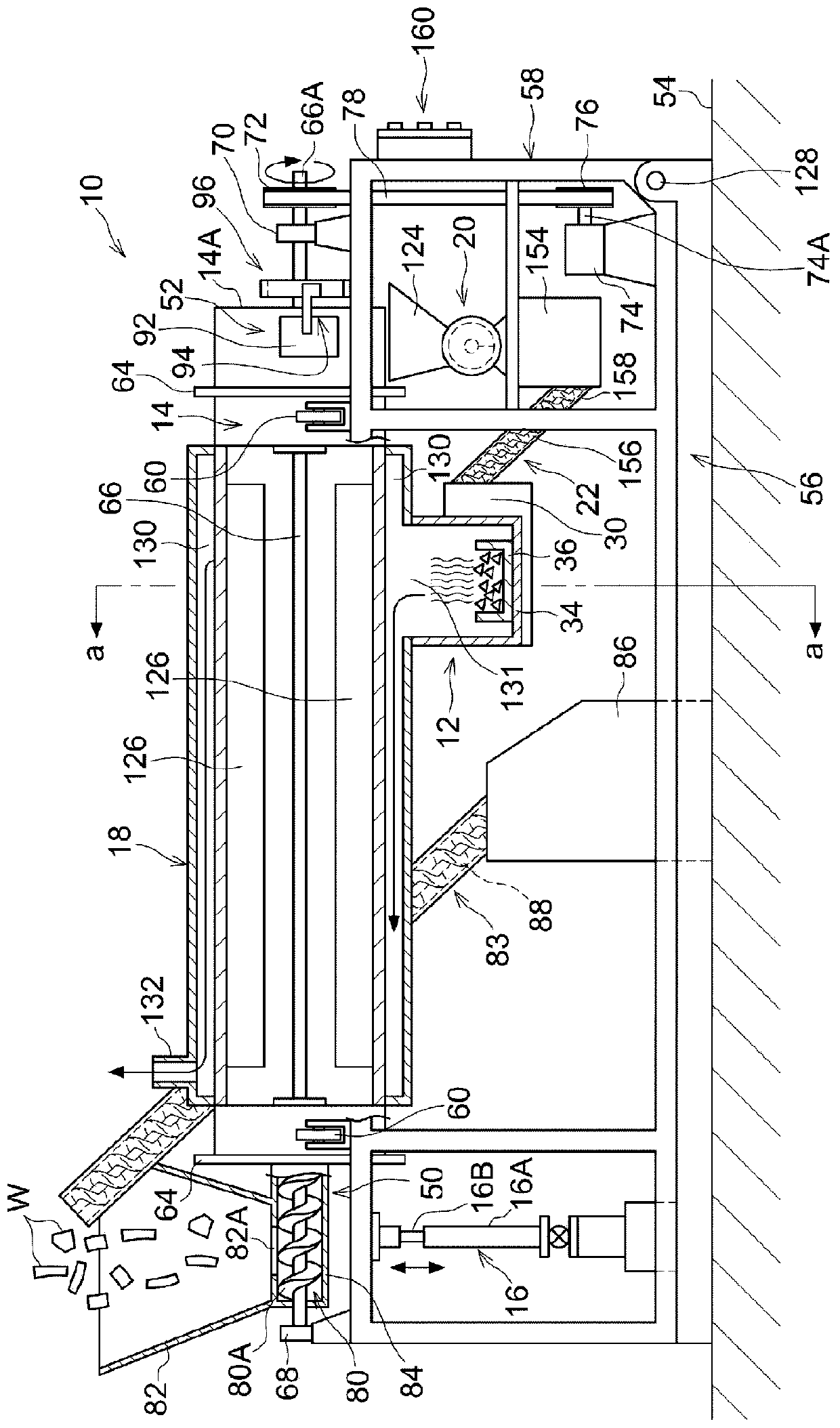

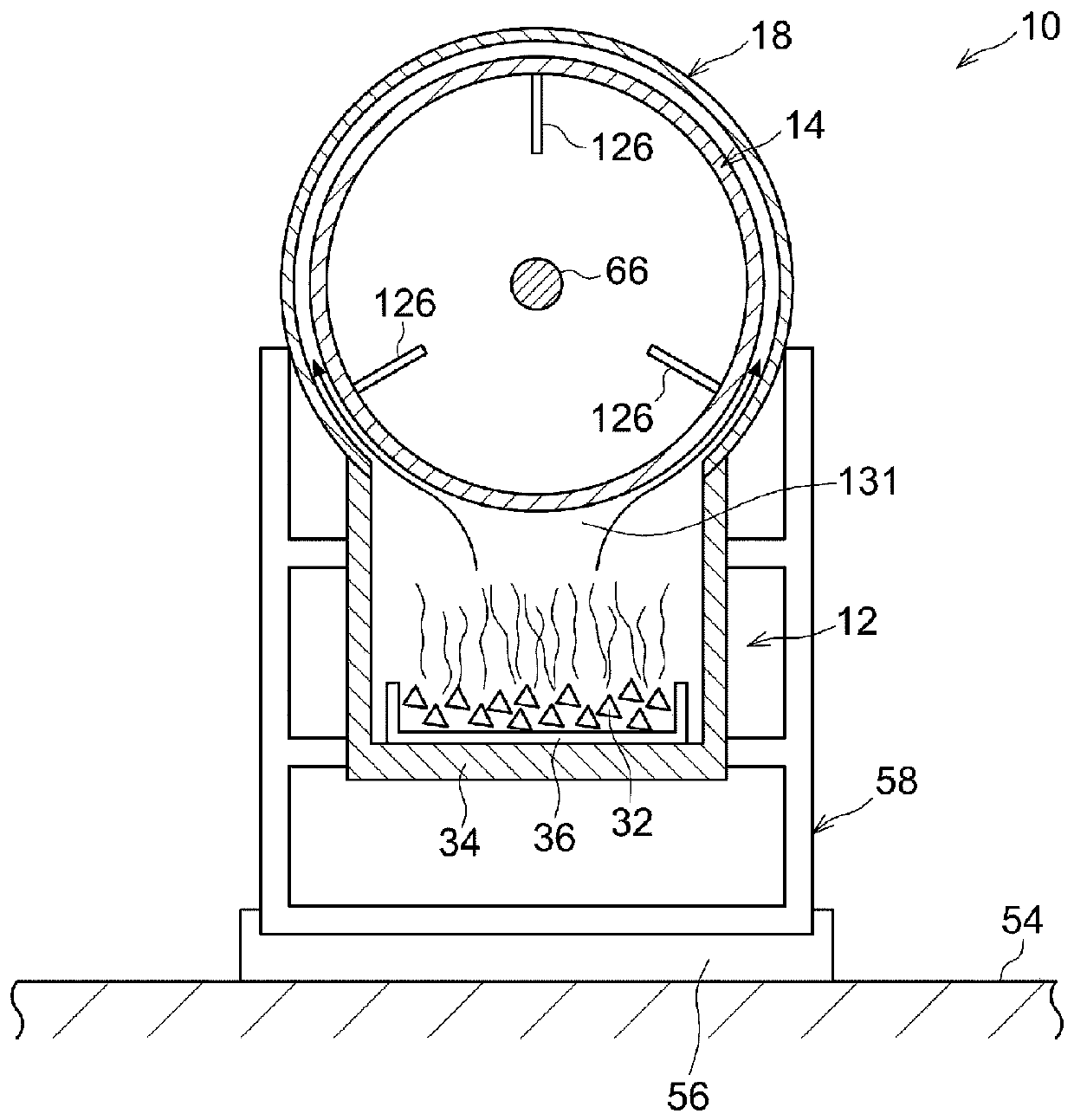

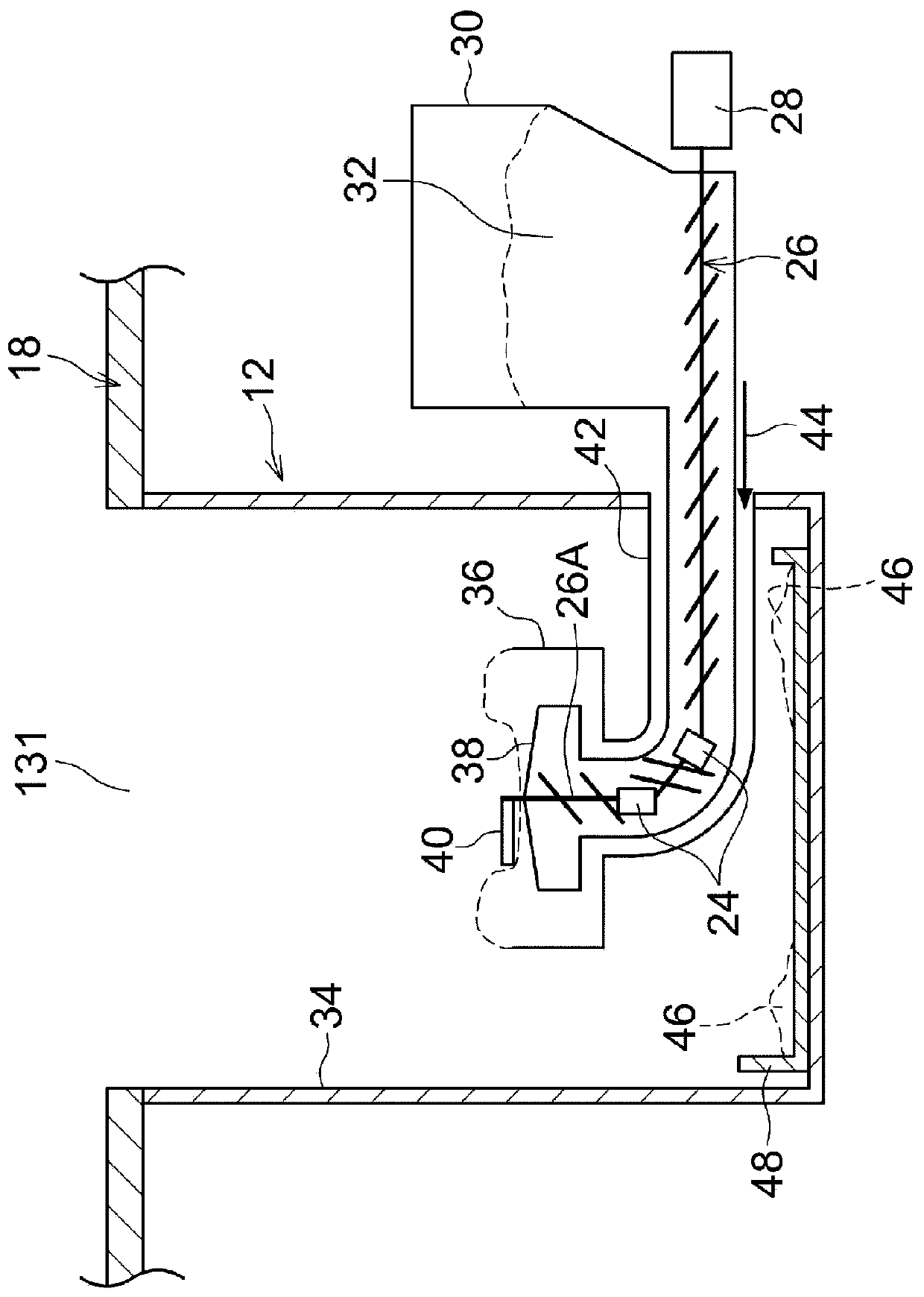

Device for producing biomass fuel

To solve problems concerning the unevenness in shape or size of a biomass fuel produced and concerning fluctuations in the degree of drying / carbonization of the biomass fuel caused by the kind of rawbiomass materials. A device comprising: a combustion furnace 12; a rotating drum 14 which includes a feed part 50 for raw biomass materials and a discharge part 52 for a biomass fuel 32 and in which drying / carbonization is conducted with the heat of the discharge gas generated in the combustion furnace 12; a tilting means 16 for tilting the rotating drum 14; a flue cover 18 for forming, between itself and the rotating drum 14, a flue for the discharge gas generated in the combustion furnace 12; a processing line 20 for making the shape and size of the biomass fuel uniform; and a return line 22through which some of the biomass fuel is returned to the combustion furnace 12. The feed part 50 is equipped with a screw conveyor 80 which feeds the raw biomass materials to the inside of the rotating drum 14 while rotating at the same speed as the rotating drum 14.

Owner:雨谷智昭

Extruder head and extruder

Owner:MESNAC

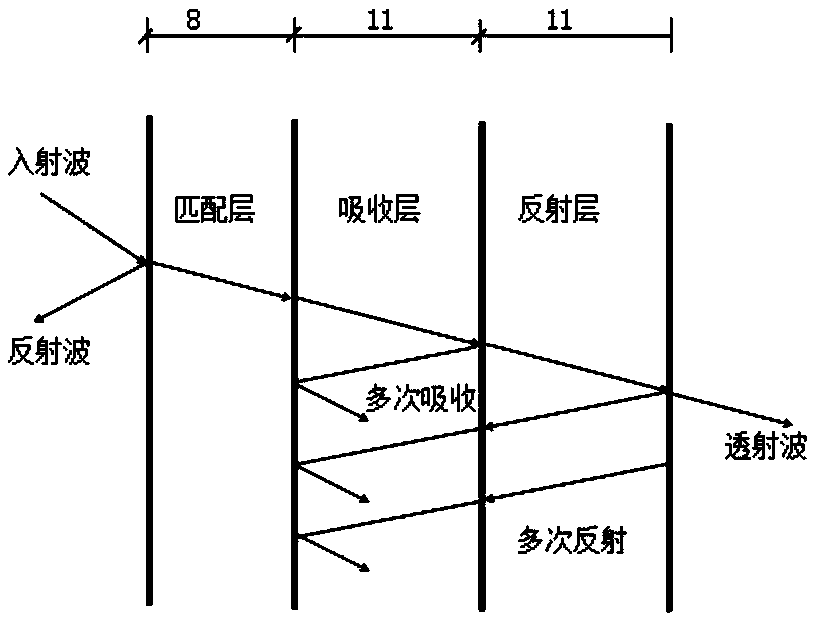

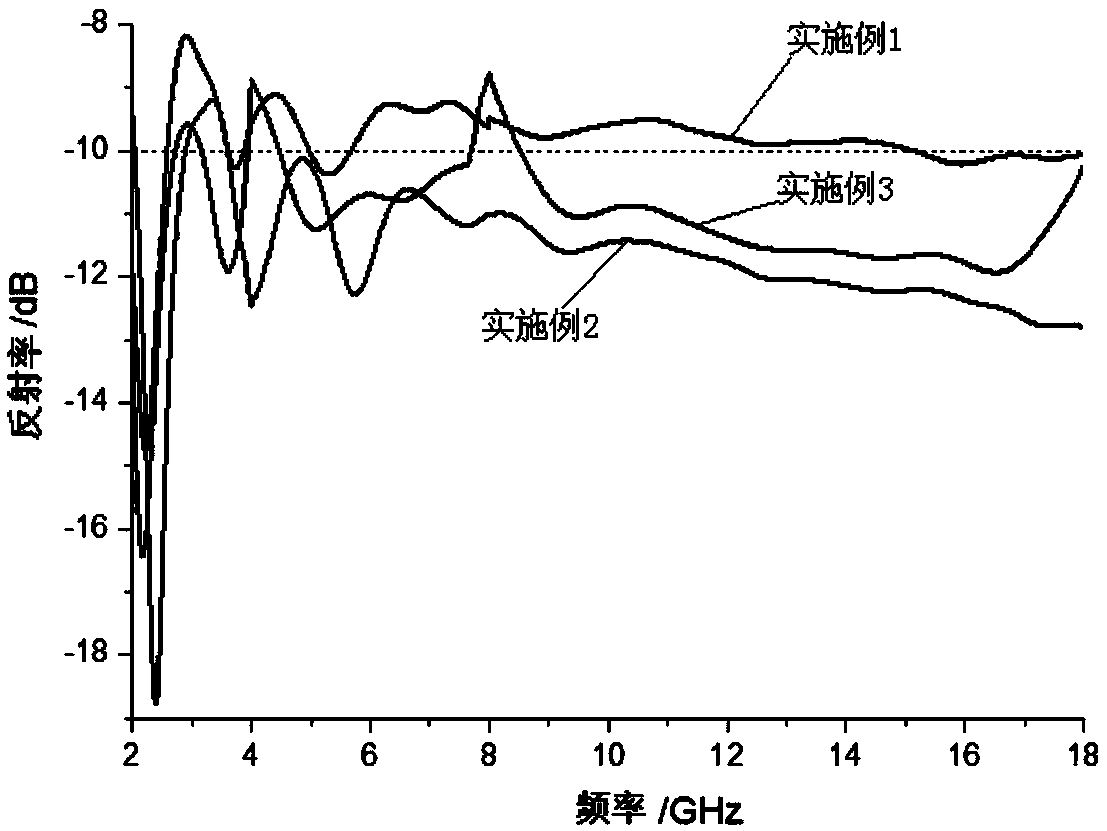

Cement-based wave absorbing plate of three-layer structure mixed with EP and NGPs wave absorbing agent and preparation method of wave absorbing plate

InactiveCN109457826ANo radioactivitySimple preparation processBuilding constructionsFiberCarbon fibers

The invention discloses a cement-based wave absorbing plate of a three-layer structure mixed with EP and an NGPs wave absorbing agent and a preparation method of the wave absorbing plate. The wave absorbing plate is composed of an upper layer plate, a middle layer plate and a lower layer plate according to a thickness ratio is 8:11:11. The upper layer plate comprises cement, silica fume, expandedperlite (EP) and a water reducing agent, wherein the silica fume, water, the expanded perlite and the water reducing agent account for 10%, 42%, 7% and 0. 32% of the mass of the cement respectively; the middle layer plate comprises the cement, the silica fume, the water, multi-layer graphene nanoplates (NGPs), nano-nickel particles and the water reducing agent, wherein the silica fume, the water,the multi-layer graphene nanoplates, the nano-nickel particles and the water reducing agent account for 10%, 32-33%, 0.025-0.05%, 0.7% and 0.33-0.35% of the mass of the cement respectively; the lowerlayer plate includes the cement, the silica fume, the water, carbon fibers, carbon black, the water reducing agent and a dispersing agent, wherein the silica fume, the water, the carbon fibers, the carbon black, the water reducing agent and the dispersing agent account for 10%, 74-80%, 0.5-1%, 4%, 0.35-0.36% and 0.35-0.38% of the mass of the cement. The wave absorbing plate is environmentally friendly and free of radioactivity, a preparation process is simple, and forming is convenient.

