Abalone and processing method thereof, frozen braised abalone and making method thereof

A production method and abalone technology, which are applied in the direction of food science and the like, can solve the problems of incomplete shape, taste and poor taste of abalone, and achieve the effect of solving the problem of poor shape and taste of abalone, soft and glutinous taste, and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

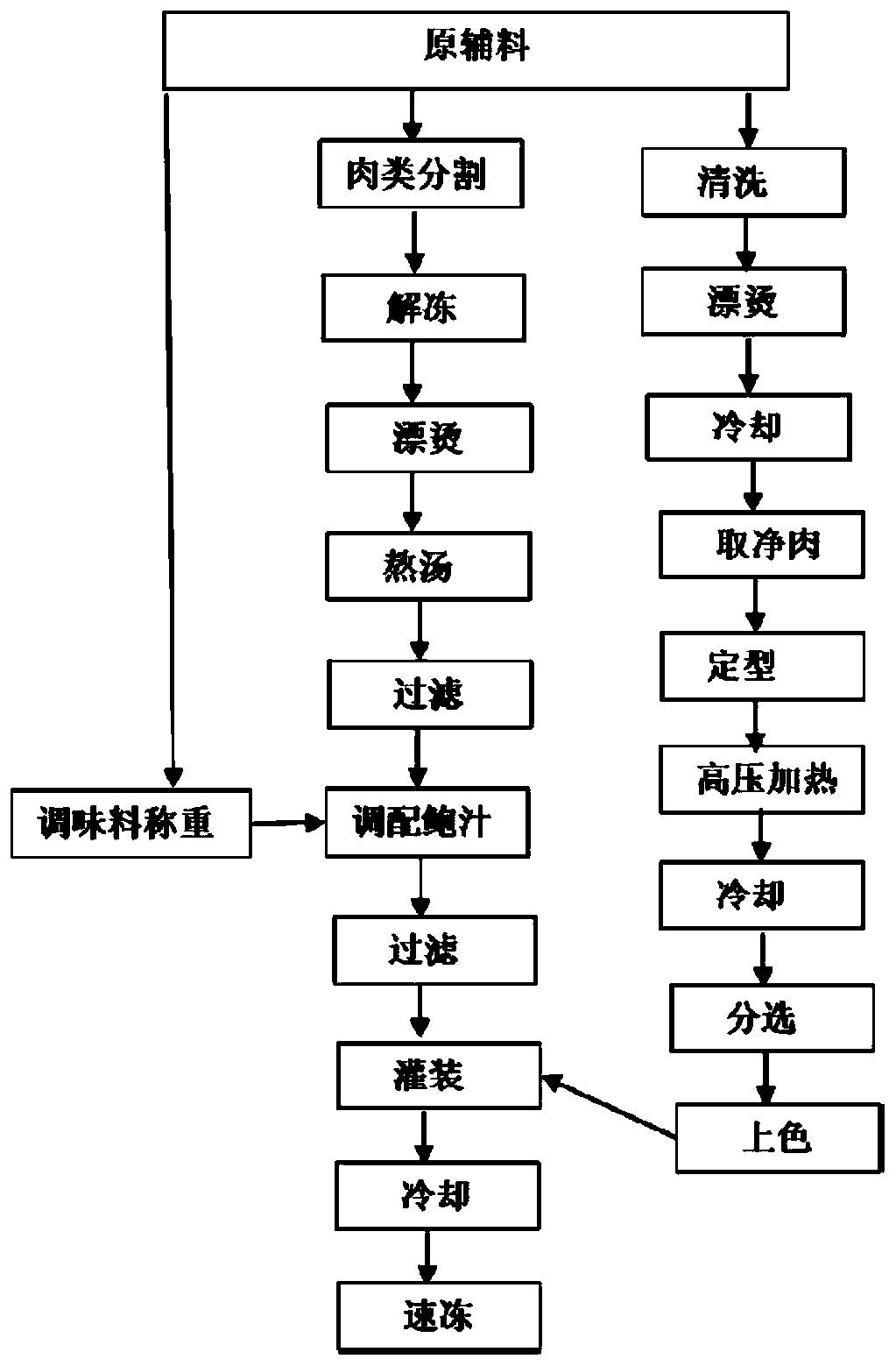

Image

Examples

Embodiment 1

[0027] S1. Clean the live abalone, then blanch it in hot water at 80°C for 2 minutes, cool it in ice water, remove the shell, remove the viscera, remove the teeth, and remove the meat to obtain abalone meat.

[0028] S2. Blanch the abalone meat obtained in step S1 in hot water at a temperature of 95° C. for 2 minutes, stirring continuously in the same direction during this period, to obtain a shaped abalone.

[0029] S3. Add water to the cooking pot and heat it to 80°C, then add the first-time shaped abalone (the volume of water is 5 times the volume of the first-time shaped abalone) into the cooking pot, cover the pot and turn the cooking pot The heating temperature is set at 108°C, the steam pressure of the heating pipeline is set at 0.26MPa, the pressure in the pot is set at 0.06MPa, the pressure relief valve is opened by 1 / 3, and the heating time is set at 2min for high-pressure heating. When the pressure in the pot drops below 0.02MPa, fully open the pressure release valv...

Embodiment 2

[0032] S1. Clean the live abalone, then blanch it in hot water at 85°C for 1.5 minutes, cool it in ice water, remove the shell, remove the viscera, remove the teeth, and remove the meat to obtain abalone meat.

[0033] S2. Blanch the abalone meat obtained in step S1 in hot water at a temperature of 90° C. for 8 minutes, stirring continuously in the same direction during this period, to obtain a shaped abalone.

[0034] S3. Add water to the cooking pot and heat it to 90°C, then add the first-time shaped abalone (the volume of water is 2 times the volume of the first-time shaped abalone) into the cooking pot, cover the pot and turn the cooking pot The heating temperature is set at 105°C, the steam pressure of the heating pipeline is set at 0.25MPa, the pressure in the pot is set at 0.05MPa, the pressure relief valve is opened by 1 / 3, and the heating time is set at 3min for high-pressure heating. When the pressure in the pot drops below 0.02MPa, fully open the pressure release va...

Embodiment 3

[0037]S1. Clean the live abalone, then blanched it in hot water at 82°C for 1.2 minutes, cooled it in ice water, removed the shell, removed the viscera, removed the teeth, and obtained the abalone meat.

[0038] S2. Blanch the abalone meat obtained in step S1 in hot water at a temperature of 92° C. for 7 minutes, stirring continuously in the same direction during this period, to obtain a shaped abalone.

[0039] S3. Add water to the cooking pot and heat it to 85°C, then add the first-time shaped abalone (the volume of water is 10 times the volume of the first-time shaped abalone) into the cooking pot, cover the pot and turn the cooking pot The heating temperature is set at 110°C, the steam pressure of the heating pipeline is set at 0.28MPa, the pressure in the pot is set at 0.08MPa, the pressure relief valve is opened to 1 / 2, and the heating time is set at 1min for high-pressure heating. When the pressure in the pot drops below 0.02MPa, fully open the pressure release valve, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com