Complex of structural elements for forming glass brick walls

A composite, glass brick technology, applied in the field of composites, which can solve the problems of weight restriction use, unpleasant shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

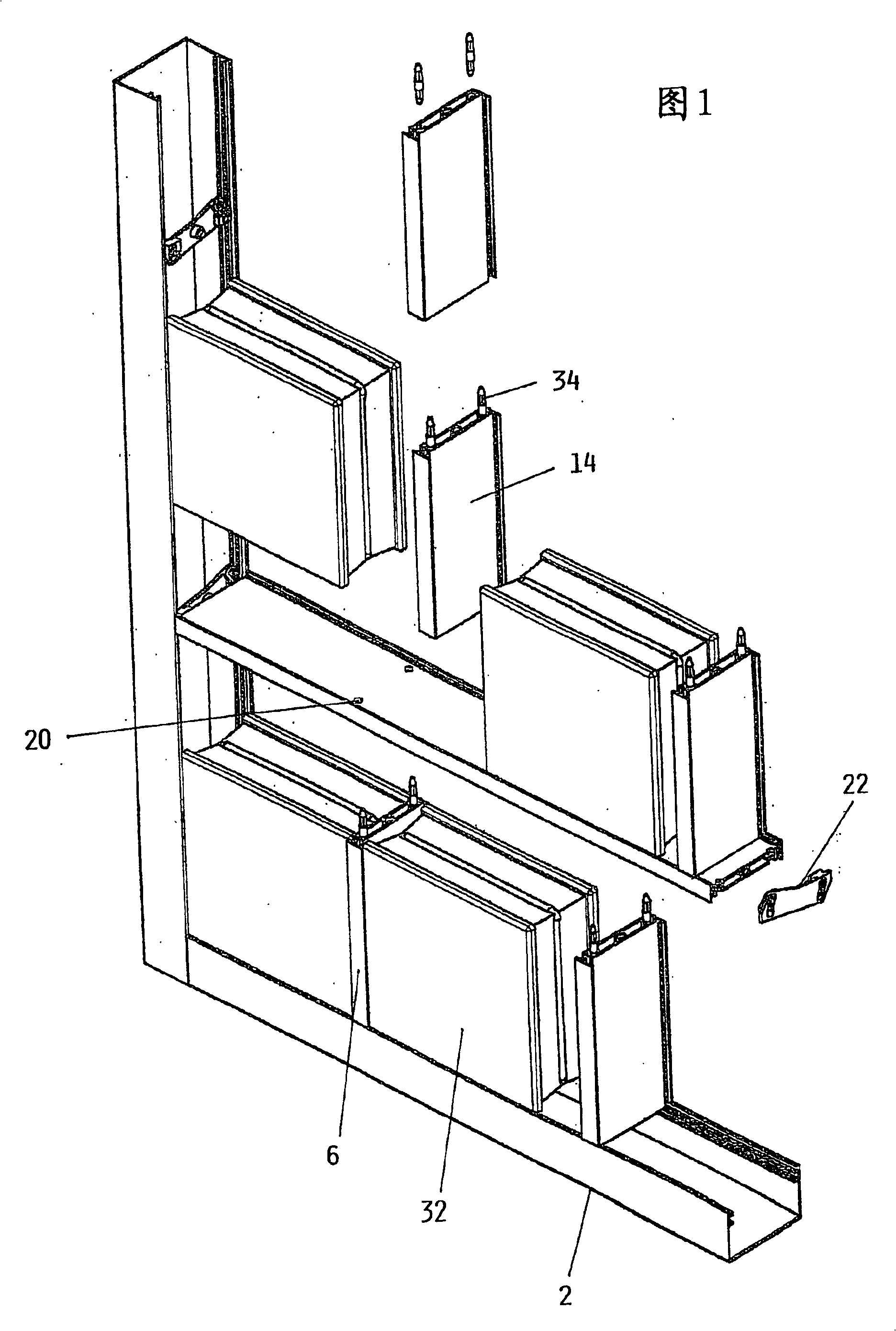

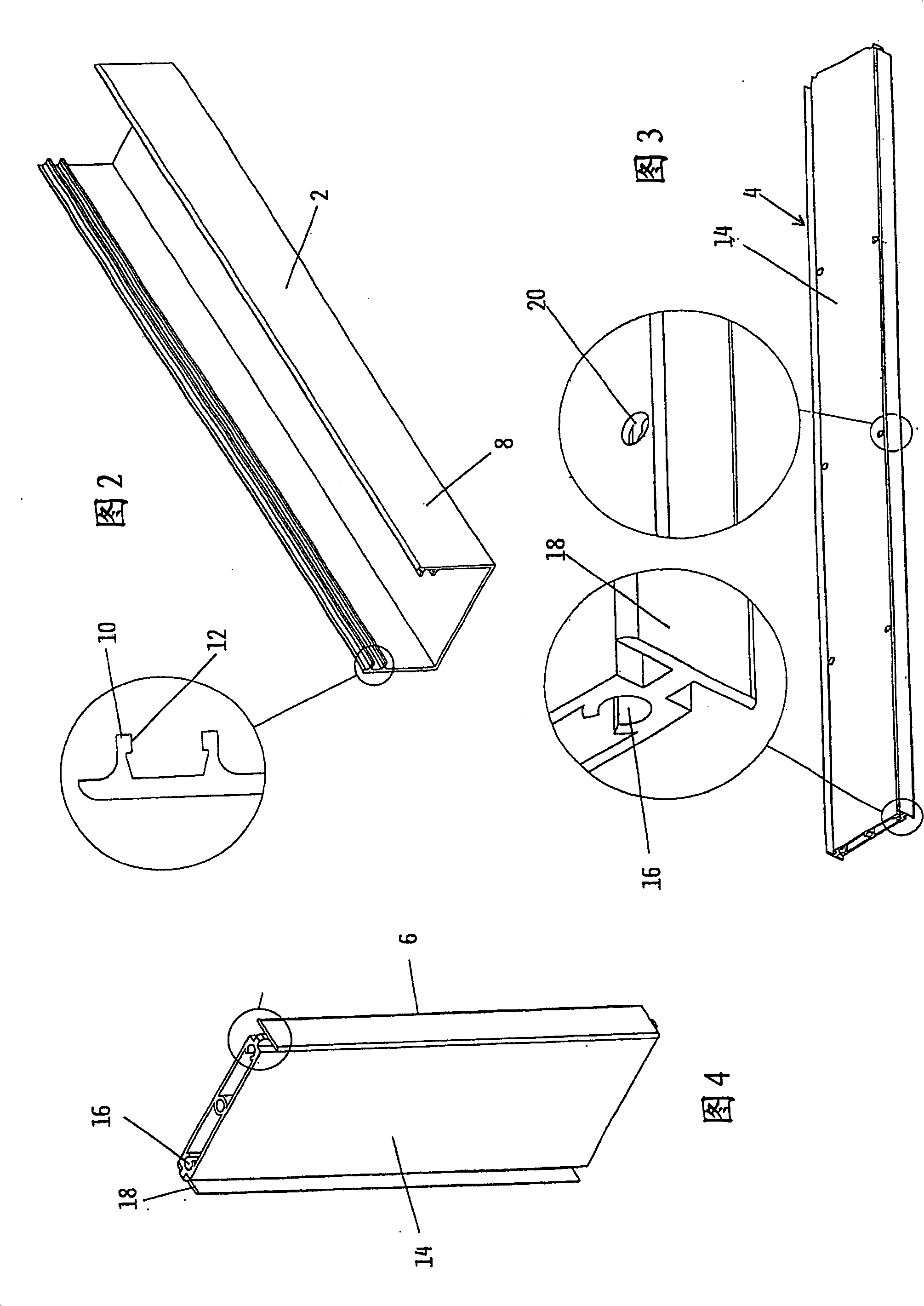

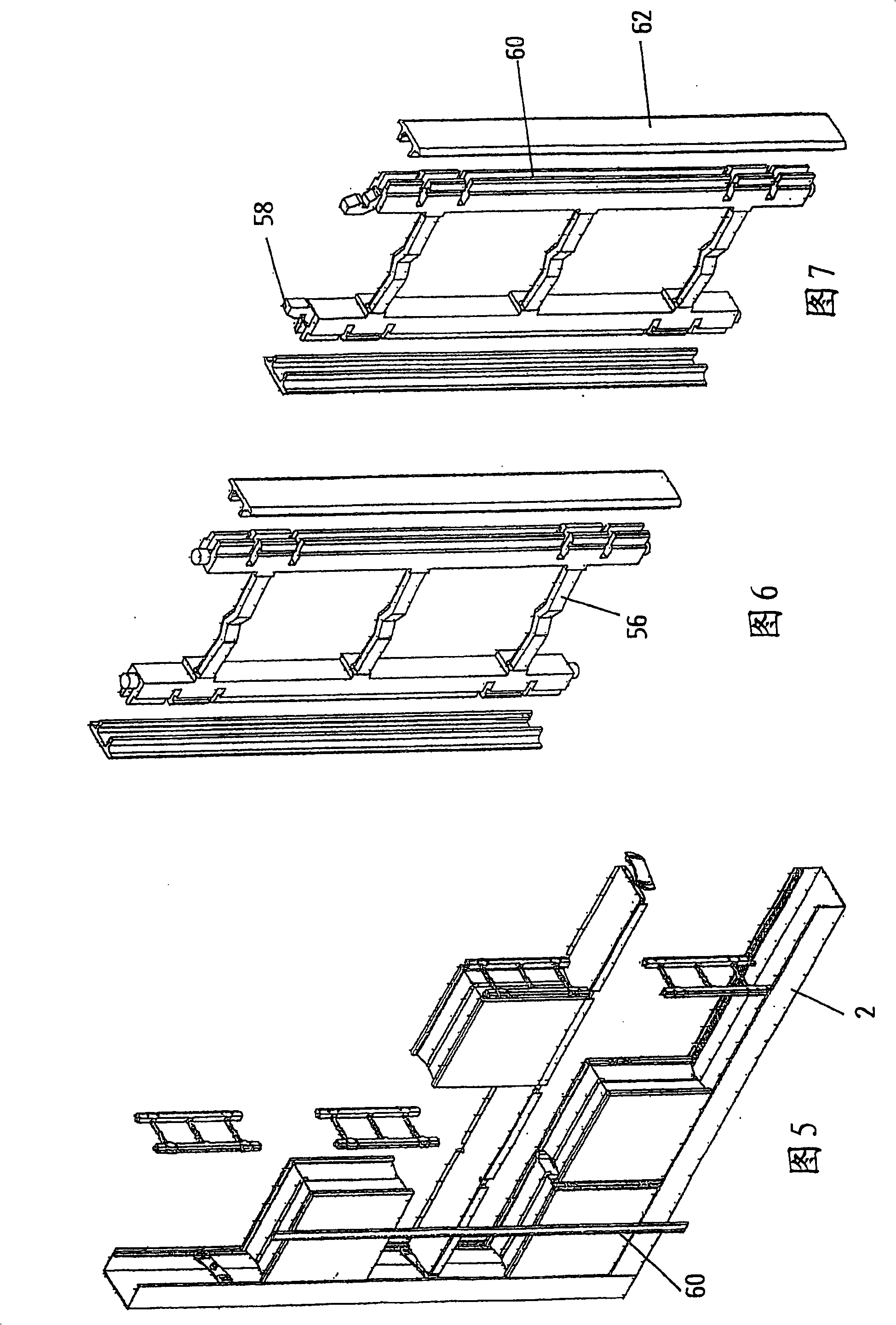

[0025] As can be seen from the drawings, the composite body of components according to the invention basically comprises a C-shaped aluminum profile 2 at the perimeter, a plurality of intermediate horizontal longitudinal beams 4 made of aluminum profiles and a plurality of vertical partitions also made of aluminum Item 6.

[0026] The peripheral aluminum profile 2 is provided on each inner surface of the side wall 8 by means of two pairs of ribs 10, each comprising engaging teeth 12 on the surface facing the other.

[0027] The horizontal stringer comprises a central web 14 at the end of which a cylindrical portion 16 is provided and from which two substantially T-shaped flanges 18 extend. There are also through holes 20 arranged at regular intervals on the central web.

[0028] The partitions 6 are substantially identical in form to the horizontal stringers, but without the holes 20 .

[0029] The composite also includes a connecting element 22 consisting of a substantially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com