Owner:YANCHENG INST OF TECH

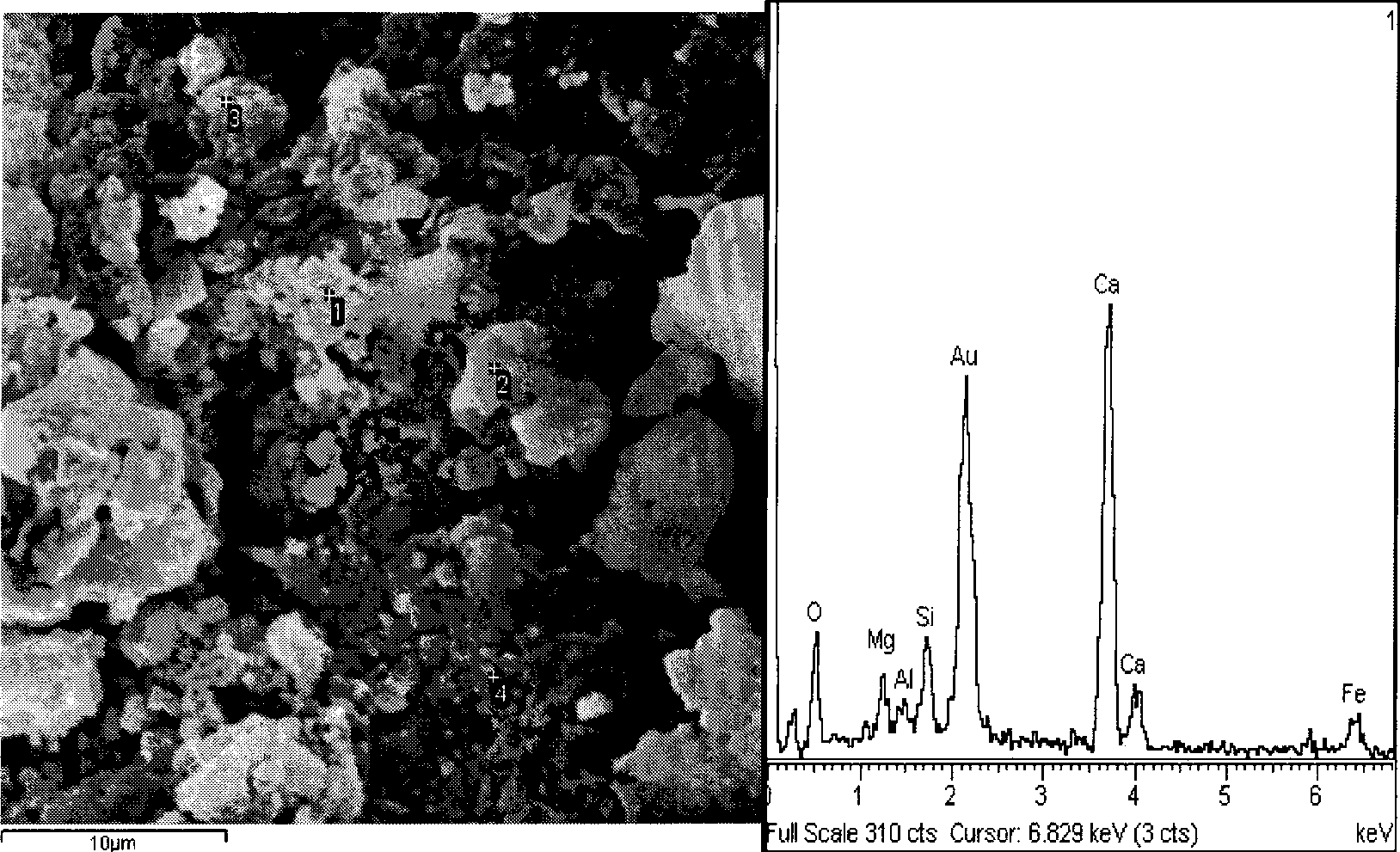

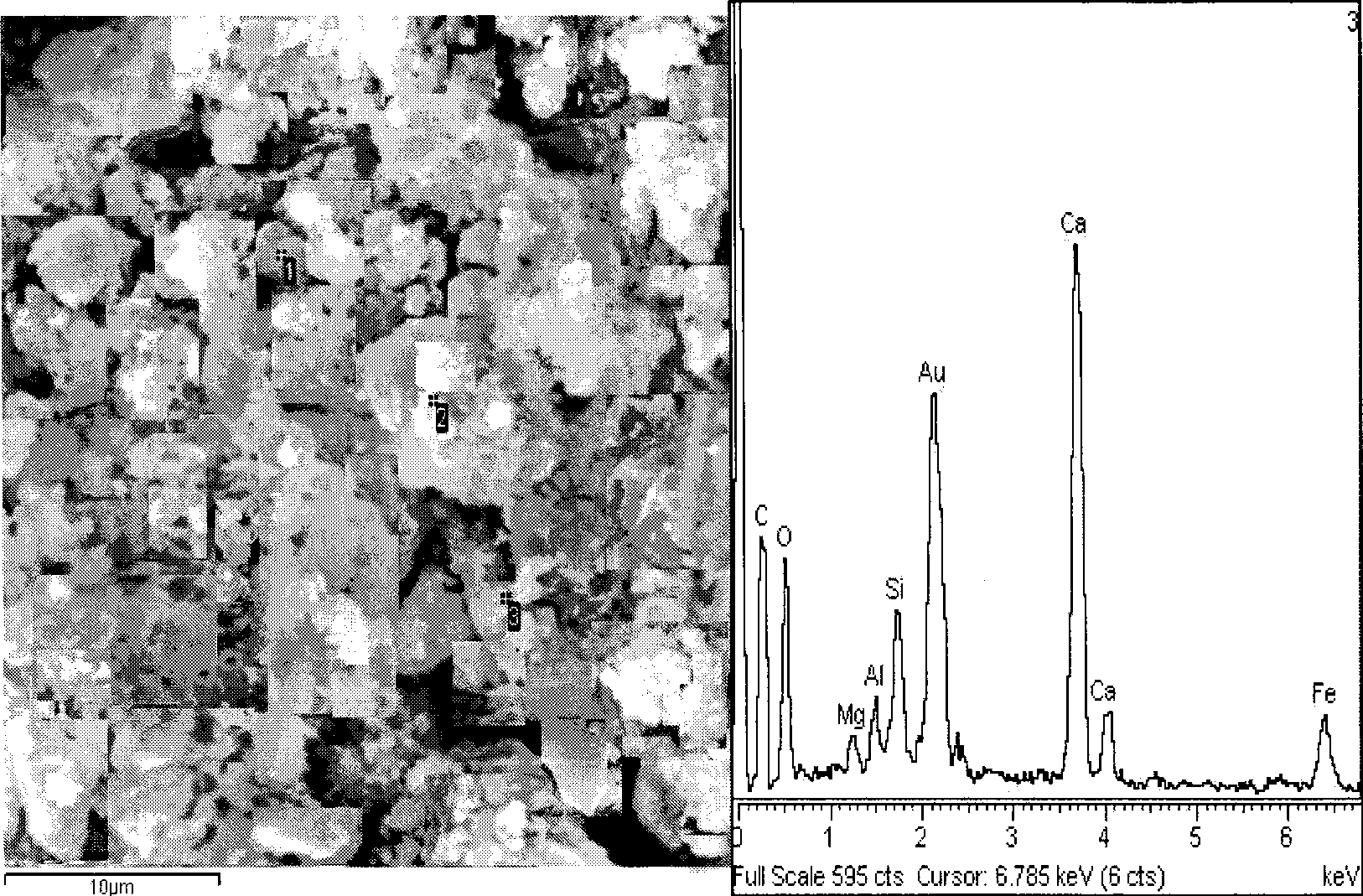

Method for producing architectural materials by using paper making sludge

The present invention belongs to the technical field of environmental protection, and relates to a method for preparing a building material by using industrial wastes (paper making sludge, different steel slag, furnace cinders, waste concrete) as main raw materials and applying an accelerated carbonation technology, in particular to the method for producing the building material by using the paper making sludge. The method comprises the following steps: according to the weight ratio of between 1 to 0.5 and 1 to 4, mixing the paper making sludge with a carbonized material; adding water into the mixture and mixing the mixture evenly; pressing the mixture into a semi-finished product of the building material; and preparing the semi-finished product of the building material into a finished product of the building material under the curing of accelerated carbonation. The method effectively makes use of the industrial wastes such as the paper making sludge, reduces the emission of the greenhouse gas of carbon dioxide, and prepares the building material with excellent performance and beautiful appearance. The method has the advantages of favorability for waste recycling, environmental protection, energy conservation, and low cost.

Owner:UNIV OF JINAN

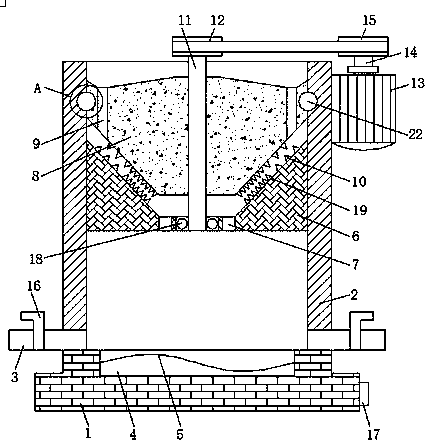

Solid smelting pretreatment equipment

InactiveCN109746076ATo achieve the effect of primary crushingEasy to smeltGrain treatmentsEngineeringPre treatment

The invention discloses solid smelting pretreatment equipment comprising an installing base. A smelting box is fixedly connected to the upper surface of the installing base. The inner bottom wall of the smelting box is provided with a discharge outlet. The upper surface of the installing base is provided with a heating cavity. An electric heating wire is fixedly installed on the inner wall of theheating cavity. Through the solid smelting pretreatment equipment, the effect of primary crushing of solid smelting materials is achieved, the smelting materials are crushed into small shapes and small sizes after crushed by primary crushing teeth, smelting is convenient, the shapes and sizes of the smelting materials are further limited, and smelting is convenient. The smelting materials can be effectively crushed by the rectangular-pyramid-shaped primary crushing teeth and advanced crushing teeth, a crushing rotor can be located rotationally, the shake problem caused by too large stress on the crushing rotor during rotary crushing is avoided, and thus the problems that smelting efficiency is liable to be lowered due to different shapes and sizes of solid smelting objects are solved effectively.

Owner:扬州市江都区正谊研磨工具厂

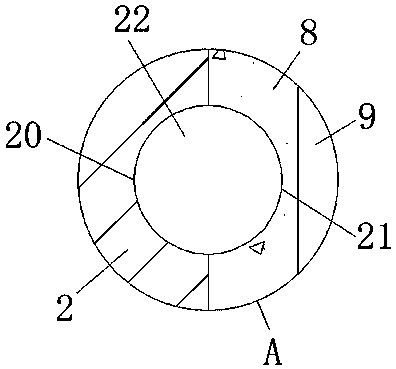

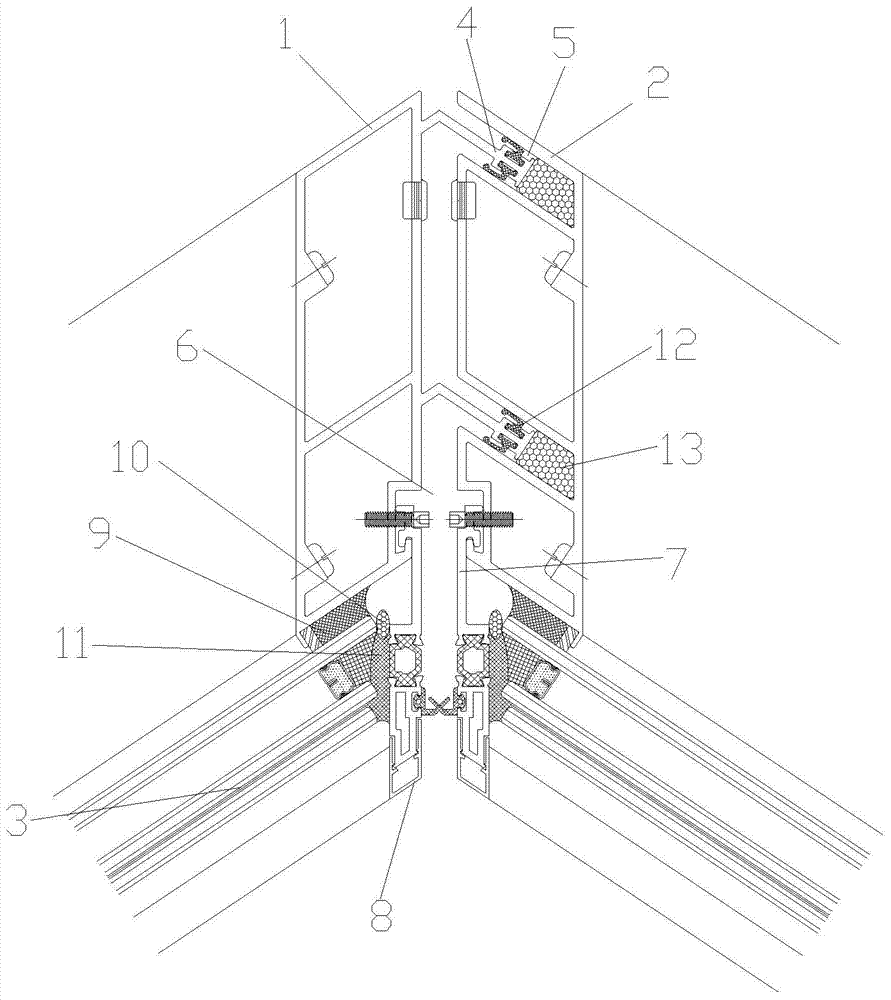

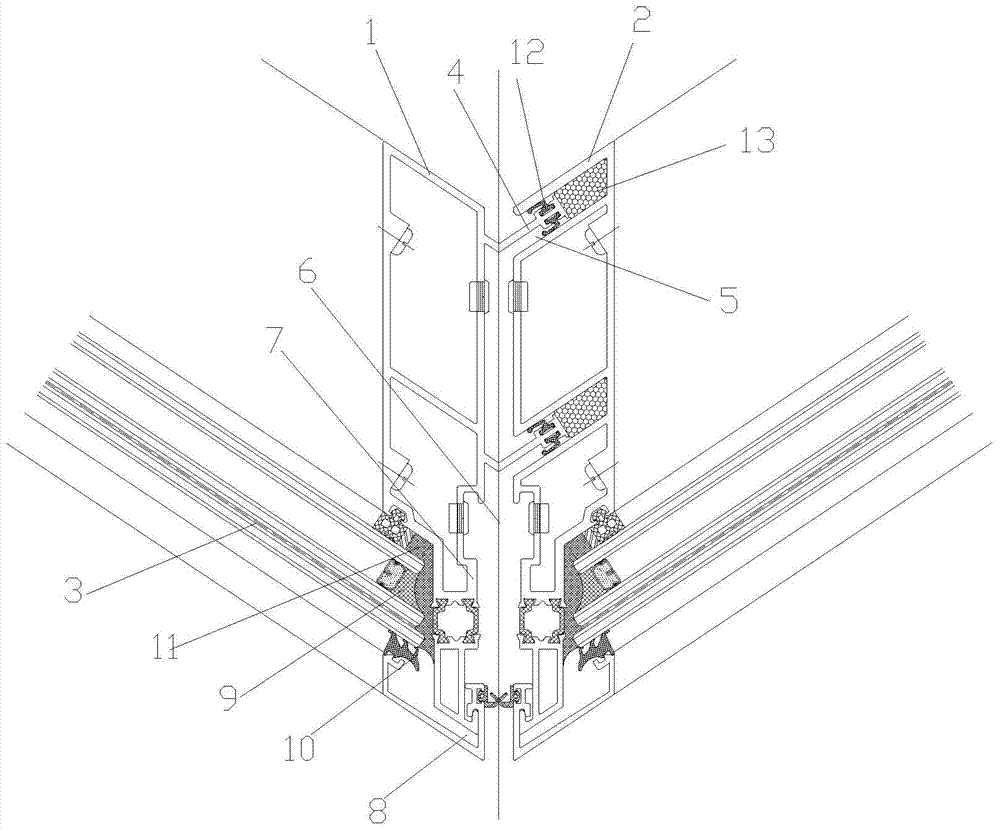

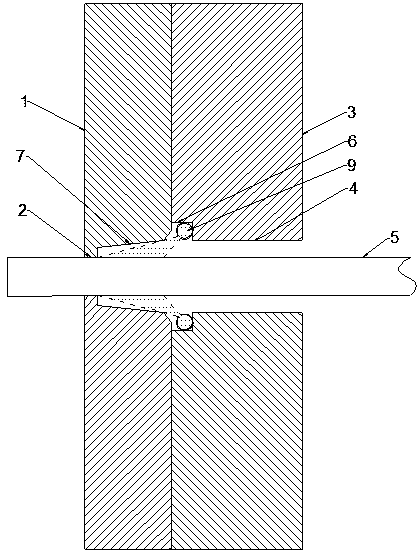

Continuous fold-type glass curtain wall

The invention discloses a continuous fold-type glass curtain wall which comprises a unit frame aluminum alloy column A, a unit frame aluminum alloy column B and hollow tempered glass. A pin on the unit frame aluminum alloy column A and a groove in the unit frame aluminum alloy column B are installed in a matching mode, and an installation groove is formed between the unit frame aluminum alloy column A and the unit frame aluminum alloy column B. An aluminum alloy side strip is fixedly installed in the installation groove through a screw, a decoration cover face is installed at one end of the aluminum alloy side strip stretching out of the installation groove, the hollow tempered glass is installed on the outside of the aluminum alloy side strip, and the hollow tempered glass, the unit frame aluminum alloy column A, the unit frame aluminum alloy column B and the aluminum side strip are fixedly bonded through silicone structure adhesive, foam strips and silicone weather-proof adhesive. The curtain wall ensures the appearance of the whole appearance, solves the glass curtain wall production installation and appearance problem, and is favorable for improving the whole efficiency.

Owner:SUZHOU GOLD MANTIS CURTAIN WALL CO LTD

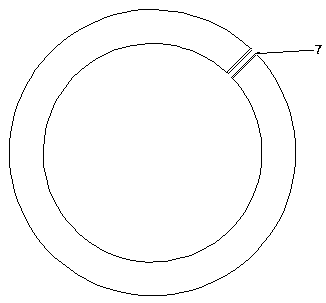

Online forced cooling method and device for extrusion die

The invention discloses an online forced cooling method and device for an extrusion die, used for metal hot extrusion forming. An annular straight slot is machined between a discharging hole of the extrusion die and a pad special for the die around the contour of a main reaction shape of the discharging hole of the extrusion die; a gas pipe is laid in the annular straight slot; cooling inert gasesare introduced into the gas pipe; the cooling gases are ejected onto a die working length and the surface of an extrusion material via tiny outlet holes in the gas pipe. According to extrusion forming production of aluminum and magnesium alloys and other products having low quenching temperature sensitivity, high-pressure forced cooling can be conveniently performed at the extrusion outlet, the extrusion material is subjected to online quenching heat treatment, and the corresponding mechanical property requirements can be met; grain coarsening caused by secondary crystallization is avoided, so that the surface quality meets the requirements, and the surface is bright; the defects in the size, shape, structure and the like of the extrusion material due to extremely high metal temperature fluctuation in the hot extrusion process can be overcome; the extrusion speed is effectively improved, and the production efficiency is improved by 10% or higher.

Owner:FUJIAN UNIV OF TECH

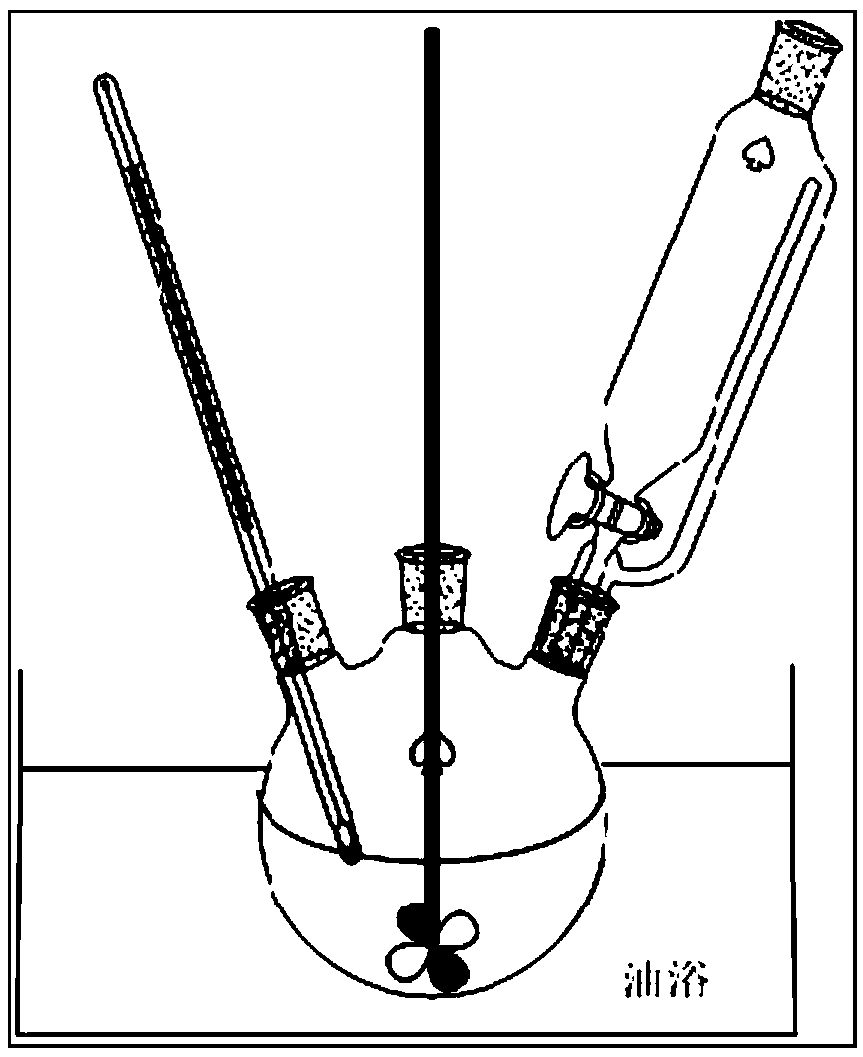

Low-molecular weight siliceous acrylic resin for photosensitive silver paste and preparation method thereof

The invention discloses low-molecular weight siliceous acrylic resin for photosensitive silver paste. The low-molecular weight siliceous acrylic resin contains the following components in percentage by mass: 30%-70% of solid components and 30%-70% of liquid components, wherein the solid components contain a non-silicon monomer, an organic silicon compound, an initiator and a chain transfer agent,the organic silicon compound accounts for 0.01%-2% of the mass of the monomer, the initiator accounts for 0.01%-2% of the mass of the monomer, and the chain transfer agent accounts for 0.01%-1% of themass of the monomer. The low-molecular weight siliceous acrylic resin has the beneficial effects that organic silicon is introduced into the small-molecular weight acrylic resin, a good developing effect is realized and also the adhesive force between an electrode and a membrane is improved. The invention also discloses a preparation method of the low-molecular weight siliceous acrylic resin forthe photosensitive silver paste.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

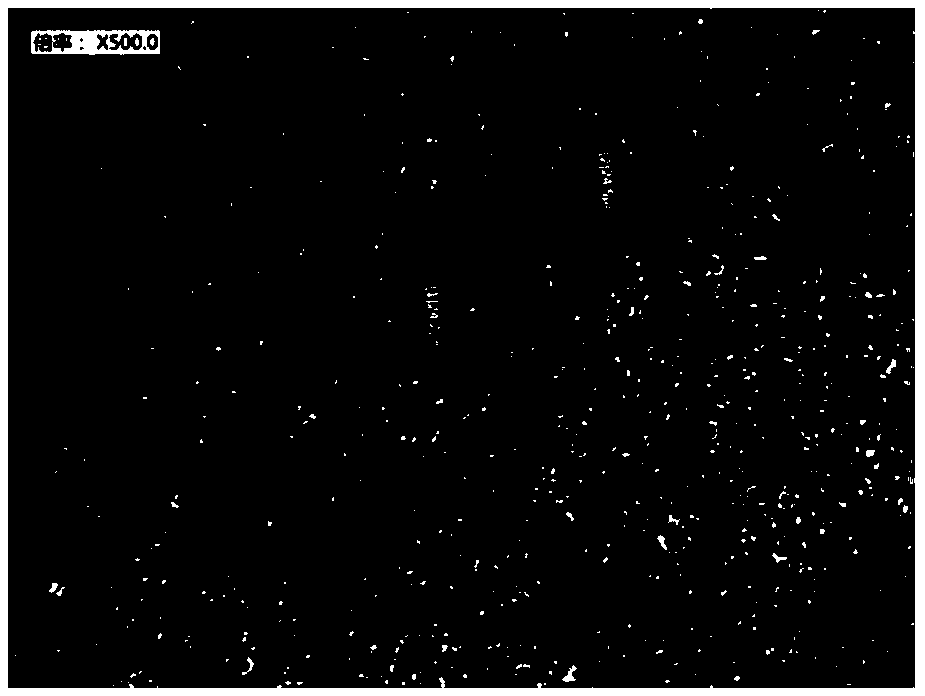

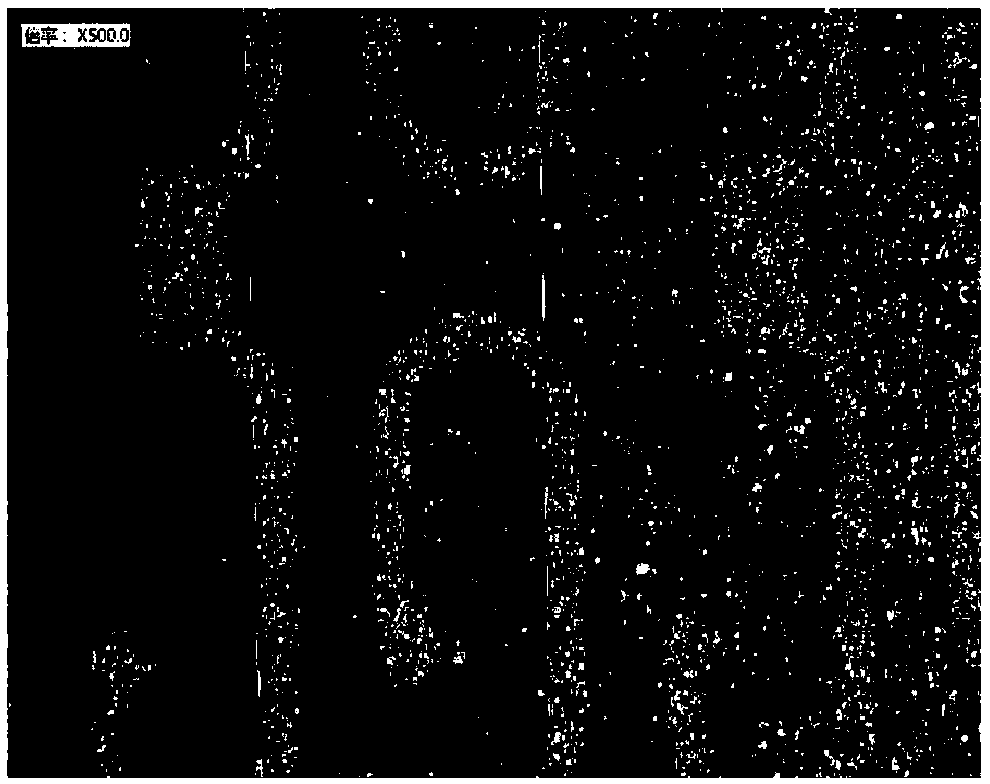

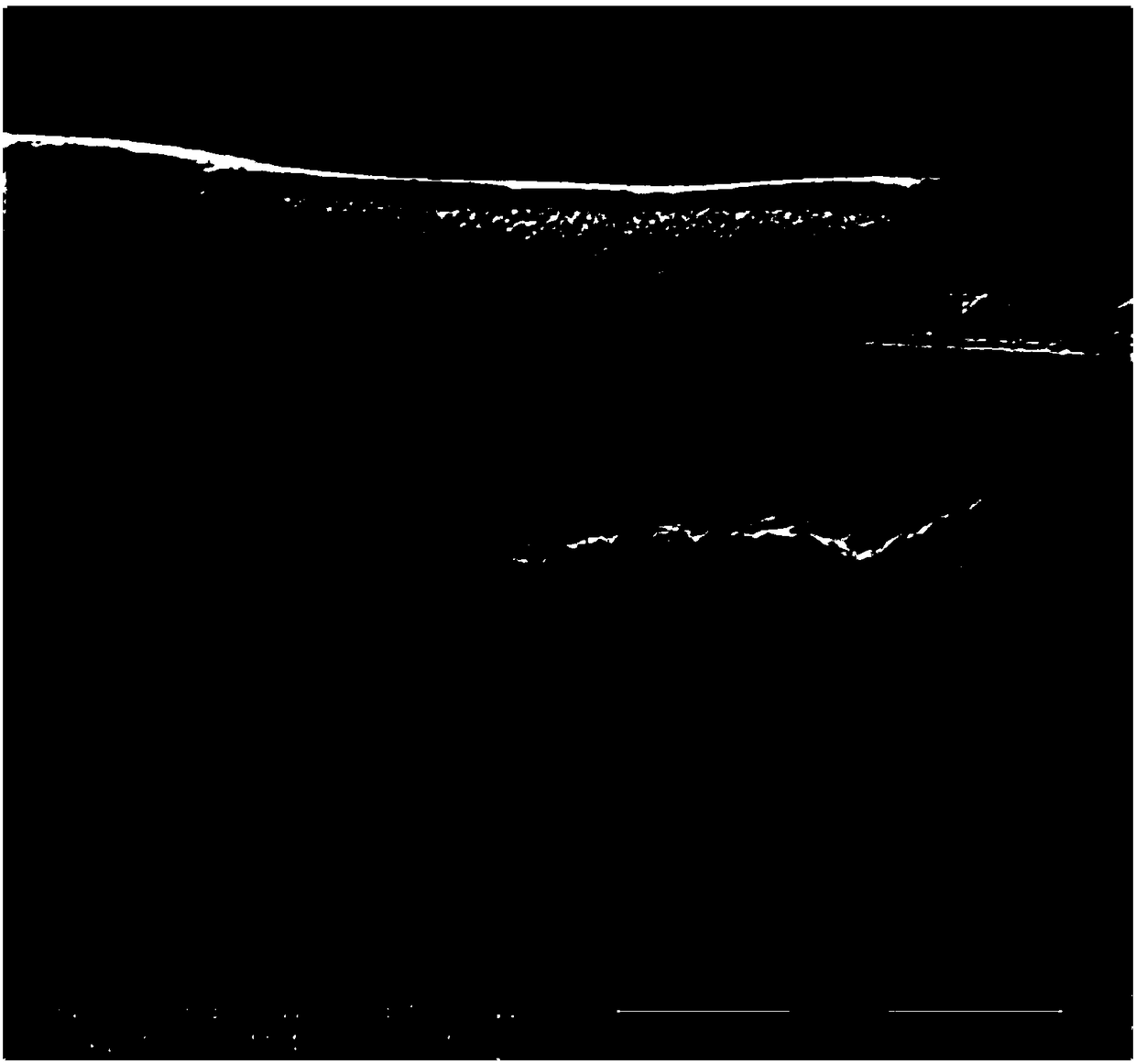

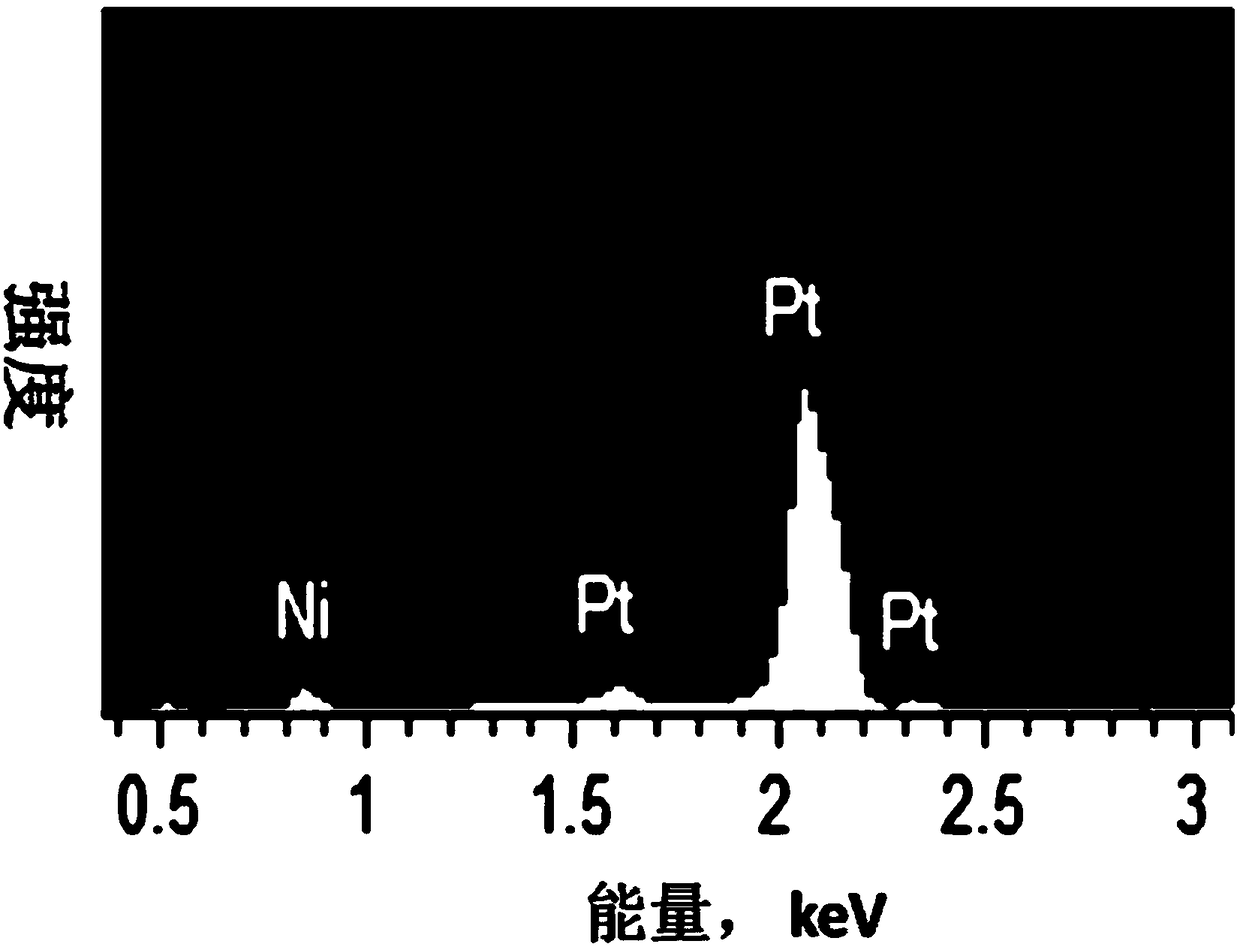

In-suit loaded type foam microporous precious metal catalyst, and preparation method thereof

The invention discloses an in-suit loaded type foam microporous precious metal catalyst, and a preparation method thereof. According to the preparation method, an amorphous alloy wire with a cross section area of S0 (or a woven product of the amorphous alloy wire) is taken as a precursor, and is immersed in an acid solution for corrosion of the amorphous alloy at certain depth of the external surface of the amorphous alloy wire through dealloying reaction so as to obtain a nanometer porous precious metal catalytic layer, and at the same time, a amorphous wire core with a cross section area ofS(S<S0) is maintained as a structure support, so that the in-suit loaded type foam microporous precious metal catalyst with a foam microporous precious metal annular external shell catalytic layer andan internal amorphous wire core composite structure. The preparation method is low in cost, is simple in operation, and is controllable, and is capable of producing the precious metal catalyst material with an excellent structure and excellent performance.

Owner:嘉兴长维新材料科技有限公司 +1

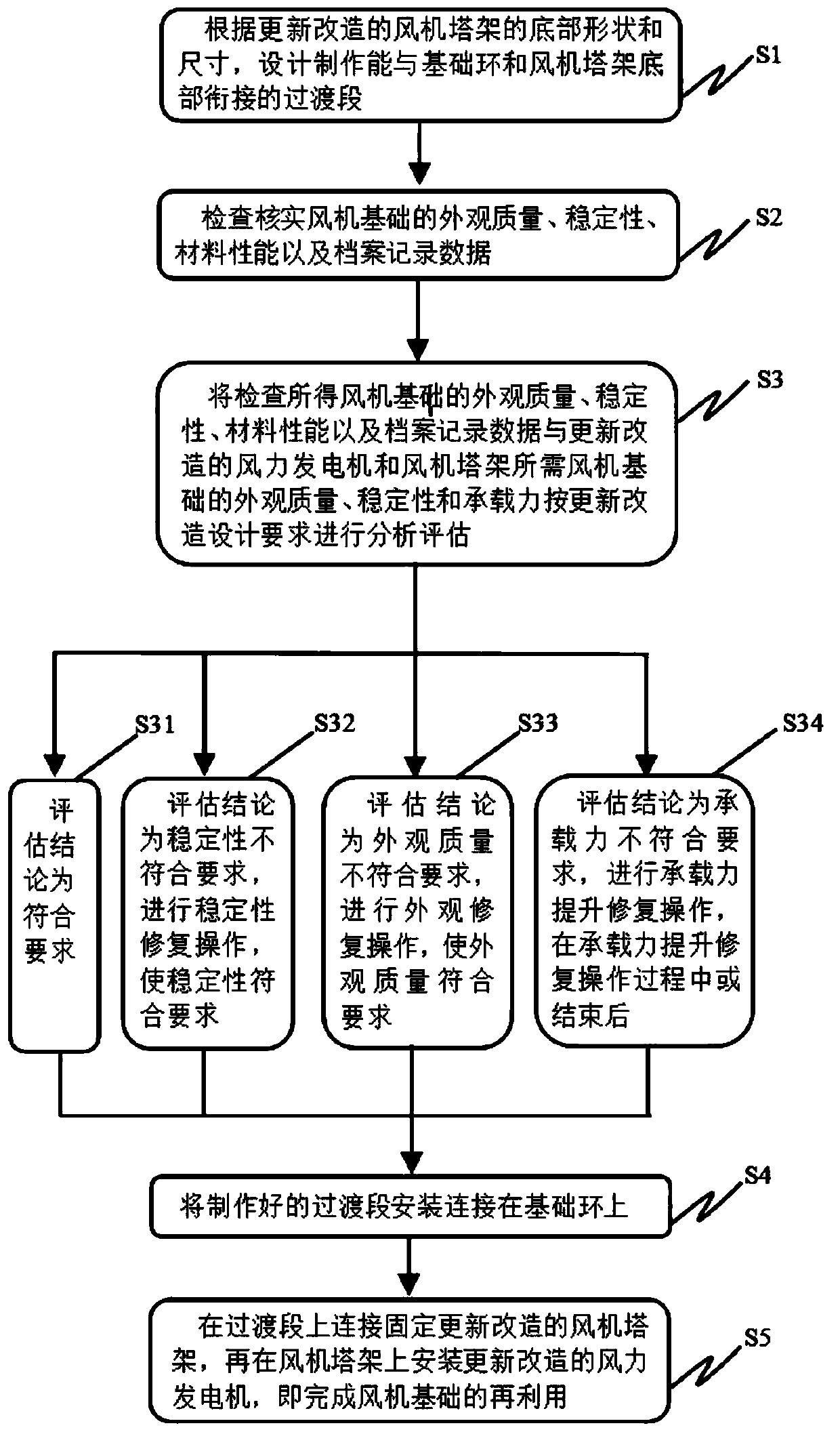

Fan foundation reutilization plan

ActiveCN111486060AAchieve reuseResolve the base ring shapeFinal product manufactureWind motor supports/mountsWind drivenArchitectural engineering

The invention provides a fan foundation reutilization plan which comprises the steps of by utilizing a transition section for connecting a fan foundation ring and a renovated and transformed fan tower, after analyzing and evaluating the appearance quality, the stability, a material performance and case record data of a fan foundation of a wind power generator requiring renovation and transformation according to a renovation and transformation design requirement, directly connecting the transition section onto the foundation ring, connecting the renovated and transformed fan tower onto the transition section, and installing a renovated and transformed wind driven generator on the renovated and transformed fan tower, so that the reutilization of the fan foundation is accomplished; or after accomplishing restoring the stability, the appearance, the bearing capacity improvement and the like of the fan foundation, connecting the transition section onto the foundation ring, and connecting and fixing the renovated and transformed fan tower onto the transition section, so that the reutilization of the fan foundation is accomplished; or after accomplishing the connection of the foundation ring and the transition section, restoring the bearing capacity improvement of the fan foundation, and accomplishing the installation of the fan tower and the wind driven generator, so that the reutilization of the fan foundation is accomplished.

Owner:中环柯昂(北京)科技有限公司

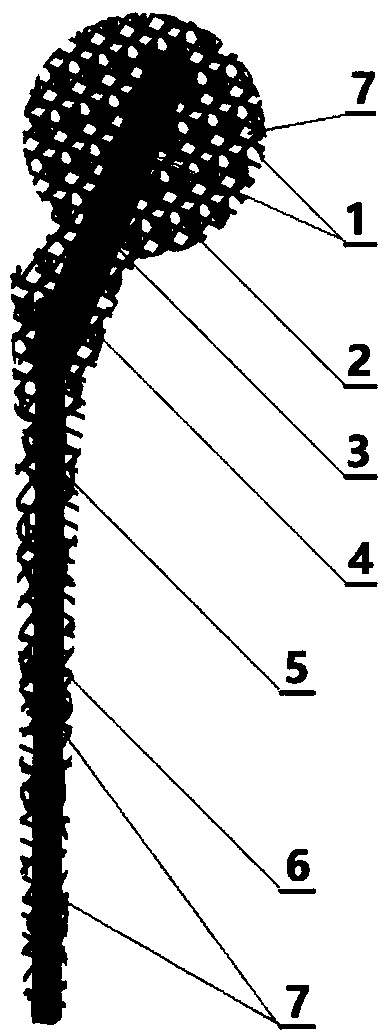

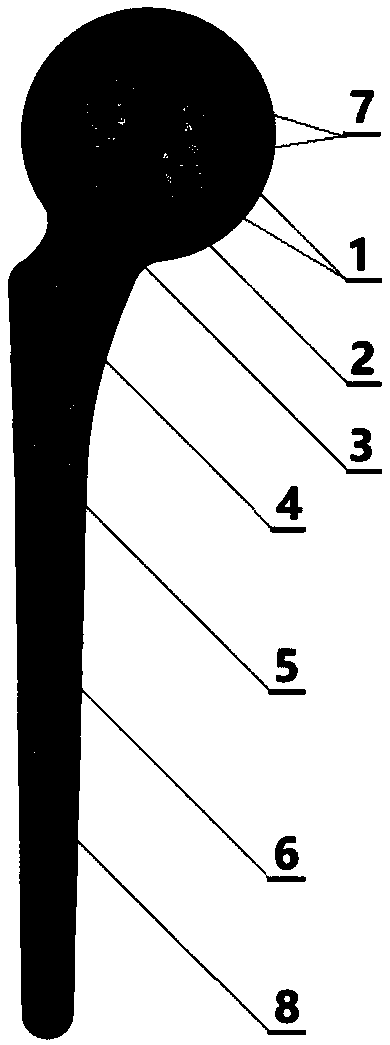

Customization joint bone cement prosthesis reinforcing supporting frame and preparation and application thereof

The invention discloses a customization joint bone cement prosthesis reinforcing supporting frame. The supporting frame is provided with a supporting frame main beam, a supporting frame secondary beamand a supporting frame net, the supporting frame net is arranged in the periphery of the supporting frame main beam and the supporting frame secondary beam, the supporting frame main beam is providedwith a supporting frame head and a supporting frame neck, and the supporting frame secondary beam is provided with a supporting frame handle. A preparation method comprises the steps of prosthesis three-dimensional model construction, prosthesis mold designing and manufacturing and prosthesis reinforcing supporting frame designing and manufacturing. According to the customization joint bone cement prosthesis reinforcing supporting frame, the supporting frame main beam, the supporting frame secondary beam, and a supporting frame net multi-pore net grid structure are designed, the supporting frame net is of a crossed curved surface multi-pore structure of an orthogonal multi-pore structure, bone cement in a liquid period is easily filled into the reinforcing supporting frame to effectivelyenhance the strength of the bone cement prosthesis, prolong the service life of the bone cement prosthesis and improve the success rate of operations, and the defects of easy fracturing caused by insufficient strength due to the fact that the mechanical characteristics of a pure bone cement prosthesis are hard and fragile after the pure bone cement prosthesis in the prior art is cured, and easy fracturing and smashing of the bone cement prosthesis when the bone cement prosthesis is taken out in a two-stage operation are overcome.

Owner:贵港市人民医院

Deformable materials, deformable structures, micro-led display devices, strain sensors

ActiveCN110065267BSolve shapeProtective equipmentSynthetic resin layered productsStructural deformationLED display

Embodiments of the present invention provide a deformable material, a deformable structure, a Micro-LED display device, and a strain sensor, which relate to the field of flexible technology and can solve the problem that the shape before deformation is different from the shape after deformation when the deformable structure is deformed. The deformable material includes a multi-layer sheet structure, each layer of the sheet-like structure includes a plurality of aldolases, the shape of the aldolase is a square, and the amino acid residues on the four corners of each aldolase The amino acid residues of the four aldolases are connected together by four disulfide bonds; the amino acid residues of the aldolases located in the adjacent sheets are connected by disulfide bonds Together.

Owner:BOE TECH GRP CO LTD +1

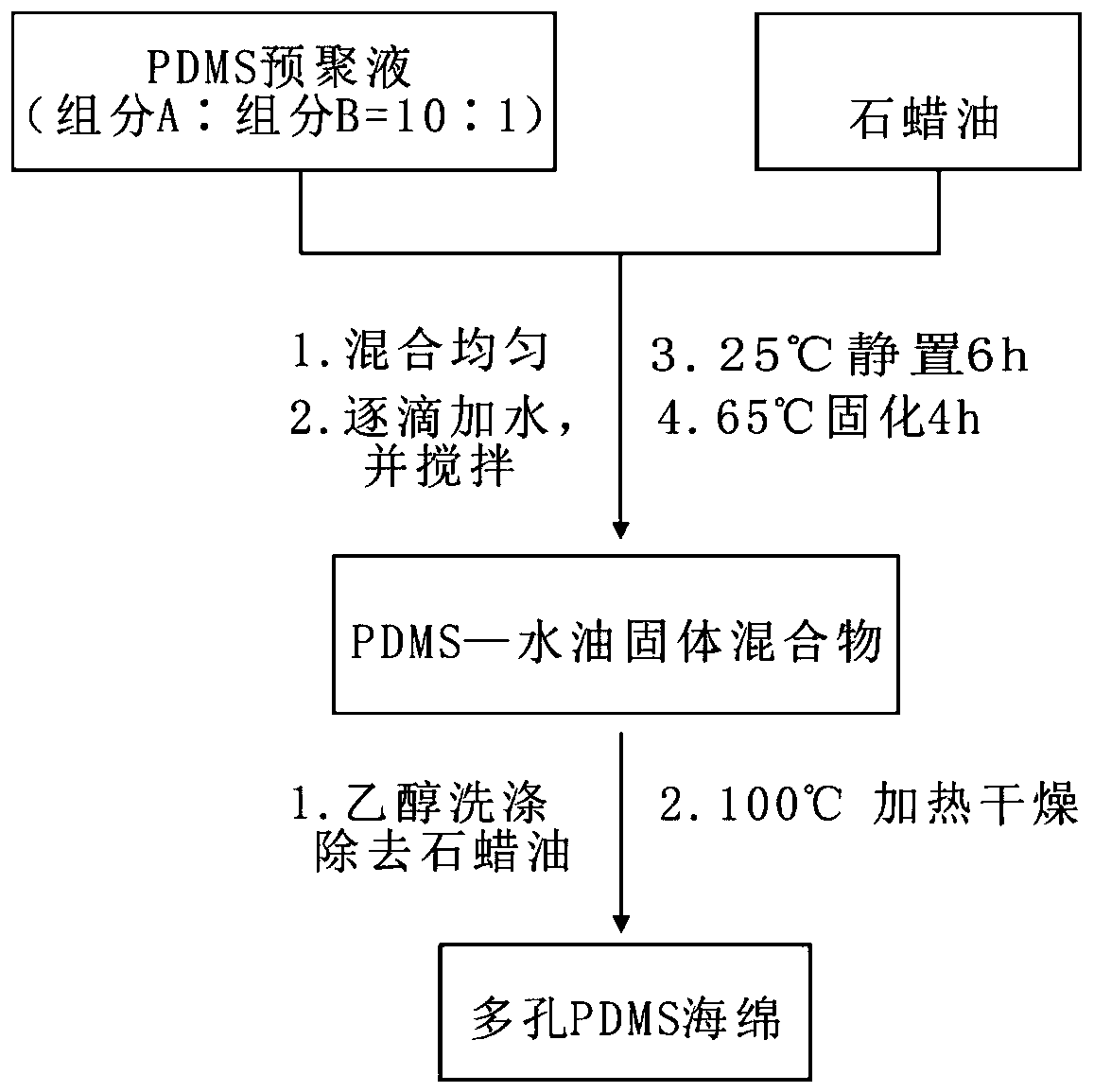

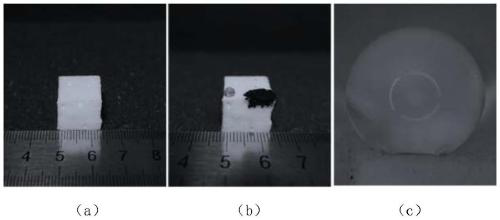

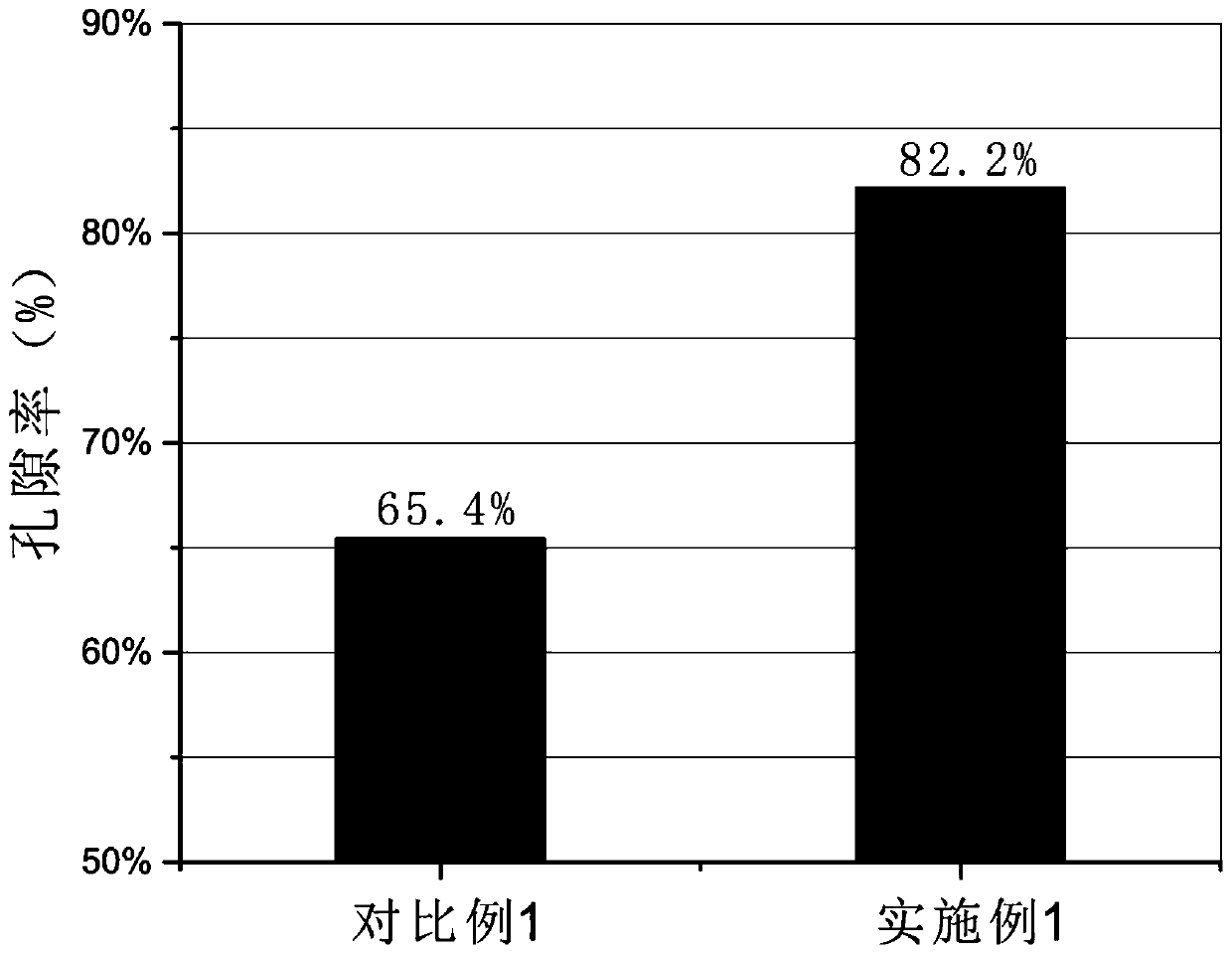

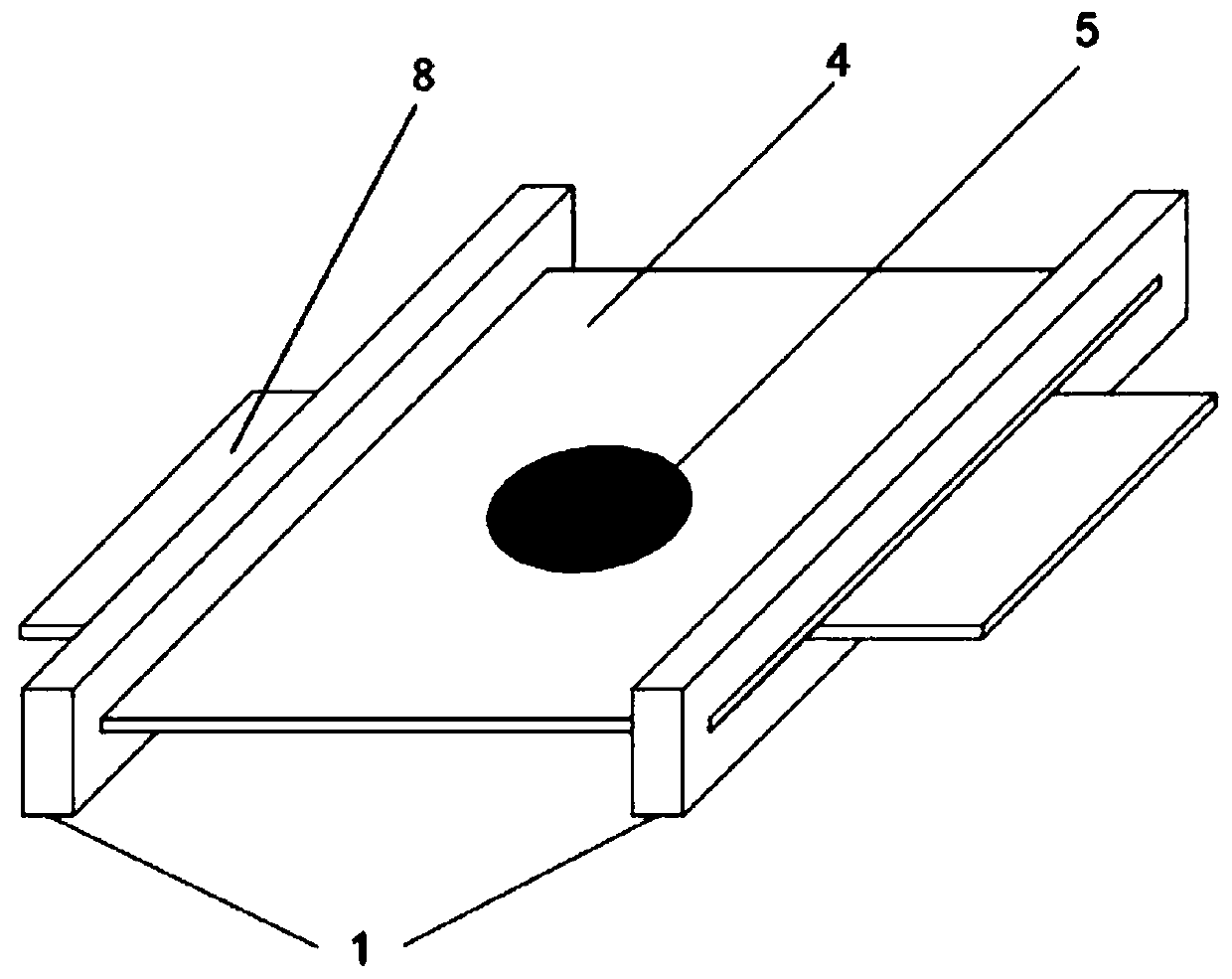

A kind of water-emulsified polydimethylsiloxane functional sponge and its preparation method and application

ActiveCN108530672BShape adjustableHigh oil absorption rateLiquid separationEmergency treatmentOrganosolv

Owner:HUAZHONG UNIV OF SCI & TECH

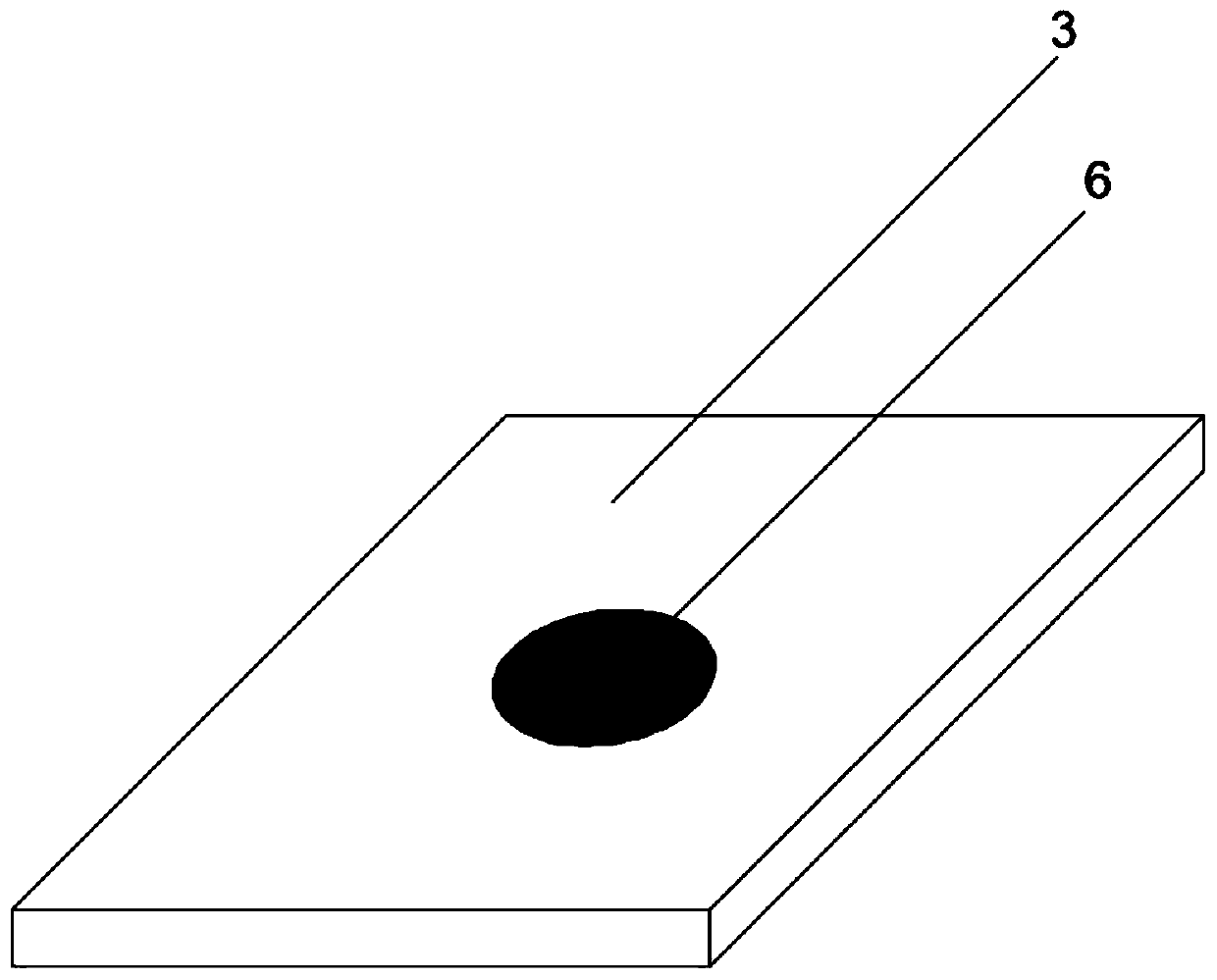

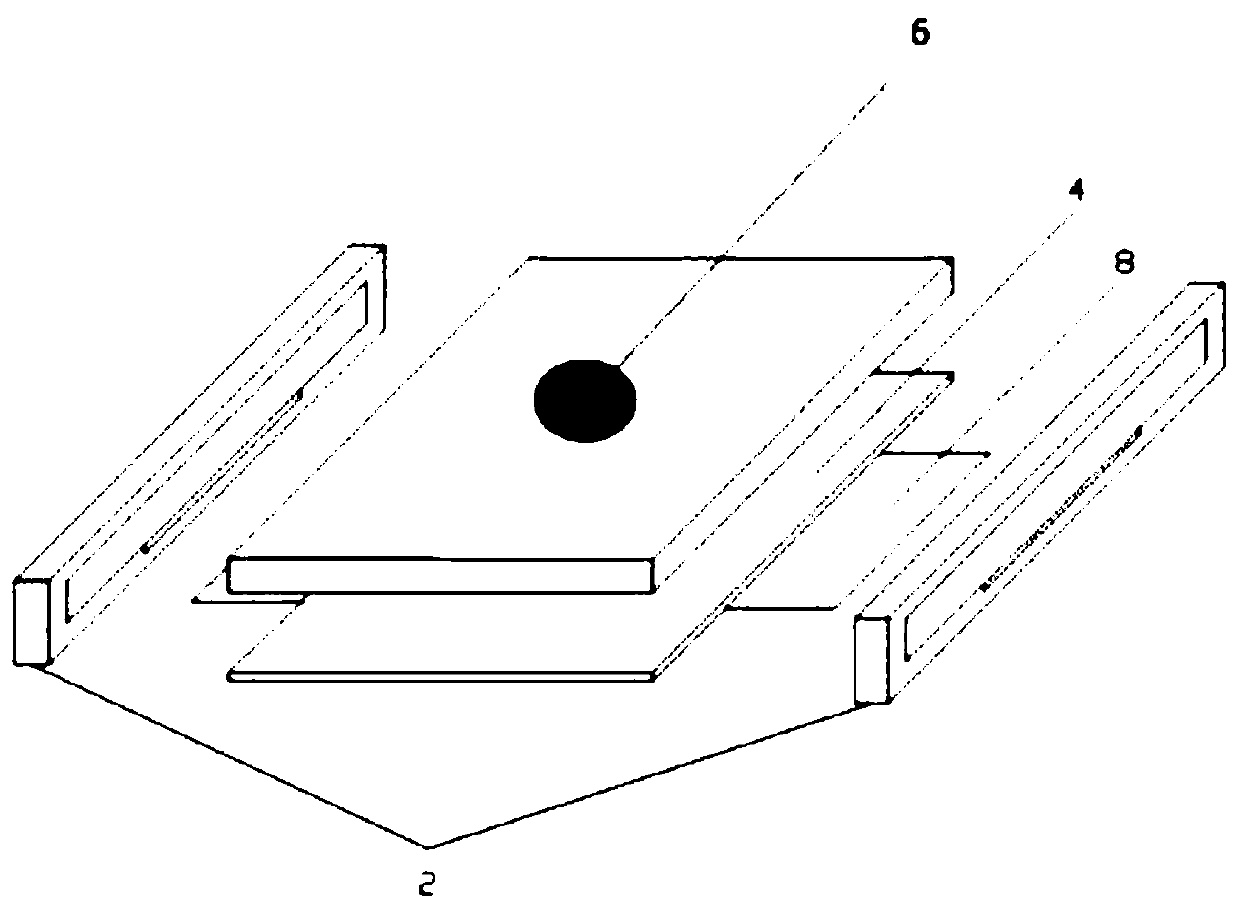

Method and mold for preparing microscopic analysis sample of double-layer asphalt diffusion system

PendingCN111562156AResolve specificationsSolve shapePreparing sample for investigationPhysical chemistryAsphalt

The invention discloses a method and mold for preparing a microscopic analysis sample of a double-layer asphalt diffusion system. The method comprises the following steps: S1, respectively heating newasphalt and old asphalt to a flowing state, respectively injecting the processed new asphalt and old asphalt into an upper-layer mold and a lower-layer mold, and performing cooling to obtain an upper-layer sample and a lower-layer sample; S2, superposing and combining the upper-layer mold and the lower-layer mold to enable the upper-layer sample and the lower-layer sample to be in contact, and then performing heating to enable the upper-layer sample and the lower-layer sample to be fully diffused; S3, cooling and demolding the upper-layer mold and the lower-layer mold, placing a double-layeranalysis sample consisting of the upper-layer sample and the lower-layer sample on a glass slide, performing heating, taking out the product, cooling and storing the product; and S4, performing asphalt microscopic test observation on the cooled and stored double-layer analysis sample. With the method, a technical problem that the specification, the shape and the quality of an analysis sample cannot be controlled in the preparation and forming process is effectively solved, the use amount of asphalt can be effectively controlled, and the authenticity of subsequent asphalt and asphalt mixture material and mechanical property evaluation is improved.

Owner:INNER MONGOLIA UNIV OF TECH

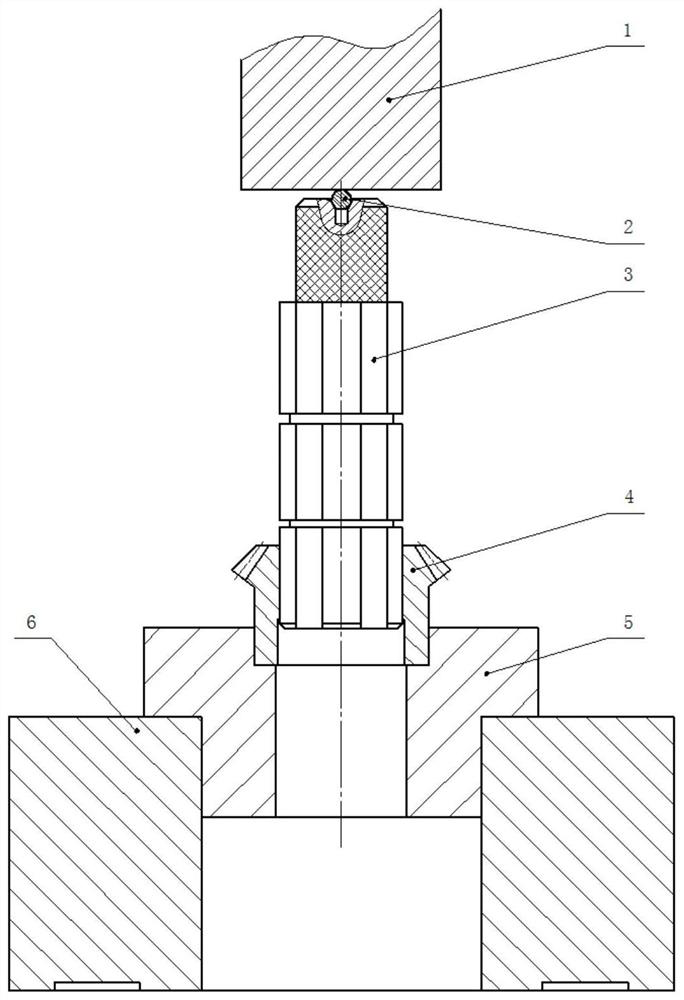

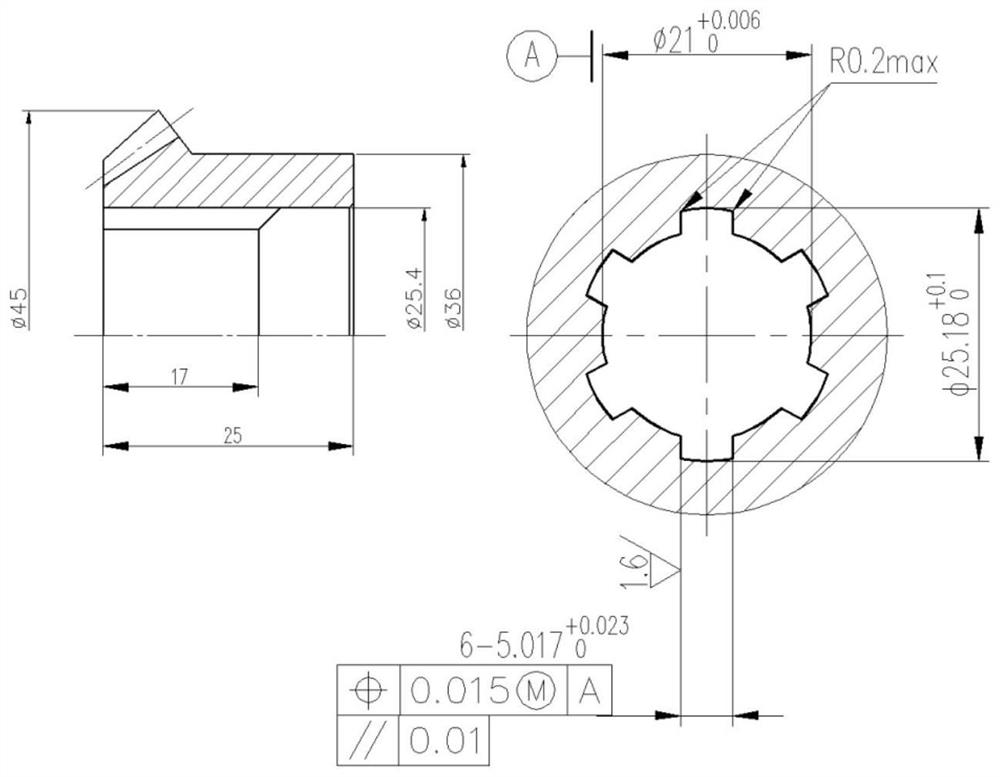

Device and method for machining rectangular splines in hard tooth surfaces

The invention discloses a device for processing rectangular splines in a hard tooth surface. The device is an adaptive centering device. The self-adaptive centering grinding device includes a grinding head, an adaptive steel ball, a grinding Rod, bushing and base, the bushing is installed and fixed in the inner hole of the base, the parts are placed in the positioning hole in the bushing, the top end of the grinding rod is provided with a center hole, and the self-adaptive steel ball is placed in the center hole of the grinding rod for grinding The rod matches the inner rectangular spline of the part, and the grinding head presses on the adaptive steel ball to push the grinding rod down to grind the inner rectangular spline of the part. The invention can ensure the dimensional accuracy, parallelism and positional degree of the inner rectangular spline.

Owner:ZHONGNAN TRANSMISSION MACHINERY FACTORY CHANGSHAAVIATION IND

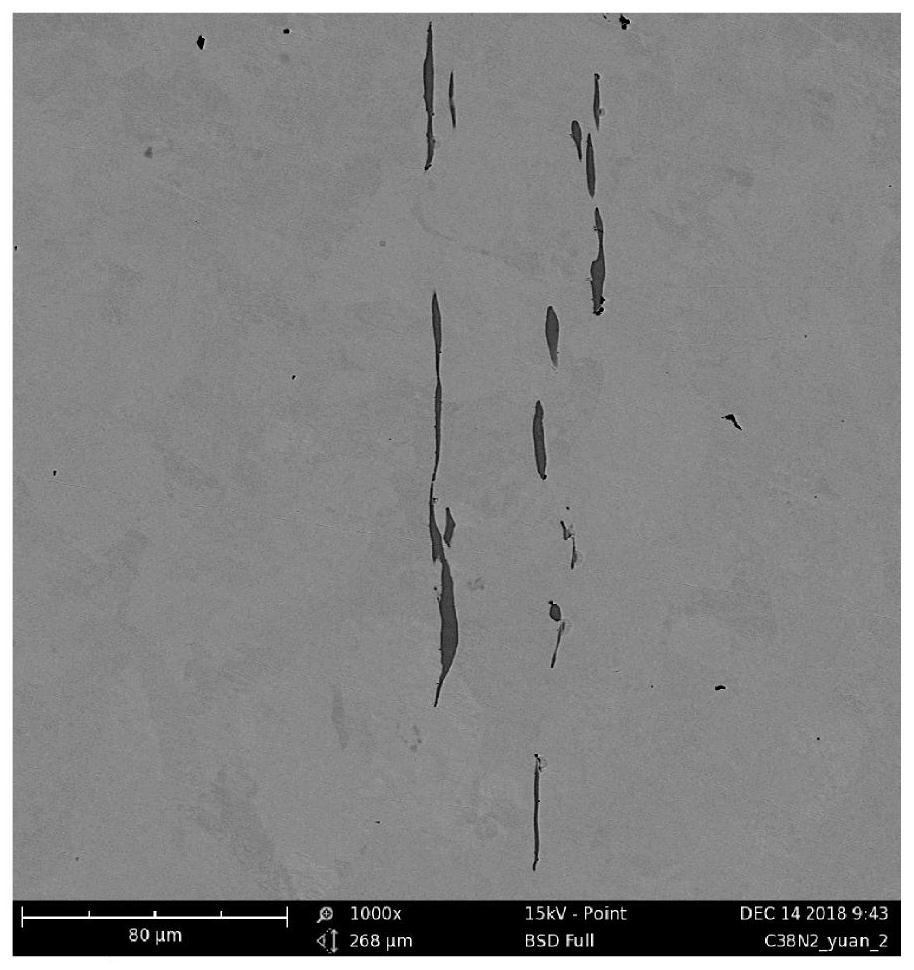

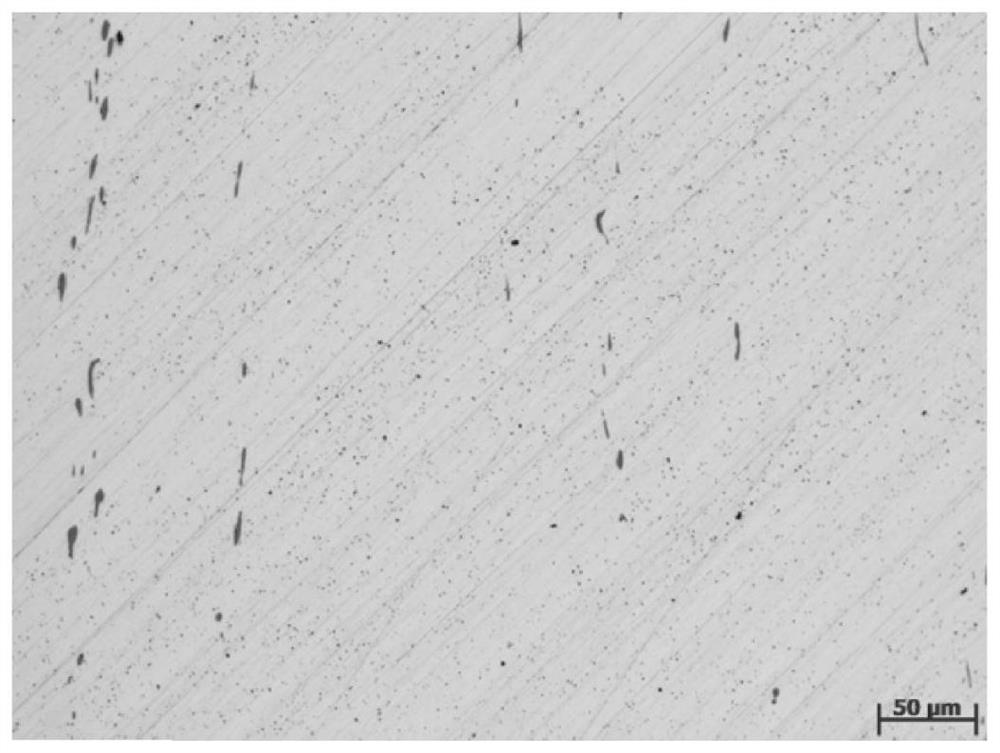

A non-modulated steel using tellurium to control the morphology of sulfide inclusions and its manufacturing method

The invention discloses a non-modulated steel which adopts tellurium to control the morphology of sulfide inclusions and a manufacturing method thereof. By adding a small amount of tellurium element to molten steel, the effect of regulating the morphology of MnS can be achieved. Problems with sulfide shape in quenched and tempered steel, improving sulfide rating. In its content control range, when the tellurium content is low, the tellurium is dissolved in MnS to increase the hardness of the inclusions, ensuring a small amount of deformation during rolling; when the tellurium content is high, the precipitated MnTe adheres to the surface of MnS , Due to the low surface energy of MnTe, it can spheroidize MnS inclusions and reduce the proportion of elongated MnS inclusions in the finished steel, thereby reducing the amount of deformation of MnS during forging. The aspect ratio of the sulfide in the finished product is less than or equal to 5, and the ratio of the aspect ratio between 1 and 3 reaches more than 90%, which significantly reduces the long or rod-shaped sulfide, improves the cutting performance of the steel, and prevents the steel from vulcanizing during deformation. aggregates.

Owner:NANJING IRON & STEEL CO LTD

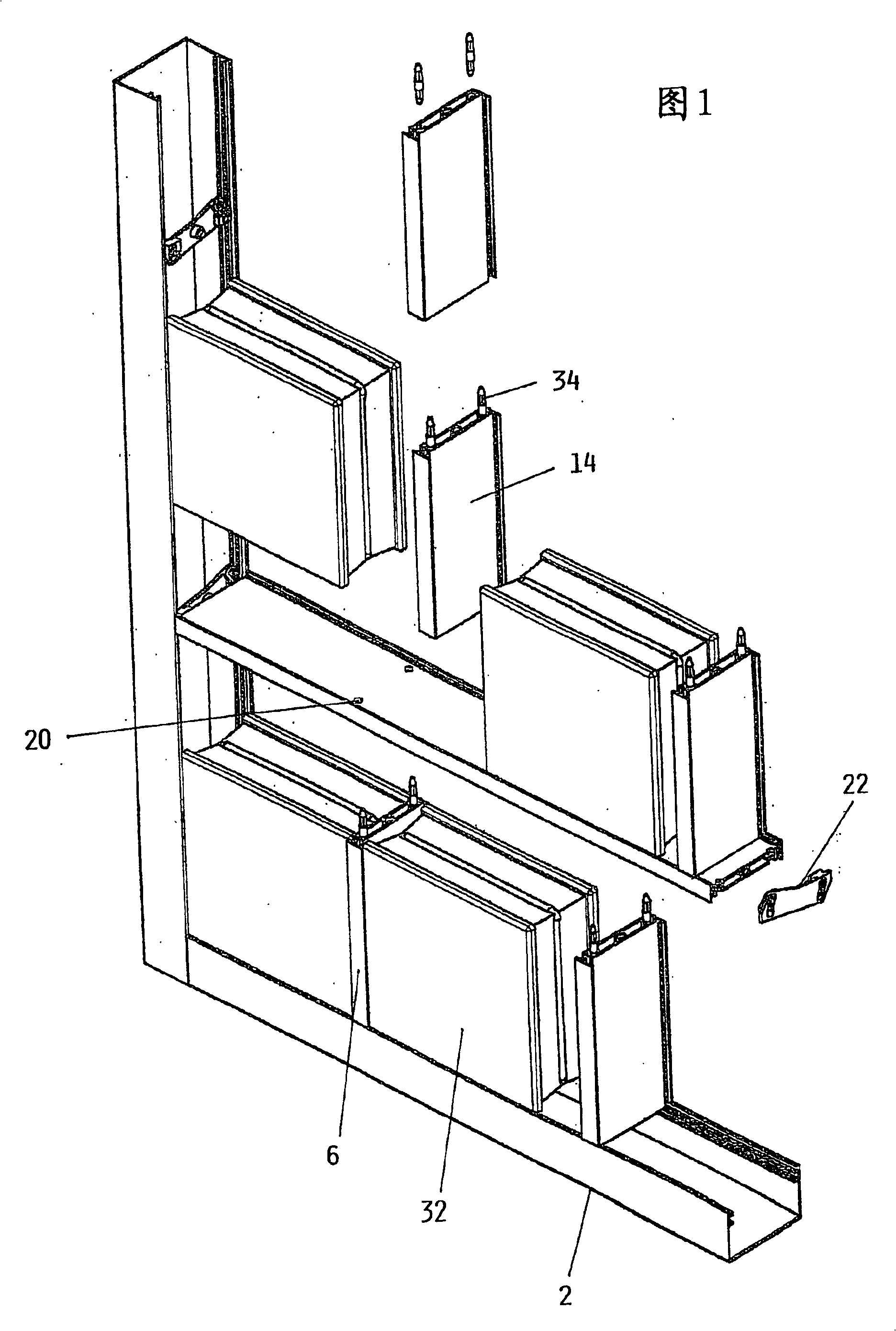

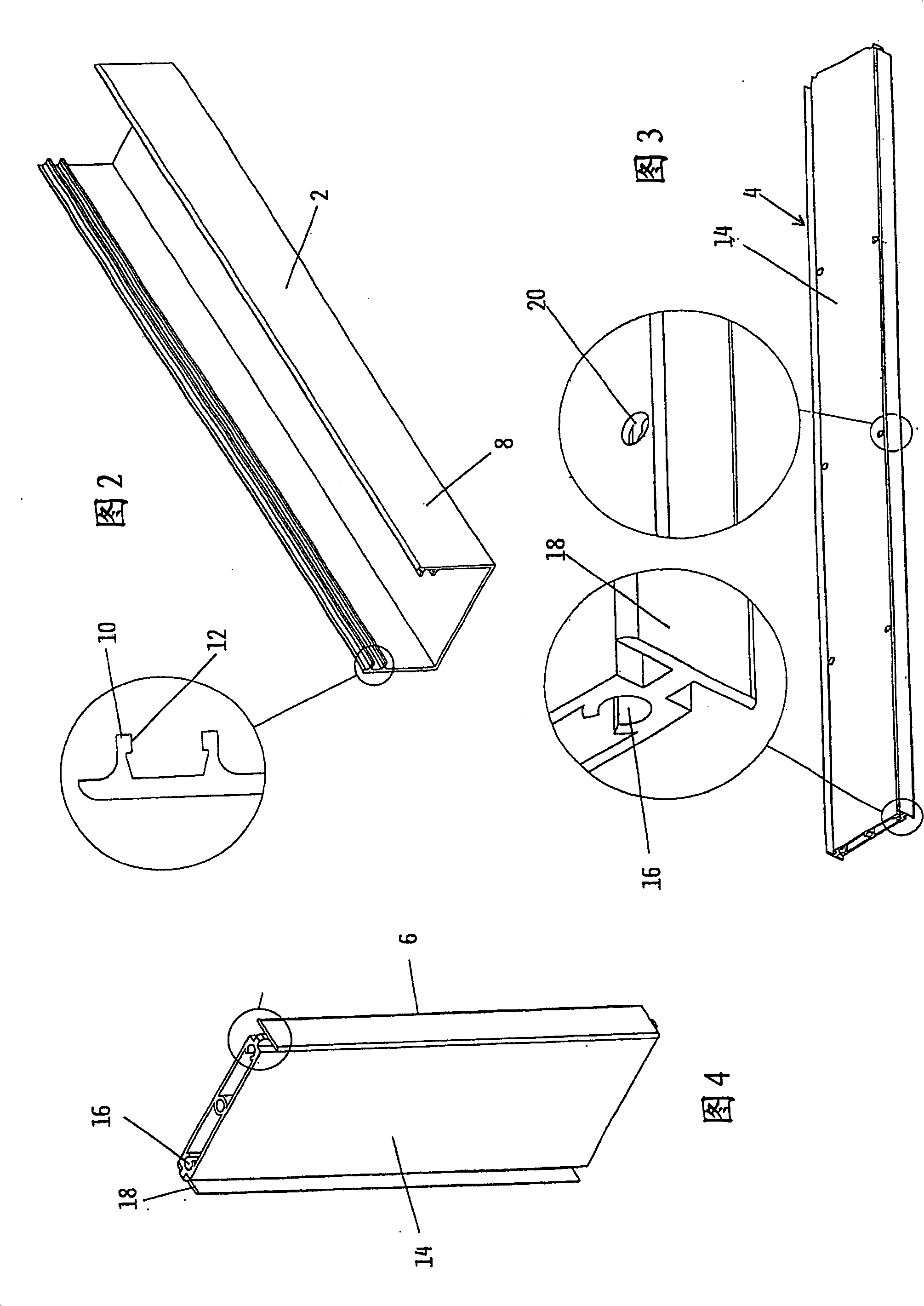

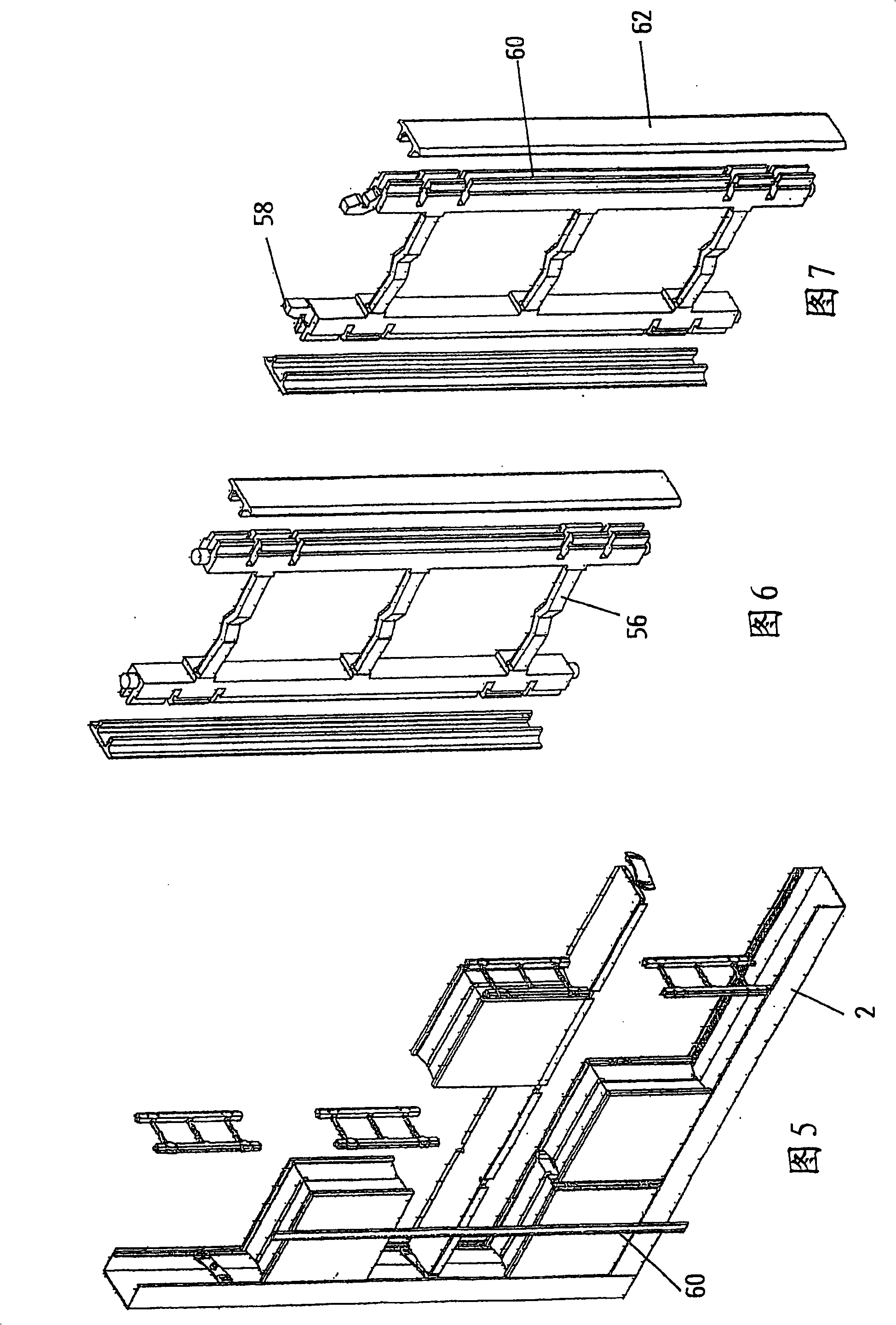

Complex of structural elements for forming glass brick walls

A complex of structural elements for forming glass brick walls, characterised by comprising: a substantially C-shaped aluminium profile bar (2) for perimetrally bounding the wall, a plurality of dividers (6) horizontally separating each glass brick from the adjacent one and having at least their exposed longitudinal edges of aluminium, a plurality of horizontal aluminium stringers (4) consisting of a horizontal web (14) provided at least along one longitudinal edge with a T-shaped appendix (18), said web being provided at regular intervals with seats for fixing the uprights of said dividers, said stringers being provided at their ends (22) with elements to be removably coupled to the interior of the vertical C-shaped profile bars.

Owner:阿盖博系统有限公司

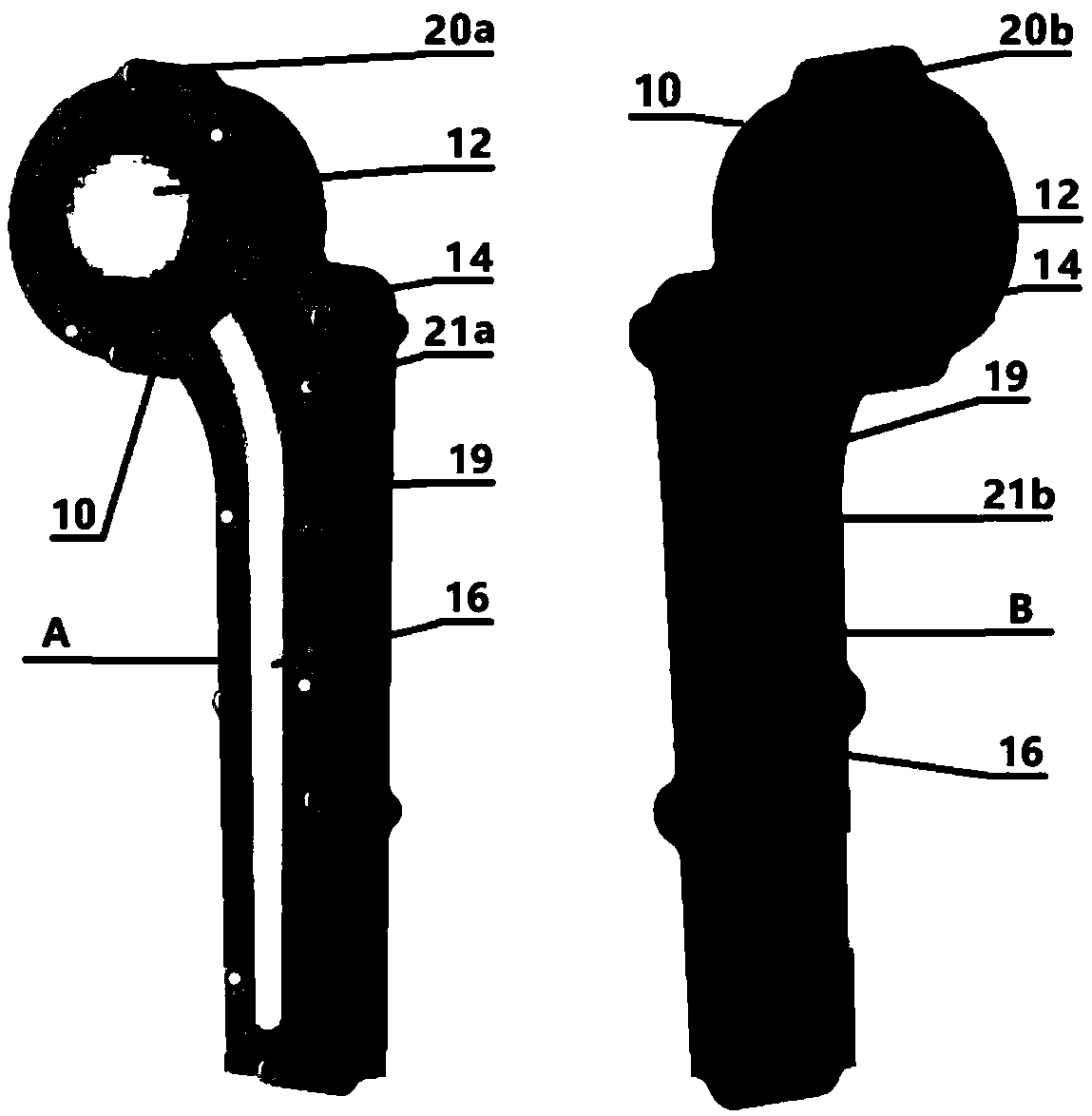

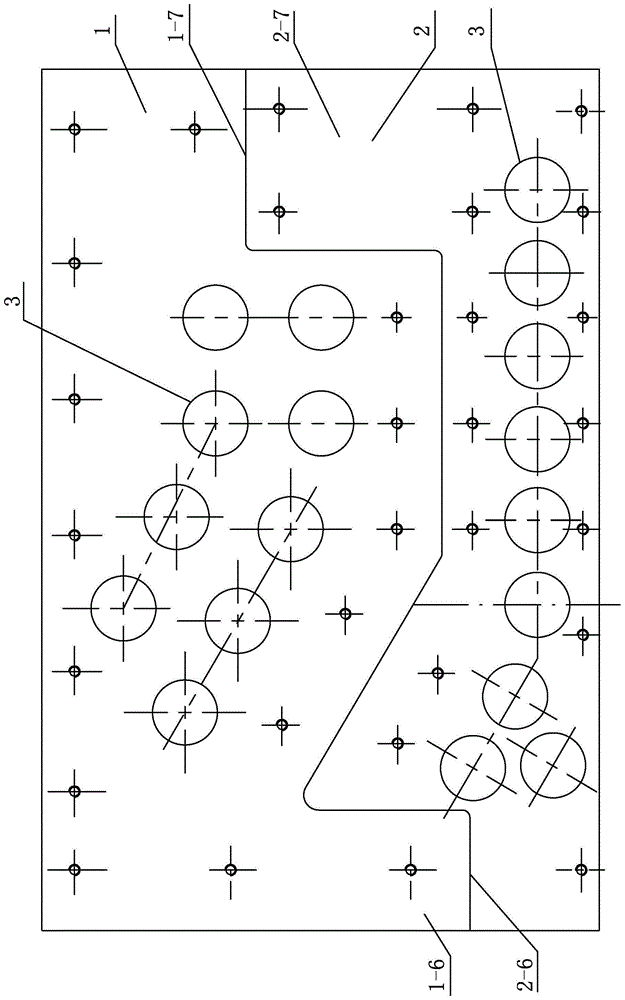

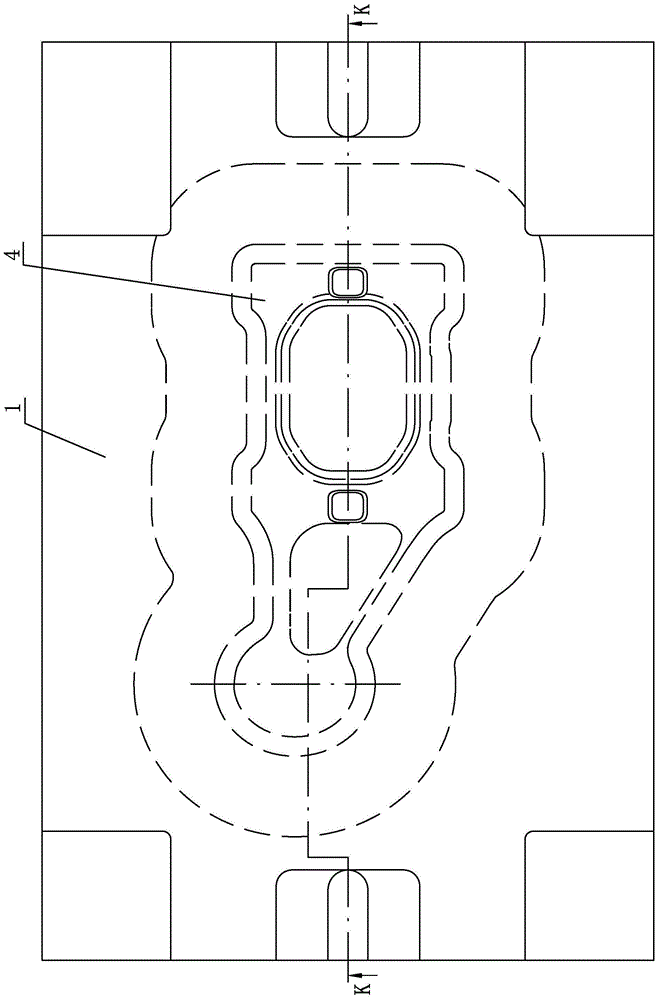

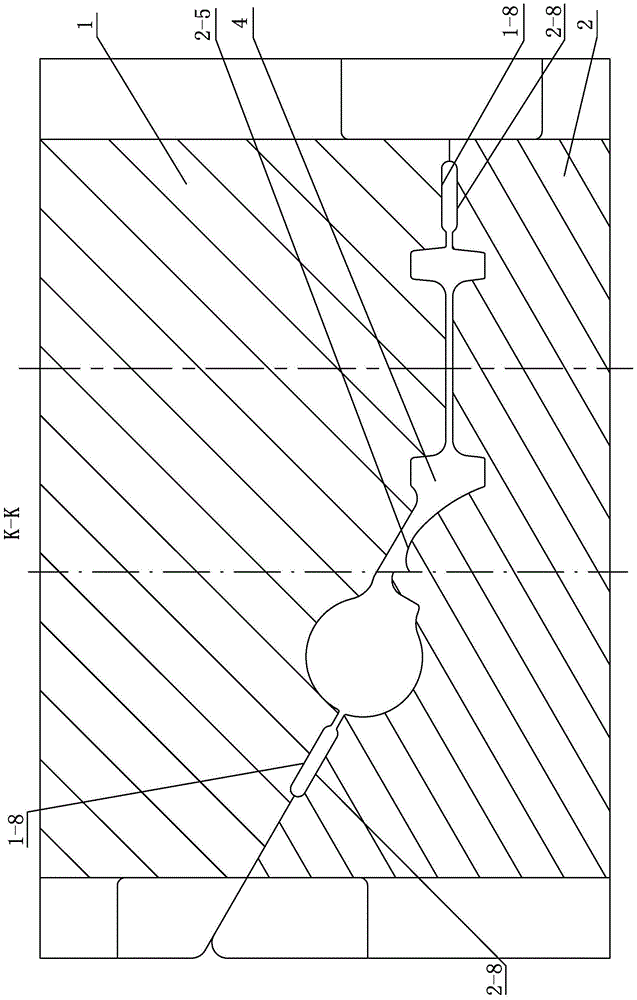

A 7a09 aluminum alloy long-wall deep-rib box-shaped ball-head rocker arm isothermal forging forming mold and method

ActiveCN105414435BQuality improvementExtended service lifeForging/hammering/pressing machinesThermal treatmentIsothermal forging

The invention provides an isothermal die-forging forming die and method for a 7A09 aluminum alloy rocker arm provided with long walls, deep ribs and a box-shaped ball head, relates to a forming die and method for a rocker arm provided with long walls, deep ribs and a box-shaped ball head, aims to overcome defects of difficulty in blank manufacturing and forming, proneness of folding, disorderliness of flow lines and coarse and large grains occurring in a conventional forging and manufacturing method for a rock arm forged piece provided with long walls, deep ribs and a box-shaped ball head and solves problems of unqualified shape and size of a finally formed aluminum forge piece due to elastic recovery after forming and difficulty in meeting use requirements for performance. The forming method mainly comprises steps as follows: I, blank manufacturing; II, first-time forging forming; III, cooling; IV, first-time pickling; V, primary defect repairing; VI, second-time forging forming; VII, second-time pickling, VIII, secondary defect repairing; IX, finish forging forming, X, third-time pickling, XI, thermal treatment of the forge piece; XII, correction treatment of the forge piece. The isothermal die-forging forming die and method are used for forming of the 7A09 aluminum alloy rocker arm provided with long walls, deep ribs and the box-shaped ball head.

Owner:HARBIN INST OF TECH

Toilet front cover support device

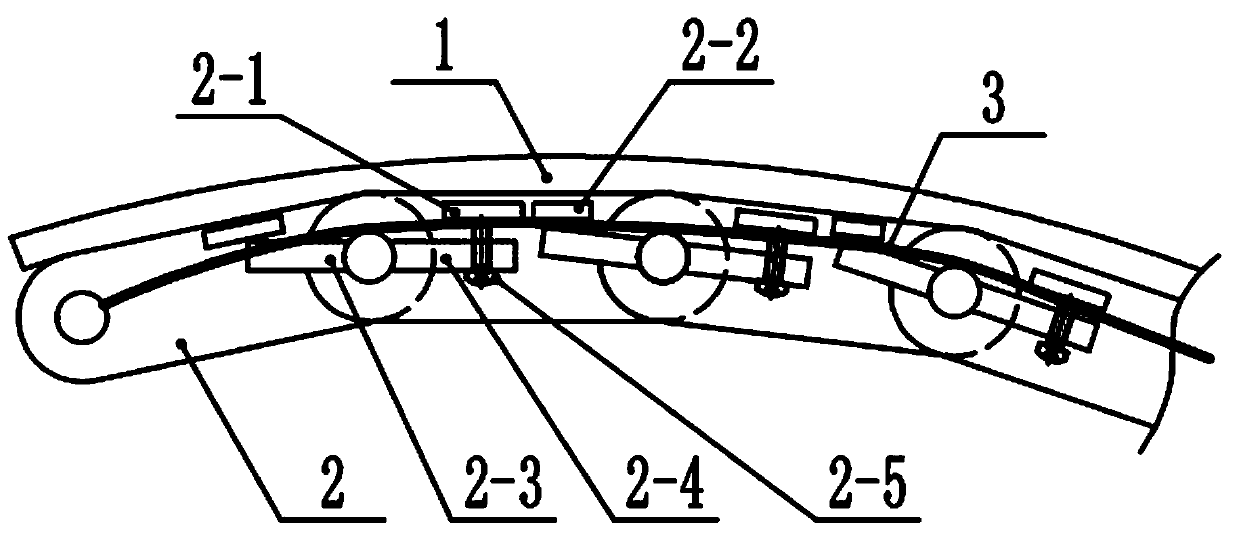

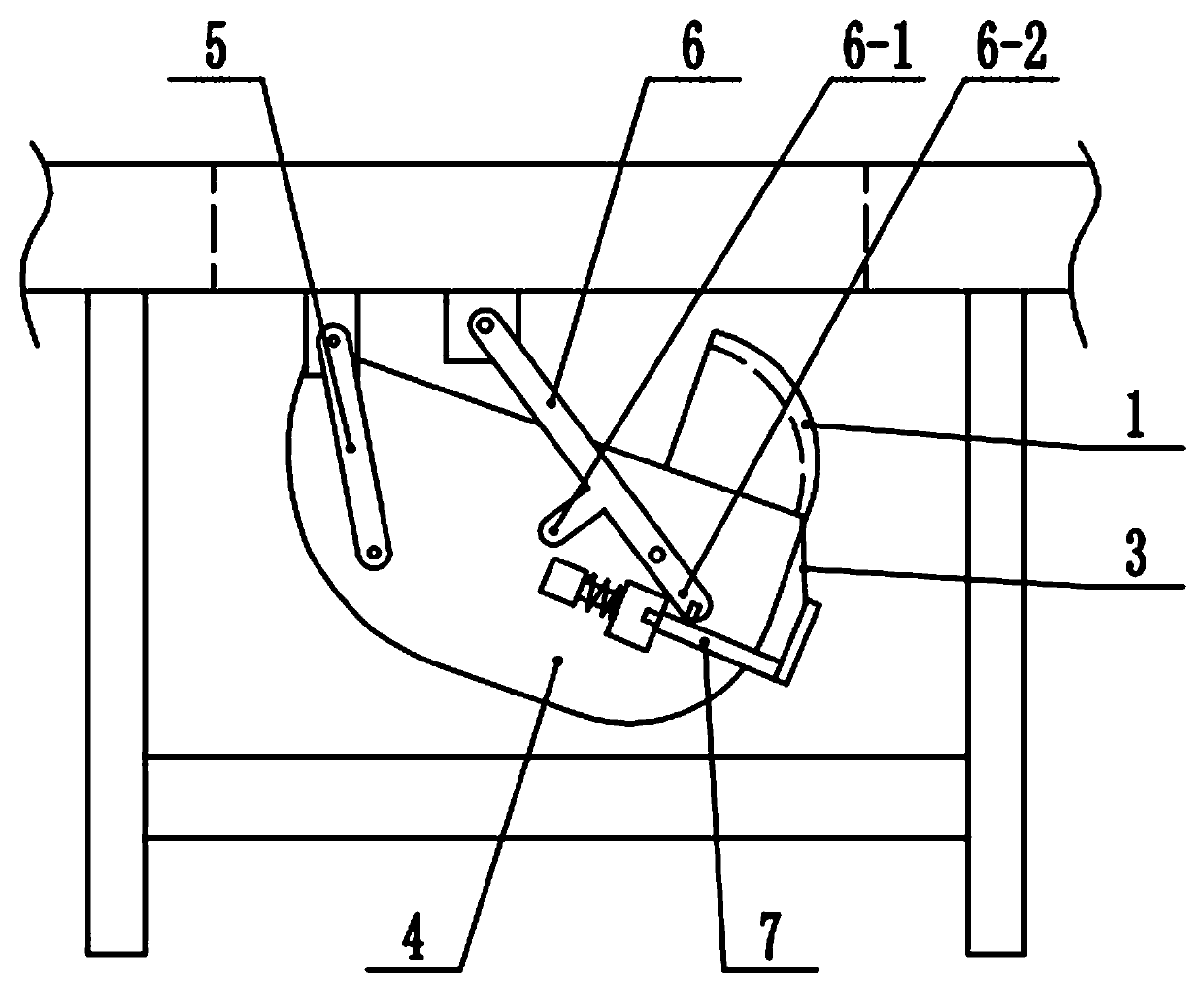

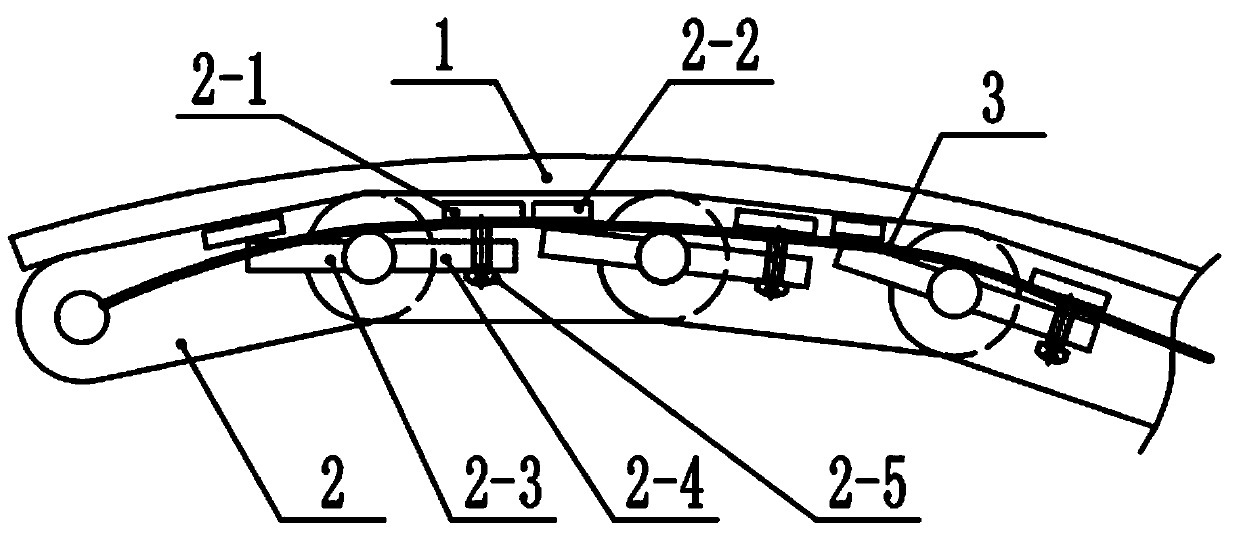

The invention provides a supporting device of a closestool front cover. The supporting device of the closestool front cover comprises a tank chain mechanism formed by a plurality of link plate units (2) rotatably connected end to end. The link plate units (2) are connected with a flexible shield (1) at the front side of the closestool so as to constrain the shape of the flexible shield (1). The rear end of the tank chain mechanism is connected with the closestool body. The supporting device of the closestool front cover further comprises a driving mechanism for driving the tank chain mechanism to be bended to the human body and a limiting mechanism for constraining the limit shape of bending the tank chain mechanism to the human body. The limit shape can be adjusted by an adjusting mechanism. The supporting device of the closestool front cover is capable of solving the problem that the shape of the flexible shield at the front side of the closestool is not matched with the lower body of a patient and the problem that the flexible shield is interfered with the lower body of the patient while the closestool is upwards opened.

Owner:山东科亿宏智能科技有限公司

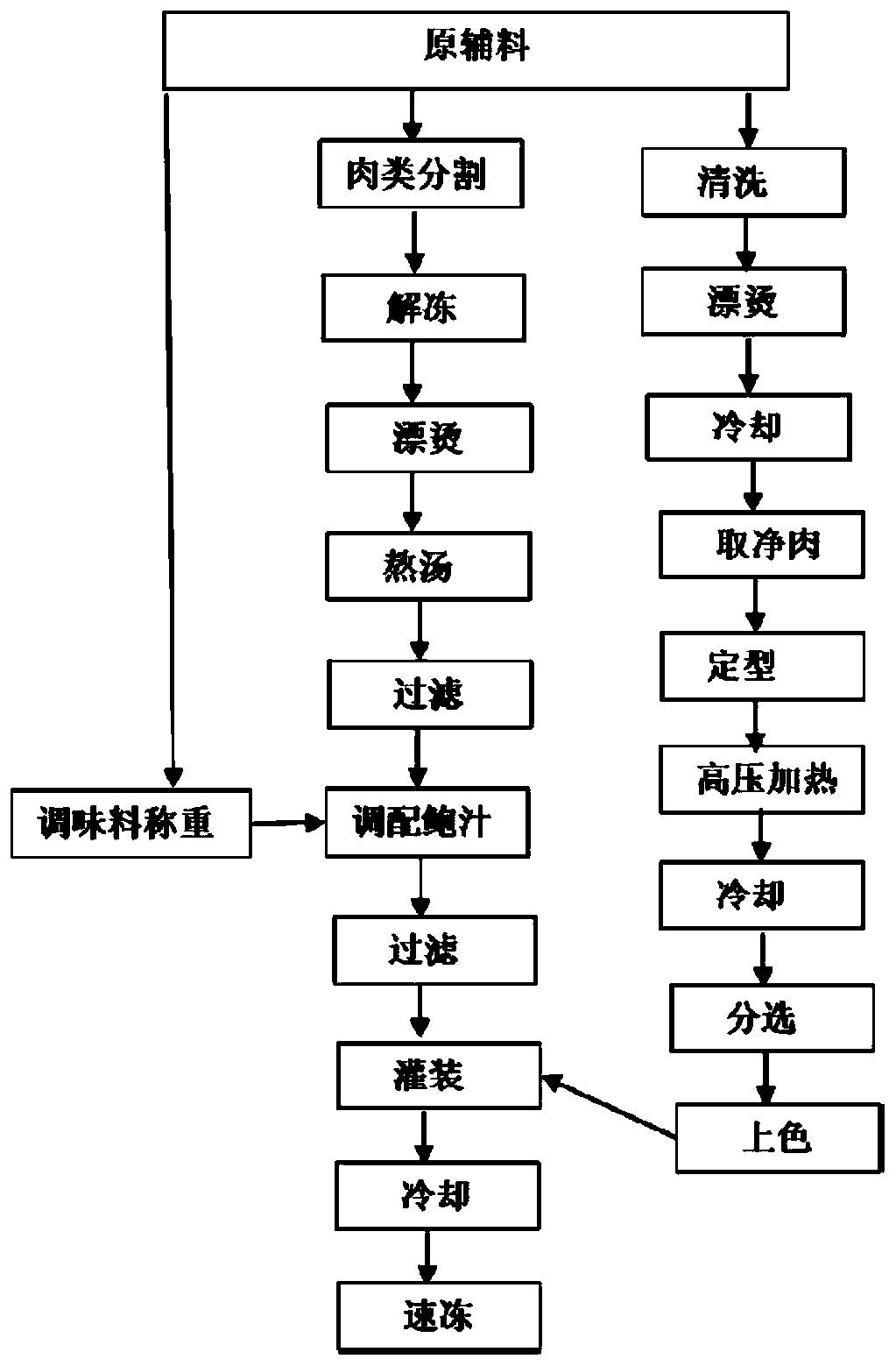

Abalone and processing method thereof, frozen braised abalone and making method thereof

PendingCN110200234AIntegrity guaranteedObvious "Yuanbao" typeFood scienceInternal pressureSteam pressure

The invention belongs to the field of abalone processing, and discloses an abalone and a processing method thereof, a frozen braised abalone and a making method thereof. The abalone processing methodincludes the steps: S1 cleaning a live abalone, blanching the cleaned live abalone in 80-90 DEG C hot water for 1-3 minutes, cooling the live abalone by ice water, removing shells, internal organs andteeth and taking pure meat to obtain abalone meat; S2 blanching the abalone meat in hot water with the temperature of 90-95 DEG C for 2-10 minutes, and continuously stirring the hot water in the samedirection during blanching to obtain a one-step shaped abalone; S3 adding water into a cooking boiler and heating the water to reach the temperature of 80-90 DEG C, adding the one-step shaped abaloneinto the cooking boiler, covering the cooking boiler with a boiler cover, setting the heating temperature of the cooking boiler to be 105-110 DEG C, setting the steam pressure of a heating pipeline to be 0.25-0.28MPa, setting the internal pressure of the boiler to be 0.05-0.08MPa, opening an exhaust valve by 1 / 3-1 / 2, setting heating time to be 1-5 minutes, performing high-pressure heating, takingout the abalone and cooling the abalone by the ice water. The abalone acquired by the method is complete, in the shape of an obvious shoe-shaped silver ingot and soft, waxy, delicious and fragrant intaste and can meet the requirements of consumers from vision to taste.

Owner:XIAMEN DAOZHIYUAN BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com